Professional Documents

Culture Documents

CertMaterialTestReport E6010 Fletweld SP 1-8

Uploaded by

gerosuca8000 ratings0% found this document useful (0 votes)

51 views1 pageYield Stregh E6010 1/8

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentYield Stregh E6010 1/8

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

51 views1 pageCertMaterialTestReport E6010 Fletweld SP 1-8

Uploaded by

gerosuca800Yield Stregh E6010 1/8

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

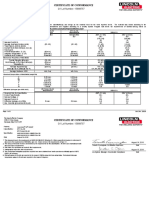

The Lincoln Electric Company

22801 St. Clair Avenue CERTIFICATE OF CONFORMANCE

Cleveland, Ohio 44117-1199

Q1 Lot Number: 15400427

Product: Fleetweld® 5P

Classification: E6010

Specification: AWS A5.1:2012, ASME SFA-5.1

Date April 20, 2017

This is to certify that the product named above is of the same classification(s) and design as the material used for the tests reported herein. The material was tested according to the

specification(s) indicated and met all requirements. It was manufactured and supplied according to a Quality System Program that meets the requirements of ISO9001 among others as

documented on The Lincoln Electric web page (http://www.lincolnelectric.com/en-us/company/Pages/certifications.aspx).

E6010

Operating Settings Requirements RESULTS

Required Size for Classification 1

Not Specified 1 mm)

5/32" (4.0 2 mm)

3/16" (4.8 3 mm)

1/4" (6.4

Current Type/Polarity DC+ DC+ DC+ DC+

Nominal Voltage, V 27 27 27

Nominal Current, A 130 165 265

Average Heat Input, kJ/mm (kJ/in) 2.2 (55) 2.4 (62) 3.5 (90)

Travel Speed, cm/min (in/min) 10 (3.8) 11 (4.3) 12 (4.8)

Pass/Layers 16/8 16/8 20/10

Preheat Temperature, °C (°F) (225 min.) 105 (225) 105 (225) 105 (225)

Interpass Temperature, °C (°F) (225 - 350) 150 (300) 150 (300) 150 (300)

Postweld Heat Treatment As-welded As-welded As-welded As-welded

Mechanical properties of weld deposits

Tensile Strength, MPa (ksi) (60 min.) 540 (78) 500 (72) 490 (72)

Yield Strength, 0.2% Offset, MPa (ksi) (48 min.) 440 (64) 410 (59) 420 (61)

Elongation % 22 min. 25 28 28

Average Impact Energy (20 min.) 53 (39) 32 (23) 79 (58)

Joules @ -29 °C (ft-lbs @ -20 °F) 47,51,61 (34,38,45) 25,34,37 (18,25,27) 75,78,84 (55,58,62)

Average Hardness, HRB Info. Only 84 80 82

Chemical composition of weld deposits (weight %)

C 0.20 max. 0.12 0.12 0.13

Mn 1.20 max. 0.48 0.44 0.56

Si 1.00 max. 0.30 0.24 0.20

S Not Specified 0.005 0.007 0.009

P Not Specified 0.010 0.008 0.008

Cr 0.20 max. 0.02 0.02 0.03

Ni 0.30 max. 0.02 0.01 0.03

Mo 0.30 max. 0.01 <0.00 0.01

V 0.08 max. 0.01 0.00 0.00

Mn+Ni+Cr+Mo+V Not Specified 0.54 0.47 0.63

1. This document meets the requirements of EN10204, type 2.2, when a specific lot or order number is referenced. It does

not meet the requirements of type 3.1. April 20, 2017

2. The electrode sizes required to be tested for this classification are 5/32 inch, 3/16 inch and 1/4 inch. All other sizes

manufactured will also meet these requirements. Toronto Cunningham, Certification Supervisor Date

3. Fillet Weld Test (positions as required): Met requirements.

4. Radiographic Inspection: Grade 2 - Met requirements. April 21, 2017

5. The strength and elongation properties reported here were obtained from tensile specimens artificially aged at 105°C Jon Ogborn, Manager, Consumable Compliance Date

(220°F) for 48 hours.

6. Strength values in SI units are reported to the nearest 10 MPa converted from actual data. Preheat and interpass

temperature values in SI units are reported to the nearest 5 degrees.

