Professional Documents

Culture Documents

Pages From Asme Sec Ix 2017-4

Uploaded by

Akhtar Ansari0 ratings0% found this document useful (0 votes)

45 views1 pagedserawe

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentdserawe

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

45 views1 pagePages From Asme Sec Ix 2017-4

Uploaded by

Akhtar Ansaridserawe

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

ASME BPVC.

IX-2017

ARTI CLE I V

WELDI N G DATA

QW-400 VARI ABLES characteristics, and technique. For convenience, variables

for each welding process are summarized in Table

QW- 401 G EN ERAL

QW-416 for performance qualification.

Each welding variable described in this Article is ap- QW- 402 J O I N TS

plicable as an essential, supplementary essential, or non- A change in the type of groove (Vee ‐

essential variable for procedure qualification when

QW- 402 . 1

groove, U ‐ groove, single ‐ bevel, double ‐ bevel, etc.).

referenced in QW-250 for each specific welding process.

Essential variables for performance qualification are re- QW-402. 2 The addition or deletion of a backing.

ferenced in QW-350 for each specific welding process. A QW- 402 . 3 A change in the nominal composition of

change from one welding process to another welding pro- the backing.

cess is an essential variable and requires requalification.

QW- 402. 4 The deletion of the backing in single ‐

ð 17Þ Q W- 401. 1 Su pplem en tary Essen ti al Vari ab le (Pro- welded groove welds. Double ‐ welded groove welds are

Supplementary essential variables are in addi-

ce d u re ) . considered welding with backing.

tion to the essential variables for each welding process. QW-402. 5 The addition of a backing or a change in its

When a procedure has been previously qualified to sa- nominal composition.

tisfy all requirements other than toughness, it is then nec- QW-402. 6 An increase in the fit‐ up gap, beyond that

essary only to prepare an additional test coupon using the initially qualified.

same procedure with the same essential variables, but ad-

ditionally with all of the required supplementary essen- QW-402. 7 The addition of backing.

tial variables, with the coupon long enough to provide QW- 402. 8 A change in nominal size or shape of the

the necessary toughness specimens. stud at the section to be welded.

When a procedure has been previously qualified to sa- QW-402. 9 In stud welding, a change in shielding as a

tisfy all requirements including toughness, but one or result of ferrule or flux type.

more supplementary essential variable is changed, then

it is only necessary to prepare an additional test coupon QW-402. 10 A change in the specified root spacing.

using the same welding procedure and the new supple- QW- 402 . 1 1 The addition or deletion of nonmetallic

mentary essential variable(s) , with the coupon long retainers or nonfusing metal retainers.

enough to provide the necessary toughness specimens.

If a previously qualified weld procedure has satisfactory QW-402. 12 The welding procedure qualification test

toughness values in the weld metal, then it is necessary shall duplicate the joint configuration to be used in pro-

only to test toughness specimens from the heat-affected duction within the limits listed, except that pipe or tube

zone when such are required. to pipe or tube may be used for qualification of a pipe

or tube to other shapes, and solid round to solid round

When essential variables are qualified by one or more may be used for qualification of a solid round to other

PQRs and supplementary essential variables are qualified shapes

by other PQRs, the ranges of essential variables estab- (a) any change exceeding ±10 deg in the angle mea-

lished by the former PQRs are only affected by the latter sured for the plane of either face to be joined, to the axis

to the extent specified in the applicable supplementary of rotation

essential variable (e.g., essential variable QW-403.8 gov- (b) a change in cross ‐ sectional area of the weld joint

erns the minimum and maximum thickness of base metal greater than 10%

qualified. When s upp lementary es sential variab le (c) a change in the outside diameter of the cylindrical

QW-403.6 applies, it modifies only the minimum thick- weld interface of the assembly greater than ± 10%

ness qualified, not the maximum). (d) a change from solid to tubular cross section at the

QW- 401. 2 The welding data includes the welding joint or vice versa regardless of (b)

variables grouped as joints, base metals, filler metals, po- QW- 402 . 13 A change in the method of joining from

sition, preheat, postweld heat treatment, gas, electrical spot to projection to seam or vice versa.

