Professional Documents

Culture Documents

Habibdsfdsf PDF

Uploaded by

Habibur RahmanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Habibdsfdsf PDF

Uploaded by

Habibur RahmanCopyright:

Available Formats

MEGHNA UTILITY CONSUMPTION FIGURES (REV0 / 22.JAN.

2018)

Nominal Cooling Water Requirement

Maximum Clean Water Consumption

FOR THOSE MACHINES MAY BE

Nominal Clean Water Consumption

Maximum Electrical Consumption

Total Maximum Natural Gas / LPG

Electrical Consumption (kWh) by

Total Maximum Air Consumption

APPROXIMATE WEIGHT (ONY

Nominal Electrical Consumption

Total Nominal Natural Gas / LPG

LAY OUT POSITION NUMBER

Total Nominal Air Consumption

INSTALLATION BASE AREA)

Emergency Power Cut Nominal

Total Maximum Cooling Water

CONSIDERED HEAVY WITH

Total Nominal Cooling Water

Total Maximum Waste Water

Maximum Natural Gas / LPG

Total Maximum Clean Water

Maximum Air Consumption

Total Nominal Waste Water

Nominal Natural Gas / LPG

Total Nominal Clean Water

Generator Recomendation

Pit / Channel Requirement

Nominal Air Consumption

Total Maximum Electrical

Maximum Cooling Water

Total Nominal Electrical

Maximum Waste Water

RESPECT TO THEIR

Consumption (Nm³/h)

Consumption (Nm³/h)

Consumption (Nm³/h)

Consumption (Nm³/h)

Nominal Waste Water

Consumption (m³/h)

Consumption (kWh)

Consumption (kWh)

Consumption (m³/h)

Requirement (m³/h)

Requirement (m³/h)

Requirement (m³/h)

(m3/h) 6 bar

(m3/h) 6 bar

(m3/h) 6 bar

(m3/h) 6 bar

(kWh)

(kWh)

(m³/h)

(m³/h)

(m³/h)

(m³/h)

(m³/h)

(m³/h)

(m³/h)

DESIGNATION QTY

Blanking & Deep Drawing Line

1 18 TONS Uncoiler-Straightener-Feeder - 15 ton 1 15 10 2 1,5 YES 15 10 2 1,5 0 0 0 0 0 0 0 0

2 Triple Blanking Shear Press 1 95 65 3 2 YES 95 65 0 0 0 0 0 0 0 0 3 2

Shear Press Cutting Tool Set 2 0 0 0 0 0 0 0 0 0 0 0 0

3 Casette Trollies 4 0 0 0 0 0 0 0 0 0 0 0 0

4 23 TONS Deep Drawing & Piercing Press 3000 Kn 2 110 85 1,5 1 5 3 YES 220 170 3 2 0 0 0 0 0 0 10 6

5 Deep Drawing Automation 2 1,5 0,5 1 0,5 3 1 2 1 0 0 0 0 0 0 0 0

6 Body Embossing Press 1000 kN 1 15 10 2 1,5 15 10 2 1,5 0 0 0 0 0 0 0 0

Body Embossing Die Set 1 0 0 0 0 0 0 0 0 0 0 0 0

Deep Drawing & Piercing Die Set 6-12 KG 2 0 0 0 0 0 0 0 0 0 0 0 0

Deep Drawing & Piercing Die Active parts as spare for 6& 12 kg 2 0 0 0 0 0 0 0 0 0 0 0 0

Deep Drawing & Piecing Die Set 35-45 KG 2 0 0 0 0 0 0 0 0 0 0 0 0

Deep Drawing & Piercing Die Active parts as spare for 35 & 45 kg 2 0 0 0 0 0 0 0 0 0 0 0 0

