Professional Documents

Culture Documents

Crack Width Calculation Report

Uploaded by

Nitesh SinghOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Crack Width Calculation Report

Uploaded by

Nitesh SinghCopyright:

Available Formats

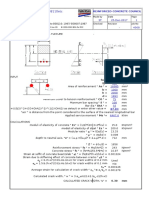

BY:BDK TATABY:BDK

CONSULTING ENGINEERS LIMITED PROJECT:SEZ PROJECT

DATE: CLIENT: COSMO FILMS LTD. DOC. NO.:

CHD.: SUBJECT: Crack Width

DATE: JOB NO.: TCE.6390A OFFICE:DV DISC.:CV SH. OF REV. NO.:

1.0.MATERIAL PROPERTIES

Grade of Concrete,fck = M25 N/mm2

Grade of steel,fy = 415 N/mm2

Modulus of elasticity of steel,Es = 200000 N/mm2 IS 456-2000 Cl.5.6.3

Modulus of elasticity of concrete,Ec = 5000 fck = 25000 N/mm2 IS 456-2000 Cl.6.2.3.1

280

Modular ratio,m = = 10.98 IS 456-2000Cl.B-2.1.2

3 cbc

2.0.SECTION PROPERTIES

C/C distance between two bars = 125 mm.

Diameter of bars,Dia = 12 mm.

Clear cover, Cmin = 50 mm.

Width of the section at the centroid of the tension steel,b = 1000 mm.

Distance from the compression face to the point at which the

crack width is being calculated,a = 350 mm.

Overall depth of the section,h = 350 mm.

Area of steel provided,As = 904.779 mm2.

Permissible crack width = 0.2 mm.

3.0.LOADS

Unfactored moment = 42.7382 kN/m.

4.0.CALCULATION

Effective depth of the section,d = 294 mm.

4.1.Calculation of Neutral axis depth,x

bx2/2 = mAst(d-x)

1000*x^2/2 = 10.99*904.779*(294-x)

500x^2 + 9934.83x - 2920839.5 = 0

Depth of neutral axis,x = 67.139 mm.

4.2. Calculation of Cracked moment of inertia,I cr

Icr = bx3/3 + mAst(d-x)2

= 1000*67.14^3/3+10.98*904.779(294-67.14)^2

= 612184608.55 mm4

4.3.Calculation of tensile stress in steel,fst

mM (d x)

fst

I cr

= 10.98*42.74*10^6*(294-67.14)/612184608.55

= 173.905 N/mm2 < 332 N/mm2 IS 456-2000 Annex-F

Tensile stress in steel is Within Limit specified in IS456-2000 Annex-F

4.4.Calculation of Crack width

Strain at the level considered fst . a x = 0.00108

1

Es d x

FILE NAME: F010R2.XLS TCE FORM NO. 010 R2

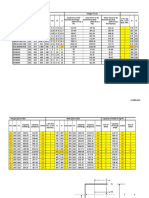

BY:BDK TATABY:BDK

CONSULTING ENGINEERS LIMITED PROJECT:SEZ PROJECT

DATE: CLIENT: COSMO FILMS LTD. DOC. NO.:

CHD.: SUBJECT: Crack Width

ax

fst OFFICE:DV

DATE: 1

JOB NO.: TCE.6390A . DISC.:CV SH. OF REV. NO.:

Es d x

b( h x)( a x )

Average steel strain m 1 = 0.00043

3EsAs(d x)

Distance from the point considered to the

surface of the nearest longitudinal bar,acr = 77.9181 mm

3a cr m

Design surface crackwidth Wcr

2(a cr c min )

1

hx

= 0.08482 mm Safe

FILE NAME: F010R2.XLS TCE FORM NO. 010 R2

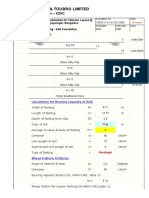

BY:BDK TATABY:BDK

CONSULTING ENGINEERS LIMITED PROJECT:SEZ PROJECT

DATE: CLIENT: COSMO FILMS LTD. DOC. NO.:

CHD.: SUBJECT: Crack Width

DATE: JOB NO.: TCE.6390A OFFICE:DV DISC.:CV SH. OF REV. NO.:

