Professional Documents

Culture Documents

Design1Solution For Air Cooled Heat Exchanger

Uploaded by

Ankit LonareOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Design1Solution For Air Cooled Heat Exchanger

Uploaded by

Ankit LonareCopyright:

Available Formats

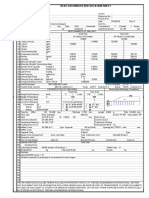

Velocity Pressure Method Calculation Sheet

Plant Name: ____________________________ Elevation: _________ Date: ________________

Location: _______________________________ Temp: ____________ Drawing #.:___________

Department: ____________________________+ Factor: ___________ Designer: _____________

1 Duct Segment Identification In Out

2 Target Volume Flowrate, Q = V*A- Chap 10 cfm 1500.0 1500.0

3 Min. Transport Velocity, V Chap 10 fpm 4000 4000

4 Maximum Duct Diameter (D= ((4*144*Q)/(pi*V)) inches 8.29 8.29

5 Selected duct diameter inches 8.00 8.00

6 Duct Area (pi*(D/12)2/4) sq. ft 0.3500 0.3500

7 Actual Duct Velocity fpm 4297.0 4297.0

8 Duct Velocity Pres, VP = (V/4005) 2

"wg 1.1500 1.1.5

9 H Maximum Slot Area = (2/11) sq ft

10 Slot area selected sq ft

11 O S Slot Velocity, Vs Chap 10 fpm

12 O L Slot Velocity Pres, VPs=(Vs/4005)2 "wg

13 D O Slot Loss Coefficient - Chap 10, Chap 3

14 T Acceleration Factor 0 or 1

15 S S Slot Loss per VP (13+14)

16 U Slot Static Pressure (12*15) "wg

17 C Duct Entry Loss Coefficient F5-14, Chap 5 0.490

18 T Acceleration Factor (1 at hoods) 1 or 0 1

19 I Duct Entry Loss per VP (17 + 18) 1.49

20 O Duct Entry Loss (8 * 19) "wg 1.714

21 N Other Losses "wg

22 Hood Static Pressure SPh (16+20+21) "wg 1.714

23 Straight Duct Length ft 35.0 10.0

24 Friction Factor (Hf) 0.0302 0.0302

25 Friction Loss per VP (23 * 24) 1.0640 0.3019

26 No. of 90 degree Elbows 1.00 1.00

27 Elbow loss coefficient (bottom of page) 0.13 0.13

28 Elbow Loss per VP (26*Loss Factor)(bottom of page) 0.13 0.13

29 No. of branch entries (1 or 0)

30 Entry loss coefficient

31 Entry Loss per VP (29*Loss Factor) (Branch)

32 Special Fittings Loss Factors

33 Duct Loss per VP (25 + 28 + 31 + 32) 1.1940 0.4319

34 Duct Loss (8*33) "wg 1.3731 0.4990

35 Duct Segment SP Loss (22 + 34) "wg 3.087 0.499

36 Other losses "wg

37 Cumulative Static Pressure "wg 3.087 0.499

38 Governing Static Pressure (at TO location) "wg -3.087 0.499

39 Corrected Volumetric Flowrate cfm

40 Corrected Velocity fpm

41 Corrected Velocity Pressure "wg

42 Resultant Velocity Pressure "wg

PERTINENT EQUATIONS: Q1 Q2

VPr = VP1+ VP2

Q3 Q3

Qcorr =Q design

√ SPgov .

SP duct

OR

or

2

H f =0. 0307

( ) V 0 . 533

=

0 . 4937

Q 0. 612 Q 0. 079∗D1.066

V Pr=

[ Q 1 +Q 2

4005∗( A1 + A 2 ) ] Branch Entry

Loss Factors

FSP=SP outlet −SPinlet −VP inlet Angle (*) Factor

Elbow Loss Factors: 10 0.06

FanTP=SP out−SP in + VPout − VPin 60*elbow = 2/3 loss 45oelbow=1/2 loss 30*elbow= 1/3 loss 15 0.09

20 0.12

SP 3=SP1 −(VP 3−V Pr ) 90oelbow 0.5 0.75 1

R/D

1.5 2 2.5

25

30

0.15

0.18

Other Information: Stamped 0.71 0.33 0.22 0.15 0.13 0.12 35 0.21

5-piece - 0.46 0.33 0.24 0.19 0.17 40 0.25

4-piece - 0.5 0.37 0.27 0.24 0.23 45 0.28

3-piece 0.9 0.54 0.42 0.34 0.33 0.33 50 0.32

60 0.44

90 1.00

see Fig 5-14

Fig 5-15

The final calculations:

