Professional Documents

Culture Documents

10210TFX Epic TFX Printable Adhesive

Uploaded by

edgar2763Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

10210TFX Epic TFX Printable Adhesive

Uploaded by

edgar2763Copyright:

Available Formats

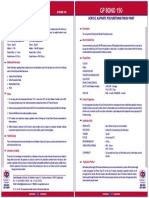

Product Information Bulletin Recommended Parameters

10210TFX Epic TFX Printable Adhesive Fabric Types

100% cotton, cotton blends

Wilflex™ Epic TFX Printable Adhesive has been formulated as a hot-split/hot-peel transfer adhesive

to be used as an adhesive backer to all Epic Transflex inks. Epic TFX Printable Adhesive can be printed

on multiple substrate paper types including: hot-peel/hot-split, cold peel and dual hot split/cold peel

transfer papers.

Highlights Mesh

ffExcellentadhesion to cotton and cotton blend fabrics. Counts: 110-158 t/in (43-62 t/cm)

ffImproves ink stretch and washability. Tension: 25-35 n/cm2

ffProvides additional ink durability when used on stretchable fabrics.

ffCan be used as foil and fabric adhesive.

Printing Tips Squeegee

ffUse 110t/in mesh (43 t/cm) as standard for large coverage and non-detailed graphics. Durometer: 60-80, 70/90, 70/90/70

ffFor fine line graphics use up to 195 t/in (77 t/cm) mesh. Edge: Square, Sharp

ffEpic Printable adhesive is printed last over the transfer inks. Stroke: Medium speed

*Do not use excess squeegee pressure.

ffSlightly under cut graphic image separations so as to allow ink to spread following heat press application.

ffPrint flat coat of Epic Printable Adhesive using a 70/90/70 triple durometer squeegee.

ffGel ink under dryer at 230°F (90°C). Do not cure ink.

ffFlash dry colors before applying printable adhesive.

Non-Phthalate Stencil

Direct: 2 over 2

Capillary/Thick Film: N/A

Compliance Off Contact: 1/16” (.2 cm)

ffNon-phthalate.

ffFor individual compliance certifications, please visit www.wilflex.com/compliance.

! Precautions Flash & Cure Temperatures

ffPerform fusion tests before production. Failure to cure ink properly may result in poor wash fastness, inferior Flash: 160°F (70°C)

adhesion and unacceptable durability. Ink gel and cure temperatures should be measured using a Thermoprobe Cure: 320°F (160°C)

placed directly in the wet ink film and verified on the production run substrate(s) and production equipment. It Transfer: 375°F (171°C)

is the responsibility of the printer to determine that the correct ink has been selected for a specific substrate and

the application processes meet your customer’s standards or specifications.

ffWhen using the adhesive as a hot peel/hot split ink do not cure adhesive through the dryer as this will result in

poor split/peel properties of the ink during heat press application. Gel ink only.

ffPretest all fabrics for desired properties before beginning production printing. Pigment Loading

ffWhen using the adhesive as a hot peel/hot split ink the transfer should be peeled immediately from the paper. EQ: 5% max

When cold peeling, allow the transfer to cool for approximately 10 seconds before removing paper. MX: N/A

PC: 5% max

ffStir plastisols before printing.

*All percentages listed at % by weight.

ffDo not dry clean, bleach or iron printed area.

ffNON-CONTAMINATION OF EPIC INKS: Do not add or mix non-Epic inks, additives or extenders with Epic inks.

All buckets, palette knives, stirring apparatus, squeegees, flood bars and screens must be cleaned properly and

free of phthalates and pvc containing inks. Non-phthalate emulsions and pallet adhesives must be used. Failure Epic Additives

to follow these precautions may cause phthalate contamination in violation of consumer protection laws and Extender: N/A

regulations. Reducer: N/A

ffAny application not referred in this product information bulletin should be pre-tested or consultation sought

*All percentages listed at % by weight.

with Wilflex Technical Services Department prior to printing.

ffEmail: techserviceswilflex@polyone.com

Storage

65-90°F (18-32°C)

Avoid direct sunlight.

Use within one year of receipt.

Clean Up

Ink degradent or press wash.

10210TFX Epic TFX Printable Adhesive : 07.2012V1

Health & Safety

MSDS: www.polyone.com or

Contact your local CSR.

