Professional Documents

Culture Documents

171 BOQ Plumbing

Uploaded by

zeamalCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

171 BOQ Plumbing

Uploaded by

zeamalCopyright:

Available Formats

PRICING PREAMBLES AND INST

5

6

7

8

9

10

11

A+ EngineersMEP Consultants Page 185

12

13

14

15

16

17

A+ EngineersMEP Consultants Page 186

PRICING PREAMBLES AND INSTRUCTIONS

The Bill of Quantities shall be read in conjunction with Instructions to Bidders, General and Special Conditions of Contract, Invitation for Bid, Technical

Specifications and Drawings and the entire satisfaction of the Engineer/Consultants.

Bill of Quantities (B.O.Q) comprises of Item rate basis. Bill of Quantities consists of various works related to HVAC. The bidder has to quote the rate (in

words and figures) against each item (for which quantity is given) in B.O.Q. The payment shall be made as per the quantum of work executed at the rates

quoted by Contractor for individual BOQ item. Contractor will have no right for any claims whatsoever like loss of profit etc. in case the actual quantum of

work executed against any BOQ item is less than the quantities given in BOQ. In case of increase in quantities beyond BOQ provisions, rate revision shall

be affected as per the provisions in conditions of contract and appendix to bid. The quantities listed in B.O.Q are generally approximate and are for

guidance of the tenderers only.

If the bidder fails to quote rate against any item (for which quantity has been provided) in bill of quantities, the same will not be paid for by employer

when executed and shall be deemed to have been included by the bidder in the rates and prices for other items in the bill of quantities.

General directions and descriptions of work and materials are not necessarily repeated, nor summarized in the Unit Priced Bill of Quantities. Reference to

the relevant sections of the contract documentation including technical specifications shall be made before entering prices against each item in the Unit

Priced Bill of Quantities.

Bidders shall fill the Unit Priced Bill of Quantities in Rupees only.

Errors will be corrected by the employer for any arithmetic errors in computation or summation as per contract conditions.

All the unit rates should be filled both in figures and words and amounts should be filled in figures only.

All columns in the Bill of Quantities shall be filled in indelible ink or type written and the total tender amount shown in the bottom. The person

authorized to sign on behalf of the Bidder shall sign in full with company seal and date at the bottom of all pages and at the end of summary sheet B.O.Q.

Any corrections shall be made by clearly striking out the previous data, writing the correct figure/data and putting signature of the authorized signatory

at the place of correction. Use of correction fluid is not allowed.

The Contractor may raise their Own Account payments on monthly basis as per the status of work on the last day of the respective month.

The works executed against the BOQ items would be paid on measurement basis.

The payment under the Payment Schedule will cover all work specified in the tender drawing and / or provided in the scope of work. The Schedule of

Payment will not get modified due to alterations of any type so far as the modifications/alterations are within the scope of work and/or provided for in

the tender drawings.

A+ EngineersMEP Consultants Page 187

In case of piping and piping thermal insulation, the payment shall be on Rft basis measured at the centre line of piping at the rate given according to N.B.

of piping.

In case of air ducting works, the payment for ducting and duct thermal insulation whose rates are given on per square feet basis shall be on basis of the

surface area of sheet metal duct. Reducers shall be measured at average size and bends, elbows etc at the centre line radius.

The Employer may opt to supply any of the materials at site free of cost to the Contractors. The cost of such items shall be deleted from the contract cost.

The Contractor shall be responsible for careful storage and consumption of these materials and he will be responsible for any loss or damage thereto. All

surplus materials on completion of the installation shall be handed back to the Employer by the Contractor.

The Employer may opt to delete any item or increase the quantity of certain items. The cost of deleted items shall be deleted from the Contract cost. The

rates quoted shall be firm for the duration of the Contract and the increased/decreased quantities of the items shall be adjusted as per rates quoted.

The quoted rates and prices in Priced Bill of Quantities will be deemed to include all plant, labor, supervision, materials, transport, all temporary works,

erection, maintenance, taxes and duties, contractor’s profit and establishment/overheads, together with preparation of design and drawings, all general

risks, insurance liabilities, compliance of labor laws and obligations set out or implied in the contract.

In case, if any discrepancy in schedule and B.O.Q, the following will be considered as latest:

a) B.O.Q

b) Schedule.

c) Specifications.

