Professional Documents

Culture Documents

DW 9000 Pedal Manual

Uploaded by

pyrealOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

DW 9000 Pedal Manual

Uploaded by

pyrealCopyright:

Available Formats

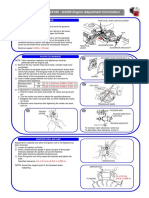

DW 9000 SERIES BASS DRUM PEDALS Remove the pedal, accessories and all packing materials from the

he pedal, accessories and all packing materials from the box and/or case, then follow these instructions to set-up and adjust your pedal to fit the way you play.

Section 1: Drive System Adjustments 2.4: Weight (optional)

Note: For a more relaxed, “floating” pedal feel, replace the standard Double The adjustable beater weight can be positioned on the beater shaft to increase the power

Two-Way Beater

Chain Drive with the optional Nylon Strap Drive (included). of the stroke. Experiment to find the optimum feel and secure the weight using the

1. Remove the chain assembly by loosening the Footboard Angle standard drum key set screw.

Adjustment Screw on the top of Rotor (using the drumkey end of the Beater Shaft

Section 3: Slotted Stroke Adjustment

9000 3-Way key) and the connecting screw and nut at the front end of Floating Rotor

(Double Chain Drive) Beater Memory Lock

To modify the distance the beater travels during the course of each stroke:

the footboard (using a phillips-head screw driver and a wrench). 1. Hold the beater ball with one hand and align the hex head of the stroke adjustment

2. Attach the nylon strap to the footboard by aligning the end of the strap Footboard Angle

screw with the access hole in the right upright post.

Adjustment Screw Beater Position Screw

that has a single hole with the screw hole in the footboard and then 2. Using the other hand, place the long hex of the 3-way drum key through the hole in

replacing and tightening the connecting screw and nut. Floating Drive Shaft the upright post and into the beater adjusting screw.

3. Connect the three-hole end of the strap to the captive nut in the Delta Plus 3. Loosen the screw and move the beater ball to the desired position while keeping the

adjustment channel on the Rotor using the drumkey screw (provided). Infinite Torque Rocker/Stroke

Adjustment Screw Adjustment key in the screw, then retighten, remove key and release.

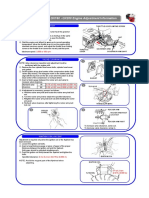

1.1: Torque Section 4: Spring Tension Adjustment

Your pedal is factory set to the most popular settings, including the standard eccentric Upright Post Spring

DW Drum Pedal Springs feature an internal noise reduction damper as well as a tension

(Accelerator) torque position. However, the 9000 Drive can be adjusted to a variety of locking mechanism. To increase or decrease the spring tension:

Hoop Clamp

torque positions. Choosing Height Adjustment 1. Loosen the round knurled nut at the base of the spring assembly.

an eccentric setting creates an 2. Push down on the spring to release the self-locking hex nut.

Spring Tension

in-direct relationship between Adjustment 3. Tighten or loosen the lock nut to the create the desired tension, then release the hex

the beater and footboard— Footboard Knurled Nut nut and retighten knurled nut to lock-in the adjustment.

increasing the velocity of Hex Nut

the pedal by shortening the Stackable Heel Section 5: Hoop Clamp Adjustments

Spur

length of the stroke— and is The DW Hoop Clamp is designed to fit a wide variety of manufacturer’s bass drum

recommended for situations Hoop Clamp Adjustment hoops. To set the space of the hoop clamp for your bass drum:

T-Screw 1. Use the allen wrench (provided) to loosen the set screw on the knurled nut.

that require increased speed

and sensitivity. A more Torque position adjustments from eccentric (far left) to concentric (far right). Pedal Plate 2. Rotate the knurled nut to narrow or widen the gap and re-tighten the set screw.

concentric (Turbo) setting maintains a direct relationship between the sprocket and Delta Hinge 3. Position the pedal on the center of the hoop and tighten the T-screw securely.

the footboard to provide a solid, powerful, consistent feel and is suggested for general- 9000 Use the provided rubber hoop protector to avoid damage to your bass drum hoop.

purpose playing situations. To adjust the torque to achieve your desired feel: Section 6: Toe Stop, Non-Skid Spurs and Velcro™

1. Locate the hex screw that holds the sliding bar on the underside of the rotor. To install the optional toe stop:

2. Using the long hex end of the 3-Way key, loosen the hex screw and slide the bar Double Pedal Linkage 1. Remove the screw and nut at the front end of the footboard using a phillips-head

forward or backward to change the shape of the cam. screw driver and a wrench.

