Professional Documents

Culture Documents

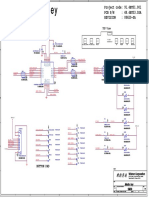

Power Supply DVP-PS01

Uploaded by

Rodrigo PerezCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Power Supply DVP-PS01

Uploaded by

Rodrigo PerezCopyright:

Available Formats

http://www.delta.com.tw/products/plc.

asp

DVPPS01 POWER OUTPUT MODULE

DVPPS02

1 Warning

This instruction will be helpful in the installation, electronic specification, function specification and troubleshooting of the DVPPS01 and

DVPPS02.

This is an OPEN TYPE DVPPS series. The DVPPS series should be kept in an enclosure away from airborne dust, high humidity,

electric shock risk and vibration. Also, it is equipped with protective methods such as some special tools or keys to open the enclosure,

so as to avoid the hazard to users and the damage to the DVPPS series.

Never connect the AC main circuit power supply to any of the output terminals, as it will damage the DVPPS series. Check all the wiring

prior to power up. To avoid any electromagnetic noise, make sure the DVPPS series is properly grounded .

2 Introduction

2.1 Model Explanation

Thank you for choosing DELTA DVP series. DVPPS series is a power module with 2 types that sorted by output circuit. 1. PS01 provides

24VDC and 1A current for output power. 2. PS02 provides 24VDC and 2A current for output power. DVPPS series is only used for Delta DVP

series. DVPPS series is separated from the PLC MPU for better space utilization and easier installation.

PS01 PS02

Nameplate Explanation

M odel MODEL : DVPPS01 M odel MODEL : DVPPS02

Input Power Supply Spec. INPUT : 100~240VAC 50 / 60Hz Input Power Supply Spec. INPUT : 100~240VAC 50 / 60Hz

Output Module Spec. OUTPUT : 24Vdc 1.0A Output M odule Spec. OUTPUT : 24Vdc 2.0A

Barcode and Serial Number PS 01 0T4360 001

Barcode and Serial Number PS 0 2 0 T4 3 70 0 0 1

Model Name Serial Number

Series name Production number

Power module Production weeks

Output current Production year (2004)

Production factory

Version

Production model

2.2 Product Profile and Outline

PS01 PS02

7 55 13.3 60

2

3

DVPPS01

5 2

5 DVPPS02

90

100

90

4 4

1

3

1

13.3

3

36.5 60

3 3

6 3 32.5 7

6 3

Unit: mm Unit: mm

1 Power LED 1 Power LED

2 Output/input terminal (fixed terminal) 2 Output/input terminal (fixed terminal)

3 DIN rail clip 3 DIN rail clip

4 DIN rail track (35mm) 4 DIN rail track (35mm)

5 I/O terminal label 5 I/O terminal label

6 Nameplate 6 Nameplate

7 Mounting holes

3 Function/Electrical Specification

Model

DVPPS01 DVPPS02

Item

Power Input 100~240 VAC (-15%~+10%), 50 / 60 Hz 100~240 VAC (-15%~+10%), 50 / 60 Hz

Output Power 24VDC (±3%), output current: 1A max. 24VDC (±3%), output current: 2A max.

Ripple & Noise Under 100mVp-p Typical at full load Under 240mVp-p Typical at full load

Efficiency 78%~87% Typical at full load

Over Load / Short Circuit Protection Auto Recovery

The diameter of grounding wire cannot be smaller than the wire diameter of terminals L and N

Grounding

(All PLC units should be grounded directly to the ground pole).