7 Edge Trimming & Joggling Machine 2 8 4 0 0 0 0 0 0 5 4

30 21 4 2 2,5 2 60 42

Edge Trimming & Joggling Tooling 2 0 0 0 0 0 0 0 0 0 0

Line Control between Decoiler and Blanking 1 2 1 2 1 0 0 0 0 0 0 0 0 0 0

Weding Line 0 0 0 0 0 0 0 0 0 0 0

8 Valve Boss Welding Machine SAW 3 45 30 1 0,5 2 1,5 135 90 3 1,5 0 0 0 0 0 0 6 4,5

9 Circumferential Seam Welding Machine SAW 6 60 45 2 1,5 360 270 12 9 0 0 0 0 0 0 0 0

10 Valve Guard Ring (Collar) Welding Machine 3 30 20 1 0,5 90 60 3 1,5 0 0 0 0 0 0 0 0

11 Foot Ring Welding Machine 4 30 20 2 1 120 80 8 4 0 0 0 0 0 0 0 0

12 Heat Treatment Furnace 1 25 20 25 2 1 240 120 25 20 2 1 0 0 0 0 240 120 0 0

13 Flux Heating furnace 1 5 5 0 0 0 0 0 0 0 0 0 0 0

Welder Hoods 1 5 5 0 0 0 0 0 0 0 0 0 0 0

Welding Ducting System 1 2 2 0 0 0 0 0 0 0 0 0 0 0

Collar & Foot Production Line 0 0 0 0 0 0 0 0 0 0 0 0

14 Un-coiler Straightener Feeder 2 tons 2 5 3 2 1 10 6 4 2 0 0 0 0 0 0 0 0

15 12.5 TONS Hydraulic Single Action Formig Press 1500 kN 2 25 18 3 2 2,5 2 50 36 6 4 0 0 0 0 0 0 5 4

16 11 TONS Hydraulic Single Action Blanking & Marking Press 2000 kN 1 45 38 2 1,5 4 3 45 38 2 1,5 0 0 0 0 0 0 4 3

17 10 TONS Hydraulic Single Action Forming Press 1000 kN 1 25 18 2 1,5 2,5 2 25 18 1,5 0 0 0 0 0 0 2,5 2 0

18 Hydraulic Single Action Forming Press 1000 kN 1 15 10 1 0,5 1,5 1 15 10 0,5 0 0 0 0 0 0 1,5 1 0

19 11 TONS Mechanical Press 1700 kN (Hydraulic Single Action Press 2000 kN) 1 45 38 2 1,5 4 3 45 38 2 1,5 0 0 0 0 0 0 4 3

20 Hydro pneumatic Press 170 kN ( Serial Number Marking ) 1 5 3 3 2 5 3 3 2 0 0 0 0 0 0 0 0

21 Round Bending Machine 2 2,5 2 5 4 0 0 0 0 0 0 0 0 0 0

22 Foot Ring Inner Seam Welding Machine 2 42 32 1 0,5 84 64 2 1 0 0 0 0 0 0 0 0

Guard Ring Stamping Die Set 6,12,35,45 kg Operation 1 1 0 0 0 0 0 0 0 0 0 0 0 0

Guard Ring Stamping Die Set 6,12,35,45 kg Active Parts Operation 1 1 0 0 0 0 0 0 0 0 0 0 0 0

Guard Ring Forming Die Set 6,12,35,45 kg Operation 2 1 0 0 0 0 0 0 0 0 0 0 0 0

Foot Ring Stamping Die Set 6,12 kg Operation 1 1 0 0 0 0 0 0 0 0 0 0 0 0

Foot Ring Forming Die Set 6,12 kg Active Parts Operation 1 1 0 0 0 0 0 0 0 0 0 0 0 0

Foot Ring Forming Die Set 6,12 kg Operation 2 1 0 0 0 0 0 0 0 0 0 0 0 0

Foot Ring Stamping Die Set 35,45 kg Operation 1 1 0 0 0 0 0 0 0 0 0 0 0 0

1-2 Meghna Utility Consumption Plus.xls

Nominal Cooling Water Requirement

Maximum Clean Water Consumption

FOR THOSE MACHINES MAY BE

Nominal Clean Water Consumption

Maximum Electrical Consumption

Total Maximum Natural Gas / LPG

Electrical Consumption (kWh) by

Total Maximum Air Consumption

APPROXIMATE WEIGHT (ONY

Nominal Electrical Consumption

Total Nominal Natural Gas / LPG

LAY OUT POSITION NUMBER

Total Nominal Air Consumption

INSTALLATION BASE AREA)

Emergency Power Cut Nominal

Total Maximum Cooling Water

CONSIDERED HEAVY WITH

Total Nominal Cooling Water

Total Maximum Waste Water

Maximum Natural Gas / LPG

Total Maximum Clean Water

Maximum Air Consumption

Total Nominal Waste Water

Nominal Natural Gas / LPG

Total Nominal Clean Water

Generator Recomendation

Pit / Channel Requirement

Nominal Air Consumption

Total Maximum Electrical

Maximum Cooling Water

Total Nominal Electrical

Maximum Waste Water

RESPECT TO THEIR

Consumption (Nm³/h)

Consumption (Nm³/h)

Consumption (Nm³/h)

Consumption (Nm³/h)

Nominal Waste Water

Consumption (m³/h)

Consumption (kWh)