® Wilflex™ inks by PolyOne. www.wilflex.com/pib TRANSFER ADDITIVE

©2013 PolyOne Corporation All Rights Reserved. Effective 5/05/2013. Not all Wilflex products are available in every country. The information in this publication is based on information and experience

believed reliable. Since many factors may affect processing for an application, processors must carry out their own tests and experiments to confirm suitability for intended use. You must make your

own determination of suitability for your intended use and environmental acceptability, the safety and health of your employees, and purchasers of your product.

You might also like

- 18000PFXCB Epic Cork BaseDocument1 page18000PFXCB Epic Cork BaseGustiyani 17No ratings yet

- 10008PFX Epic Special Effects Clear 16Document1 page10008PFX Epic Special Effects Clear 16johann HernandezNo ratings yet

- Eso266 NPT Barrier BaseDocument1 pageEso266 NPT Barrier BasejpdarNo ratings yet

- LETTERFLEX PERFECTOS. Speciality InksDocument27 pagesLETTERFLEX PERFECTOS. Speciality InksKhalil TradersNo ratings yet

- Application Instructions - FiberPlusDocument1 pageApplication Instructions - FiberPlusFreddy YorroNo ratings yet

- Kiwo PolyPlus MP TechnicalInformation PDFDocument2 pagesKiwo PolyPlus MP TechnicalInformation PDFobedNo ratings yet

- Brochure Guidelines For Preprinted Media - Oce Copy Press Technology - GB - April2011Document8 pagesBrochure Guidelines For Preprinted Media - Oce Copy Press Technology - GB - April2011zoka4175No ratings yet

- GTX Direct to Film Manual V2Document12 pagesGTX Direct to Film Manual V2Marjorie PalumboNo ratings yet

- مواصفات الدهان المطلوبDocument3 pagesمواصفات الدهان المطلوبmohamed zakiNo ratings yet

- Fenomastic Pure Colou Emulsion Matt (AZAD) Nasser A. AL - Hawasi Ras TanuraDocument3 pagesFenomastic Pure Colou Emulsion Matt (AZAD) Nasser A. AL - Hawasi Ras TanuraAzadAhmadNo ratings yet

- LANCO™ TF 1780 Lanco™ TF 1780 Ef: ApplicationsDocument2 pagesLANCO™ TF 1780 Lanco™ TF 1780 Ef: ApplicationsHai NguyenNo ratings yet

- DFT-067 F3946 01302015 FinalDocument4 pagesDFT-067 F3946 01302015 FinalMani KaruppiahNo ratings yet

- MF Photo GlossDocument2 pagesMF Photo GlossSean WrightNo ratings yet

- Serie RI-Jet 100 Ritrama Monomérico Blanco BrilloDocument4 pagesSerie RI-Jet 100 Ritrama Monomérico Blanco BrilloMaxwell MatosNo ratings yet

- Technical Data Sheet: 80 4520 Printing Paste To Improve The Adhesion On PlasticsDocument3 pagesTechnical Data Sheet: 80 4520 Printing Paste To Improve The Adhesion On PlasticsKisgyörgy ZoltánNo ratings yet

- Primeiros Passos Com DropboxDocument2 pagesPrimeiros Passos Com DropboxlrobertothNo ratings yet

- Index Fidia P - Mineral Roof Deck Plant Room Acciona W2E Kwinana 03-2019Document6 pagesIndex Fidia P - Mineral Roof Deck Plant Room Acciona W2E Kwinana 03-2019Biju_PottayilNo ratings yet

- Colorpro E SeriesDocument2 pagesColorpro E SeriessarwarwarsiNo ratings yet

- Jazeera Tetra Zinc l1Document3 pagesJazeera Tetra Zinc l1salam nazarNo ratings yet

- EA4 Finish MetalDocument3 pagesEA4 Finish MetalAzmeer YusufNo ratings yet

- Technical Data Sheet: 80 4518 Xpression Thixotropic AgentDocument2 pagesTechnical Data Sheet: 80 4518 Xpression Thixotropic AgentKisgyörgy ZoltánNo ratings yet

- Hi Pon 50 10 Polyester PU Primer Ver 2.0 PDFDocument4 pagesHi Pon 50 10 Polyester PU Primer Ver 2.0 PDFPushpendraNo ratings yet

- Application Guide Penguard Midcoat PDFDocument6 pagesApplication Guide Penguard Midcoat PDFsajan shaNo ratings yet

- Tds - Stretchable - Conductive - Ink - Setcit12410 - Eng - 0 EptanovaDocument2 pagesTds - Stretchable - Conductive - Ink - Setcit12410 - Eng - 0 EptanovaParul BatraNo ratings yet

- Internal Painting System - Data SheetDocument10 pagesInternal Painting System - Data SheetShaffi MohammedNo ratings yet