A+ EngineersMEP Consultants Page 188

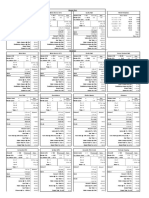

Project No.: 191 Date: 7th August 20

Client: Aga Khan University Hospital, Karachi Revision: N

BOQ for HVAC Works in Anatomy Lab, AKU, Karachi

Material Installation

Item Rate Amount Rate Amount

Description QTY Unit

No. (Rs.) (Rs.) (Rs.) (Rs.)

(3) x (5) (3) x (7)

1 2 3 4 5 6 7 8

A TAP WATER (INSIDE BUILDING)

1 PPR Pipes (Section 22 05 73)

PPR piping as per DIN 8077-8078, PN20 for Tap Water System from

main riser to fixtures complete with all fittings, flanges, unions,

gaskets and specialties expansion loops (or expansion joints) as

required and recommended by the manufacturer, particularly at

building expansion joint including all cutting, fitting, fixing and

cleaning, wall and slab sleeves, clamp as provided by the pipe

manufacturer, CP clamps, hangers and supports, making

connections with fixtures, valves and specials, chiseling, making

wall and floor openings and making good, pressure testing, painting

of MS components with primer and 1 coat of synthetic enamel

approved paint in approve dcolor, covering pipes in buried in walls

and floors with 12mm thick polyethylene tape, complete in all

respect.

The distance between pipe supports to be as recommednded by

the manufacturer.

Pipes shall be of Dadex, Wavin or approved equal.

1.1 Ø 25mm OD 100 Rft

1.2 Ø 32mm OD 25 Rft

A+ EngineersMEP Consultants Page 200

Material Installation

1.3 Ø 40mm

Item OD 40 Rft

Description QTY Unit

No.

A+ EngineersMEP Consultants Page 201

Material Installation

1.4 Ø 50mm

Item OD 20 Rft

Description QTY Unit

No.

1.5 Ø 65mm OD 15 Rft

1.6 Ø 75mm OD 10 Rft

2 G.I Pipes (Section 22 05 73)

BSS medium weight BS-1378, G.I. piping from main supply

connection from RO Plant to riser as shown on drawing with all

fittings and specials, including all cutting, fitting, fixing and cleaning

wall and slab sleeves, CP clamps, hangers and supports, making

connection with fixtures, valves and specials, chiseling, pressure

testing, making complete in all respects.

For size 50mmØ and above flanged joints shall be provided for

dismantling the pipes.

The piping to be IIL or approved equal.

2.1 Ø 2" NB 160 Rft

2.2 Ø 1" NB 50 Rft

3 Valves and Specialties. (Cold Water Supply)

The

Gate valves andPPR

Valve for specialties

Pipe Sizestomentioned

be of Econosto/

below Gala/ Hattersley/

Scon/ Tozen PN16 or approved equal.

3.1 Ø 40mm OD 1 No.

3.2 Ø 50mm OD 5 No.

3.3 Ø 65mm OD 2 No.

3.4 Ø 75mm OD 5 No.

Gate Valve for G.I Pipe Sizes mentioned below

3.4 Ø 2" NB 1 No.

3.5 Ø 1" NB 1 No.

Sub-total Carried to Summary

A+ EngineersMEP Consultants Page 202

Material Installation

B HOT WATER SUPPLY SYSTEM

Item Description QTY Unit

No.

1 PPR Pipes (Section 22 05 73)

PPR piping as per DIN 8077-8078, PN20 for hot water system from

storage type electric heater to fixtures complete with all fittings,

flanges, unions, gaskets and specialties expansion loops (or

expansion joints) as required and recommended by the

manufacturer, particularly at building expansion joint including all

cutting, fitting, fixing and cleaning, wall and slab sleeves, clamp as

provided by the pipe manufacturer, CP clamps, hangers and

supports, making connections with fixtures, valves and specials,

chiseling, making wall and floor openings & making good and

pressure testing. Insulating pipe with 20mm thick fiberglass 96

Kg/cum density insulation and 28g G.I cladding and 15mm

fiberglass 96 Kg/cum density insulation on buried in wall piping,

painting, covering pipes in walls and floors with 12mm thick

polyethylene tape, complete in all respects.