Operation: 0℃~55℃ (Temperature), 50~95% (Humidity), Pollution degree 2;

Operation/Storage Environment

Storage: -25℃~70℃ (Temperature), 5~95% (Humidity)

Underwriters Laboratories, Inc.: UL508 Listed (Industrial Control Equipment)

Agency Approvals

European Community EMC Directive 89/336/EEC and Low Voltage Directive 73/23/EEC

Weight (g) 158 250

4 Installation and Wiring

4.1 Mounting Arrangements and Wiring

■ DIN Rail Installation

For heat dissipation. Make sure to

The DVPPS can be secured to a cabinet by using the DIN rail that is 35mm

provide a minimum clearance of

high with a depth of 7.5mm. When mounting the DVPPS on the DIN rail, be

50mm between the unit and all

sure to use the end bracket to stop any side-to-side motion of the DVPPS,

sides of the cabinet. (as shown

thus to reduce the chance of the wires being pulled loose. On the bottom of

below)

the DVPPS is a small retaining clip. To secure the DVPPS to the DIN rail,

place it onto the rail and gently push up on the clip. To remove it, pull down > 50mm

on the retaining clip and gently pull the DVPPS away from the DIN rail. > 50mm

DVP MPU

> 50mm

Please see the figure on the right: > 50mm

■ Direct mounting: Tighten M4 screws into direct mount hole.

■ Wiring Notes:

1. Please use O-type or Y-type terminals for I/O wiring terminals. The specification for the terminals is

Below 6.2

as shown on the left. Tighten PLC terminal screws to a torque of 5~8 kg-cm (4.3~6.9 in-lbs).

To suit M3.5 screw terminals 2. Please avoid tiny metal material enter DVPPS01/PS02 when screwing and wiring. After finishing

wire, remove the affix that pasted on the heat sink for heat dissipation.

Below 6.2

3. Use Copper Conductors Only, 60℃.

4.2 Wiring Notes

■ Environment

1. DO NOT store the DVPPS01/PS02 in a dusty, smoky, or corrosive atmosphere.

2. DO NOT store the DVPPS01/PS02 in an environment with high temperature or high humidity.

3. DO NOT install PLC on a shelf or on an unstable surface.

■ Power Input Wiring

Power input of DVPPS01/PS02 is AC input; following items should be noticed:

1. Connect the AC input (100VAC ~ 240VAC) to terminals L and N. Any AC110V or AC220V connected to the +24V terminal will

permanently damage the DVPPS01/PS02.

2. Please use wires of 1.6mm and above for the grounding.

3. If the power-cut time is less than 10ms, the DVPPS01/PS02 still operates unaffectedly. If the power-cut time is too long, the

DVPPS01/PS02 will stop operating and all the outputs will be Off.

5 Trial Run

☼ Power indicator, Running and Test

The “POWER” LED at the front of DVPPS01/PS02 will be lit (in green) if the power is on. If the indicator is not ON, it indicates that the

power supply is not enough or short circuit. Please check your power wiring.

6 Troubleshooting

Judge the errors by the indicators on the front panel. When errors occurred on DVPPS01/PS02, please check:

☼ 「POWER」LED

The “POWER” LED at the front of the MPU will be lit (in green) if the power is on. If the indicator is not on when the MPU is powered up,

please check if power supply is normal. If the indicator is not on when the MPU is powered up and with the input power being normal, it is

an indication that the PLC is malfunction. Please have this machine replaced or have it repaired at a dealer near you.

You might also like

- Smart x835 DatasheetDocument4 pagesSmart x835 DatasheetBeni SetiawanNo ratings yet

- Calculate Size of Diesel Generator SetDocument1 pageCalculate Size of Diesel Generator SetN_LocusNo ratings yet

- Catalogue Brushless DC Drives GB 02 2007Document56 pagesCatalogue Brushless DC Drives GB 02 2007Bianca CerveiraNo ratings yet

- Bapatla Engineering College EEE Lab ExperimentsDocument44 pagesBapatla Engineering College EEE Lab Experimentspardhu_y4No ratings yet

- AM440/AM440D: User's Manual Manual Del UsuarioDocument28 pagesAM440/AM440D: User's Manual Manual Del UsuarioJordi Sala DelgadoNo ratings yet

- Measurement Concepts and InstrumentsDocument3 pagesMeasurement Concepts and InstrumentsRohini SanthanakumarNo ratings yet

- MAN-2004-0001-C - User Guide - Pcorr and Permalog Using WebCorr App PDFDocument56 pagesMAN-2004-0001-C - User Guide - Pcorr and Permalog Using WebCorr App PDFGabiBaciuNo ratings yet