- Sublimation Paper ListDocument8 pagesSublimation Paper ListJeshu ValleNo ratings yet

- Fenomastic Stain Resistant EmulsionDocument3 pagesFenomastic Stain Resistant Emulsionمحمد عزتNo ratings yet

- Fiberline 402FR90 - TDSDocument1 pageFiberline 402FR90 - TDSPhuong The NguyenNo ratings yet

- Mipa P 85 Technical Data SheetDocument2 pagesMipa P 85 Technical Data SheetGeorgianaNo ratings yet

- Printperfekt AM5: CharacterizationDocument3 pagesPrintperfekt AM5: CharacterizationHazem FaroukNo ratings yet

- Grand Polycoat PolyurethaneDocument1 pageGrand Polycoat PolyurethaneAniket GaikwadNo ratings yet

- Fenomastic My Home Rich MattDocument3 pagesFenomastic My Home Rich Mattمحمد عزتNo ratings yet

- Jotun Paint Bathroom FenomasticDocument3 pagesJotun Paint Bathroom FenomasticDipin Nediya ParambathNo ratings yet

- Avery As606 Transf. Vellum-S2025n-Bg40brDocument2 pagesAvery As606 Transf. Vellum-S2025n-Bg40brAhmad HaririNo ratings yet

- Jotashield Topcoat Matt AA: Technical Data SheetDocument3 pagesJotashield Topcoat Matt AA: Technical Data SheetMahmoud EldusokyNo ratings yet

- Ai763 Pp60 Top Clear S4000-Pet30Document2 pagesAi763 Pp60 Top Clear S4000-Pet30Iván CsörgőNo ratings yet

- Aftek Fyreflex Jun14 Tds - Fire SealantDocument4 pagesAftek Fyreflex Jun14 Tds - Fire SealantYndia SorianoNo ratings yet

- Jotun-Fenomastic Pure Colours Enamel Gloss TDS PDFDocument3 pagesJotun-Fenomastic Pure Colours Enamel Gloss TDS PDFmark jade moratilloNo ratings yet

- Interior Emulsion Paint Technical DataDocument3 pagesInterior Emulsion Paint Technical Dataمحمد عزتNo ratings yet

- Get The Best Results: Océ Copypress TechnologyDocument9 pagesGet The Best Results: Océ Copypress TechnologyJPauloNo ratings yet

- Instruction 665 EsDocument6 pagesInstruction 665 EsSandro LozanoNo ratings yet

- High Build Epoxy Coating for Steel and ConcreteDocument2 pagesHigh Build Epoxy Coating for Steel and ConcreteTejinder KumarNo ratings yet

- Pionite Standard Laminate Tech Bulletin 6.2020Document4 pagesPionite Standard Laminate Tech Bulletin 6.2020rfrankivNo ratings yet

- Pro Epishield Floor SealerDocument2 pagesPro Epishield Floor SealerAnkush RanaNo ratings yet

- Mara® Flex FXDocument4 pagesMara® Flex FXTomek OsuchNo ratings yet

- UMA Advanced Technology Primer Sealer Bonder (White) : Technical Data XIM-03Document2 pagesUMA Advanced Technology Primer Sealer Bonder (White) : Technical Data XIM-03Jonathan ArboledaNo ratings yet

- Evo_Top_A75_englishDocument2 pagesEvo_Top_A75_englishUtpalNo ratings yet

- W1.04.04 Wanda Basecoat SB Color MMDocument4 pagesW1.04.04 Wanda Basecoat SB Color MMabdrauf243No ratings yet

- NP PU Rec FinishDocument4 pagesNP PU Rec FinishChip ChopNo ratings yet

- Perfection Pro Eng A4 20190131Document3 pagesPerfection Pro Eng A4 20190131Cristina CojocariuNo ratings yet

- Macal® 8200 Pro: Technical Data SheetDocument2 pagesMacal® 8200 Pro: Technical Data SheetMOHAMEDNo ratings yet

- Nippon Paint 8048 protects steelDocument3 pagesNippon Paint 8048 protects steelArmanda SiryogiawanNo ratings yet

- Nippon EA9 Finish HBDocument3 pagesNippon EA9 Finish HBHamza GhaniNo ratings yet

- Durosan 03 Exterior SemiglossDocument3 pagesDurosan 03 Exterior Semiglossمحمد عزتNo ratings yet

- Durosan 02 INT MATT (I) : Technical Data SheetDocument3 pagesDurosan 02 INT MATT (I) : Technical Data Sheetمحمد عزتNo ratings yet