1.1 Ø 25mm OD 30 Rft

1.2 Ø 32mm OD 15 Rft

1.3 Ø 40mm OD 10 Rft

1.4 Ø 50mm OD 15 Rft

2 Valves and Specialties. (Hot Water Supply)

The valves and specialties to be of Econosto/ Gala/ Hattersley/

Scon/ Tozen PN16 or approved equal.

Gate Valve (Section 23 05 23)

2.1 Ø 32mm OD (Rate Only) - No.

A+ EngineersMEP Consultants Page 203

Material Installation

2.2 Ø 40mm

Item OD 2 No.

Description QTY Unit

No.

2.3 Ø 50mm OD 2 No.

A+ EngineersMEP Consultants Page 204

Material Installation

3 Hot Water Electric Heater (Section 22 06 30)

Item Description QTY Unit

No.

3.1 5KW Storage type Electric Operated hot water generator for 2 No.

domestic hot water supply to Toilet as per specified schedule.

Sub-Total Carried to Summary

C TOILET FIXTURES & ACCESSORIES (Section 22 40 00)

1 Water Closets European Style wall hung with close coupled 8 No.

cisterns, cistern fittings and acrylic seat cover with trap of Porta

Model HD291P, China or approved equal (White Color).

2 C.P. Angle Valve for cisterns water inlet, Grohetec No. 22958 00M 8 No.

with escutcheon or approved equal.

3 C.P. connectors with nuts and fittings, Grohetec No. 45170 or 8 No.

approved equal.

4 Combination set of Muslim Showers with Bib cock, flexible hose, 8 No.

valve nozzle spout, Model FXHOY-0059WC (Zilver) or approved

equal for Employers.

5 Wash Basin single centre hole, with brackets suitable for counter 10 No.

top fitting from below, of Porta model HDWL015, or approved

equal.

6 C.P. Tee Valves for wash basins cold and hot water inlet, Grohetec 20 No.

Model No. 22958 00M with escutcheon or approved equal.

7 C.P. bottle trap 1.5” with pipe for wash basin waste connection, 10 No.

Asia or approved equal.

8 Complete cold water valve for wash basins, Zilver Model E-CL101-1- 10 No.

35 or approved equal.

Sub-total Carried to Summary

A+ EngineersMEP Consultants Page 205

Material Installation

D SOIL, WASTE & VENT SYSTEM (Section 22 13 16)

Item Description QTY Unit

No.

1 Drain Piping Within Building

uPVC non pressure piping as per BS3214:1992 ISO-3633:1991

including all fittings and specials for soil, waste and vent stacks and

horizontal runs, concealed in floors, and connecting to GTs and

manholes, including all cutting, fitting, chiseling, making good,

fixing and cleaning, wall and floor openings, pressure testing after

laying and final testing of complete systems at specified test

pressure, complete in all respects.

The piping to be Dadex Nikasi Type B/Hepworth or approved equal.

1.1 Ø 1 1/2" NB 40 Rft

1.2 Ø 2" NB 85 Rft

1.3 Ø 3" NB 350 Rft

1.4 Ø 4" NB 380 Rft

2 Drain Piping Outside Building (Buried In Ground)

uPVC Class D pressure pipe conforming to BS3505 and

PS3051:1991 including all fittings, rubber rings, cleaners, jointing,

solution, fittings, shall be Dadex Eternit or approved equal.

All piping shall be laid underground. The work includes excavation,

digging ground upto the 4.5-9 ft deep, cutting/roads, back filling,

commissioning, flushing, pressure testing and interconnection with

existing systems or main city manhole system, complete in all

respects.

The piping to be Dadex/Hepworth manufacturer or approved

equal.

A+ EngineersMEP Consultants Page 206

Material Installation

2.1 Ø 4"

Item NB 20 Rft

Description QTY Unit

No.

A+ EngineersMEP Consultants Page 207

Material Installation

3 Floor Cleanout

Item Description QTY Unit

No. Clean-outs, polished SS top and recessed top covers including

jointing and testing, complete in all respects, Smith type 4051 or

approved equal.

3.1 Ø 3" NB (Rate Only) - No.

3.2 Ø 4" NB 14 No.

