Professional Documents

Culture Documents

1 Selectarc b90 FT Web Anglais

Uploaded by

foxmancementOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

1 Selectarc b90 FT Web Anglais

Uploaded by

foxmancementCopyright:

Available Formats

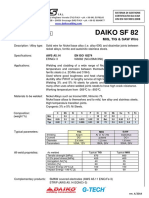

TECHNICAL DATA SHEET

www.fsh-welding.ca DESCRIPTION

B90 AC/DC+ NICKEL ALLOY

Inconel type electrode. Semi-synthetic basic coated electrode with 140% recovery and an Inconel

600 type nickel base deposit. Used for repairing and joining of Nickel alloys, 5 and 9 % Nickel steels

cryogenic stainless steels (down to –196°C), Incoloy 800 and other high temperature steels. High

performance for joining dissimilar materials as stainless steels / low alloyed steels, stainless steels /

Nickel alloys. Deposit insensitive to cracks, very good resistance to acids, salt and alkaline solutions,

molten salt (ex. cyanide), flux of brazing, oxidising and carburization atmosphere (avoid sulphurous

atmosphere).

CLASSIFICATION

AWS A5.11 : ENiCrFe-3 UNS : W 86182 EN/ISO14172 : E-Ni 6182 (NiCr15Fe6Mn)

TYPICAL APPLICATIONS

Oven parts, burners, heat treatment equipment, cement works, moulds, tanks, transport and storage

of liquid gas. Chemical industries, petrochemical industries, glassworks, civil engineering, repairing

and maintenance workshops.

BASE MATERIALS : 5%Ni, 9%Ni, 600, 601, 800, 800H, DS

PROCEDURE

Rebaking 1h at 250-300°C (482 - 572°F). Joints to weld must be clean, exempt from grease, cracks.

Weld with a minimum heat input in order to eliminate the phenomena of hot cracks. For welding

carbon steels a preheating of 200-500°C (392- 932°F), depending on the carbon equivalent, is

recommended.

MECHANICAL PROPERTIES

Tensile strength: > 87 000 psi (> 600 MPa)

Yield strength: > 55 000 psi (> 380 MPa)

Elongation: > 30 %

Impact (Charpy V): > 80 J at +20ºC, > 60 J at -196ºC

TYPICAL WELD METAL COMPOSITION (%)

C Si Mn Cr Nb Fe Mo Ni

< 0.05 0.5 5.5 16.0 2.0 <10 0.2 Rem

WELDING PARAMETERS

Diameter: 5.0 mm (3/16”) 4.0 mm (5/32”) 3.2 mm (1/8”) 2.5 mm (3/32”)

Amperage: 160 A 135 A 110 A 75 A

WELDING POSITIONS

1G/PA 2F/PB 2G/PC 3G/PF 4G/PE

MIG wire and TIG rods are also available: Selectarc MIG / TIG B90 (AWS A5.14: ERNiCr-3)

Rev.: 14_12

Specialized welding alloys and technology. For technical assistance or for ordering :

2204, 46e avenue

L a c h i n e ( M t l ), Q u é b e c

Canada H8T 2P3

info@fsh-welding.ca

www.fsh-welding.ca

Tél : 514.631.7670

1.800.361.9097

Fax : 514.636.3339

You might also like

- Boehler CN 13 4-MC - SWDocument1 pageBoehler CN 13 4-MC - SWSebastian AcostaNo ratings yet

- Boehler CN 13 4-MC FDocument1 pageBoehler CN 13 4-MC FFilipe CordeiroNo ratings yet

- Consumables To Match Cast & Wrought Alloy 800: Astm Bs en & DinDocument3 pagesConsumables To Match Cast & Wrought Alloy 800: Astm Bs en & Dinankitniranjan1390No ratings yet

- 3 Soudotec p20 Et h13 FT Web AnglaisDocument1 page3 Soudotec p20 Et h13 FT Web AnglaisHari KiranNo ratings yet

- Böhler CN 13/4-Mc Hi: Classifi CationsDocument1 pageBöhler CN 13/4-Mc Hi: Classifi CationsBranko FerenčakNo ratings yet

- Pinnacle Alloys ENiCrFe 3 12.16Document2 pagesPinnacle Alloys ENiCrFe 3 12.16satnamNo ratings yet