The fan Sp = Spo - Spin - Vpin

= 0.499 - (-3.09) - 1.15

= 2.439 fpm

The fan TP = SP o - SP in + VP o - VP in

= 0.499 - (- 3.09) + 1.15 -1.15

= 3.589 fpm

BHP =( Fan TP * Q)/(6362 * n)

= ( 3.589 * 1500) / ( 6362 * 0.9)

= 0.94 hp

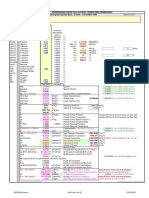

Velocity Pressure Method Calculation Sheet

Plant Name: ____________________________ Elevation: _________ Date: ________________

Location: _______________________________ Temp: ____________ Drawing No.:___________

Department: ____________________________+ Factor: ___________ Designer: _____________

1 Duct Segment Identification

2 Target Volume Flowrate, Q =V*A - Chap 10 cfm

3 Min. Transport Velocity V Chap 10 fpm

4 Maximum Duct Diameter (D= ((4*144*Q)/(pi*V))0.5 inches

5 Selected duct diameter inches

6 Duct Area (pi*(D/12) /4)

2

sq. ft

7 Actual Duct Velocity fpm

8 Duct Velocity Pres, VP = (V/4005) 2

"wg

9 H Maximum Slot Area = (2/11) sq ft

10 Slot area selected sq ft

11 O S Slot Velocity, Vs Chap 10 fpm

12 O L Slot Velocity Pres, VPs = (Vs/4005) 2

"wg

13 D O Slot Loss Coefficient - Chap 10, Chap 3

14 T Acceleration Factor 0 or 1

15 S S Duct Loss per VP (13+14)

16 U Duct Static Pressure (12*15) "wg

17 C Duct Entry Loss Factor F5-14, Chap 10

18 T Acceleration Factor (1 at hoods) 1 or 0

19 I Duct Entry Loss per VP (17 + 18)

20 O Duct Entry Loss (8 * 19) "wg

21 N Other Loss "wg

22 Hood Static Pressure SPh (16+20+21) "wg

23 Straight Duct Length ft

24 Friction Factor (Hf)

25 Friction Loss per VP (23 * 24)

26 No. of 90 degree Elbows

27 Elbow loss coefficient (Bottom of Page)

28 Elbow Loss per VP (26*Loss Factor)(bottom of page)

29 No. of branch Entries ( 1 or 0)

30 Entry Los s Coefficient

31 Entry Loss per VP (29*Loss Factor) (Branch)

32 Special Fittings Loss Factors

33 Duct Loss per VP (25 + 28 +31 + 32)

34 Duct Loss (8*33) "wg

35 Duct SP Loss (22 + 34) "wg

36 Other Losses "wg

37 Cumulative Static Pressure "wg

38 Governing Static Pressure (at TO location) "wg

39 Corrected Volumetric Flowrate cfm

40 Corrected Velocity fpm

41 Corrected Velocity Pressure "wg

42 Resultant Velocity Pressure "wg

PERTINENT EQUATIONS:

Qcorr =Qdesign

√ SPgov .

SP duct

VPr =

Q1 Q

VP1 + 2 VP2

V 0 .533 Q3 Q3

( ) 0.4937

H f =0.0307 0.612 = 0.079 1.066

Q Q ∗D

FSP=SP outlet −SPinlet −VPinlet 2

FanTP=SP out−SPin + VPout −VPin V Pr=

[ Q1 +Q2

4005∗( A1 +A 2 ) ]

SP 3=SP1−(VP3−V Pr)

Other Information:

Branch Entry Elbow Loss Factors:

Loss Factors 60*elbow = 2/3 loss 45oelbow=1/2 loss 30*elbow= 1/3 loss

Angle (*) Factor

10 0.06 R/D

15 0.09 90 elbow

o

0.5 0.75 1 1.5 2 2.5

20 0.12 Stamped 0.71 0.33 0.22 0.15 0.13 0.12

25 0.15 5-piece - 0.46 0.33 0.24 0.19 0.17

30 0.18 4-piece - 0.5 0.37 0.27 0.24 0.23

35 0.21 3-piece 0.9 0.54 0.42 0.34 0.33 0.33

40 0.25

45 0.28

50 0.32

60 0.44

90 1.00

see Fig 5-14

Fig 5-15

You might also like

- Velocity Pressure Method Calculation SheetDocument7 pagesVelocity Pressure Method Calculation SheetPhyu Mar Thein Kyaw100% (1)