4 Floor Drain

S. S. Floor Drains for Drainage with grating and trap, shut off

arrangement including jointing and testing, complete in all

respects, complete in all respects, Smith type 2220 or approved

equal.

4.1 Ø 3" NB 21 No.

5 Vent COWL, complete in all respects similar to Smith Type 1748 or

approved equal.

5.1 Ø 4" NB 3 No.

Drain System Outside Building

6 Sewer External drainage Manholes of 1:2:4 CC construction with - No.

minimum 150mm thick walls, benching and heavy duty CI

Manholes Covers as detailed in the drawings 24”x24” inside and

21”x21” covers.

7 CI Gully Traps (GTs) including piping connections at locations and 2 No.

levels shown on drawings.

Sub-total Carried to Summary

E Miscellaneous

1 Painting, Coating & Wrapping. 1 Job

2 Shop Drawings. 1 Lot

A+ EngineersMEP Consultants Page 208

Material Installation

3 Provide 3 sets As-Installed Drawings and CD of drawings on

Item 1 Lot

Description QTY Unit

No. AutoCAD R2010.

A+ EngineersMEP Consultants Page 209

Material Installation

4 Structural openings.

Item 1 Lot

Description QTY Unit

No.

5 Cost of testing, starting-up, commissioning, balancing, adjusting 1 Job

and handing over of complete system as per specifications.

6 One month test run. 1 Job

Sub-total Carried to Summary

Grand Total Cost of Plumbing and Draiange Works (Rs.)

A+ EngineersMEP Consultants Page 210

Date: 7th August 2017

Revision: Nil

VAC Works in Anatomy Lab, AKU, Karachi

Total

Amount

(Rs.)

(6) + (8)

9

A+ EngineersMEP Consultants Page 211

Total

A+ EngineersMEP Consultants Page 212

Total

A+ EngineersMEP Consultants Page 213

Total

A+ EngineersMEP Consultants Page 214

Total

A+ EngineersMEP Consultants Page 215

Total

A+ EngineersMEP Consultants Page 216

Total

A+ EngineersMEP Consultants Page 217

Total

A+ EngineersMEP Consultants Page 218

Total

A+ EngineersMEP Consultants Page 219

Total

A+ EngineersMEP Consultants Page 220

Total

A+ EngineersMEP Consultants Page 221

You might also like

- Residential Plumbing Fixtures Bill of QuantitiesDocument3 pagesResidential Plumbing Fixtures Bill of QuantitiesLennox SantiagoNo ratings yet

- Atlanta 2022 Pricelist COMPLETEDocument4 pagesAtlanta 2022 Pricelist COMPLETEKCI Engg DepartmentNo ratings yet

- Schedule - Updated9182411975908974007Document4 pagesSchedule - Updated9182411975908974007Alfric AbinsayNo ratings yet

- Plumbing BOQDocument13 pagesPlumbing BOQ85sunaNo ratings yet

- Boq (110912)Document144 pagesBoq (110912)Ali AlaliNo ratings yet

- Progress S-Curve 15-21 July 2019Document27 pagesProgress S-Curve 15-21 July 2019Smith SongkhlaNo ratings yet

- Reyes Commerical Project Cost EstimateDocument1 pageReyes Commerical Project Cost Estimatesarih manlapazNo ratings yet

- BOQ Pharma UtilitiesDocument109 pagesBOQ Pharma UtilitiesSajeshKumarNo ratings yet

- Electrical WorksheetDocument19 pagesElectrical Worksheetnitin yadavNo ratings yet

- Public Toilet Gulshan2 - PlumbingDocument14 pagesPublic Toilet Gulshan2 - Plumbingsbiswas21No ratings yet

- Villa MEP BOQDocument3 pagesVilla MEP BOQIsuru Deshan WijewardanaNo ratings yet

- WTP BoqDocument26 pagesWTP Boqkajale_shrikant2325No ratings yet

- HVAC B.O.Q Cost Breakdown Master Sheet For Construction ProjectsDocument6 pagesHVAC B.O.Q Cost Breakdown Master Sheet For Construction ProjectsSanjeevan KrishnasamyNo ratings yet

- Eaab BomceDocument22 pagesEaab BomceBert EngNo ratings yet

- Boq For L&T City HotelsDocument4 pagesBoq For L&T City HotelsSundara MoorthyNo ratings yet