- Inconel 112-DatasheetDocument1 pageInconel 112-DatasheetrobertNo ratings yet

- Metrode Rail Welding Electrode Data SheetDocument1 pageMetrode Rail Welding Electrode Data SheetSyed AbudhakirNo ratings yet

- Railrod: Data SheetDocument1 pageRailrod: Data Sheetmohamed AdelNo ratings yet

- Carbo 4370 Mpr-E307Document1 pageCarbo 4370 Mpr-E307ali torabiNo ratings yet

- Lasting Connections with Seamless Cored WireDocument2 pagesLasting Connections with Seamless Cored WireDavid RodriguesNo ratings yet

- Inconel 601 Alloy 601 Uns n06601 Din 2.4851Document3 pagesInconel 601 Alloy 601 Uns n06601 Din 2.4851SamkitNo ratings yet

- Tetra S 316L-G: Technical Data Sheet Cored Welding WireDocument1 pageTetra S 316L-G: Technical Data Sheet Cored Welding WirePeter TvardzíkNo ratings yet

- Inconel Electrode for Fabrication and RepairDocument1 pageInconel Electrode for Fabrication and RepairjmsmechNo ratings yet

- Carbon Steel 01Document1 pageCarbon Steel 01amekkehNo ratings yet

- Join & Repair High-Carbon Steels with NiCr HLSDocument1 pageJoin & Repair High-Carbon Steels with NiCr HLSwalter091011No ratings yet

- UTP For OffshoreDocument16 pagesUTP For Offshorekamals55No ratings yet

- Ni base flux cored wireDocument1 pageNi base flux cored wireBBalopesabbNo ratings yet

- Diamondspark Ni1 RC: Seamless Cored WireDocument2 pagesDiamondspark Ni1 RC: Seamless Cored Wiresanul mulyNo ratings yet

- Diamondspark 52 MC: Seamless Metal-Cored WireDocument2 pagesDiamondspark 52 MC: Seamless Metal-Cored WireDavid RodriguesNo ratings yet

- Nickel-base filler metals GTAW rodsDocument1 pageNickel-base filler metals GTAW rodsc131508No ratings yet

- E16 8 2Document4 pagesE16 8 2Branko FerenčakNo ratings yet

- Maxflux SAF-8 (LS) : Agglomerated Basic Flux For Submerged Arc WeldingDocument1 pageMaxflux SAF-8 (LS) : Agglomerated Basic Flux For Submerged Arc WeldingPrashant KumarNo ratings yet

- ENiFe CI 55 1Document2 pagesENiFe CI 55 1akashmalayiNo ratings yet

- CF10MC (1.4571)Document3 pagesCF10MC (1.4571)Gilcimar Cavalcante GilcimarNo ratings yet

- Section 2 - Nikko Welding ConsumablesDocument9 pagesSection 2 - Nikko Welding Consumablesangga franugrahaNo ratings yet

- Consumables For E911 Crmo Steel: En/Din AstmDocument3 pagesConsumables For E911 Crmo Steel: En/Din Astmmohamed AdelNo ratings yet

- E8018-B6 Data SheetDocument2 pagesE8018-B6 Data SheetMurad AlmoudiNo ratings yet

- B Bã-Hler Nibas 70 20-Fd Fcaw 02Document1 pageB Bã-Hler Nibas 70 20-Fd Fcaw 02kamals55No ratings yet

- Официальный дистрибьютор ЗАО «Ресурс» т/ф 8 (383) 363-26-24, 291-93-02 630020 Россия г.Новосибирс ул.Объединения д.9 e-mail: resurszao@Document1 pageОфициальный дистрибьютор ЗАО «Ресурс» т/ф 8 (383) 363-26-24, 291-93-02 630020 Россия г.Новосибирс ул.Объединения д.9 e-mail: resurszao@brayanNo ratings yet

- item11-LNT NiCroMo 59.23Document1 pageitem11-LNT NiCroMo 59.23VVan TanNo ratings yet