- 021SAACK Burner Operating Instructions PDFDocument136 pages021SAACK Burner Operating Instructions PDFmekidmu tadesse100% (1)

- Geometric Dilution of Precision ComputationDocument25 pagesGeometric Dilution of Precision ComputationAntonius NiusNo ratings yet

- NRSPDocument27 pagesNRSPMuhammad Farhan67% (3)

- 31.PEAK Depressurization RATEDocument1 page31.PEAK Depressurization RATEDILIP MATALNo ratings yet

- ParalDocument9 pagesParalTahirJabbarNo ratings yet

- Gas Conditioning System Specification Sheet: Process InformationDocument3 pagesGas Conditioning System Specification Sheet: Process InformationNITIN P SHAHNo ratings yet

- Gas Liquid Separator DesignDocument3 pagesGas Liquid Separator DesignSoheil MoradiNo ratings yet

- Calculo HP K-60 AbDocument23 pagesCalculo HP K-60 Abgustavo barbozaNo ratings yet

- Modified Vyas formula for S.D.P. treatment of organic and aqueous wasteDocument11 pagesModified Vyas formula for S.D.P. treatment of organic and aqueous wasteNITIN P SHAHNo ratings yet

- Waymouth CalculationDocument8 pagesWaymouth CalculationSURJYA TAMULINo ratings yet

- Qaverage Phase-1 Phase-2 Qpeak Phase-1 Phase-2 m3/d m3/d m3/hr m3/hr M3/sec M3/secDocument7 pagesQaverage Phase-1 Phase-2 Qpeak Phase-1 Phase-2 m3/d m3/d m3/hr m3/hr M3/sec M3/secHemantk8731100% (1)

- Properties of liquid hydrocarbons in pumpsDocument1 pageProperties of liquid hydrocarbons in pumpsmahesh_eilNo ratings yet

- Control Valve Sizing - EnggcyclopediaDocument4 pagesControl Valve Sizing - EnggcyclopediaazitaggNo ratings yet

- Linear Mixing CalcDocument12 pagesLinear Mixing CalcClarence AG YueNo ratings yet

- Choosing the right hydraulic separatorDocument3 pagesChoosing the right hydraulic separatoramandaNo ratings yet

- LAMPIRAN C Spesifikasi PeralatanDocument89 pagesLAMPIRAN C Spesifikasi PeralatanRahmaisa HarahapNo ratings yet

- Quick estimation compressor settle out conditionsDocument1 pageQuick estimation compressor settle out conditionsAhmed GattoufiNo ratings yet

- Steam HXDocument1 pageSteam HXrajachemNo ratings yet

- Insulation Thickness by UOPDocument4 pagesInsulation Thickness by UOPOmar EzzatNo ratings yet

- h-101 TwiceDocument20 pagesh-101 TwiceAdela ShofiaNo ratings yet

- API 2000 guidance for inert gas blanketing of tanksDocument2 pagesAPI 2000 guidance for inert gas blanketing of tankssandeshNo ratings yet

- Calculation of Height of The Siphon SystemDocument2 pagesCalculation of Height of The Siphon SystemHsein WangNo ratings yet

- 3-Phase Sparator Sizing (Vertical and Horizontal)Document30 pages3-Phase Sparator Sizing (Vertical and Horizontal)WickyNo ratings yet

- Ventilation DesignDocument4 pagesVentilation DesignPhyu Mar Thein KyawNo ratings yet

- Double FdexchangerDocument8 pagesDouble FdexchangerBoško IvanovićNo ratings yet

- Basis: Basis: 100 Mol/h Property: GPSA and Elliott ManualDocument6 pagesBasis: Basis: 100 Mol/h Property: GPSA and Elliott ManualsterlingNo ratings yet

- Double Pipe Heat Exchanger Analysis (Example 5.1) : Water WaterDocument3 pagesDouble Pipe Heat Exchanger Analysis (Example 5.1) : Water WaterBagusRekaNo ratings yet