- Sarthi Skybay - D - Plumbing Internal, Duct, Terrace BOQDocument171 pagesSarthi Skybay - D - Plumbing Internal, Duct, Terrace BOQamolNo ratings yet

- 8th Floor Plumbing BOQDocument6 pages8th Floor Plumbing BOQsathish virupaksheNo ratings yet

- Civil BOQ New (Revised) 29!8!2011Document16 pagesCivil BOQ New (Revised) 29!8!2011AshwinBafnaNo ratings yet

- 1424 - BoQ and Cost EstimateDocument13 pages1424 - BoQ and Cost EstimateVampire_knight;)No ratings yet

- Cold water storage requirements for restaurantsDocument11 pagesCold water storage requirements for restaurantsAwokeNo ratings yet

- Breakdown Estimate Land CoDocument2 pagesBreakdown Estimate Land CoNick OperarioNo ratings yet

- Estimate Barpali....Document42 pagesEstimate Barpali....Sagarika SahooNo ratings yet

- 4-BILL NO. 4 Main Building Full MEPDocument276 pages4-BILL NO. 4 Main Building Full MEPDelwar HossainNo ratings yet

- Architect: Arcop Project: Kinshasa: Subject: Abstract of Bill of Quantities For Pumbing Works Villa DevelopmentDocument10 pagesArchitect: Arcop Project: Kinshasa: Subject: Abstract of Bill of Quantities For Pumbing Works Villa DevelopmentAbhishek aby5No ratings yet

- Plumbing BOQDocument13 pagesPlumbing BOQPavan GowdaNo ratings yet

- Quotation For Plumb, Elect & TilesDocument3 pagesQuotation For Plumb, Elect & TilesAnonymous jlLBRMAr3ONo ratings yet

- 2 Plumbing and Drainage Tender DocumentDocument195 pages2 Plumbing and Drainage Tender DocumentlewisNo ratings yet

- Boq - Zari SpaDocument4 pagesBoq - Zari SpaRizwan Aziz100% (1)

- 1727 Plumbing Estimation SheetDocument1 page1727 Plumbing Estimation SheetMohammed JassimNo ratings yet

- BoqDocument16 pagesBoqSara AdNo ratings yet

- Item No Description Unit No Rate Amount: JacuzziDocument12 pagesItem No Description Unit No Rate Amount: JacuzziTes FitNo ratings yet

- Somaliland Water Supply Bill of QuantityDocument3 pagesSomaliland Water Supply Bill of QuantitysubxaanalahNo ratings yet

- Jewel of the Creek Project Hospitality BuildingsDocument173 pagesJewel of the Creek Project Hospitality BuildingsAizhar John QuindozaNo ratings yet

- 529997276.xlsx General Requirements/1: IncludedDocument33 pages529997276.xlsx General Requirements/1: Includedbassma QuNo ratings yet

- Construction of Yashoda Hospital Expansion Phase 1 Plumbing Project SummaryDocument54 pagesConstruction of Yashoda Hospital Expansion Phase 1 Plumbing Project SummaryCherryl Chrissie JamesNo ratings yet

- CRS-ITP2 Plumbing BOM Rev. by AEC 04122017 - FB CommDocument11 pagesCRS-ITP2 Plumbing BOM Rev. by AEC 04122017 - FB CommRhowelle TibayNo ratings yet

- Building Permit Technical SpecificationDocument87 pagesBuilding Permit Technical SpecificationPipoy ReglosNo ratings yet

- Modern Bangladesh Food Storage Lighting PlansDocument6 pagesModern Bangladesh Food Storage Lighting PlansboranbNo ratings yet

- LG Hiwall VRV InstallationDocument5 pagesLG Hiwall VRV InstallationAshutosh Kumar DubeyNo ratings yet

- Budgetary Estimate - Pre ESA Equipment Setting CostDocument23 pagesBudgetary Estimate - Pre ESA Equipment Setting CostKevin J. MillsNo ratings yet

- Perimeter Fence Detailed CostDocument8 pagesPerimeter Fence Detailed CostOdessa Fortu LandichoNo ratings yet

- Contractora Estimate Cost - Propelat RapDocument192 pagesContractora Estimate Cost - Propelat RapMr. RudyNo ratings yet