- AUTROD 316LSiDocument2 pagesAUTROD 316LSijoao guilhermeNo ratings yet

- C 70 SuperthermDocument2 pagesC 70 SuperthermMandeep SinghNo ratings yet

- Welding Consumables For Hydro Power StationsDocument16 pagesWelding Consumables For Hydro Power StationsMohamed FaragNo ratings yet

- Material No. EN Symbol (Short) Aisi/Sae UNS Afnor BS Alloy Registered Work's Labelen StandardsDocument1 pageMaterial No. EN Symbol (Short) Aisi/Sae UNS Afnor BS Alloy Registered Work's Labelen StandardschetanNo ratings yet

- High-alloy creep resistant stick electrode for 9% Cr steelsDocument1 pageHigh-alloy creep resistant stick electrode for 9% Cr steelsmisthahNo ratings yet

- Datasheet-Sandvik-188mn-En-V2017-10-17 10 - 15 Version 1Document3 pagesDatasheet-Sandvik-188mn-En-V2017-10-17 10 - 15 Version 1szystNo ratings yet

- Electrode Booklet F Web 100Document1 pageElectrode Booklet F Web 100satnamNo ratings yet

- 24UTP Railway GBDocument8 pages24UTP Railway GBwpsssamsungNo ratings yet

- Utp 86 FNDocument1 pageUtp 86 FNc131508No ratings yet

- Bohler Welding 1%nickel - CatalogueDocument8 pagesBohler Welding 1%nickel - CatalogueTasmanijskaNemaNo ratings yet

- UTP 6222 MoDocument1 pageUTP 6222 ModantegimenezNo ratings yet

- Sandvik WeldingDocument3 pagesSandvik WeldingRam KadamNo ratings yet

- Stick electrodes for welding steels and stainless steelsDocument46 pagesStick electrodes for welding steels and stainless steelsAdeKusumahNo ratings yet

- High-alloyed TIG rod for heat resistant steelsDocument1 pageHigh-alloyed TIG rod for heat resistant steelsSerhii MishchenkoNo ratings yet

- Metrode E2209 (B-60) ElectrodeDocument6 pagesMetrode E2209 (B-60) ElectrodeClaudia MmsNo ratings yet

- 1564 Fox Ev 85 ElettrodoDocument1 page1564 Fox Ev 85 ElettrodoAminNo ratings yet

- Esab DublexDocument8 pagesEsab DublexSuphi YükselNo ratings yet

- Matching Alloy 625 Welding ConsumablesDocument5 pagesMatching Alloy 625 Welding Consumablesharan2000No ratings yet

- MIP Bohler Welding Austwqrwq2332e3eddwria 98Document1 pageMIP Bohler Welding Austwqrwq2332e3eddwria 98maxi27No ratings yet

- 2594 TigDocument1 page2594 TigAnonymous skBAwexNo ratings yet

- URB25Document4 pagesURB25malika_00No ratings yet

- Product Data Sheet OK 67.55: E 'Manual Metal-Arc Welding'Document2 pagesProduct Data Sheet OK 67.55: E 'Manual Metal-Arc Welding'rajNo ratings yet

- Material No. EN Symbol (Short) Aisi/Sae UNS Afnor BS Alloy Registered Work's Label StandardsDocument1 pageMaterial No. EN Symbol (Short) Aisi/Sae UNS Afnor BS Alloy Registered Work's Label StandardschetanNo ratings yet

- item8-LNT NiCro60.20Document1 pageitem8-LNT NiCro60.20VVan TanNo ratings yet

- B - Boehler NiMo 1-IG - de - en - 5Document1 pageB - Boehler NiMo 1-IG - de - en - 5cristian popescuNo ratings yet

- 02.CARBO - RC 3 Blau eDocument1 page02.CARBO - RC 3 Blau eMario CastilloNo ratings yet

- E7018 PDFDocument3 pagesE7018 PDFPrakash RajNo ratings yet

- SISTEMA DI GESTIONE CERTIFICATO DA ICIMDocument1 pageSISTEMA DI GESTIONE CERTIFICATO DA ICIMRhyan EdwinNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Failure AnalyzingDocument46 pagesFailure Analyzingdot11No ratings yet

- Performance Measurement Using Overall Equipment Effectiveness (OEE) : Literature Review and Practical Application DiscussionDocument47 pagesPerformance Measurement Using Overall Equipment Effectiveness (OEE) : Literature Review and Practical Application DiscussionLadyayu Ayu BachriNo ratings yet