78

You might also like

- Asme Sec Ix PT QW Article IVDocument139 pagesAsme Sec Ix PT QW Article IVjorgeNo ratings yet

- Distortion in Weld JointDocument54 pagesDistortion in Weld JointDiVik BhargAva100% (1)

- Welding QA Quidelines For FabricationDocument12 pagesWelding QA Quidelines For FabricationRyan Vizcarra FerrerNo ratings yet

- Standard and Utility Parts CatalogDocument395 pagesStandard and Utility Parts Catalogau7usa50% (2)

- ASME Sec IXDocument46 pagesASME Sec IXShyam Singh100% (2)

- Asme Section IxDocument71 pagesAsme Section Ixranjitkumar1977100% (2)

- Welding Procedure SpecificationDocument6 pagesWelding Procedure SpecificationJorge SanchezNo ratings yet

- ASME Sec IX Flashcards - QuizletDocument10 pagesASME Sec IX Flashcards - Quizletqazi12No ratings yet

- QW 381Document1 pageQW 381Waqas WaqasNo ratings yet

- Basic Workholding TechniquesDocument112 pagesBasic Workholding Techniquessuperalitos100% (1)

- Procedure Qualification RecordDocument10 pagesProcedure Qualification Recordlamia97No ratings yet

- Astm A513 PDFDocument20 pagesAstm A513 PDFpradelles89% (9)

- Asme Sec Ix 2021Document79 pagesAsme Sec Ix 2021abdelkader bensatal100% (1)

- Mfjo770 Activity ScheduleDocument1 pageMfjo770 Activity ScheduleAkhtar AnsariNo ratings yet

- Asme 9 DatosDocument47 pagesAsme 9 Datosvichu_villamarNo ratings yet

- KPIs FOR MEASURING THE SUCCESS OF SHUTDOWN PDFDocument67 pagesKPIs FOR MEASURING THE SUCCESS OF SHUTDOWN PDFMohamed F Morsy60% (5)

- Variables For Wps/Welder Qualification Variable WPS Welder: ParagDocument2 pagesVariables For Wps/Welder Qualification Variable WPS Welder: Paragahmed sobhyNo ratings yet

- QW-403 6Document1 pageQW-403 6Solikhul HarisNo ratings yet

- Equipment AssemblyDocument8 pagesEquipment AssemblyAkhtar AnsariNo ratings yet

- PART 66 ASME IX - Part 2 Essential Variable For Welder QualificationDocument13 pagesPART 66 ASME IX - Part 2 Essential Variable For Welder Qualificationravindra_jivaniNo ratings yet

- Aws and Asme WpsDocument59 pagesAws and Asme Wpsfaizalzol100% (1)

- API 510 - DAY 3: G T Technical & Management Institute PVT - LTD.Document102 pagesAPI 510 - DAY 3: G T Technical & Management Institute PVT - LTD.hamedNo ratings yet

- Capacities of Various Plant and MachineryDocument4 pagesCapacities of Various Plant and MachineryRightie CubeNo ratings yet

- ASME Sec IX Groove To Fillet WeldDocument3 pagesASME Sec IX Groove To Fillet WeldAzhar Ali0% (1)

- Asme Ix QW PDFDocument183 pagesAsme Ix QW PDFAnonymous 4e7GNjzGW100% (4)

- ASME IX Temper Bead WeldingDocument4 pagesASME IX Temper Bead WeldingAhmadiBinAhmadNo ratings yet

- 05-Welder Certification PDFDocument11 pages05-Welder Certification PDFAnonymous bfxeE1zvY100% (1)

- Think and Grow Rich Made EasyDocument116 pagesThink and Grow Rich Made EasyAkhtar AnsariNo ratings yet

- Asme Boiler & Pressure Vessel CodeDocument33 pagesAsme Boiler & Pressure Vessel CodeYuwantoniAl100% (1)

- More Tricks With The: "Quorn"Document5 pagesMore Tricks With The: "Quorn"Dan HendersonNo ratings yet

- S690ql ThyssenkruppDocument7 pagesS690ql ThyssenkruppSivabalan100% (1)

- Welder Performance Qualification WPQDocument3 pagesWelder Performance Qualification WPQramzi5ben5ahmed100% (1)

- Butt JointsDocument21 pagesButt JointsRaj1-23No ratings yet

- BookshelfDocument4 pagesBookshelfJerry Kn100% (2)