Page 1 of 1 Cert. No. 30050

You might also like

- CIBSE Pipe Sizing V2.2Document9 pagesCIBSE Pipe Sizing V2.2mohamed adelNo ratings yet

- Reaction rate determination and simulation of hydrogenation processDocument3 pagesReaction rate determination and simulation of hydrogenation processToMemNo ratings yet

- Summer Internship Project-NishantDocument80 pagesSummer Internship Project-Nishantnishant singhNo ratings yet

- Q1Display 15843280Document3 pagesQ1Display 15843280Oscar BasantesNo ratings yet

- Q1 Lot Number: 15888757: Certificate of ConformanceDocument2 pagesQ1 Lot Number: 15888757: Certificate of ConformanceDesdeAquiHastaAllaNo ratings yet

- Excalibur 11018M MR CertDocument2 pagesExcalibur 11018M MR CertAminNo ratings yet

- Certificate of Conformance: Q1 Lot Number: 15163483Document1 pageCertificate of Conformance: Q1 Lot Number: 15163483interx00No ratings yet

- Q1 Lot Number: 14997588: Certificate of ConformanceDocument3 pagesQ1 Lot Number: 14997588: Certificate of ConformanceOscar BasantesNo ratings yet

- .072" (1.8 MM) AWS D1.8:2016 March 01, 2022: Innershield® NR®-232Document1 page.072" (1.8 MM) AWS D1.8:2016 March 01, 2022: Innershield® NR®-232yousab creator2No ratings yet

- Lincoln (Data Sheet) Murex E7024Document2 pagesLincoln (Data Sheet) Murex E7024PubcrawlNo ratings yet

- Pipeliner® NR®-208-XP: (Applies Only To U.S. Products)Document2 pagesPipeliner® NR®-208-XP: (Applies Only To U.S. Products)Pablo PazNo ratings yet

- PORON 4701-50 Firm Global Standards Data Sheet-1Document2 pagesPORON 4701-50 Firm Global Standards Data Sheet-1Layeeq AhmedNo ratings yet

- L-50 Lincolnweld 980Document1 pageL-50 Lincolnweld 980geloram66No ratings yet

- Lincolnweld 888 & LA-85Document2 pagesLincolnweld 888 & LA-85Pablo PazNo ratings yet

- Technical Data: 02014W104KATDocument9 pagesTechnical Data: 02014W104KATndfgdfs oishdfNo ratings yet

- Certificate of ConformanceDocument1 pageCertificate of ConformanceedwinNo ratings yet

- Coslight GFM-200ZDocument1 pageCoslight GFM-200ZLê Hữu Ái100% (1)

- Datasheet for GFM-300Z Battery specifications and discharge characteristicsDocument1 pageDatasheet for GFM-300Z Battery specifications and discharge characteristicsUCTT BLU MONo ratings yet

- B DPCS CharPropCVandCA DATA v024-WEBDocument2 pagesB DPCS CharPropCVandCA DATA v024-WEBguivc.ethernet.32No ratings yet

- TroubleshootingDocument6 pagesTroubleshootingKolo BenduNo ratings yet

- Certificado Lote Er70s-6Document1 pageCertificado Lote Er70s-6willariasNo ratings yet

- Data Sheet: Rd520 Axius® Rupture DiscDocument3 pagesData Sheet: Rd520 Axius® Rupture DiscbondsivamaniNo ratings yet

- Q1 DisplayDocument1 pageQ1 DisplayOscar BasantesNo ratings yet

- Grinnell Mechanical Products Mechanical Outlet Coupling General Description Technical Data Installation / AssemblyDocument4 pagesGrinnell Mechanical Products Mechanical Outlet Coupling General Description Technical Data Installation / AssemblyСергей КолесниковNo ratings yet

- Datasheet For GFM-400Z Battery: Specifications Discharging Characteristics Curves (25 C)Document1 pageDatasheet For GFM-400Z Battery: Specifications Discharging Characteristics Curves (25 C)UCTT BLU MONo ratings yet

- GBU10 Glass Passivated Single-Phase Bridge Rectifier Data SheetDocument2 pagesGBU10 Glass Passivated Single-Phase Bridge Rectifier Data Sheetmarcelo giussaniNo ratings yet

- SF-71 en EngDocument2 pagesSF-71 en EngbvbarcNo ratings yet

- FT Series: FTA12-200 12V200Ah FTA12-200 12V200AhDocument2 pagesFT Series: FTA12-200 12V200Ah FTA12-200 12V200AhALEX ALEXNo ratings yet

- Qmot Qsh6018 ManualDocument14 pagesQmot Qsh6018 ManualleftoverchopsNo ratings yet

- Data Sheet: Applications Designation Chemical CompositionDocument2 pagesData Sheet: Applications Designation Chemical CompositionManankNo ratings yet

- RDamper CatalogDocument12 pagesRDamper CatalogEvandro MoreiraNo ratings yet

- MG CatalogDocument21 pagesMG CatalogSanket IchakeNo ratings yet

- Physical: .100" and .100" × .100" Straight, Solder Tails 929 SeriesDocument3 pagesPhysical: .100" and .100" × .100" Straight, Solder Tails 929 Seriesyamaha640No ratings yet