FILE NAME: F010R2.XLS TCE FORM NO. 010 R2

You might also like

- Tata Consulting Engineers LimitedDocument24 pagesTata Consulting Engineers LimitedNitish TakalkarNo ratings yet

- Water TankDocument26 pagesWater Tankabhi aroteNo ratings yet

- Crack WidthDocument4 pagesCrack Widthnavneet3bawaNo ratings yet

- Composite Slab DesignDocument6 pagesComposite Slab DesignFranklyn GenoveNo ratings yet

- Design circular column uni-axial bi-axial load capacityDocument7 pagesDesign circular column uni-axial bi-axial load capacityDhananjay ShindeNo ratings yet

- Base Plate With Shear KeyDocument3 pagesBase Plate With Shear Keyvpjagannaath100% (1)

- Corbel DesignDocument3 pagesCorbel DesignLim EcNo ratings yet

- Eccentric-Footing 2Document5 pagesEccentric-Footing 2Yash GoyalNo ratings yet

- Bolted Web Plate ConnectionDocument20 pagesBolted Web Plate ConnectionjatinNo ratings yet

- Beam To Column End Plate ConnectionDocument10 pagesBeam To Column End Plate ConnectionParchuri PraveenNo ratings yet

- Rafter & Rafter connection designDocument3 pagesRafter & Rafter connection designnikmmmecNo ratings yet

- Crack WidthDocument5 pagesCrack WidthchanakyaNo ratings yet

- Strip Beam Design 24 07 19Document37 pagesStrip Beam Design 24 07 19Ahammad KabeerNo ratings yet

- 2.column Base Plate (Fixed Type)Document15 pages2.column Base Plate (Fixed Type)ZevanyaRolandTualakaNo ratings yet

- Retaining Wall DesignDocument9 pagesRetaining Wall DesignEngr Benalito A Catap IIINo ratings yet

- PedestalP2 - (350x350) 7Document23 pagesPedestalP2 - (350x350) 7Feroz Khan PatthanNo ratings yet

- Design of Welded Plate GirderDocument25 pagesDesign of Welded Plate GirderJinshad UppukodenNo ratings yet

- RCCen14 Crack WidthDocument3 pagesRCCen14 Crack WidthJilJilNo ratings yet

- Crack Width CheckDocument2 pagesCrack Width CheckJitendra SinghNo ratings yet

- Design Z Section PurlinDocument9 pagesDesign Z Section PurlinSudipta HuiNo ratings yet

- Circular Water Tank Design: Capacity of Tank Free Board Total HeightDocument2 pagesCircular Water Tank Design: Capacity of Tank Free Board Total HeightyasirjurabaNo ratings yet

- CFRP CalculationDocument49 pagesCFRP Calculationmasud parveg100% (1)

- Base Slab Crack Width CalculationDocument3 pagesBase Slab Crack Width CalculationSheikh Mizanur RahmanNo ratings yet

- Dynamic Active Earth Pressure On Retaining StructuresDocument10 pagesDynamic Active Earth Pressure On Retaining StructurescristiannecivilNo ratings yet

- Crack Width Calculation For Rectangular RC BeamDocument1 pageCrack Width Calculation For Rectangular RC BeamRomyMohanNo ratings yet

- Shear Connection For Ismb 300 TO ISMB350 COL: Bolt CalculationDocument4 pagesShear Connection For Ismb 300 TO ISMB350 COL: Bolt CalculationNitin SakpalNo ratings yet

- Multi Storey Bldg Pile Foundation DesignDocument5 pagesMulti Storey Bldg Pile Foundation DesignIlmtalabNo ratings yet

- Job Pile Design-450 (R1)Document3 pagesJob Pile Design-450 (R1)Kyle Foreman100% (1)

- Pile Cap - Pedestal - Beam Design - Add-On Ammonia ConverterDocument22 pagesPile Cap - Pedestal - Beam Design - Add-On Ammonia ConverterShuvam SarkarNo ratings yet

- RCC Members Desgns Is456&Is3370Document25 pagesRCC Members Desgns Is456&Is3370RAJESHWARRAO BANDARINo ratings yet