- Performance Evaluation by Using Overall Equipment Effectiveness (OEE) : An Analyzing ToolDocument5 pagesPerformance Evaluation by Using Overall Equipment Effectiveness (OEE) : An Analyzing ToolfoxmancementNo ratings yet

- Equipment Evaluation Tool Based On The Manufacturing System Design DecompositionDocument9 pagesEquipment Evaluation Tool Based On The Manufacturing System Design DecompositionfoxmancementNo ratings yet

- ENGINEERING DESIGN GUILDLINES Plant Cost Estimating Rev1.2webDocument23 pagesENGINEERING DESIGN GUILDLINES Plant Cost Estimating Rev1.2webfoxmancementNo ratings yet

- Abb Power Grids HVDocument77 pagesAbb Power Grids HVfoxmancementNo ratings yet

- Bearing Failure Case StudyDocument11 pagesBearing Failure Case StudyfoxmancementNo ratings yet

- Example Form Equipment Performance Evaluation (Epe) Radiographic UnitDocument3 pagesExample Form Equipment Performance Evaluation (Epe) Radiographic UnitfoxmancementNo ratings yet

- Storage Recs Anim 03114pv PDFDocument16 pagesStorage Recs Anim 03114pv PDFPhilip Verne FerrerNo ratings yet

- Implementing A Successful OM Strategy For Solar PVDocument10 pagesImplementing A Successful OM Strategy For Solar PVfoxmancementNo ratings yet

- Motor-operated mechanisms for high-voltage disconnectors and earthing switchesDocument4 pagesMotor-operated mechanisms for high-voltage disconnectors and earthing switchesfoxmancementNo ratings yet

- Storage Recs Anim 03114pv PDFDocument16 pagesStorage Recs Anim 03114pv PDFPhilip Verne FerrerNo ratings yet

- Linked inDocument1 pageLinked infoxmancementNo ratings yet

- What Are The 4 Different Arc Flash PPE Categories in NFPA 70EDocument2 pagesWhat Are The 4 Different Arc Flash PPE Categories in NFPA 70EfoxmancementNo ratings yet

- AMP Brochure Program 2018-2019Document8 pagesAMP Brochure Program 2018-2019foxmancementNo ratings yet

- The Tale of Two CitiesDocument229 pagesThe Tale of Two CitiesfoxmancementNo ratings yet

- AUC SSE Professional Programs Spring 2019 ScheduleDocument36 pagesAUC SSE Professional Programs Spring 2019 SchedulefoxmancementNo ratings yet

- Tips and Tricks Slide ShareDocument56 pagesTips and Tricks Slide SharefoxmancementNo ratings yet

- Solar Cash Flow ModelDocument34 pagesSolar Cash Flow ModelfoxmancementNo ratings yet

- Countryside and Farm Visual VocabularyDocument4 pagesCountryside and Farm Visual VocabularyfoxmancementNo ratings yet

- Cbi Skills FrameworkDocument14 pagesCbi Skills Frameworkfoxmancement100% (1)

- Simle Grammar Book كتاب بسيط لأهم قواعد اللغة الانجليزية وشرح مفصل للازمنةDocument48 pagesSimle Grammar Book كتاب بسيط لأهم قواعد اللغة الانجليزية وشرح مفصل للازمنةMervat IbrahimNo ratings yet

- Project Management Template Examples v1 PDFDocument157 pagesProject Management Template Examples v1 PDFlifemillion2847No ratings yet

- S7 - Standard FunctionsDocument756 pagesS7 - Standard FunctionsAkram SayeedNo ratings yet

- RCM Course SyllabusDocument5 pagesRCM Course SyllabusfoxmancementNo ratings yet

- 2486 PDFDocument162 pages2486 PDFMuhammadMahmoudNo ratings yet

- Continuous improvement through small ongoing changesDocument3 pagesContinuous improvement through small ongoing changesfoxmancementNo ratings yet