- Brief of Variables: Smaw Gtaw Gmaw SawDocument3 pagesBrief of Variables: Smaw Gtaw Gmaw SawAdilMunirNo ratings yet

- Essential and Non-Essential Variables For WPS - PQRDocument4 pagesEssential and Non-Essential Variables For WPS - PQRNatarajan MurugesanNo ratings yet

- Asme 9 TipsDocument13 pagesAsme 9 TipsnasrpkNo ratings yet

- H 99 Sec 9 QwivDocument79 pagesH 99 Sec 9 QwivJhon HernandezNo ratings yet

- Table QW-442 Table QW-442 Table QW-432 QW-404.5: ASME BPVC - IX-2023Document1 pageTable QW-442 Table QW-442 Table QW-432 QW-404.5: ASME BPVC - IX-2023ahmadrizkiqcNo ratings yet

- Sec Viii D2 Art F-3Document2 pagesSec Viii D2 Art F-3Manus79No ratings yet

- Asme Ix 2 PDFDocument34 pagesAsme Ix 2 PDFAli Ben AmorNo ratings yet

- Extracted Pages From ASME BPVC 2021 Section IX-2Document2 pagesExtracted Pages From ASME BPVC 2021 Section IX-2Roberto Carlos Arana ChumpitazNo ratings yet

- Summary of Changes in ASME Section IX, 2002 AddendaDocument6 pagesSummary of Changes in ASME Section IX, 2002 AddendaAnonymous 6LwW4qi6TiNo ratings yet

- ASME Section IX Code Edition 2017 Summary of Changes: Working Together For A Safer WorldDocument38 pagesASME Section IX Code Edition 2017 Summary of Changes: Working Together For A Safer WorldWagner ClaudioNo ratings yet

- WPS PQR For Alumunium Reactor TankDocument31 pagesWPS PQR For Alumunium Reactor TankAlirza Aliyev100% (1)

- Asme Sec Ix 2021: KG - Pandithan Iwe Technical AdviserDocument80 pagesAsme Sec Ix 2021: KG - Pandithan Iwe Technical AdviserjswldeepNo ratings yet

- Pages From Asme Sec Ix 2017-3Document1 pagePages From Asme Sec Ix 2017-3Akhtar AnsariNo ratings yet

- WPS, PQR & WQT According To ASME Section IX - 2019Document50 pagesWPS, PQR & WQT According To ASME Section IX - 2019Anon YmousNo ratings yet

- How To Write A Welding Procedure Specification (WPS)Document5 pagesHow To Write A Welding Procedure Specification (WPS)Mohamed Atef100% (1)

- Part QW Welding Article IDocument13 pagesPart QW Welding Article IHiago BragaNo ratings yet

- How To Write A Welding Procedure SpecificationDocument5 pagesHow To Write A Welding Procedure SpecificationBN JadhavNo ratings yet

- Variables For Welding 11-3-2016 - 264B1DF6 PDFDocument2 pagesVariables For Welding 11-3-2016 - 264B1DF6 PDFSameh AminNo ratings yet

- Asme Sec 9Document12 pagesAsme Sec 9ckkashyap0007No ratings yet

- Variable E SE NE Description of Variable As in Code 2011a QW SMAW Welding Variables For WPS - ASME Sec IX 2011aDocument7 pagesVariable E SE NE Description of Variable As in Code 2011a QW SMAW Welding Variables For WPS - ASME Sec IX 2011aSaut Maruli Tua SamosirNo ratings yet

- 7.lap Hammer TestDocument2 pages7.lap Hammer TestOckto Ferry Harahap EtsfNo ratings yet

- Asme IX BQ Art 11Document5 pagesAsme IX BQ Art 11Maria Alexandra Lange LenzNo ratings yet

- PW3Document49 pagesPW3Mujaffar ShaikhNo ratings yet

- Asme Sec Ix PT QB Article Xiv - Brazing DataDocument24 pagesAsme Sec Ix PT QB Article Xiv - Brazing Datasamitha505No ratings yet

- 303 2Document1 page303 2SARSAN NDTNo ratings yet

- Summary of Important Points in Asme IxDocument36 pagesSummary of Important Points in Asme IxRedzuanNo ratings yet