- Line Size Calculation For Cooling Water Pipes: Pipe Size Provided Is OKDocument40 pagesLine Size Calculation For Cooling Water Pipes: Pipe Size Provided Is OKjitendra shindeNo ratings yet

- Pressure Safety Valve DatasheetDocument10 pagesPressure Safety Valve DatasheetsithulibraNo ratings yet

- Desuperheater Boiler Feed Water RequirementDocument2 pagesDesuperheater Boiler Feed Water Requirementmehul10941No ratings yet

- Calculation Title: Seagas Pipeline Design - MinervaDocument1 pageCalculation Title: Seagas Pipeline Design - Minerva秦东旺No ratings yet

- Dispersion of Gases CalculationsDocument4 pagesDispersion of Gases CalculationsPeddy Nesa0% (1)

- كل انواع الفلاش سبريتر الطورين والثلاث اطوار مهمDocument42 pagesكل انواع الفلاش سبريتر الطورين والثلاث اطوار مهمamir loloNo ratings yet

- Tube Side Velocity CalculationDocument20 pagesTube Side Velocity CalculationNitin KurupNo ratings yet

- Calculating Gas Properties with Mixing Rule SpreadsheetDocument2 pagesCalculating Gas Properties with Mixing Rule Spreadsheetvictor javier nuñezNo ratings yet

- Input Output: Combustion Calculations For Fuel GasDocument33 pagesInput Output: Combustion Calculations For Fuel GasgsdaundhNo ratings yet

- TEMA SheetDocument2 pagesTEMA SheetFrancisco RenteriaNo ratings yet

- Design of Heat ExchangersDocument23 pagesDesign of Heat ExchangersKhalid Turki100% (2)

- Filter Separator Revised Feb 19 2004Document1 pageFilter Separator Revised Feb 19 2004motalebyNo ratings yet

- Calculation For Steam Blow Rev03Document6 pagesCalculation For Steam Blow Rev03tauqeerNo ratings yet

- Observations Water in DF Out DF Oil DF Flow Ml/s Flow ft3/hrDocument2 pagesObservations Water in DF Out DF Oil DF Flow Ml/s Flow ft3/hrUmair FareedNo ratings yet

- RD 810Document73 pagesRD 810Ashish MishraNo ratings yet

- Calculation of time needed to mix liquids with pitch blade impellersDocument10 pagesCalculation of time needed to mix liquids with pitch blade impellershadiNo ratings yet

- Density of WaterDocument5 pagesDensity of WaterJean Pajuelo0% (1)

- STM Dosing and Feeding Systems For Air Pollution ControlDocument42 pagesSTM Dosing and Feeding Systems For Air Pollution ControlJoseph RileyNo ratings yet

- Perancangan CycloneDocument20 pagesPerancangan CycloneDavid LambertNo ratings yet

- Flammability WorksheetDocument6 pagesFlammability WorksheetshailendraNo ratings yet

- 10.9. Gas Liquid Separators: Chemical EngineeringDocument6 pages10.9. Gas Liquid Separators: Chemical EngineeringsterlingNo ratings yet

- Duct velocity and inside velocity calculationsDocument4 pagesDuct velocity and inside velocity calculationsAnonymous pVoSWn8yh0No ratings yet

- ATFE Installation Costing for Xylene Distillation ProjectDocument27 pagesATFE Installation Costing for Xylene Distillation ProjectPrathmesh GujaratiNo ratings yet

- Calculation of Friction Losses, Power, Developed Head and Available Net Positive Suction Head of A PumpDocument11 pagesCalculation of Friction Losses, Power, Developed Head and Available Net Positive Suction Head of A Pumpthanh_79No ratings yet

- Spreadsheet Heat Loss from a PipeDocument1 pageSpreadsheet Heat Loss from a PipeJogender DhayalNo ratings yet

- Calc BoilersDocument3 pagesCalc Boilerssathish14No ratings yet

- AHU 20sep11Document36 pagesAHU 20sep11Tạ Tuấn CườngNo ratings yet

- Equilibrium Vapor-Liquid CalculationsDocument8 pagesEquilibrium Vapor-Liquid Calculationsdhea novitaNo ratings yet

- Recommended Equal Friction MethodDocument2 pagesRecommended Equal Friction MethodPhyu Mar Thein KyawNo ratings yet