Auxiliary Pedal Primary Pedal

3. Retighten the hex screw once the desired position is achieved. 2. Align the hole in the toe stop with the hole in the footboard and replace and tighten

1.2: Footboard Angle the connecting screw and nut.

To change the footboard height and angle, loosen the adjusting key screw on the top All DW Bass Drum Pedals include built-in adjustable spurs and non-skid Velcro™ on

of the Rotor and slide the chain or strap forward or backward to achieve the desired 9002 the bottom of the pedal plates to prevent bass drum crawl. The Velcro™ automatically

footboard height. Then tighten the adjusting key screw. This adjustment can be used to grips on most types of carpeting. To adjust the spurs, simply turn the knurled portion

compensate for changes made by adjusting the torque or to independently modify the clockwise for more skid control or counter-clockwise for less. Be careful when you use

footboard angle to a more comfortable position. Double Pedal Linkage Adjustment the spurs as they may damage the floor.

Section 2: Beater Ball Adjustments Use the provided 3-Way key or any standard drum key to secure the linkage to the primary pedal

by tightening the key screw. Rotate the beater, casting and hex shaft on the auxiliary pedal to the Note: Some of the screws on the pedal have been treated with a chemical lock to prevent

2.1: Height correct playing position, attach the linkage and tighten the auxiliary side key screw. Loosen the unwanted loosening during playing. In order to loosen the chemical lock holding these screws,

The length of the beater rod can be adjusted to achieve the desired feel and impact two sets of key screws on the middle section of the linkage and adjust the length and angle of you may first need to heat them with a hair dryer for 2-3 minutes.

position. Loosen the beater position screw and raise or lower the beater rod to the the linkage to the desired position, then retighten the set screws. Set the linkage memory lock to

desired position and then tighten the screw. Generally, the beater should hit the center of maintain the desired distance every time you set-up.

the drum or an area 1-2 inches above the center.

2.2: Memory Lock Customizing Your Pedal with the DW Bass Drum Pedal Stacking Heel Kit (part #1236 sold separately)

1. Place the beater memory lock loosely on the beater shaft and place the beater shaft

in a normal playing position in the beater hub. Elevator Heel Platform (U.S. Patent No. 6359205) below or above the original section and re-attach the stacked heel sections using the longer screws (provided). The

DW’s advanced 9-Position “Elevator” Heel Plates provide a following chart indicates which screws (supplied) should be used in conjunction with the Elevator heel sections to

2. Slide the memory lock down the shaft so that it fits into the notches on the beater

hub.

unique method for drummers to achieve a more comfortable pedal 1 2 3 modify the height of your heel.

playing position without sacrificing speed, power or accuracy. By using

3. Adjust the beater to the desired playing position and tighten the drumkey screw different combinations of the heel sections, the height of the heel can heel positionheel

position sections top screws bottom screws

on the beater hub as well as the set screw on the memory lock with the small allen be adjusted independently of the angle of the footboard. The “Eleva- #1 A 3/4” -

wrench (provided). The beater ball should be positioned at a right angle to the memory tor” positions range from normal (#1) and slightly elevated (#2-3) to 4 5 6 #2 A/B 3/4” -

lock so that the beater can be reversed from the soft felt to the hard plastic side by

raised (#4-7) and extreme (#8-9). Position #8, for example, is recom- A #3 B/A 7/16” 7/16”

mended for achieving a smoother, more effortless heel-toe sliding #4 A/C - 1 1/4”

slightly raising the beater and rotating it 180 degrees. technique, while positions #2 and #3 offer a subtle but effective way to B #5 A/C 3/4” 7/16”