- InteliATS NT 2.5 New Features r1Document7 pagesInteliATS NT 2.5 New Features r1fernando lozanoNo ratings yet

- TWDLMDA20DRT Product Data SheetDocument10 pagesTWDLMDA20DRT Product Data Sheetjoel_garcia_leeNo ratings yet

- EN - ACS480 - HW - D - A4 Web PDFDocument180 pagesEN - ACS480 - HW - D - A4 Web PDFERICK OSWALDONo ratings yet

- Fluke+PM6685,+PM6685R+Prog +Frequency+Counter PDFDocument94 pagesFluke+PM6685,+PM6685R+Prog +Frequency+Counter PDFtaryoNo ratings yet

- Writing A Simulink Device Driver Block: A Step by Step GuideDocument63 pagesWriting A Simulink Device Driver Block: A Step by Step GuidecuffioNo ratings yet

- Operation Manual: Variable Frequency DriveDocument185 pagesOperation Manual: Variable Frequency DriveLuis Angel Cayetano FloresNo ratings yet

- MT6070iH 7Document2 pagesMT6070iH 7Leopoldo PeñaNo ratings yet

- Design of Brushless Permanent Magnet Machines-1Document2 pagesDesign of Brushless Permanent Magnet Machines-1harshalvikas50% (2)

- Ac DC 206i ManualDocument4 pagesAc DC 206i Manualstef1463No ratings yet

- Compaq Deskpro 386s Manual PDFDocument276 pagesCompaq Deskpro 386s Manual PDFEvan DarrowNo ratings yet

- 8px3 PresentationDocument14 pages8px3 PresentationpitarrilloNo ratings yet

- Straight Twist Joint1Document22 pagesStraight Twist Joint1al_198967% (3)

- Service Manual RAINBOW 180E EnglishDocument54 pagesService Manual RAINBOW 180E EnglishJaroslaw BrzozowskiNo ratings yet

- Philips Mod. 29PT5631-85R Chasis L01.1UDocument645 pagesPhilips Mod. 29PT5631-85R Chasis L01.1USAMSOON27No ratings yet

- Technical Specification: Group Standards Department ©Document3 pagesTechnical Specification: Group Standards Department ©Mohamed MusaNo ratings yet

- Working Instructions DOC26 ACN634 R9i PP300 RevcDocument38 pagesWorking Instructions DOC26 ACN634 R9i PP300 RevcJezer LugoNo ratings yet

- 45IECMC D-Line F Line ContactorsDocument33 pages45IECMC D-Line F Line ContactorsCLAVOTNo ratings yet

- Ekor - RPS: Multifunctional Protection Unit Volume 1 of 3Document144 pagesEkor - RPS: Multifunctional Protection Unit Volume 1 of 3Mayrita M Rojas100% (1)

- 0613CT0001 PDFDocument180 pages0613CT0001 PDFhimanshu yadavNo ratings yet

- ANSI MV Recloser Quick Reference Guide 7SR224 Three-Phase enDocument4 pagesANSI MV Recloser Quick Reference Guide 7SR224 Three-Phase enlast730No ratings yet

- TAS-311DG, - 321DG, - 331DG Configuration Manual 4189300012 UKDocument34 pagesTAS-311DG, - 321DG, - 331DG Configuration Manual 4189300012 UKNikolayNo ratings yet

- Automatic Transfer Switch - ContactorDocument17 pagesAutomatic Transfer Switch - ContactorAdam SatrioNo ratings yet

- 2 N 6504Document8 pages2 N 6504lgrome73No ratings yet

- DC Machines: Parts of DC MachineDocument51 pagesDC Machines: Parts of DC MachineKUMARNo ratings yet

- Sony Ta Dx80Document14 pagesSony Ta Dx80heladiomontesdeoca100% (3)

- Mastech MS2203 ManualDocument35 pagesMastech MS2203 ManualaleksandarlaskovNo ratings yet

