Professional Documents

Culture Documents

Mill Drive Configurations - MAPLA Paper

Uploaded by

idontlikeebooks0 ratings0% found this document useful (0 votes)

25 views2 pagesMill Drive Configurations - MAPLA Paper

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentMill Drive Configurations - MAPLA Paper

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

25 views2 pagesMill Drive Configurations - MAPLA Paper

Uploaded by

idontlikeebooksMill Drive Configurations - MAPLA Paper

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 2

Table 1: Possible electrical mill configurations

Motor Speed

Motor Type 750 – 1500 160 – 215 9 – 15 rpm Driving Equipment

rpm with rpm without without

Reducer Reducer Pinion

Fixed Speed Wound Rotor x Liquid Resistance Starter

Induction x DOL with air clutch

Synchronous x x DOL with air clutch

Single Variable Speed Wound Rotor x SER with Liquid Resistance Starter

Pinion Induction x VSI, CSI

Synchronous x VSI, CSI, LCI

Synchronous x VSI, LCI, CCV

Permanent Magnet x VSI

Fixed Speed Wound Rotor x Liquid Resistance Starter

Synchronous x x Quadramatic

Dual Variable Speed Wound Rotor x SER with Liquid Resistance Starter

Pinion Induction x VSI

Synchronous x VSI, LCI

Synchronous x VSI, LCI, CCV

Gearless Variable Speed Synchronous x CCV

DOL: Direct On Line CSI: Current Source Inverter

SER: Slip Energy Recovery LCI: Load Commutated Inverter

VSI: Voltage Source Inverter CCV: Cycloconverter

Mill Drives

Solutions

Fixed Speed Variable Speed

Solution Solution

Synchronous Asynchronous Cyclovonverter Voltage Source Inverter Current Source Inverter

(AC-AC Drives) (DC Voltage Link) (DC Current Link)

Wound Rotor Motor 2-level Load Commutated Inverter

Squirrel Cage Motor Multilevel Slip Energy Recovery

Slip Energy Recovery

Figure 1: Drive classifications

You might also like

- AC DC Electric MotorsDocument64 pagesAC DC Electric MotorsHamza Ahmad100% (2)

- 03 Field Oriented Control PDFDocument41 pages03 Field Oriented Control PDFAnkit Prajapati100% (1)

- Synchronous Generator TheoryDocument18 pagesSynchronous Generator TheorySyarief100% (1)

- Emergency Generator - Paralleling Switchgear Power Switching Control Methodologies For LV and MV ApplicationsDocument49 pagesEmergency Generator - Paralleling Switchgear Power Switching Control Methodologies For LV and MV ApplicationsTrần Quang Tuyên100% (1)

- Shortcircuit ANSIDocument48 pagesShortcircuit ANSIVasudevan KunjithapathamNo ratings yet

- Panelboard and Switchboard PDFDocument32 pagesPanelboard and Switchboard PDFGerardo M. James BravoNo ratings yet

- VFD Rocky Preso 2Document68 pagesVFD Rocky Preso 2Sunil VaishnavNo ratings yet

- Manual Case - 1825 - 1840 - 1845cDocument8 pagesManual Case - 1825 - 1840 - 1845cFrancisco BarrosNo ratings yet

- 02 Intro To FOCDocument55 pages02 Intro To FOCRam Krishan SharmaNo ratings yet

- Static Frequency Converters: Power Service GMBHDocument16 pagesStatic Frequency Converters: Power Service GMBHMohamed BerririNo ratings yet

- Itp - HV MotorsDocument5 pagesItp - HV MotorsidontlikeebooksNo ratings yet

- E2 Preventive Maintenance Manual1Document68 pagesE2 Preventive Maintenance Manual1Jeffry KarundengNo ratings yet

- en Lock NutsDocument68 pagesen Lock NutsAlvaro Munoz100% (1)

- Chapter 3 Synchronous GeneratorDocument21 pagesChapter 3 Synchronous Generatorahmad abufaresNo ratings yet

- Food PackagingDocument107 pagesFood PackagingVikram SinghNo ratings yet

- Elektronika Daya (Kuliah)Document37 pagesElektronika Daya (Kuliah)Hajrul Jhonn RamboNo ratings yet

- Computer Hardware Servicing 7 & 8Document4 pagesComputer Hardware Servicing 7 & 8Jush Clide100% (2)

- Modern Design For Variable Speed Motor-GeneratorsDocument18 pagesModern Design For Variable Speed Motor-Generatorsmunagala balasubramanyamNo ratings yet

- Gold Medallion Assessors Guide v1.2 2023Document9 pagesGold Medallion Assessors Guide v1.2 2023idontlikeebooksNo ratings yet