2.3: Playing Surface increase control. 7 8 9 #6 A/C/B 3/4” 3/4”

To install the Elevator heel sections, first turn the pedal over and C #7 B/A/C 7/16” 1 1/4”

The 101 Two-Way Beater (standard) has both a curved, medium felt side for a rounder, remove the three screws holding the original heel (A) to the pedal #8 C/B/A - 1 1/2”

warmer attack and a flat, hard plastic side for a sharper, brighter attack, much like wood plate. In order to loosen chemical lock holding the three screws, you #9 C/B/A 1 1/4” 7/16”

but lighter in weight. may first need to heat them with a hair dryer for 2-3 minutes. Place additional Elevator heel sections (B, C) either

DW 9000 SERIES BASS DRUM PEDAL ACCESSORIES 9002 Double Bass Drum Pedal

SM101 Two-Way Bass Drum Beater 9000 Single Bass Drum Pedal

SM102 Large Felt Bass Drum Beater

SM103 Medium Felt Bass Drum Beater

SM104 Solid Maple Wood Bass Drum Beater

SM105 NEW! HardCore Bass Drum Beater

SM808 5-Key pack (includes standard, large, keychain, drill bit and speed keys)

SM809 9000 Pedal 3-Way Key PEDALS

SM1207 Delta Hinge

SM1236

SMSVKIT

Stacking Heel Kit (includes stacker heels and screws)

Drummer’s Survival Kit (includes plastic case) BASS DRUM T hanks for purchasing this DW product. It has been designed and

manufactured to provide a lifetime of trouble-free service. Please

take a moment to familiarize yourself with the exclusive features

DW 9000 SERIES and operating suggestions contained in this manual in order to

ensure its optimum performance. Should you have any further ques-

tions, feel free to contact your local authorized DW dealer.

M A N U A L O W N E R ’ S — Don Lombardi

president, Drum Workshop, Inc.

103 104 101 102 105 SMSVKIT

D W P E DA LS

809 1207 1236 5-YEAR LIMITED WARRANTY

For a period of five years from the date of purchase, Drum Workshop, Inc.

guarantees the original owner, when presented with proof of purchase, that

all 9000, 5000 and 7000 Series Bass Drum Pedal cast parts are free of ma-

terial and manufacturing defects. This warranty is limited to cast parts only;

such as the base casting, footboard, beater hub, sprocket, heel and cam cast-

ing. This warranty does not include moving parts; such as the spring assem-

808 bly, beater ball, radius rod, hex shaft, ball bearings, etc. If under normal play-

The Drummer’s Choice® ing conditions parts covered in this limited five year warranty fail, they will

be replaced at no charge. Return the pedal to your authorized DW dealer

or, if there is not a dealer in your area, contact DW directly. DO NOT send

DRUM WORKSHOP, INC pedal to DW without first receiving a Return Authorization Number. Ship-

3450 Lunar Court • Oxnard, CA 93030 USA ping charges to DW will be paid by the consumer. DW’s maximum liability

www.dwdrums.com pursuant to this warranty is limited to the monetary value of the product

that is the subject of the warranty claim. This is a summary only; please see

specifications subject to change without notice

the actual limited warranty for additional terms and conditions.

PR-OM-9000 © DW 2004

Contact your authorized DW dealer

for additional accessories and replacement parts.

You might also like

- Fender Stratocaster Setup PDFDocument3 pagesFender Stratocaster Setup PDFzaracusca100% (2)

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- CIRC 314-AN 178 INP EN EDENPROD 195309 v1Document34 pagesCIRC 314-AN 178 INP EN EDENPROD 195309 v1xloriki_100% (1)

- DW 9500 ManualDocument2 pagesDW 9500 ManualCesarNo ratings yet

- DW 9000 Pedal ManualDocument2 pagesDW 9000 Pedal ManualBartos GáborNo ratings yet

- Normativa Técnica Salvadoreña de AccesibilidadDocument2 pagesNormativa Técnica Salvadoreña de AccesibilidadmattkidoNo ratings yet