- Overvoltage Protection of The S7-200 Analog Input ModuleDocument10 pagesOvervoltage Protection of The S7-200 Analog Input Modulewww.otomasyonegitimi.comNo ratings yet

- E51325 Rev 2 - 546dp Sensor PDFDocument2 pagesE51325 Rev 2 - 546dp Sensor PDFMajidNo ratings yet

- Driver DFC MotorDocument24 pagesDriver DFC Motorda.dientuhnNo ratings yet

- Hoh Singh VP 70 Manual English 1Document32 pagesHoh Singh VP 70 Manual English 1David Zoracá HNo ratings yet

- Manual Solve ElecDocument28 pagesManual Solve ElecHenry HcNo ratings yet

- Input Power ParametersDocument35 pagesInput Power ParameterskarthikNo ratings yet

- Powerlink Connect 9.5 Quick Start GuideDocument23 pagesPowerlink Connect 9.5 Quick Start GuideĐình ThếNo ratings yet

- DIY Boost Converter How To Step Up DC Voltage Effi PDFDocument5 pagesDIY Boost Converter How To Step Up DC Voltage Effi PDFHans Sebastian Navarrete LopezNo ratings yet

- Simulation & Modeling of BLDC MotorDocument20 pagesSimulation & Modeling of BLDC Motorsam clastineNo ratings yet

- MBES - Lab 7-8 PDFDocument23 pagesMBES - Lab 7-8 PDFDurraiz ShuaibNo ratings yet

- Chapter - E15: Site Testing and CommissioningDocument2 pagesChapter - E15: Site Testing and CommissioningvenkateshbitraNo ratings yet

- Service Manual SMT-190DNDocument79 pagesService Manual SMT-190DNEzequiel Milá de la RocaNo ratings yet

- RMCS 3002Document10 pagesRMCS 3002Dhiraj MistryNo ratings yet

- 1 - IGARD GCHK-100 Mining Relay Instruction ManualDocument21 pages1 - IGARD GCHK-100 Mining Relay Instruction ManualJhann Oliva GalvezNo ratings yet

- Power EngineeringDocument1 pagePower EngineeringWak TacuNo ratings yet

- Eurotherm 601 VFD ManualDocument30 pagesEurotherm 601 VFD ManualOvalle JorgeNo ratings yet

- Constructional Features of DC MotorDocument34 pagesConstructional Features of DC MotorBala SankarNo ratings yet

- ME440 Handheld Data Logger: Rogowski Technology (Shanghai) Co., LTDDocument26 pagesME440 Handheld Data Logger: Rogowski Technology (Shanghai) Co., LTDLuis GonzalezNo ratings yet

- Indice de Relay'sDocument16 pagesIndice de Relay'shectorhscNo ratings yet

- VTS5000 User ManualDocument201 pagesVTS5000 User ManualraviwppNo ratings yet

- GettingStarted CPU31xC enDocument8 pagesGettingStarted CPU31xC enLucia OrtegaNo ratings yet

- Control industrial outputs with VIPA digital modulesDocument24 pagesControl industrial outputs with VIPA digital modulesGlauco SantiagoNo ratings yet

- DVP Serial Communication Module ManualDocument66 pagesDVP Serial Communication Module ManualNguyễn Quốc HọcNo ratings yet

- Datasheet InfineonDocument12 pagesDatasheet InfineonjuliolocNo ratings yet

- SM30 - Media Key - Rev SaDocument1 pageSM30 - Media Key - Rev SajjoaquimmartinsNo ratings yet

- Fuseless Selection Type 2, Iq 50ka, IS/IEC:60947-4-1: IE1 IE2Document4 pagesFuseless Selection Type 2, Iq 50ka, IS/IEC:60947-4-1: IE1 IE2Amey KhawaleNo ratings yet

- Receptaculo Con Tapa y Caja Mod. ARE-6424Document7 pagesReceptaculo Con Tapa y Caja Mod. ARE-6424Rolando GilNo ratings yet

- Pogee: Power Technology PakistanDocument6 pagesPogee: Power Technology PakistanmsaadullahNo ratings yet