- Description of Item Unit Other Serial Number Saloon PF Qty Goods PF Qty Total QuantityDocument4 pagesDescription of Item Unit Other Serial Number Saloon PF Qty Goods PF Qty Total Quantityapi-19745405No ratings yet

- Plumbing Estimates SampleDocument17 pagesPlumbing Estimates SampleLoren ViejayNo ratings yet

- Supply of Pipe and Fittings BlankDocument7 pagesSupply of Pipe and Fittings BlankMiko AbiNo ratings yet

- Standard Costing For Fit Out Mechanical WorksDocument2 pagesStandard Costing For Fit Out Mechanical WorksAllan Pesimo BalgosNo ratings yet

- OASE FT Catalogue EnglishDocument260 pagesOASE FT Catalogue Englishckyprianou100% (1)

- Estimating & CostingDocument9 pagesEstimating & CostingArui RegarNo ratings yet

- Block Price BOQDocument11 pagesBlock Price BOQArunKumar ChandrasekarNo ratings yet

- Drawing List MEP SERVICES - Detailed Desi: Ajara Hospital - Warangal Ajara HospitalDocument6 pagesDrawing List MEP SERVICES - Detailed Desi: Ajara Hospital - Warangal Ajara HospitalSanjay SahulNo ratings yet

- Tender For ElectricalDocument104 pagesTender For ElectricalbalabhaviniNo ratings yet

- Plumbing 22Document1 pagePlumbing 22DEEPAK SINGHNo ratings yet

- MATERIAL REQUIREMENTS FOR ABLUTION BLOCK AND WASH ROOMDocument3 pagesMATERIAL REQUIREMENTS FOR ABLUTION BLOCK AND WASH ROOMPatrick Sipatela100% (1)

- Bill of Quantities & Price Schedule - Lobby InteriorsDocument14 pagesBill of Quantities & Price Schedule - Lobby InteriorsAnonymous P7VckOJZUgNo ratings yet

- Project: XXXXX Location: XXXXX Client: XXXXX Consultant: XXXXX Date: 16-12-2015 Revision: XXXXXDocument77 pagesProject: XXXXX Location: XXXXX Client: XXXXX Consultant: XXXXX Date: 16-12-2015 Revision: XXXXXSangram Biplab Manabendra Thakur100% (3)

- Cost EstimationDocument4 pagesCost EstimationAmit Kumar MishraNo ratings yet

- Labor Production Table for Air-Con & Ventilation WorksDocument27 pagesLabor Production Table for Air-Con & Ventilation WorksPaoleene CunananNo ratings yet

- 16P038 Alehasa-BOQ Type 1 - With PC RatesDocument80 pages16P038 Alehasa-BOQ Type 1 - With PC RatesjatinNo ratings yet

- Mimar Engineering Consultants RatesDocument16 pagesMimar Engineering Consultants RatesAmy FitzpatrickNo ratings yet

- Volume 3 - BOQSDocument99 pagesVolume 3 - BOQSIrfanButtNo ratings yet

- SublimationDocument10 pagesSublimationzeamalNo ratings yet

- Freud's Theories Reveal Hidden MotivationsDocument69 pagesFreud's Theories Reveal Hidden MotivationszeamalNo ratings yet

- Creativity in AdvertisingDocument30 pagesCreativity in AdvertisingzeamalNo ratings yet

- Creativity in AdvertisingDocument30 pagesCreativity in AdvertisingzeamalNo ratings yet

- Summary SheetDocument5 pagesSummary SheetzeamalNo ratings yet

- Gillette's Strategy of InnovationDocument6 pagesGillette's Strategy of InnovationzeamalNo ratings yet

- Accacat Paper t3 Maintaining Financial ReDocument32 pagesAccacat Paper t3 Maintaining Financial ReKian Yen0% (1)

- Kiln Audit Heat Balance Tool - Data Entry Sheet 4 - CoolerDocument1 pageKiln Audit Heat Balance Tool - Data Entry Sheet 4 - CoolerMohamed SelimNo ratings yet

- Electrical Network of The Automotive Multi-Sectional Thermoelectric Generator With MPPT Based Device UsageDocument10 pagesElectrical Network of The Automotive Multi-Sectional Thermoelectric Generator With MPPT Based Device UsageMouna MorchidNo ratings yet