- Calculation Sheet for Stairs Reinforcement DesignDocument18 pagesCalculation Sheet for Stairs Reinforcement Designsarafan leewan0% (1)

- Tank Vent Calculation SpreadsheetDocument3 pagesTank Vent Calculation SpreadsheetJack SonNo ratings yet

- Valve Sizing Calculation8Document2 pagesValve Sizing Calculation8PIDNo ratings yet

- Velocity Pressure Calculation Method: Ventilation Design Work SheetDocument4 pagesVelocity Pressure Calculation Method: Ventilation Design Work SheetMichael J. BaneNo ratings yet

- Additional Design Problems: SolutionDocument8 pagesAdditional Design Problems: SolutionMarcus BragaNo ratings yet

- Using The ASME VIII-1 Nozzle F Factor (UG-37)Document8 pagesUsing The ASME VIII-1 Nozzle F Factor (UG-37)Liu YangtzeNo ratings yet

- Determination of Bolt Torque For Flanged ConnectionsDocument2 pagesDetermination of Bolt Torque For Flanged ConnectionsVishwajeetNo ratings yet

- FitzerDocument2 pagesFitzerAnkit LonareNo ratings yet

- Collapse Tests of Pipe Casing and Tubing: February 2000Document10 pagesCollapse Tests of Pipe Casing and Tubing: February 2000Ankit LonareNo ratings yet

- Sample Sitevisitreport-Nfg AsfDocument1 pageSample Sitevisitreport-Nfg AsfAnkit LonareNo ratings yet

- Annexure ADocument2 pagesAnnexure ARajesh LingamalluNo ratings yet

- Flange RotationDocument1 pageFlange RotationAnkit LonareNo ratings yet

- Metric: Hex Nut Style 2 Class 12Document1 pageMetric: Hex Nut Style 2 Class 12Ankit LonareNo ratings yet

- Tax Invoice: Gohtldandg538YpdDocument2 pagesTax Invoice: Gohtldandg538YpdAnkit LonareNo ratings yet

- Ansi b36.10 Pipe SizeDocument9 pagesAnsi b36.10 Pipe SizeSpoonful BurnsideNo ratings yet

- HJJDocument3 pagesHJJAnkit LonareNo ratings yet

- Inconel Alloy C 276 PDFDocument8 pagesInconel Alloy C 276 PDFBharatbhushanNo ratings yet

- Useful Formulas & Fan LawsDocument2 pagesUseful Formulas & Fan LawsEngr_WRQNo ratings yet

- IntroductionDocument17 pagesIntroductionMitul PrajapatiNo ratings yet

- Sample WFCDocument1 pageSample WFCSarah Shibu ThomasNo ratings yet

- Ase Documents EN1591 BasisDocument8 pagesAse Documents EN1591 BasisSharat ChandraNo ratings yet

- Surface Modeling Proe WF 2Document46 pagesSurface Modeling Proe WF 2seventhhemanthNo ratings yet

- Solution PropertiesDocument29 pagesSolution PropertiesdhavaleshNo ratings yet

- Main Paper Rabas1981Document22 pagesMain Paper Rabas1981Ankit LonareNo ratings yet

- CFD of PumpDocument180 pagesCFD of PumpFarCfdNo ratings yet

- Test Plan - Immersed HX Tank - May2012-1Document1 pageTest Plan - Immersed HX Tank - May2012-1Ankit LonareNo ratings yet

- A 193337Document280 pagesA 193337Ankit LonareNo ratings yet

- Design Air SystemsDocument41 pagesDesign Air Systemssmacna100% (12)

- FitzerDocument2 pagesFitzerAnkit LonareNo ratings yet

- A 193337Document280 pagesA 193337Ankit LonareNo ratings yet

- RadiatorDocument46 pagesRadiatorjd4u100% (1)

- Test Plan - Immersed HX Tank - May2012-1Document4 pagesTest Plan - Immersed HX Tank - May2012-1Ankit LonareNo ratings yet

- HX1Document124 pagesHX1mvsscribdNo ratings yet

- DSI May12 PresentatiDocument14 pagesDSI May12 PresentatimbarradNo ratings yet

- Wang 2017Document11 pagesWang 2017Ankit LonareNo ratings yet

- Helium Leak Test in Line: Enhanced Reliability For Heat Exchanger TubesDocument6 pagesHelium Leak Test in Line: Enhanced Reliability For Heat Exchanger TubesAnkit LonareNo ratings yet