- S 1551 PDFDocument5 pagesS 1551 PDFDeco DluxeNo ratings yet

- The Electric Car RevolutionDocument4 pagesThe Electric Car Revolutionshangeetha rajmohanNo ratings yet

- Design of A Transformer-Less Grid-Tie Inverter Using Dual-Stage Buck & Boost ConvertersDocument9 pagesDesign of A Transformer-Less Grid-Tie Inverter Using Dual-Stage Buck & Boost Convertersankur rathiNo ratings yet

- VOTANO 100 Brochure ENU PDFDocument12 pagesVOTANO 100 Brochure ENU PDFnadalllabeedNo ratings yet

- GTU Power Electronics 1 exam questionsDocument1 pageGTU Power Electronics 1 exam questionsTejash NaikNo ratings yet

- Strato2000 Service Manual - Rev3 PDFDocument325 pagesStrato2000 Service Manual - Rev3 PDFMaximus Decimus MeridiusNo ratings yet

- Current time relay monitoringDocument10 pagesCurrent time relay monitoringvicNo ratings yet

- Commissioning Check ListDocument15 pagesCommissioning Check ListAnuradheNo ratings yet

- Netsure™ 7100 Series - 48 VDC Power System: Installation ManualDocument220 pagesNetsure™ 7100 Series - 48 VDC Power System: Installation ManualDebabrata Saha100% (1)

- BE3251 Basic Electrical and Electronics Engineering Question Bank 1Document1 pageBE3251 Basic Electrical and Electronics Engineering Question Bank 1Sangeetha RajaNo ratings yet

- DatasheetDocument2 pagesDatasheetEdgarNo ratings yet

- 2005 State Corporation Commission Report Underground LinesDocument116 pages2005 State Corporation Commission Report Underground LinesScott A. SurovellNo ratings yet

- Efm 02 PDFDocument2 pagesEfm 02 PDFveemandalNo ratings yet

- Chapter-1: 1.1.1 The Principle of WindmillDocument22 pagesChapter-1: 1.1.1 The Principle of WindmillVijay BavikattiNo ratings yet

- Electricity Sec-2, 16.12.2022.Document11 pagesElectricity Sec-2, 16.12.2022.christalNo ratings yet

- 2500kVA-Generator Data 2Document9 pages2500kVA-Generator Data 2İrfan Demiray100% (1)

- Schneider Select Product Catalog TechnicalDocument64 pagesSchneider Select Product Catalog Technicaldom007thyNo ratings yet

- ADL200G Series Frequency Converter Operation ManualDocument180 pagesADL200G Series Frequency Converter Operation ManualAbenetherNo ratings yet

- Racid inDocument8 pagesRacid inshyam_krishnan_16No ratings yet

- Peristaltic Pumps: Spectra Field-Pro Athena AlexisDocument4 pagesPeristaltic Pumps: Spectra Field-Pro Athena Alexisحساب 1No ratings yet

- Klockner Moeller HPL0211-2004 - 11 - IZM - GBDocument79 pagesKlockner Moeller HPL0211-2004 - 11 - IZM - GBMario Penelo RivaNo ratings yet

- CR48-3G B Datasheet PDFDocument4 pagesCR48-3G B Datasheet PDFHermogenescarrilloNo ratings yet

- Ecotecnia 48 750 Variable-Speed Wind TurbineDocument4 pagesEcotecnia 48 750 Variable-Speed Wind TurbineMarcWorldNo ratings yet

- Wap7 Testing DetailedDocument31 pagesWap7 Testing DetailedKrishna Mohan Chauhan100% (1)

- Chapter 3 DC Machines (Part2)Document40 pagesChapter 3 DC Machines (Part2)Simon LumNo ratings yet

- Hydropower in NepalDocument16 pagesHydropower in NepalSandeep Tuladhar100% (1)

- Special Purpose MotorsDocument16 pagesSpecial Purpose MotorsHari ReddyNo ratings yet

- ABB Load Interrupter Switchgear Customer PresentationR2Document14 pagesABB Load Interrupter Switchgear Customer PresentationR2Mahyar MashayekhiNo ratings yet