- Api 510 PTR 7Document3 pagesApi 510 PTR 7HemaNo ratings yet

- ASMEDocument20 pagesASMENorazzah AbdullahNo ratings yet

- QW-162 Guided-Bend Test Procedure: QW-466.1 Figure QW-466.2 Figure QW-463.1 (F)Document2 pagesQW-162 Guided-Bend Test Procedure: QW-466.1 Figure QW-466.2 Figure QW-463.1 (F)Gangadhar SahuNo ratings yet

- Procedure Qualification Record (PQR)Document2 pagesProcedure Qualification Record (PQR)Ankit KumarNo ratings yet

- AsmeDocument11 pagesAsmeManoj BallaNo ratings yet

- Asme Ix Changes 2017Document4 pagesAsme Ix Changes 2017END - PTSC S.A.S.No ratings yet

- Ix+ 3. (WPQ) Welding Performance QualificationsDocument7 pagesIx+ 3. (WPQ) Welding Performance QualificationsAMAL VISHNUNo ratings yet

- Asme Ix WPS TestDocument6 pagesAsme Ix WPS Testmuhammad hadiNo ratings yet

- Interpretation 22-774Document1 pageInterpretation 22-774Shyam KrishnanNo ratings yet

- ANSI AWS Writing and Qualifying Welding Procedures - Technical BulletinsDocument4 pagesANSI AWS Writing and Qualifying Welding Procedures - Technical Bulletinscleiton.wtecNo ratings yet

- Part QW Welding: Article I Welding General RequirementsDocument6 pagesPart QW Welding: Article I Welding General RequirementsmohammadNo ratings yet

- PQRDocument4 pagesPQRmoonstar_dmeNo ratings yet

- Inspection Call Request Format - 46967 - 018 - Dated 04.08.2022Document1 pageInspection Call Request Format - 46967 - 018 - Dated 04.08.2022Akhtar AnsariNo ratings yet

- Inspection Call Request Format - 441715 - 003 - Dated 04.08.2022Document1 pageInspection Call Request Format - 441715 - 003 - Dated 04.08.2022Akhtar AnsariNo ratings yet

- Inspection Call Request Format - 47758 - 004 - Dated 04.08.2022Document1 pageInspection Call Request Format - 47758 - 004 - Dated 04.08.2022Akhtar AnsariNo ratings yet

- Photo Annexure To IR No.189123-231221-01Document3 pagesPhoto Annexure To IR No.189123-231221-01Akhtar AnsariNo ratings yet

- EXCEL Formulas BibleDocument42 pagesEXCEL Formulas BibleParkash Chander RughaniNo ratings yet

- Akhtar Ansari - TPI - FRT PDFDocument5 pagesAkhtar Ansari - TPI - FRT PDFAkhtar AnsariNo ratings yet

- Akhtar Ansari - TPI - FRT PDFDocument5 pagesAkhtar Ansari - TPI - FRT PDFAkhtar AnsariNo ratings yet

- Akhtar Ansari - TPI - FRT PDFDocument5 pagesAkhtar Ansari - TPI - FRT PDFAkhtar AnsariNo ratings yet

- Akhtar Ansari - TPI - FRT PDFDocument5 pagesAkhtar Ansari - TPI - FRT PDFAkhtar AnsariNo ratings yet

- ST 52 DIN 2391 Part 2 (Germany) : StandardsDocument1 pageST 52 DIN 2391 Part 2 (Germany) : StandardsKandregula Mohan BabuNo ratings yet

- Akhtar Ansari - TPI - FRT PDFDocument5 pagesAkhtar Ansari - TPI - FRT PDFAkhtar AnsariNo ratings yet

- Akhtar Ansari - TPI - FRT PDFDocument5 pagesAkhtar Ansari - TPI - FRT PDFAkhtar AnsariNo ratings yet

- Project CharterDocument27 pagesProject CharterAkhtar AnsariNo ratings yet

- Akhtar Ansari - TPI - FRT PDFDocument5 pagesAkhtar Ansari - TPI - FRT PDFAkhtar AnsariNo ratings yet

- Training On: 5S Housekeeping TrainingDocument1 pageTraining On: 5S Housekeeping TrainingAkhtar AnsariNo ratings yet

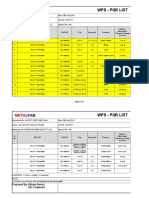

- Wps - PQR List: Page 1 of 4Document4 pagesWps - PQR List: Page 1 of 4Akhtar AnsariNo ratings yet