- Depth of Fixity & Pile DesignDocument2 pagesDepth of Fixity & Pile DesignSoumya BandyopadhyayNo ratings yet

- Crack Width Calculation for ColumnDocument3 pagesCrack Width Calculation for ColumnAnil kumar RNo ratings yet

- Crack Width Check For Water Tank BaseDocument4 pagesCrack Width Check For Water Tank BaseShamim Ahsan ZuberyNo ratings yet

- Actual Base Plate Design-V1.2-42-210Document6 pagesActual Base Plate Design-V1.2-42-210Livian TeddyNo ratings yet

- Water Tank - Is 3370-Mbbr Tank - 1 & 2Document4 pagesWater Tank - Is 3370-Mbbr Tank - 1 & 2Dhayalan PalanisamyNo ratings yet

- Calculation Sheet: 71197 Design For Pile Cap - Two Piles PP DJM MVLDocument3 pagesCalculation Sheet: 71197 Design For Pile Cap - Two Piles PP DJM MVLV.m. RajanNo ratings yet

- Pile Cap Design - ColumnsDocument7 pagesPile Cap Design - ColumnsMohit VatsNo ratings yet

- Water Tank - Is 3370-Sludge TankDocument4 pagesWater Tank - Is 3370-Sludge TankDhayalan PalanisamyNo ratings yet

- Pile Cap Design 6pileDocument18 pagesPile Cap Design 6pileAnkit GhildiyalNo ratings yet

- Project: 34M Stadium Mast - Philips India Limited Description: D-28/SM/TLL Pile Cap Design For CompressionDocument4 pagesProject: 34M Stadium Mast - Philips India Limited Description: D-28/SM/TLL Pile Cap Design For CompressionEr Ravi VishwakarmaNo ratings yet

- IS800_2007_Tube Design CalculationDocument4 pagesIS800_2007_Tube Design CalculationLandon MitchellNo ratings yet

- RCC12 Bending and Axial ForceDocument4 pagesRCC12 Bending and Axial ForceCioabla Bogdan100% (1)

- Design of Grade Slab for Medical Research CentreDocument7 pagesDesign of Grade Slab for Medical Research CentreersivarajNo ratings yet

- Corbel designDocument4 pagesCorbel designnonameNo ratings yet

- Connection Design SteelDocument19 pagesConnection Design Steelबिजेन्द्र प्रधानNo ratings yet

- Design Data: Design For Base Plate (Fixed)Document4 pagesDesign Data: Design For Base Plate (Fixed)Wibawa WorksNo ratings yet

- Wall DesignDocument13 pagesWall DesignAnantPawarNo ratings yet

- Cantilever Retaining Wall - RameswaramDocument23 pagesCantilever Retaining Wall - RameswaramD.V.Srinivasa RaoNo ratings yet

- Isolated Trapezoidal Footing DesignDocument6 pagesIsolated Trapezoidal Footing Designhemantkle2uNo ratings yet

- JSW Severfield Structure Ltd. composite column design EC4Document3 pagesJSW Severfield Structure Ltd. composite column design EC4RonakShahNo ratings yet

- Design of Base PlateDocument3 pagesDesign of Base Plateravi4paperNo ratings yet

- RCC Chimney Calculation SheetDocument16 pagesRCC Chimney Calculation Sheetbhargavramudu 2019No ratings yet

- FRP Strengthening of Reinforced Concrete ColumnsDocument15 pagesFRP Strengthening of Reinforced Concrete ColumnsPauloAndresSepulvedaNo ratings yet

- Design of Open Well StaircaseDocument2 pagesDesign of Open Well StaircaseAnish Neupane100% (1)

- Pile Cap Design (4-Piles)Document4 pagesPile Cap Design (4-Piles)Uttam Kumar GhoshNo ratings yet

- Corbel DesignDocument5 pagesCorbel DesignHari prasad GaddamNo ratings yet

- Design of Pile Caps - Mahila Samakya BuildingsDocument8 pagesDesign of Pile Caps - Mahila Samakya BuildingsD.V.Srinivasa RaoNo ratings yet

- Spreadsheets To BS 8110etc: Advisory Group Grid Line 1 ST 25-Dec-2017 1 - 4068Document4 pagesSpreadsheets To BS 8110etc: Advisory Group Grid Line 1 ST 25-Dec-2017 1 - 4068vaideehNo ratings yet