- Conformity of Structural Steel Products and StructuresDocument5 pagesConformity of Structural Steel Products and StructuresStephen HicksNo ratings yet

- Flow, Slope &pipe Dia. Calculation Using Manning's FormulaDocument8 pagesFlow, Slope &pipe Dia. Calculation Using Manning's FormulaAhmed KhalifaNo ratings yet

- NEW Energy ProductsDocument67 pagesNEW Energy ProductsMirela VihacencuNo ratings yet

- Damagix PPE ManualDocument23 pagesDamagix PPE ManualPaul Uwaya100% (2)

- Arteche PQfor WaterDocument20 pagesArteche PQfor WaterLuis Roberto FariasNo ratings yet

- Analysis of Brushless ACAnd DCMachinesDocument12 pagesAnalysis of Brushless ACAnd DCMachinesdsaNo ratings yet

- Electric DrivesDocument19 pagesElectric DrivesJohn OcampoNo ratings yet

- MPL A320pDocument17 pagesMPL A320pmidwarNo ratings yet

- Motor&Drive BasicsDocument35 pagesMotor&Drive BasicsSenthil KumarNo ratings yet

- Item Bank ID 403148 Item Bank Name Power Electronics Controlled Drives 2015 PatternDocument3 pagesItem Bank ID 403148 Item Bank Name Power Electronics Controlled Drives 2015 PatternHota bNo ratings yet

- S9H1D-H4 Wdg.63 - Technical Data SheetDocument9 pagesS9H1D-H4 Wdg.63 - Technical Data SheetAkram SulaimanNo ratings yet

- Dimensionado de DOL-Star Delta Starter VERDUNDocument19 pagesDimensionado de DOL-Star Delta Starter VERDUNritzeelNo ratings yet

- CDM Rotor DynamicsDocument12 pagesCDM Rotor DynamicsVainqueur MkvaNo ratings yet

- 4 SGDocument26 pages4 SGthettinNo ratings yet

- Dynapac CA270D Dynapac CA270D: Single Drum Vibratory Rollers Single Drum Vibratory RollersDocument2 pagesDynapac CA270D Dynapac CA270D: Single Drum Vibratory Rollers Single Drum Vibratory RollersJaherNo ratings yet

- ABB Medium Voltage DrivesDocument4 pagesABB Medium Voltage Drivesabdur rafayNo ratings yet

- Chapter 15Document71 pagesChapter 15Mogaka LucasNo ratings yet

- Review of Permanent-Magnet Brushless DC Motor Basic Drives Based On Analysis and Simulation StudyDocument29 pagesReview of Permanent-Magnet Brushless DC Motor Basic Drives Based On Analysis and Simulation StudymitulNo ratings yet

- CA150D CA150D: Single Drum Vibratory Rollers Single Drum Vibratory RollersDocument1 pageCA150D CA150D: Single Drum Vibratory Rollers Single Drum Vibratory RollersYeison Jair Guaca TrujilloNo ratings yet

- Review of Permanent-Magnet Brushless DC Motor Basic DrivesDocument28 pagesReview of Permanent-Magnet Brushless DC Motor Basic DrivesIan SilveiraNo ratings yet

- 10-Tutorial of Induction MotorDocument48 pages10-Tutorial of Induction Motorrida.hamza.muhammadNo ratings yet

- Generator Data SheetDocument3 pagesGenerator Data SheetAhmad TaufikNo ratings yet

- Ac Induction Motor: Electrotechnics MSC Laboratory Session N°3 Bércesi GáborDocument16 pagesAc Induction Motor: Electrotechnics MSC Laboratory Session N°3 Bércesi GáborFabiano Bezerra BezerraNo ratings yet

- Uninterruptible Power Supplies: Pasokan Listrik Yang Tidak Pernah TerputusDocument21 pagesUninterruptible Power Supplies: Pasokan Listrik Yang Tidak Pernah TerputusDinda PratiwiNo ratings yet

- Common DC BUS Strategy: © Siemens, 2001Document11 pagesCommon DC BUS Strategy: © Siemens, 2001rodrigomessiasNo ratings yet

- Electric Utility ApplicationsDocument23 pagesElectric Utility Applicationssukhbat sodnomdorjNo ratings yet

- Power Plant Data Query Regarding Protection Setting ReviewDocument2 pagesPower Plant Data Query Regarding Protection Setting ReviewRendi Way SinurayaNo ratings yet

- Diesel Generators 10kwDocument8 pagesDiesel Generators 10kwSAQIB AKHTARNo ratings yet