- 1 - Primacore LW71 1.2 E208038900Document1 page1 - Primacore LW71 1.2 E208038900Suli HartoNo ratings yet

- Datasheet Nema23Document1 pageDatasheet Nema23Juan De La TorreNo ratings yet

- V90D6412Document1 pageV90D6412ardalanxoshnawNo ratings yet

- VRLA Rechargeable Battery: Application FeaturesDocument1 pageVRLA Rechargeable Battery: Application FeaturesbrobataNo ratings yet

- FT Series: FTB12-150 12V150AhDocument2 pagesFT Series: FTB12-150 12V150AhJohn Edwin MuñozNo ratings yet

- Data Sheet: Three Phase Induction Motor - Squirrel CageDocument3 pagesData Sheet: Three Phase Induction Motor - Squirrel CageKamil KościelakNo ratings yet

- PT Paver Strength CalculationsDocument3 pagesPT Paver Strength CalculationsEr Narayan ApawatNo ratings yet

- 005 - Fuel+SystemDocument92 pages005 - Fuel+Systemeduan laraNo ratings yet

- Sacred Sun Fta 12-200Document2 pagesSacred Sun Fta 12-200ALEX ALEXNo ratings yet

- 17PS-M 3.6o HYBRID SPECIFICATIONS AND DIAGRAMSDocument1 page17PS-M 3.6o HYBRID SPECIFICATIONS AND DIAGRAMSBen sayari Mohamed AmineNo ratings yet

- Jacketed Tubing (MS-02-188) R1Document6 pagesJacketed Tubing (MS-02-188) R1herysyam1980No ratings yet

- COILBXDocument1 pageCOILBXMUKESHNo ratings yet

- Quality certificate analysisDocument6 pagesQuality certificate analysisClaudia TiradoNo ratings yet

- Power Unit (85A Models) : Maintenance SpecificationDocument1 pagePower Unit (85A Models) : Maintenance SpecificationPHUONG NGUYENNo ratings yet

- Poron 4701-30 Very SoftDocument2 pagesPoron 4701-30 Very SoftItzelMalagonVeraNo ratings yet

- Wts AEM Automotive SMD Fuses 2016.12Document22 pagesWts AEM Automotive SMD Fuses 2016.12AlexNo ratings yet

- MBRF2035-MBRF20150 Schottky Barrier Rectifier Ratings and SpecificationsDocument2 pagesMBRF2035-MBRF20150 Schottky Barrier Rectifier Ratings and SpecificationsY. Leonel MolinaNo ratings yet

- Surface-Mount Fuses: 2410 Very Fast-Acting Chip FusesDocument4 pagesSurface-Mount Fuses: 2410 Very Fast-Acting Chip Fusesreza yousefiNo ratings yet

- Steel Grade: Material Data SheetDocument5 pagesSteel Grade: Material Data SheetNaveen HlNo ratings yet

- OMI 2 Pole PDFDocument2 pagesOMI 2 Pole PDFedgartepe4324No ratings yet

- PowerPact J-Frame Moulded Case Circuit Breakers - JJA36250Document4 pagesPowerPact J-Frame Moulded Case Circuit Breakers - JJA36250techtricNo ratings yet

- 180 Series Servo Motors: Dimension: Unit MMDocument1 page180 Series Servo Motors: Dimension: Unit MMMax QuintanillaNo ratings yet

- Three Phase Induction Motor Data SheetDocument7 pagesThree Phase Induction Motor Data SheetA aaa AaaNo ratings yet

- Capsun (SMD) VEN SeriesDocument2 pagesCapsun (SMD) VEN Serieshes545No ratings yet

- Effect of Temperature on Energy and Impact Strength of MaterialsDocument4 pagesEffect of Temperature on Energy and Impact Strength of MaterialsMilka PutriNo ratings yet

- Engine SpecsDocument18 pagesEngine Specsvadim vadimNo ratings yet

- PLH190FT (12V190AH) : PLH Series-Long Standby LifeDocument2 pagesPLH190FT (12V190AH) : PLH Series-Long Standby LifeAlayn1807No ratings yet

- DbcommDocument2 pagesDbcommJosé Manuel FigueroaNo ratings yet

- Bonnie Forge Couple DimensionsDocument14 pagesBonnie Forge Couple DimensionsTodd AlexanderNo ratings yet

- RAPID Piping ITPDocument38 pagesRAPID Piping ITPgerosuca800100% (1)