- GP Primeguard 235Document1 pageGP Primeguard 235Krunal RudaniNo ratings yet

- Durosan 03 Exterior Matt (I) : Technical Data SheetDocument3 pagesDurosan 03 Exterior Matt (I) : Technical Data Sheetمحمد عزتNo ratings yet

- Application Instructions - SubliFlockDocument1 pageApplication Instructions - SubliFlockFreddy YorroNo ratings yet

- En 011 Epifanes PP Varnish ExtraDocument2 pagesEn 011 Epifanes PP Varnish ExtraJim BobNo ratings yet

- Maya Music in Oxford Music OnlineDocument6 pagesMaya Music in Oxford Music OnlineLucas de Freitas100% (1)

- Abstract Vision of de ZayasDocument21 pagesAbstract Vision of de ZayasOlga NikolovaNo ratings yet

- Cost Estimation AssignmentDocument14 pagesCost Estimation AssignmentnandiniapayaNo ratings yet

- East Asian ArtDocument4 pagesEast Asian ArtMenchie PaynorNo ratings yet

- GDP ProductDocument113 pagesGDP ProductTonyNo ratings yet

- History of Art Timeline (1) - Compressed-CompressedDocument86 pagesHistory of Art Timeline (1) - Compressed-CompressedRamya shriNo ratings yet

- Jameson Frederic Postmodernism and Consumer SocietyDocument13 pagesJameson Frederic Postmodernism and Consumer SocietyLelia MarcauNo ratings yet

- Lps Construction Manual - Part 2Document630 pagesLps Construction Manual - Part 2Carl Williams100% (1)

- Computer Aided Engineering Design Prof. Anupam Saxena Department of Mechanical Engineering Indian Institute of Technology, Kanpur Lecture - 2Document26 pagesComputer Aided Engineering Design Prof. Anupam Saxena Department of Mechanical Engineering Indian Institute of Technology, Kanpur Lecture - 2Kudrat SharmaNo ratings yet

- Aluflam Fixed Windows MarineDocument3 pagesAluflam Fixed Windows MarinenookboatNo ratings yet

- Floral Styles and DesignsDocument35 pagesFloral Styles and DesignsGarden Club of Virginia100% (1)

- Shot BlastingDocument2 pagesShot BlastingDinesh DhaipulleNo ratings yet

- Art AppDocument73 pagesArt Appcharles babasaNo ratings yet

- Vera Venus Making MagDocument3 pagesVera Venus Making MagLi MihaNo ratings yet

- Arts and CultureDocument3 pagesArts and Culturejade tagab100% (1)

- Barcoo Independent 050609Document6 pagesBarcoo Independent 050609barcooindependentNo ratings yet

- Maintenance by RoboticsDocument17 pagesMaintenance by RoboticsDebasis BhowmikNo ratings yet

- Bamboo LivingDocument19 pagesBamboo LivingREBogartNo ratings yet

- Making and Using A: Brenda HoddinottDocument7 pagesMaking and Using A: Brenda HoddinottONALTIKIRKALTI100% (1)

- PROC5Document20 pagesPROC5Aweke ZewduNo ratings yet

- MUSIC Impressionism Expressionism 20th Century Music StylesDocument8 pagesMUSIC Impressionism Expressionism 20th Century Music StylesJoe Mart MedranoNo ratings yet

- Rock Garden, Chandigarh: Case Study ofDocument21 pagesRock Garden, Chandigarh: Case Study ofHarsh DadheechNo ratings yet

- Task 1 - MYP 2 - SummativeDocument5 pagesTask 1 - MYP 2 - SummativeYassin HafezNo ratings yet

- Sefar Handbook For Screen PrintersDocument183 pagesSefar Handbook For Screen PrintersRichardGreaves100% (5)

- A Day Out British English Teacher Ver2Document6 pagesA Day Out British English Teacher Ver2grondin sandrineNo ratings yet

- Richard McGuire - Five DialsDocument61 pagesRichard McGuire - Five DialsfufnzgNo ratings yet

- SPECIFICATIONDocument213 pagesSPECIFICATIONnadeem UddinNo ratings yet

- James K. Feibleman - Aesthetics PDFDocument488 pagesJames K. Feibleman - Aesthetics PDFmarkacohen12121100% (1)

- Paint DetackificationDocument15 pagesPaint DetackificationbexigaobrotherNo ratings yet

- Gentileschi's Judith Slaying HolofernesDocument2 pagesGentileschi's Judith Slaying Holofernesplanet2o100% (3)