Consumption (kWh)

Consumption (m³/h)

Requirement (m³/h)

Requirement (m³/h)

Requirement (m³/h)

(m3/h) 6 bar

(m3/h) 6 bar

(m3/h) 6 bar

(m3/h) 6 bar

(kWh)

(kWh)

(m³/h)

(m³/h)

(m³/h)

(m³/h)

(m³/h)

(m³/h)

(m³/h)

DESIGNATION QTY

Foot Ring Stamping Die Set 35,45 kg Active Parts Operation 1 1 0 0 0 0 0 0 0 0 0 0 0 0

Foot Ring Forming Die Set 35,45 kg Operation 2 1 0 0 0 0 0 0 0 0 0 0 0 0

Finishing Line 0 0 0 0 0 0 0 0 0 0 0 0

23 Cylinder Halves Degreasing Unit 1 45 35 1,5 0,5 1,5 0,5 43 20 Yes 45 35 0 0 1,5 0,5 1,5 0,5 43 20 0 0

24 Shot Blasting Machine 1 117 75 16 12 117 75 16 12 0 0 0 0 0 0 0 0

25 Zinc Spray Metallization Unit semi automatic 1 100 60 160 120 100 60 160 120 0 0 0 0 0 0 0 0

26 Powder Coating Line & Curing ; semi automatic 1 70 40 70 180 130 43 20 70 40 180 130 0 0 0 0 43 20 0 0

27 Second colar painting line & curing semi automatic 1 30 20 30 80 50 30 15 30 20 80 50 0 0 0 0 30 15 0 0

Testing Line 0 0 0 0 0 0 0 0 0 0 0 0

28 Hydrostatic Testing Units semi automatic 3 6 4 10 8 0,1 0,1 0,01 0,01 18 12 24 0,3 0,3 0,03 0,03 0 0 0 0 0

29 Pneumatic Leakage Testing Machine semi utomatic 1 4 3 20 15 0,1 0,1 0,01 0,01 0 0 0 0 4 3 15 0,1 0,1 0,01 0,01 0 0 0 0 0

30 Valve Boss Cleaning Machine 1 2 1 2 1 0 0 0 0 0 0 0 0 0 0

31 Valve Screwing Machine 2 3 1,5 6 3 0 0 0 0 0 0 0 0 0 0

32 Basic Conveyor Systems ( As per Layout at diffeent sections ) 1 30 20 30 20 0 0 0 0 0 0 0 0 0 0

Industrial Cylinder Liner 0 0 0 0 0 0 0 0 0 0 0 0

33 Double Head Circumferential Welding Unit 1 120 90 4 3 120 90 4 3 0 0 0 0 0 0 0 0

34 Longitudinal Welding Unit 1 60 45 2 1,5 2 1 60 45 2 1,5 0 0 0 0 0 0 2 1

35 Round Bending Machine 35-45 KG 1 7,5 4 0 0 7,5 4 0 0 0 0 0 0 0 0 2 1

36 Semi Automatic Hydrostatic Testıng Unıt for 35/ 45 kg 1 4 2 10 8 0,1 0,1 0,01 0,01 4 2 8 0,1 0,1 0,01 0,01 0 0 0 0 0

37 Semi Automatic Pneumatic Leakage Testing Unit fr 35/45 kg 1 2 1,5 10 7 0,1 0,1 0,01 0,01 0 0 0 0 2 1,5 7 0,1 0,1 0,01 0,01 0 0 0 0 0

Lab. Equipment 0 0 0 0 0 0 0 0 0 0 0 0

Tensile Machine, Universal Testing machine (50 kN) 1 3 1,8 3 1,8 0 0 0 0 0 0 0 0 0 0

X-Ray Mahine with all Accessories 1 12 9 12 9 0 0 0 0 0 0 0 0 0 0

Die Set for the Sample Preparation 1 0 0 0 0 0 0 0 0 0 0 0 0

38 Burst Test Equipment 1 2 1,2 2 2 0,5 0,5 0,5 0,5 0 0 0 Yes 2 1,2 2 0,5 0,5 0,5 0,5 0 0 0 0 0

0 0 0 0 0 0 0 0 0 0 0 0

39 Complete Slitting Line 1 250 200 250 200 0 0 0 0 0 0 0 0 0 0

Spare Parts for the warranty period 1 0 0 0 0 0 0 0 0 0 0 0 0

40 Cooling Tower 1 7,5 5 7,5 7,5 5 0 0 0 0 0 0 0 0 0 0

41 Compressor ( Atlas Copco ) + Dryer + Accumulator 1 55 40 55 55 40 0 0 0 0 0 0 0 0 0 0

TOTAL 187,5 2381 1704,5 564 356,6 2,6 1,06 2,06 0,5 356 179 44 28,5

2-2 Meghna Utility Consumption Plus.xls

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- HGU User ManualDocument72 pagesHGU User Manuallomayani100% (1)