- MFJO723 - As Built DrawingDocument9 pagesMFJO723 - As Built DrawingAkhtar AnsariNo ratings yet

- Rir 0002Document1 pageRir 0002Akhtar AnsariNo ratings yet

- Attendance Sheet - 5S Housekeeping TrainingDocument1 pageAttendance Sheet - 5S Housekeeping TrainingAkhtar Ansari100% (1)

- Load Test Report For Spreader Bar A & BDocument2 pagesLoad Test Report For Spreader Bar A & BAkhtar AnsariNo ratings yet

- Memo StyleDocument5 pagesMemo StyleAkhtar AnsariNo ratings yet

- MFJO738A - Prssure Test CertificateDocument10 pagesMFJO738A - Prssure Test CertificateAkhtar AnsariNo ratings yet

- MFJO738A - RT Film - Pipe SpoolDocument2 pagesMFJO738A - RT Film - Pipe SpoolAkhtar AnsariNo ratings yet

- Memo StyleDocument5 pagesMemo StyleAkhtar AnsariNo ratings yet

- NDE Request: Metalfab Middle East FZ LLCDocument1 pageNDE Request: Metalfab Middle East FZ LLCAkhtar AnsariNo ratings yet

- 3 HardeningDocument14 pages3 HardeningyuvarajchiNo ratings yet

- 016 TS Hardox Cutting of Hardox Wear Plate UK PDFDocument4 pages016 TS Hardox Cutting of Hardox Wear Plate UK PDFNenad SmiljkovicNo ratings yet

- Gear Data 20-6Document3 pagesGear Data 20-6Kallol MahalanabisNo ratings yet

- Setup SheetDocument9 pagesSetup SheetJeevaRamanNo ratings yet

- Orthogonal & Oblique CuttingDocument2 pagesOrthogonal & Oblique CuttingShivanshu shekhar100% (3)

- Module - IntroductioninMetalWorkDocument19 pagesModule - IntroductioninMetalWorkDaniel Daryl CalingNo ratings yet

- MP Unit 2Document61 pagesMP Unit 2Abhishek KhatavkarNo ratings yet

- ch06 PDFDocument6 pagesch06 PDFjannNo ratings yet

- Zed Purlins Roll Forming LeafletDocument6 pagesZed Purlins Roll Forming LeafletTakis ApostolidesNo ratings yet

- 07 Rawlbolts Plugs AnchorsDocument1 page07 Rawlbolts Plugs AnchorsLincolnNo ratings yet

- B MetaboDocument16 pagesB Metaboedi saputra ediNo ratings yet

- Lesson 3 - Covered Electrodes For Welding Mild Steels PDFDocument1 pageLesson 3 - Covered Electrodes For Welding Mild Steels PDFMelissa MurrayNo ratings yet

- CK6132A CNC Lathe MachineDocument2 pagesCK6132A CNC Lathe MachineMUHAMMAD NAUMANNo ratings yet

- 01 Bs 3692 Grade 88 Bolt Nut CompressDocument1 page01 Bs 3692 Grade 88 Bolt Nut Compresssssaiyed786yahoo.com ShoebNo ratings yet

- Crystal Report Viewer 2Document4 pagesCrystal Report Viewer 2jeswinNo ratings yet

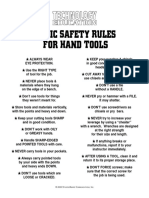

- Hand Tool SafetyDocument1 pageHand Tool SafetymardyNo ratings yet

- 2 Inoculation of Cast IronDocument2 pages2 Inoculation of Cast IronAdams Godoy0% (1)

- How To Build A Drill Press Table - The Family HandymanDocument2 pagesHow To Build A Drill Press Table - The Family HandymanahdickwongNo ratings yet

- The Huck Bobtail System: Engineered For Ease of Installation, High Strength, and Vibration ResistanceDocument9 pagesThe Huck Bobtail System: Engineered For Ease of Installation, High Strength, and Vibration ResistanceGIRONHNo ratings yet

- Single Point Cutting ToolDocument16 pagesSingle Point Cutting ToolSoumik DasNo ratings yet

- MEM560 Chapter 3 NotesDocument115 pagesMEM560 Chapter 3 NotesIrfanNo ratings yet