- Voith Thyricon Excitation SystemDocument8 pagesVoith Thyricon Excitation SystemKeshab ShresthaNo ratings yet

- Germany and Japan's Remarkable Post-WWII Economic ComebackDocument5 pagesGermany and Japan's Remarkable Post-WWII Economic ComebackHANNALEENo ratings yet

- Seller'S Disclosure and Condition of Property Addendum (Residential)Document8 pagesSeller'S Disclosure and Condition of Property Addendum (Residential)Barbara BishopNo ratings yet

- 262 Controlled Switching of HVAC Circuit Breaker PDFDocument34 pages262 Controlled Switching of HVAC Circuit Breaker PDFepriNo ratings yet

- DVC6200Document4 pagesDVC6200Jesus BolivarNo ratings yet

- Syllabus of Diploma in Electrical EngineeringDocument17 pagesSyllabus of Diploma in Electrical EngineeringJoson Chan100% (1)

- Hum BirdDocument179 pagesHum BirdSuman ChhetryNo ratings yet

- How Electric Cars Work: A Guide to EV TechnologyDocument4 pagesHow Electric Cars Work: A Guide to EV TechnologyCarla LoiaconoNo ratings yet

- Adelino Horizontal Multistage PumpDocument13 pagesAdelino Horizontal Multistage PumpJaved HasanNo ratings yet

- 2ND YEAR PHYSICS Full Book Topical MCQS With ANSWERSDocument47 pages2ND YEAR PHYSICS Full Book Topical MCQS With ANSWERSArhamNo ratings yet

- Installation Manual E-Brick en LoresDocument80 pagesInstallation Manual E-Brick en LoresvideoramirezNo ratings yet

- Test 48Document9 pagesTest 48Thị VyNo ratings yet

- Krff302ess01 Tech Sheet - w10787422 - Rev CDocument10 pagesKrff302ess01 Tech Sheet - w10787422 - Rev CJesikaGomezSaavedraNo ratings yet

- JCM Hybrid Controller User ManualDocument13 pagesJCM Hybrid Controller User ManualMtvc LbNo ratings yet

- Xref 2010Document1 pageXref 2010Axel Mahya AvichenaNo ratings yet

- Bomba Electrica 1500gpm 300HP (Medidas)Document1 pageBomba Electrica 1500gpm 300HP (Medidas)Fire ChileNo ratings yet

- Arcline® PP.: TIG Quality at MIG Productivity in Aluminium WeldingDocument12 pagesArcline® PP.: TIG Quality at MIG Productivity in Aluminium WeldingRaajNo ratings yet

- Exhaust ManifoldDocument5 pagesExhaust ManifoldDeepak Chachra100% (1)

- GCP: Google Cloud PlatformDocument25 pagesGCP: Google Cloud Platformalya khan100% (1)

- Rectificador A Diodos Siemens-Sitras-Rec-Pi-EnDocument6 pagesRectificador A Diodos Siemens-Sitras-Rec-Pi-EnVictor Manuel BonettoNo ratings yet

- Valve RecessionDocument26 pagesValve RecessionHamid HasanNo ratings yet

- More power in less space with SMA SUNNY CENTRAL UPDocument4 pagesMore power in less space with SMA SUNNY CENTRAL UPBrahadeesh Perinkolam MuraliNo ratings yet

- Transformer REFDocument4 pagesTransformer REFs_banerjeeNo ratings yet

- Installation Instructions: Mico Basic 8.6Document2 pagesInstallation Instructions: Mico Basic 8.6Servizio TecnicoNo ratings yet

- Lab 5Document9 pagesLab 5Cem UsmangilNo ratings yet

- Energy Consumption Benchmark Guide: Cement Clinker ProductionDocument14 pagesEnergy Consumption Benchmark Guide: Cement Clinker ProductionVisnu SankarNo ratings yet

- Ptmail - m1021 - Ss - Ev Ultimate Market Intelligence ReportDocument23 pagesPtmail - m1021 - Ss - Ev Ultimate Market Intelligence ReportPIYUSH GOPALNo ratings yet

- WCR For Canon Motor Relay FailureDocument1 pageWCR For Canon Motor Relay FailureIqmal WahabNo ratings yet