- IS 2848 - Specition For PRT SensorDocument25 pagesIS 2848 - Specition For PRT SensorDiptee PatingeNo ratings yet

- Biotechnology Eligibility Test (BET) For DBT-JRF Award (2010-11)Document20 pagesBiotechnology Eligibility Test (BET) For DBT-JRF Award (2010-11)Nandakumar HaorongbamNo ratings yet

- Self-Learning Module in General Chemistry 1 LessonDocument9 pagesSelf-Learning Module in General Chemistry 1 LessonGhaniella B. JulianNo ratings yet

- Operation Manual TempoLink 551986 enDocument12 pagesOperation Manual TempoLink 551986 enBryan AndradeNo ratings yet

- Government of The Punjab Primary & Secondary Healthcare DepartmentDocument3 pagesGovernment of The Punjab Primary & Secondary Healthcare DepartmentYasir GhafoorNo ratings yet

- Issue 189Document38 pagesIssue 189Oncampus.net100% (1)

- Illegal FishingDocument1 pageIllegal FishingDita DwynNo ratings yet

- Chapter 1Document2 pagesChapter 1Nor-man KusainNo ratings yet

- Purp Com Lesson 1.2Document2 pagesPurp Com Lesson 1.2bualjuldeeangelNo ratings yet

- Wei Et Al 2016Document7 pagesWei Et Al 2016Aline HunoNo ratings yet

- Mehdi Semati - Media, Culture and Society in Iran - Living With Globalization and The Islamic State (Iranian Studies)Document294 pagesMehdi Semati - Media, Culture and Society in Iran - Living With Globalization and The Islamic State (Iranian Studies)Alexandra KoehlerNo ratings yet

- Mono - Probiotics - English MONOGRAFIA HEALTH CANADA - 0Document25 pagesMono - Probiotics - English MONOGRAFIA HEALTH CANADA - 0Farhan aliNo ratings yet

- Case Study - Help DocumentDocument2 pagesCase Study - Help DocumentRahNo ratings yet

- 2019 BioscienceJDocument14 pages2019 BioscienceJPatrícia Lima D'AbadiaNo ratings yet

- Cats - CopioniDocument64 pagesCats - CopioniINES ALIPRANDINo ratings yet

- Exercise C: Cocurrent and Countercurrent FlowDocument6 pagesExercise C: Cocurrent and Countercurrent FlowJuniorNo ratings yet

- Lesson Plan 12 Climate ChangeDocument5 pagesLesson Plan 12 Climate ChangeRey Bello MalicayNo ratings yet

- Pic Attack1Document13 pagesPic Attack1celiaescaNo ratings yet

- Networks Lab Assignment 1Document2 pagesNetworks Lab Assignment 1006honey006No ratings yet

- Lay Out New PL Press QltyDocument68 pagesLay Out New PL Press QltyDadan Hendra KurniawanNo ratings yet

- Divide Fractions by Fractions Lesson PlanDocument12 pagesDivide Fractions by Fractions Lesson PlanEunice TrinidadNo ratings yet

- Strategy GlossaryDocument15 pagesStrategy GlossaryMahmoud SaeedNo ratings yet

- Unitary Small Air-Conditioners and Air-Source Heat Pumps (Includes Mixed-Match Coils) (RATED BELOW 65,000 BTU/H) Certification ProgramDocument65 pagesUnitary Small Air-Conditioners and Air-Source Heat Pumps (Includes Mixed-Match Coils) (RATED BELOW 65,000 BTU/H) Certification ProgramAmer GaladNo ratings yet

- Spiral Granny Square PatternDocument1 pageSpiral Granny Square PatternghionulNo ratings yet

- ĐỀ CƯƠNG ANH 9 - CK2 (23-24)Document7 pagesĐỀ CƯƠNG ANH 9 - CK2 (23-24)thuyhagl2710No ratings yet

- Programming Language II CSE-215: Dr. Mohammad Abu Yousuf Yousuf@juniv - EduDocument34 pagesProgramming Language II CSE-215: Dr. Mohammad Abu Yousuf Yousuf@juniv - EduNaruto DragneelNo ratings yet

- List of DEA SoftwareDocument12 pagesList of DEA SoftwareRohit MishraNo ratings yet