- Infografia SMRPDocument1 pageInfografia SMRPFerrel Infante AcuñaNo ratings yet

- CMRP Road MapDocument2 pagesCMRP Road MapfoxmancementNo ratings yet

- 22MnB5 PDFDocument2 pages22MnB5 PDFjlplazaolaNo ratings yet

- Granshot Iron Granulation Technology: Raw Materials and IronmakingDocument4 pagesGranshot Iron Granulation Technology: Raw Materials and IronmakingROWHEITNo ratings yet

- Form Qw-482 Format For Welding Procedure Specification (WPS) (See QW-200,1, Section Ix, ASME Boiler and Pressure Vessel Code)Document4 pagesForm Qw-482 Format For Welding Procedure Specification (WPS) (See QW-200,1, Section Ix, ASME Boiler and Pressure Vessel Code)Rajkumar ArikumarNo ratings yet

- Application Instructions: HempelDocument4 pagesApplication Instructions: HempelSharath ReddyNo ratings yet

- Azocol Z 1Document3 pagesAzocol Z 1Antonio EspiagoNo ratings yet

- Imidazoles: Contact UsDocument2 pagesImidazoles: Contact Usian lesterNo ratings yet

- Hytherm S NewDocument2 pagesHytherm S NewOliver OliverNo ratings yet

- Datasheet For Steel Grades High Alloy Aquamet 22Document3 pagesDatasheet For Steel Grades High Alloy Aquamet 22MarioNo ratings yet

- Metal Casting ProcessesDocument169 pagesMetal Casting ProcessesSajeed Shaik100% (1)

- Mapei Grinding Aid Increases Cement Mill ProductionDocument2 pagesMapei Grinding Aid Increases Cement Mill Productionimsurender87No ratings yet

- Geosynthetic Institute: GRI Test Method GM19Document12 pagesGeosynthetic Institute: GRI Test Method GM19HeiderHuertaNo ratings yet

- Customs Tariff Concessions 7301 - 7310Document37 pagesCustoms Tariff Concessions 7301 - 7310rhysaaNo ratings yet

- Matte Tin FaqDocument2 pagesMatte Tin FaqBill TangelNo ratings yet

- Arc Welding Equipment and ProcessesDocument40 pagesArc Welding Equipment and Processesali100% (1)

- Etch Primer Is 5666Document3 pagesEtch Primer Is 5666Er Aftab ShaikhNo ratings yet

- WetScrubberVsDryScrubberSelectionDocument2 pagesWetScrubberVsDryScrubberSelectionShwetha Hd100% (2)

- Stauff Sanitary Hanger BrochureDocument32 pagesStauff Sanitary Hanger BrochurekitofanecoNo ratings yet

- JJ104 Workshop Technology Chapter8 Oxy-Acetylene Welding 1Document24 pagesJJ104 Workshop Technology Chapter8 Oxy-Acetylene Welding 1Ah Tiang100% (3)

- Study of Parameters and Methods in Underwater WeldingDocument27 pagesStudy of Parameters and Methods in Underwater WeldingamanNo ratings yet

- MS HSD Bs-Vi SpecsDocument3 pagesMS HSD Bs-Vi SpecsKusunuru SandeepNo ratings yet

- FmeaDocument5 pagesFmeaBuiTrungNo ratings yet

- PTG Gas Filter SeparatorsDocument8 pagesPTG Gas Filter SeparatorsRosa SparksNo ratings yet

- Flanges Awwa c207Document28 pagesFlanges Awwa c207inacioprojNo ratings yet

- Drywall Manual 2017 - FinishingDocument15 pagesDrywall Manual 2017 - Finishingomar100% (1)

- SP7021M00U18 000 A PDFDocument3 pagesSP7021M00U18 000 A PDFPedro Casimiro GámizNo ratings yet

- Accessories To Egypt WHDocument1 pageAccessories To Egypt WHrezo615No ratings yet

- 11kv and LV Pin InsulatorsDocument1 page11kv and LV Pin InsulatorsMosa Elnaid ElnaidNo ratings yet

- Shearing MachineDocument36 pagesShearing MachineAntehun MekonnenNo ratings yet

- Acson Copper CatalogDocument4 pagesAcson Copper CatalogTengku MunzirNo ratings yet

- Slide 13 Bending and FormingDocument68 pagesSlide 13 Bending and Formingjohn doeNo ratings yet