- Beam designDocument54 pagesBeam designLagnajit DasNo ratings yet

- Aci Beam Crack Width Bot ZDocument2 pagesAci Beam Crack Width Bot ZParthiban ArivazhaganNo ratings yet

- Welded Splice Connection-R2Document16 pagesWelded Splice Connection-R2Nitesh Singh100% (1)

- Strap Footing PDFDocument7 pagesStrap Footing PDFMohammed Sumer100% (1)

- FormworkDocument24 pagesFormworkSreedhar Reddy SajjalaNo ratings yet

- Lec17 PDFDocument14 pagesLec17 PDFNitesh SinghNo ratings yet

- List of Pending Tests: Test Name SamplestatusDocument13 pagesList of Pending Tests: Test Name SamplestatusNitesh SinghNo ratings yet

- Lec 1Document11 pagesLec 1Roshan SinghNo ratings yet

- 10 Ce 129Document2 pages10 Ce 129Nilay GandhiNo ratings yet

- 24 Sample ChapterDocument14 pages24 Sample ChapterRomyMohanNo ratings yet

- S T S T: Larsen & Toubro LimitedDocument4 pagesS T S T: Larsen & Toubro LimitedNitesh SinghNo ratings yet

- Design of StaircaseDocument4 pagesDesign of StaircaseahmedNo ratings yet

- Lec19 PDFDocument14 pagesLec19 PDFNitesh SinghNo ratings yet

- RFP StructuralDocument35 pagesRFP StructuralNitesh SinghNo ratings yet

- SBC DesignDocument5 pagesSBC DesignNitesh SinghNo ratings yet

- Lec16 PDFDocument7 pagesLec16 PDFNitesh SinghNo ratings yet

- CW ChannelDocument40 pagesCW ChannelNitesh SinghNo ratings yet

- Larsen & Toubro Limited: ECC Division - EDRCDocument11 pagesLarsen & Toubro Limited: ECC Division - EDRCNitesh SinghNo ratings yet

- CW ChannelDocument40 pagesCW ChannelNitesh SinghNo ratings yet

- Crack Width Calculation ReportDocument3 pagesCrack Width Calculation ReportNitesh SinghNo ratings yet

- Kirby - Typ Base PlateDocument19 pagesKirby - Typ Base PlateNitesh Singh100% (1)

- Truss PDFDocument18 pagesTruss PDFNitesh SinghNo ratings yet

- Sump Design - IS 456-2000Document26 pagesSump Design - IS 456-2000Nitesh SinghNo ratings yet

- IS Design Code Vs AS Code PDFDocument8 pagesIS Design Code Vs AS Code PDFNitesh SinghNo ratings yet

- Composite Slab DesignDocument13 pagesComposite Slab Design_jesseca100% (2)

- Circular Steel Tank Design CalculationDocument9 pagesCircular Steel Tank Design CalculationNitesh SinghNo ratings yet

- Design of Brick Drain Wall and Base CalculationsDocument8 pagesDesign of Brick Drain Wall and Base CalculationsNitesh SinghNo ratings yet

- Design of Lift Footing MKD. F8Document3 pagesDesign of Lift Footing MKD. F8Nitesh SinghNo ratings yet

- Circular Steel Tank Design CalculationDocument9 pagesCircular Steel Tank Design CalculationNitesh SinghNo ratings yet

- Trench Wall Design - IS456-2000Document7 pagesTrench Wall Design - IS456-2000Nitesh SinghNo ratings yet

- Design Drawing Practice On Rectangular Combined Footing Numerical 2 PDFDocument8 pagesDesign Drawing Practice On Rectangular Combined Footing Numerical 2 PDFsm31No ratings yet

- Ret Walls-MCN PDFDocument15 pagesRet Walls-MCN PDFDivyadristiNo ratings yet

- Analysis of Excessive Hydrogen Generation in TransformersDocument8 pagesAnalysis of Excessive Hydrogen Generation in TransformersandikaubhNo ratings yet

- GU - Cabine MT BT (EN) - 1VCP000591 1511Document88 pagesGU - Cabine MT BT (EN) - 1VCP000591 1511Fatmir JashariNo ratings yet