- EG-112 ManualDocument14 pagesEG-112 ManualpetropaoNo ratings yet

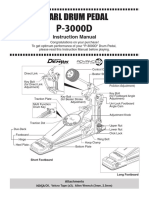

- P-3000D Pearl Eliminator Demon Drive (Single Pedal) Instruction ManualDocument5 pagesP-3000D Pearl Eliminator Demon Drive (Single Pedal) Instruction ManualDizzyNo ratings yet

- Assembling A Can SealerDocument12 pagesAssembling A Can SealerPlantain frankyNo ratings yet

- Service Information: Trek Madone 7-Series Brake AssemblyDocument4 pagesService Information: Trek Madone 7-Series Brake AssemblyLucasNo ratings yet

- Adjustment Instructions: From WM No 5044 OnwardsDocument6 pagesAdjustment Instructions: From WM No 5044 OnwardsMohammedasifNo ratings yet

- Brake Lever Setup Important Information Setup Procedure: DATA SHEET: Ds-Brleval ISSUE S1003Document2 pagesBrake Lever Setup Important Information Setup Procedure: DATA SHEET: Ds-Brleval ISSUE S1003mamatnamakuNo ratings yet

- Erlewine Neck Jig InstructionsDocument9 pagesErlewine Neck Jig InstructionsPaulNo ratings yet

- Race Sag (With Rider) : Suspension: Setting The SagDocument2 pagesRace Sag (With Rider) : Suspension: Setting The SagfaizNo ratings yet

- ServiceManual 505-6 enDocument12 pagesServiceManual 505-6 enRene CrefcoeurNo ratings yet

- Ma 4211000 WMDocument5 pagesMa 4211000 WMCarlos ReyesNo ratings yet

- To Decrease Arc:: Gear Driven SprinklersDocument2 pagesTo Decrease Arc:: Gear Driven SprinklersBernianuNicoletaNo ratings yet

- Quick Start Guide: English Français Deutsch EspañolDocument12 pagesQuick Start Guide: English Français Deutsch EspañolIshtiaq Anmol Engr IshtiaqNo ratings yet

- Safety Precautions: Assembling The CraneDocument1 pageSafety Precautions: Assembling The CraneNotnow CalmNo ratings yet

- TRANZX INSTALL MANUAL 2x INTERNAL v0Document5 pagesTRANZX INSTALL MANUAL 2x INTERNAL v0dan nadNo ratings yet

- Hop On Stroller Platform - Fitting GuideDocument5 pagesHop On Stroller Platform - Fitting GuideFasanovie NmNo ratings yet

- Electric Chainsaw: Instruction ManualDocument10 pagesElectric Chainsaw: Instruction Manualshabab_14No ratings yet

- sc510 PDFDocument45 pagessc510 PDFrosmel ricraNo ratings yet

- Vibrating Drum TrainingxDocument31 pagesVibrating Drum TrainingxAung Myo OoNo ratings yet

- Manual Orion EQ2Document8 pagesManual Orion EQ2cicerosaNo ratings yet

- Bowen Full Circle Releasing Spears HandbookDocument16 pagesBowen Full Circle Releasing Spears HandbookAboozar FathinejadNo ratings yet

- Axial Fan Series O&M ManualDocument11 pagesAxial Fan Series O&M ManualSebastian PrzybylowiczNo ratings yet

- Engine: Cam TimingDocument86 pagesEngine: Cam TimingXimena Justiniano LeytonNo ratings yet

- SteeringDocument52 pagesSteeringRamón Eduardo ColmenaresNo ratings yet

- Parrot Bike Spinner assembly instructionsDocument1 pageParrot Bike Spinner assembly instructionsMasterbin2010No ratings yet

- Billet Throttle InstructionsDocument1 pageBillet Throttle InstructionsMark SawickiNo ratings yet

- 钻杆维修手册 enDocument15 pages钻杆维修手册 enAlex MazaNo ratings yet

- Manual - Rotary 3 Speed HubsDocument2 pagesManual - Rotary 3 Speed Hubsbostin011No ratings yet

- Pearl Drum Pedal: Instruction ManualDocument5 pagesPearl Drum Pedal: Instruction ManualNerminBrkovićNo ratings yet