- EMECDocument73 pagesEMECdivyansh singhNo ratings yet

- Fawde 20 KvaDocument4 pagesFawde 20 KvatritiluNo ratings yet

- FEE 532 Power System Stability IIDocument30 pagesFEE 532 Power System Stability IIFelix Onchong'aNo ratings yet

- Basics of ParallelingDocument32 pagesBasics of ParallelingKashif RasheedNo ratings yet

- Dynapac Ca610d En-20171208.152747Document2 pagesDynapac Ca610d En-20171208.152747Tidjani SallNo ratings yet

- Dynapac CA610DDocument2 pagesDynapac CA610DShova MuhammadNo ratings yet

- Step 1: Let's Look at A Typical Motor: Stator Cooling FanDocument17 pagesStep 1: Let's Look at A Typical Motor: Stator Cooling FanrodrigomessiasNo ratings yet

- KJDSKJV715Document3 pagesKJDSKJV715mohsen_cumminsNo ratings yet

- Mariposa Motorizada Visteon PDFDocument2 pagesMariposa Motorizada Visteon PDFIgnacio MuguiroNo ratings yet

- Electric Motor Drive PDFDocument20 pagesElectric Motor Drive PDFMoaz ShafiNo ratings yet

- 01 Electrical BasicsDocument99 pages01 Electrical Basicskola naresh kumarNo ratings yet

- P1500 Open (N)Document3 pagesP1500 Open (N)Nyoman SuryasaNo ratings yet

- HPK MotorsDocument13 pagesHPK MotorsBrentildaNo ratings yet

- Perkins 150 KVADocument4 pagesPerkins 150 KVAsigit aryantoNo ratings yet

- Shunt Compensation - 2Document24 pagesShunt Compensation - 2Jayarajan Jayarajan C NNo ratings yet

- Dynamic Modeling of Induction Motors: AC Motor Control and EV ApplicationsDocument20 pagesDynamic Modeling of Induction Motors: AC Motor Control and EV ApplicationsKhaled Abushafa AwailiNo ratings yet

- Shortcircuit ANSIDocument48 pagesShortcircuit ANSIVasudevan KunjithapathamNo ratings yet

- Electric Actuator DatasheetDocument1 pageElectric Actuator DatasheetPT PUTRA SETIAWAN PRIMANo ratings yet

- Perkins 60 Kva Silent StamfordDocument3 pagesPerkins 60 Kva Silent StamfordM. Rizky FauziNo ratings yet

- Y87 Genset Technical Datasheet: Standby Power Prime Power Frequency Rated Voltage Rated SpeedDocument6 pagesY87 Genset Technical Datasheet: Standby Power Prime Power Frequency Rated Voltage Rated SpeedCRISTIAN CAMILO NAIZAQUE CASTAÑEDANo ratings yet

- Yanmar 12.5 KvaDocument4 pagesYanmar 12.5 KvaFian -No ratings yet

- Psar35 m5 Rescue V December 2022Document37 pagesPsar35 m5 Rescue V December 2022idontlikeebooksNo ratings yet

- Water Safety Risk Assessment Guide v1.0Document4 pagesWater Safety Risk Assessment Guide v1.0idontlikeebooksNo ratings yet

- STT Vertimill Retrofit 03282022Document2 pagesSTT Vertimill Retrofit 03282022idontlikeebooksNo ratings yet

- Bronze Medallion (BM) Theory Questions (Assessment Task 1)Document23 pagesBronze Medallion (BM) Theory Questions (Assessment Task 1)idontlikeebooksNo ratings yet

- Lime Slaking 101 Whitepaper 4-06-22Document8 pagesLime Slaking 101 Whitepaper 4-06-22idontlikeebooksNo ratings yet

- AISI Type W2 Tool Steel, Water Quenched at 775°C (1425°F), and TemperedDocument2 pagesAISI Type W2 Tool Steel, Water Quenched at 775°C (1425°F), and TemperedidontlikeebooksNo ratings yet

- TeSys Giga Contactors - LC1G225KUENDocument5 pagesTeSys Giga Contactors - LC1G225KUENidontlikeebooksNo ratings yet

- Memo 2023 Age Championships Water Safety RosterDocument3 pagesMemo 2023 Age Championships Water Safety RosteridontlikeebooksNo ratings yet

- NL48Document1 pageNL48idontlikeebooksNo ratings yet

- 2023 State Age Championships Final Event Information 1Document10 pages2023 State Age Championships Final Event Information 1idontlikeebooksNo ratings yet

- WEG Indústrias S.A.: Performance Curves Related To SpeedDocument1 pageWEG Indústrias S.A.: Performance Curves Related To SpeedidontlikeebooksNo ratings yet