- Raman BandsDocument2 pagesRaman Bandspreyas1No ratings yet

- Diebold ManualDocument2 pagesDiebold Manualjoseperezlopes069No ratings yet

- Doubble EncriptionDocument60 pagesDoubble Encriptiondeepak kumarNo ratings yet

- Fire ZoneDocument8 pagesFire ZoneKannan NNo ratings yet

- Operations Management 1St Edition Cachon Test Bank Full Chapter PDFDocument36 pagesOperations Management 1St Edition Cachon Test Bank Full Chapter PDFwayne.martin885100% (11)

- Temperarura4 PDFDocument371 pagesTemperarura4 PDFmario yanezNo ratings yet

- UCE802 Earthquake SyllabusDocument2 pagesUCE802 Earthquake Syllabuskullu88No ratings yet

- CHAPTER 6 Coordinate Geometry Module ExercisesDocument15 pagesCHAPTER 6 Coordinate Geometry Module ExercisesBid Hassan75% (8)

- Thrust Bearing CalculationsDocument162 pagesThrust Bearing Calculationslahiru1983100% (1)

- Sisweb Sisweb Techdoc Techdoc Print Pag - pdf1Document91 pagesSisweb Sisweb Techdoc Techdoc Print Pag - pdf1MatiussChesteerNo ratings yet

- SAT-101 User Manual: Document No: MAN-0013 Issue No: 4 Dated: 24 Aug 2004Document24 pagesSAT-101 User Manual: Document No: MAN-0013 Issue No: 4 Dated: 24 Aug 2004VM ServicesNo ratings yet

- Class - 8 PT3 - Portion 2023 24 - 1Document5 pagesClass - 8 PT3 - Portion 2023 24 - 1gurdeepbeniwal97No ratings yet

- Lecture - 12 - Project EvaluationDocument68 pagesLecture - 12 - Project EvaluationEngr. Md. Ashraful AlamNo ratings yet

- BA (Hons) Philosophy CurriculumDocument123 pagesBA (Hons) Philosophy CurriculumDARSHAN RAAJANNo ratings yet

- Basic Chromatography Notes 1Document27 pagesBasic Chromatography Notes 1Aufa InsyirahNo ratings yet

- Two Sigma - LeetCodeDocument2 pagesTwo Sigma - LeetCodePeeyushNo ratings yet

- 9th-Implementing Lockout Function With IEC61850 PDFDocument11 pages9th-Implementing Lockout Function With IEC61850 PDFBharath SaiNo ratings yet

- Spe 58987 Propped Fracturing in Gas Carbonate Formations MexicoDocument12 pagesSpe 58987 Propped Fracturing in Gas Carbonate Formations MexicoJose Gregorio FariñasNo ratings yet

- DocDocument6 pagesDocapi-287506055No ratings yet

- Wilo Fire Fighting BrochureDocument20 pagesWilo Fire Fighting BrochureAkhmad Darmaji DjamhuriNo ratings yet

- Yokogawa 2015 Centum VP For Batch ControlDocument9 pagesYokogawa 2015 Centum VP For Batch ControlArzymanNo ratings yet

- Flight Planning For ATTDocument106 pagesFlight Planning For ATTTienek Lee100% (1)

- I. 8-Bit Microprocessors Architecture, Instruction Set and Their ProgrammingDocument4 pagesI. 8-Bit Microprocessors Architecture, Instruction Set and Their ProgrammingSaorabh KumarNo ratings yet

- OOPS AbapDocument188 pagesOOPS Abapraky036950% (2)

- Rex - O. Ed. Wagner - W-Waves - BiocommDocument13 pagesRex - O. Ed. Wagner - W-Waves - BiocommLeon BlažinovićNo ratings yet

- Financial management project report for cement factoryDocument106 pagesFinancial management project report for cement factoryAksh KhandelwalNo ratings yet

- Chapter 5 Lennard Jones PotentialDocument6 pagesChapter 5 Lennard Jones PotentialMuhamad RayhanNo ratings yet

- Welding robot aviation plug terminal definitionDocument4 pagesWelding robot aviation plug terminal definitionPhươngNguyễnNo ratings yet