- GX120-160-200 Ajuste de MotorDocument1 pageGX120-160-200 Ajuste de Motormelgar segundoNo ratings yet

- HTTPS::WWW - Lsengineers.co - Uk:media:advice centre:GX160:GX160 Adjustment InformationDocument1 pageHTTPS::WWW - Lsengineers.co - Uk:media:advice centre:GX160:GX160 Adjustment InformationSady KanettiNo ratings yet

- V-Belt Drives 0905Document3 pagesV-Belt Drives 0905FV AllanNo ratings yet

- Cleaver CI-03AT - 4+ż (Auto Rotation Blade) User Manual 0601 (Eng) PDFDocument2 pagesCleaver CI-03AT - 4+ż (Auto Rotation Blade) User Manual 0601 (Eng) PDFAli Yudi0% (1)

- SERIES M2 Final VersionDocument24 pagesSERIES M2 Final VersiondarkdavincizNo ratings yet

- ShaftpullerinstructionsDocument2 pagesShaftpullerinstructionsjitmarineNo ratings yet

- Adjust tape head alignment for optimal soundDocument8 pagesAdjust tape head alignment for optimal soundMadeline CurryNo ratings yet

- Dealer's Manual: (English)Document10 pagesDealer's Manual: (English)Rodney AtibulaNo ratings yet

- Rotational Inertia Accessory Kit Instruction Sheet ME 3420Document2 pagesRotational Inertia Accessory Kit Instruction Sheet ME 3420Muzaher Ali KhanNo ratings yet

- Replacement Plumb Bobs Manual ME 9868ADocument3 pagesReplacement Plumb Bobs Manual ME 9868A이지민No ratings yet

- YQ115 Series Hydraulic Power Tong ManualDocument90 pagesYQ115 Series Hydraulic Power Tong Manualramudo Z100% (1)

- BASS SETUP - Yamaha Bass - ManualDocument7 pagesBASS SETUP - Yamaha Bass - ManualVirgil Popescu100% (1)

- Coulombs LawDocument8 pagesCoulombs LawDaniel Esteban Pinto ChaparroNo ratings yet

- 741_1R_eDocument4 pages741_1R_eMohammedasifNo ratings yet

- Ridgid Precision Flaring Tools ManualDocument1 pageRidgid Precision Flaring Tools ManualmaftmutoNo ratings yet

- Manual Tuareg OnikaDocument6 pagesManual Tuareg OnikaCaio RezendeNo ratings yet

- Ibanez ZR TremoloDocument2 pagesIbanez ZR TremolootringalNo ratings yet

- TK19 2020 Domane Service Manual en-GBDocument16 pagesTK19 2020 Domane Service Manual en-GBOswaldo VillanuevaNo ratings yet

- thrustor-brakes-CRANE CONTROLDocument7 pagesthrustor-brakes-CRANE CONTROLanjmit sharmaNo ratings yet

- Celestron Pro HD Wedge - Model #93664Document20 pagesCelestron Pro HD Wedge - Model #93664Mario Gallardo CaballeroNo ratings yet

- Speedfire Manual enDocument8 pagesSpeedfire Manual enJuan Carlos Alonso RodriguezNo ratings yet

- Typical TW3-P335 Parts and Instruction ManualDocument41 pagesTypical TW3-P335 Parts and Instruction ManualJanos KornfeldNo ratings yet

- Instructions TN3170 Reset LeverDocument1 pageInstructions TN3170 Reset Leverjuanjuanjo1No ratings yet

- P 930 Manual Manual eDocument3 pagesP 930 Manual Manual eRomain MadarNo ratings yet

- 90 MM 1Document6 pages90 MM 1Pedro PgNo ratings yet

- Professional Series: PGP Installation: Arc Adjustments: Nozzle InstallationDocument2 pagesProfessional Series: PGP Installation: Arc Adjustments: Nozzle InstallationDaus AlexandruNo ratings yet

- Flip Shopstop ManualDocument2 pagesFlip Shopstop Manual123anthonyNo ratings yet