- Turbogenerators - Reference ListDocument12 pagesTurbogenerators - Reference ListidontlikeebooksNo ratings yet

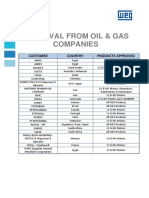

- Oil & Gas - Reference ListDocument1 pageOil & Gas - Reference ListidontlikeebooksNo ratings yet

- ITP - AutomationDocument43 pagesITP - AutomationidontlikeebooksNo ratings yet

- WEG Application Book 261 Brochure EnglishDocument33 pagesWEG Application Book 261 Brochure EnglishidontlikeebooksNo ratings yet

- ITP - Frames 63 To 355 Low VoltageDocument5 pagesITP - Frames 63 To 355 Low VoltageidontlikeebooksNo ratings yet

- Pulp & PaperDocument18 pagesPulp & PaperidontlikeebooksNo ratings yet

- Synchronous Machines - Reference ListDocument6 pagesSynchronous Machines - Reference ListidontlikeebooksNo ratings yet

- Synchronous Motors - Reference ListDocument2 pagesSynchronous Motors - Reference ListidontlikeebooksNo ratings yet

- Reference List - Drives WAA For Projects 2004-2005Document5 pagesReference List - Drives WAA For Projects 2004-2005idontlikeebooksNo ratings yet

- Reference List - WMDocument20 pagesReference List - WMidontlikeebooksNo ratings yet

- Latrine Slabs and SeatsDocument4 pagesLatrine Slabs and SeatsGreen Action Sustainable Technology GroupNo ratings yet

- Budget Cost For Fire Protection SystemDocument1 pageBudget Cost For Fire Protection SystemBen LimNo ratings yet

- Mohammad Abu Shattal July2017Document3 pagesMohammad Abu Shattal July2017Mohammad Abu ShattalNo ratings yet

- Pernos NelsonDocument4 pagesPernos NelsonJuan Manuel BazánNo ratings yet

- Cycloc Data Sheet SoloDocument13 pagesCycloc Data Sheet SoloJuli RayuliNo ratings yet

- 95-8472-3.1 505 CgsDocument27 pages95-8472-3.1 505 CgsJuan RimachiNo ratings yet

- Limit State of ServiceabilityDocument20 pagesLimit State of ServiceabilityNavi RengarajanNo ratings yet

- Wood Door Submittal SheetsDocument9 pagesWood Door Submittal SheetsIwan PermanaNo ratings yet

- Install EquipmentDocument8 pagesInstall EquipmentDeyeck VergaNo ratings yet

- Philips PD7000 PDFDocument34 pagesPhilips PD7000 PDFboroda2410No ratings yet

- Kuka Branchenflyer Food en 140523 ScreenDocument12 pagesKuka Branchenflyer Food en 140523 ScreencabecavilNo ratings yet

- Adafruit Mics5524 Gas Sensor BreakoutDocument12 pagesAdafruit Mics5524 Gas Sensor BreakoutWerliock MorlorumNo ratings yet

- Brown White Minimalist Home Decoration PresentationDocument110 pagesBrown White Minimalist Home Decoration PresentationMiMipan DRNo ratings yet

- Advanced COMPOSITE METERIALSDocument2 pagesAdvanced COMPOSITE METERIALSgangadharmlNo ratings yet

- Mazda Protege 5 Control SystemDocument14 pagesMazda Protege 5 Control SystemJGAR2009No ratings yet

- AgisDocument20 pagesAgisFabian Andres Blanco GNo ratings yet

- Wheels and Tyres: - Types of Wheel, Construction of Wired Wheel, DiscDocument15 pagesWheels and Tyres: - Types of Wheel, Construction of Wired Wheel, DiscajaiNo ratings yet

- PREFACE 1978 Laminar Flow Forced Convection in DuctsDocument2 pagesPREFACE 1978 Laminar Flow Forced Convection in Ductsakamaka99No ratings yet

- Eaton 9130 DatasheetDocument2 pagesEaton 9130 Datasheetjveraf_No ratings yet

- Solid Waste Management Detailed Project ReportDocument6 pagesSolid Waste Management Detailed Project ReportPem DromaNo ratings yet

- Premium Lumber, Limited: Comm3501 - Production and Operations ManagementDocument20 pagesPremium Lumber, Limited: Comm3501 - Production and Operations ManagementRegan HinesNo ratings yet

- E110 - Motor Installation Checklist Rev 00 11.11Document2 pagesE110 - Motor Installation Checklist Rev 00 11.11nayumNo ratings yet