- F4a41, F4a51, F5a51Document4 pagesF4a41, F4a51, F5a51Vadim Urupa67% (3)

- Comparison of Design Calculations of Deep Beams Using Various International CodesDocument10 pagesComparison of Design Calculations of Deep Beams Using Various International CodesHabibur RahmanNo ratings yet

- Bhaluka Project Capacity With Estimated Costing of All MC & Others For OperationDocument2 pagesBhaluka Project Capacity With Estimated Costing of All MC & Others For OperationHabibur RahmanNo ratings yet

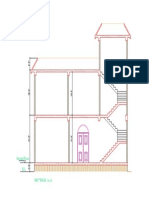

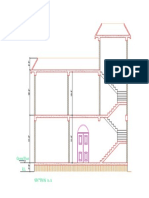

- 12 Storied Residential BuildingDocument67 pages12 Storied Residential BuildingHabibur RahmanNo ratings yet

- 1 PDFDocument1 page1 PDFHabibur RahmanNo ratings yet

- A C D E B: Column Layout Plan NDocument1 pageA C D E B: Column Layout Plan NHabibur RahmanNo ratings yet

- A C D E B: 1St Floor Plan AREA 1790.00 SQFTDocument1 pageA C D E B: 1St Floor Plan AREA 1790.00 SQFTHabibur RahmanNo ratings yet

- Footing Schedule: 10 MM Ø at 4" / 8" C/C Clear Cover 1 "Document1 pageFooting Schedule: 10 MM Ø at 4" / 8" C/C Clear Cover 1 "Habibur RahmanNo ratings yet

- PICLU measurmentDETAILS 17 - 05-2020 01 PDFDocument1 pagePICLU measurmentDETAILS 17 - 05-2020 01 PDFHabibur RahmanNo ratings yet

- DUPLAX For Alamin (20-03-19) - Model 04 PDFDocument1 pageDUPLAX For Alamin (20-03-19) - Model 04 PDFHabibur RahmanNo ratings yet

- Pikul Uncle Slab Re-Bar Details 05-05-2020-01Document1 pagePikul Uncle Slab Re-Bar Details 05-05-2020-01Habibur RahmanNo ratings yet

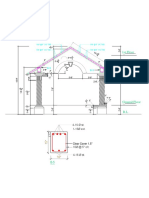

- Slanting Roof PDFDocument1 pageSlanting Roof PDFHabibur RahmanNo ratings yet

- Column Schedule: Index Below G.L. Grd. TO 1st. Floor. 1st Floor. StirrupsDocument1 pageColumn Schedule: Index Below G.L. Grd. TO 1st. Floor. 1st Floor. StirrupsHabibur RahmanNo ratings yet

- Column Schedule: Index Below G.L. Grd. TO 1st. Floor. 1st Floor. StirrupsDocument1 pageColumn Schedule: Index Below G.L. Grd. TO 1st. Floor. 1st Floor. StirrupsHabibur RahmanNo ratings yet

- From Saiful DUPLAX Sani04 PDFDocument1 pageFrom Saiful DUPLAX Sani04 PDFHabibur RahmanNo ratings yet

- Working of Ground Floor Layout Plan: StoreDocument1 pageWorking of Ground Floor Layout Plan: StoreHabibur RahmanNo ratings yet

- 1 PDFDocument1 page1 PDFHabibur RahmanNo ratings yet

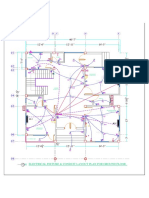

- A C D E B: N Electrical Fixture & Conduit Layout Plan For Ground FloorDocument1 pageA C D E B: N Electrical Fixture & Conduit Layout Plan For Ground FloorHabibur RahmanNo ratings yet

- Proposal FeeDocument5 pagesProposal FeeHabibur Rahman100% (1)

- Tffi ( : Ffiq Ffi Fu Q Ffi Fu FR .Ffi (,6 (Qffiqq Rffiq CffiDocument1 pageTffi ( : Ffiq Ffi Fu Q Ffi Fu FR .Ffi (,6 (Qffiqq Rffiq CffiHabibur RahmanNo ratings yet