- The Inner Workings of a Watch - A Simple Guide for Enthusiasts of Clockwork MechanismsFrom EverandThe Inner Workings of a Watch - A Simple Guide for Enthusiasts of Clockwork MechanismsNo ratings yet

- 9 Patch Panel PG 2009-V8 EDocument9 pages9 Patch Panel PG 2009-V8 EpyrealNo ratings yet

- Logic Studio Instruments and EffectsDocument668 pagesLogic Studio Instruments and Effectspyreal100% (2)

- Every Decision On Sec 13 Cases-Past and ActiveDocument13 pagesEvery Decision On Sec 13 Cases-Past and Activepyreal100% (4)

- HA4600 ENG Rev BDocument12 pagesHA4600 ENG Rev Bpyreal100% (2)

- Acer LCD Monitor AL2016Wx User's ManualDocument11 pagesAcer LCD Monitor AL2016Wx User's Manualpyreal100% (4)

- Behringer MDX2200 ENG Rev EDocument30 pagesBehringer MDX2200 ENG Rev Epyreal100% (6)

- Frontier Design TranzPort - Logic GuideDocument4 pagesFrontier Design TranzPort - Logic Guidepyreal100% (4)

- Ensemble Users GuideDocument32 pagesEnsemble Users Guidepyreal100% (2)

- Frontier Design TranzPort - Logic LayoutDocument1 pageFrontier Design TranzPort - Logic Layoutpyreal100% (2)

- Presonus Firepod ManualDocument22 pagesPresonus Firepod Manualpyreal100% (5)

- DW 5000D3 Pedal ManualDocument6 pagesDW 5000D3 Pedal ManualsdeeksterNo ratings yet

- AG Memo of LawDocument50 pagesAG Memo of Lawpyreal100% (2)

- Keeley CompressorDocument2 pagesKeeley Compressorpyreal100% (3)

- Trinity United Church of Christ Bulletin Mar 16 2008Document32 pagesTrinity United Church of Christ Bulletin Mar 16 2008pyreal100% (2)

- Trumpet Magazine Excerpt May 2006Document3 pagesTrumpet Magazine Excerpt May 2006pyreal100% (3)

- Trinity United Church of Christ Bulletin Mar 2 2008Document36 pagesTrinity United Church of Christ Bulletin Mar 2 2008pyreal100% (6)

- T1073-5405 Warman-Lemire 2008-03-25 - CHRCDocument343 pagesT1073-5405 Warman-Lemire 2008-03-25 - CHRCpyreal100% (2)

- Trinity United Church of Christ Bulletin Jan 27 2008Document34 pagesTrinity United Church of Christ Bulletin Jan 27 2008pyreal100% (3)

- Trinity United Church of Christ Bulletin Jan 20 2008Document42 pagesTrinity United Church of Christ Bulletin Jan 20 2008pyreal100% (7)

- Trinity United Church of Christ Bulletin Jan 6 2008Document30 pagesTrinity United Church of Christ Bulletin Jan 6 2008pyreal100% (13)

- Trinity United Church of Christ Bulletin Jan 6 2008Document30 pagesTrinity United Church of Christ Bulletin Jan 6 2008pyreal100% (13)

- Trinity United Church of Christ Bulletin Feb 17 2008Document38 pagesTrinity United Church of Christ Bulletin Feb 17 2008pyreal100% (1)

- Trinity United Church of Christ Bulletin Feb 10 2008Document34 pagesTrinity United Church of Christ Bulletin Feb 10 2008pyreal100% (2)

- Trinity United Church of Christ Bulletin Feb 24 2008Document38 pagesTrinity United Church of Christ Bulletin Feb 24 2008pyreal100% (1)

- Trinity United Church of Christ Bulletin 5/22/05Document34 pagesTrinity United Church of Christ Bulletin 5/22/05pyrealNo ratings yet

- Trinity United Church of Christ Bulletin Mar 9 2008Document32 pagesTrinity United Church of Christ Bulletin Mar 9 2008pyreal100% (11)

- Trinity United Church of Christ Bulletin Feb 3 2008Document34 pagesTrinity United Church of Christ Bulletin Feb 3 2008pyrealNo ratings yet