- Astm A480Document25 pagesAstm A480gerosuca800No ratings yet

- Smith Meter Prime 4Document2 pagesSmith Meter Prime 4gerosuca800No ratings yet

- Dewaltdh4240b 2Document22 pagesDewaltdh4240b 2gerosuca800No ratings yet

- 256267a1Document5,083 pages256267a1Елизавета ШепелеваNo ratings yet

- 277Document18 pages277Rosy Andrea NicolasNo ratings yet

- Prof. Michael Murray - Some Differential Geometry ExercisesDocument4 pagesProf. Michael Murray - Some Differential Geometry ExercisesAnonymous 9rJe2lOskxNo ratings yet

- IEC-60721-3-3-2019 (Enviromental Conditions)Document12 pagesIEC-60721-3-3-2019 (Enviromental Conditions)Electrical DistributionNo ratings yet

- CIGB B164 Erosion InterneDocument163 pagesCIGB B164 Erosion InterneJonathan ColeNo ratings yet

- Crash Cart - General Checklist For Medical Supplies On Crash CartsDocument3 pagesCrash Cart - General Checklist For Medical Supplies On Crash CartsYassen ManiriNo ratings yet

- Interna Medicine RheumatologyDocument15 pagesInterna Medicine RheumatologyHidayah13No ratings yet

- Youth, Time and Social Movements ExploredDocument10 pagesYouth, Time and Social Movements Exploredviva_bourdieu100% (1)

- Principles of Management NotesDocument61 pagesPrinciples of Management Notestulasinad123No ratings yet

- About Version ControlDocument6 pagesAbout Version ControlMaria Kristina Cassandra HeukshorstNo ratings yet

- UT Dallas Syllabus For Ee3311.002.07f Taught by Gil Lee (Gslee)Document3 pagesUT Dallas Syllabus For Ee3311.002.07f Taught by Gil Lee (Gslee)UT Dallas Provost's Technology GroupNo ratings yet

- Conserve O Gram: Understanding Histograms For Digital PhotographyDocument4 pagesConserve O Gram: Understanding Histograms For Digital PhotographyErden SizgekNo ratings yet

- Mama Leone's Profitability AnalysisDocument6 pagesMama Leone's Profitability AnalysisLuc TranNo ratings yet

- Design and Analysis of Algorithms Prof. Madhavan Mukund Chennai Mathematical Institute Week - 01 Module - 01 Lecture - 01Document8 pagesDesign and Analysis of Algorithms Prof. Madhavan Mukund Chennai Mathematical Institute Week - 01 Module - 01 Lecture - 01SwatiNo ratings yet

- IT SyllabusDocument3 pagesIT SyllabusNeilKumarNo ratings yet

- Nqs PLP E-Newsletter No68Document5 pagesNqs PLP E-Newsletter No68api-243291083No ratings yet

- Samsung 55 Inch LCD LED 8000 User ManualDocument290 pagesSamsung 55 Inch LCD LED 8000 User ManuallakedipperNo ratings yet

- CCEE SWD Basic Levers ToolDocument28 pagesCCEE SWD Basic Levers ToolDivina Margarita Gómez AlvarengaNo ratings yet

- Mythic Magazine 017Document43 pagesMythic Magazine 017William Warren100% (1)

- Dr. Malik's Farms BrochureDocument18 pagesDr. Malik's Farms BrochureNeil AgshikarNo ratings yet

- Lab ReportDocument5 pagesLab ReportHugsNo ratings yet

- Electronic Harassment Strahlenfolter - A Short History of Sound Weapons Pt2 - InfrasoundDocument10 pagesElectronic Harassment Strahlenfolter - A Short History of Sound Weapons Pt2 - InfrasoundFrank-BoenischNo ratings yet

- Caribbean Examinations Council Caribbean Secondary Certificate of Education Guidelines For On-Site Moderation SciencesDocument9 pagesCaribbean Examinations Council Caribbean Secondary Certificate of Education Guidelines For On-Site Moderation SciencesjokerNo ratings yet

- Riedijk - Architecture As A CraftDocument223 pagesRiedijk - Architecture As A CraftHannah WesselsNo ratings yet

- Ipo Exam Revised SyllabusDocument1 pageIpo Exam Revised Syllabusজ্যোতিৰ্ময় বসুমতাৰীNo ratings yet

- Ilham Bahasa InggrisDocument12 pagesIlham Bahasa Inggrisilhamwicaksono835No ratings yet

- Sheqxel Bbs Participation Dashboard TemplateDocument39 pagesSheqxel Bbs Participation Dashboard TemplateMuhammad Adytio DarmawanNo ratings yet

- AC7114-2 Rev N Delta 1Document34 pagesAC7114-2 Rev N Delta 1Vijay YadavNo ratings yet