- 1 PDFDocument1 page1 PDFHabibur RahmanNo ratings yet

- DUPLAX For Alamin (20-03-19) - Model PDFDocument1 pageDUPLAX For Alamin (20-03-19) - Model PDFHabibur RahmanNo ratings yet

- Working of 1St Floor Layout Plan: VER 9'-9'X 6'-10" Prayer Room 11'-5"X7'-4"Document1 pageWorking of 1St Floor Layout Plan: VER 9'-9'X 6'-10" Prayer Room 11'-5"X7'-4"Habibur RahmanNo ratings yet

- DUPLAX For Alamin (20-03-19) - Model 06 PDFDocument1 pageDUPLAX For Alamin (20-03-19) - Model 06 PDFHabibur RahmanNo ratings yet

- A C D E B: Column Layout Plan NDocument1 pageA C D E B: Column Layout Plan NHabibur RahmanNo ratings yet

- NO Measurement by Griess MethodDocument9 pagesNO Measurement by Griess MethodhardianNo ratings yet

- MCSL-045 Solved Assignments 2014-15Document6 pagesMCSL-045 Solved Assignments 2014-15manishNo ratings yet

- The Essentials of Directional Protection and SelectivityDocument27 pagesThe Essentials of Directional Protection and SelectivityMarcus Figueroa100% (1)

- Econ 103 - 01Document3 pagesEcon 103 - 01perrerNo ratings yet

- Synopsis (Alumni Association)Document17 pagesSynopsis (Alumni Association)vishygNo ratings yet

- 2018 Academic Sector Annual Report PDFDocument213 pages2018 Academic Sector Annual Report PDFEsperanza ReyesNo ratings yet

- Move Order APIDocument11 pagesMove Order APIsubbaraocrm100% (3)

- Current Fault Codes: Code Text StatusDocument39 pagesCurrent Fault Codes: Code Text StatusNovakurniawanNo ratings yet

- Coomaraswamy, SarpabandhaDocument3 pagesCoomaraswamy, SarpabandhakamakarmaNo ratings yet

- Characteristics of Supercritical Flow in Rectangular ChannelDocument10 pagesCharacteristics of Supercritical Flow in Rectangular ChannelFatihNo ratings yet

- Wireless Body Area Networks: A SurveyDocument29 pagesWireless Body Area Networks: A Surveyabdul hananNo ratings yet

- Saudi Aramco Inspection ChecklistDocument3 pagesSaudi Aramco Inspection ChecklistManoj KumarNo ratings yet

- Handheld YokogawaDocument38 pagesHandheld YokogawaArturo Gasperin BarrigaNo ratings yet

- Gym Mega ForceDocument3 pagesGym Mega ForceAnonymous iKb87OINo ratings yet

- Sony CR1220 PDFDocument2 pagesSony CR1220 PDFdiego742000No ratings yet

- Xenon Xenalight Surgical Lighting SystemsDocument2 pagesXenon Xenalight Surgical Lighting SystemsQasim AliNo ratings yet

- Data CenterDocument108 pagesData CenterKhanh Nato100% (5)

- The Beginner's Guide To SynthsDocument11 pagesThe Beginner's Guide To SynthsAnda75% (4)

- Family Surveyed 2017 - TimberDocument26 pagesFamily Surveyed 2017 - TimberAlibasher Macalnas0% (1)

- SBI Clerk Mains Bolt 2023 OliveboardDocument160 pagesSBI Clerk Mains Bolt 2023 OliveboardMaahi ThakorNo ratings yet

- Java - Informatica Scenario Based Interview Questions (Convert Columns Into Rows)Document6 pagesJava - Informatica Scenario Based Interview Questions (Convert Columns Into Rows)Sri Kanth SriNo ratings yet

- Building 101 - 25 Tips For A Tropical HomeDocument11 pagesBuilding 101 - 25 Tips For A Tropical HomeMelanie CabforoNo ratings yet

- Database AssignmentDocument29 pagesDatabase AssignmentAdasa EdwardsNo ratings yet

- T-Spice User's Guide: Release 16.3 June 2015Document579 pagesT-Spice User's Guide: Release 16.3 June 2015Laxmi GuptaNo ratings yet

- PESTLE Analysis Patanjali Ayurved LTDDocument7 pagesPESTLE Analysis Patanjali Ayurved LTDvaidehi50% (2)

- ProductBrochure A35F A40F en 30A1006561Document24 pagesProductBrochure A35F A40F en 30A1006561Ji UvexNo ratings yet

- Is 13687 1993Document15 pagesIs 13687 1993ADIPESHNo ratings yet