- Trinity United Church of Christ Bulletin 5/29/05Document30 pagesTrinity United Church of Christ Bulletin 5/29/05pyreal100% (1)

- Private Schools Provide Better EducationDocument2 pagesPrivate Schools Provide Better EducationcitraNo ratings yet

- Chap 2 Debussy - LifejacketsDocument7 pagesChap 2 Debussy - LifejacketsMc LiviuNo ratings yet

- Hyperbaric WeldingDocument17 pagesHyperbaric WeldingRam KasturiNo ratings yet

- Letter of MotivationDocument4 pagesLetter of Motivationjawad khalidNo ratings yet

- Monodisperse Droplet Generators As Potential Atomizers For Spray Drying Technology PDFDocument11 pagesMonodisperse Droplet Generators As Potential Atomizers For Spray Drying Technology PDFfishvalNo ratings yet

- Taking Back SundayDocument9 pagesTaking Back SundayBlack CrowNo ratings yet

- Magnetic Pick UpsDocument4 pagesMagnetic Pick UpslunikmirNo ratings yet

- Naukri LalitaSharma (3y 4m)Document2 pagesNaukri LalitaSharma (3y 4m)rashika asraniNo ratings yet

- CANAL (T) Canal Soth FloridaDocument115 pagesCANAL (T) Canal Soth FloridaMIKHA2014No ratings yet

- European GMP Annex 1 - 2008 Edition - 'Pmeasuring'Document3 pagesEuropean GMP Annex 1 - 2008 Edition - 'Pmeasuring'Khairul AnwarNo ratings yet

- Front Wheel Steering System With Movable Hedlights Ijariie5360Document6 pagesFront Wheel Steering System With Movable Hedlights Ijariie5360Ifra KhanNo ratings yet

- Background of The Study Statement of ObjectivesDocument4 pagesBackground of The Study Statement of ObjectivesEudelyn MelchorNo ratings yet

- 中美两国药典药品分析方法和方法验证Document72 pages中美两国药典药品分析方法和方法验证JasonNo ratings yet

- Entrepreneurship Project On Jam, Jelly & PicklesDocument24 pagesEntrepreneurship Project On Jam, Jelly & Picklesashish karshinkarNo ratings yet

- 07 Raction KineticsDocument43 pages07 Raction KineticsestefanoveiraNo ratings yet

- Elevator Traction Machine CatalogDocument24 pagesElevator Traction Machine CatalogRafif100% (1)

- 40 26Document3 pages40 26Maxi452No ratings yet

- Hypophosphatemic Rickets: Etiology, Clinical Features and TreatmentDocument6 pagesHypophosphatemic Rickets: Etiology, Clinical Features and TreatmentDeysi Blanco CohuoNo ratings yet

- Fundermax Exterior Technic 2011gb WebDocument88 pagesFundermax Exterior Technic 2011gb WebarchpavlovicNo ratings yet

- Compare Blocks - ResultsDocument19 pagesCompare Blocks - ResultsBramantika Aji PriambodoNo ratings yet

- Air Wellness QRSDocument2 pagesAir Wellness QRSapi-3743459No ratings yet

- Phenomenological of in Church and TV WorshipDocument18 pagesPhenomenological of in Church and TV WorshipCindy TirtaNo ratings yet

- KAC-8102D/8152D KAC-9102D/9152D: Service ManualDocument18 pagesKAC-8102D/8152D KAC-9102D/9152D: Service ManualGamerAnddsNo ratings yet

- Answer Key p2 p1Document95 pagesAnswer Key p2 p1Nafisa AliNo ratings yet

- Madu Rash Tak AmDocument4 pagesMadu Rash Tak AmAdv. Govind S. TehareNo ratings yet

- Caterpillar Ep15krtDocument37 pagesCaterpillar Ep15krtIvan MajikNo ratings yet

- Artifact and Thingamy by David MitchellDocument8 pagesArtifact and Thingamy by David MitchellPedro PriorNo ratings yet

- Material and Energy Balance: PN Husna Binti ZulkiflyDocument108 pagesMaterial and Energy Balance: PN Husna Binti ZulkiflyFiras 01No ratings yet