Professional Documents

Culture Documents

Schiedel Chimney Systems

Uploaded by

Ali ÖzgençCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Schiedel Chimney Systems

Uploaded by

Ali ÖzgençCopyright:

Available Formats

CI/SfB (59) f5

CERTIFICATE NO. 01/0121

Schiedel Chimney Systems,

Kingscourt Road, Carrickmacross, Co. Monaghan.

Tel: 042 9661256

Fax: 042 9662494

Email: office@schiedel.ie

Website: www.schiedel.ie

Schiedel Chimney Systems

Revetment de cheminee en beton leger

Schornsteinauskleidung

The Irish Agrément Board is designated by Government to issue European Technical Approvals.

Irish Agrément Board Certificates establish proof that the certified products are ‘proper materials’ suitable for

their intended use under Irish site conditions, and in accordance with the Building Regulations 1997 to 2007.

The Irish Agrément Board operates in association with

the National Standards Authority of Ireland (NSAI) as the National Member of UEAtc.

maintain the temperatures of the flue gases and allow

them to pass freely up the chimney. The insulation also

allows the clay flue liner to expand and contract without

damage. The third layer is the lightweight concrete block

made from a mix of expanded clay, sand and cement

which encases the system and provides additional

insulation.

This Certificate certifies compliance with the

requirements of the Building Regulations 1997 to 2007.

USE:

The Schiedel Chimney Systems are designed to offer

fast and efficient erection on site and are suitable for all

types of domestic heat appliances. They can

accommodate both open fire and closed appliances

using fuels up to 50kW. The system is delivered by

specified length to site on a series of pallets and

contains all the materials necessary to construct a

chimney from the base to chimney pot. A chimney

system is installed on site by the main contractor using

the installation guidelines provided by Schiedel Chimney

Systems. The systems are suitable for use in domestic

prefabricated constructions such as timber and steel

frame as well as traditional masonry construction. With

the exception of the Multi System, only one fuel

appliance is to be used for each chimney system unless

otherwise specified in the instruction guides.

It is essential that all Schiedel Chimney Systems are

constructed in accordance with the requirements of this

Certificate and the manufacturer’s instructions.

PRODUCT DESCRIPTION:

DESIGN, MANUFACTURE & MARKETING:

This Certificate relates to Schiedel Chimney Systems, a

The Schiedel Chimney Systems are designed,

prefabricated range of chimney systems for use in

manufactured and marketed by:

domestic accommodation (factory-made insulated

chimney). The chimney systems are available in several

Schiedel Chimney Systems,

options as described in Section 2.1. The concept of the

Kingscourt Road,

Schiedel Chimney Systems involves a 3-layer

Carrickmacross,

construction. The first inner layer consists of a flue liner

Co. Monaghan.

manufactured in accordance with IS EN 1457:1999

Tel: 042 9661256

(2006) Chimneys – Clay/ceramic flue liners –

Fax: 042 9662494

Requirements and test methods surrounded by a

Email: office@schiedel.ie

second layer of flexible insulation slabs or tubes with a

Website: www.schiedel.ie

nominal apparent density of 100kg/m3 designed to

Readers are advised to check that this Certificate has not been withdrawn or superseded by a later issue by contacting the

Irish Agrément Board, NSAI, Glasnevin, Dublin 9 or online at http://www.nsai.ie/modules/certificates/uploads/pdf/IAB010121.pdf

Part One / Certification 1

1.1 ASSESSMENT installed. All installations should refer to the conditions

In the opinion of the Irish Agrément Board (IAB), the set out in section 3.7 of this Certificate.

Schiedel Chimney Systems if used in accordance with

this Certificate can meet the requirements of the Building J2 – Discharge of Products of Combustion

Regulations 1997 to 2007, as indicated in Section 1.2 of The Schiedel Chimney Systems have adequate

this Irish Agrément Certificate. provision for the discharge of the products of combustion

to the outside air, as the flues, flue pipes and chimney of

1.2 BUILDING REGULATIONS 1997 to 2007 the chimney system have been assessed as being of:

REQUIREMENT: • Sufficient size.

• Contain openings only necessary for inspection,

Part D – Materials and Workmanship cleaning and efficient working of the appliance.

D3 – The Schiedel Chimney Systems as certified in this • Are lined with suitable materials.

Certificate, are comprised of proper materials fit for their • Are constructed at roof level so as to discharge in a

intended use (see Part 4 of this Certificate). safe manner.

D1 – The Schiedel Chimney Systems meet the Where chimney stacks are constructed at roof level so

requirements for workmanship. as to assist in the discharge of products of combustion,

the heights of the chimney stack should be in

Part A - Structure accordance with Section 4.3 of this Certificate.

A1 – Loading

The systems have adequate strength and stability and J3 – Protection of Building

can satisfy the Regulation provided they are correctly When used in accordance with Part 4 of this Certificate,

installed and supported and the maximum height the Schiedel Chimney Systems meet the requirements

restrictions are observed as shown in Table 3 (see Parts of this Regulation.

2 and 3 of this Certificate).

Part B – Fire Safety Concrete or brick coping

B3 (1) – Internal Fire Spread (Structure)

Expansion plate

The Schiedel Chimney Systems will retain their stability

for a reasonable period in the event of fire.

Chimney tray required

B3 (2, 3) – Internal Fire Spread (Structure)

The Schiedel Chimney Systems do not breach the party Corbel to support external

wall, and used in accordance with this Certificate will finish (brick or block)

inhibit the spread of fire and smoke within the building.

High grade ceramic liner

Part C – Site Preparation and Resistance to Moisture jointed with high Holes to facilitate

C4 – Resistance to Weather and Ground Moisture temperature sealant reinforcement bars

The Schiedel Chimney Systems are composed of where necessary

durable materials and when built in accordance with this

Certificate using conventional flashing dpc methods, will Standard gap of 40mm

to be kept between

meet the requirements of this Regulation. The chimneys outer surface of

must be protected from contact with the ground by a chimney and structural

traditional damp proof system. timbers

Part E – Sound

E1 – Airborne Sound (Walls)

Party walls and compartment walls incorporating the Special size

concrete blocks

Schiedel Chimney Systems are constructed to meet the

airborne sound requirements of this Regulation (ref. Fig Timber frame wall

3). As the chimney systems do not breach the walls that attached to chimney

they are tied to, the sound insulation values of the walls with flexible timber

frame stainless steel

are not reduced. Fire chamber formed with

ties

concrete lintel and hollow

blocks

Part J – Heat Producing Appliances

J1 – Air Supply

Traditional foundation

The Schiedel Chimney Systems meet this requirement, required

however attention is drawn to the need to locate air

ducts to obviate draughts within the room the chimney is Fig 1: Open Fire Internal Chimney System (Timber)

located. For appliances that require combustion air from

outside the dwelling the Schiedel Air System should be

Certificate No. 01/0121 / Schiedel Chimney Systems 2

Part Two / Technical Specification and Control Data 2

2.1 PRODUCT DESCRIPTION 2. Schiedel Back to Back (Party Wall) Chimney

The Schiedel Chimney Systems are factory-made System

insulated chimneys that are available in several options. This solution facilitates the construction of back to back

Each chimney is delivered to site on pallets containing chimneys on both sides of a party wall. The system is

all the materials required to construct a chimney from available in two options, one for timber and steel frame

base to chimney pot, apart from the fire back which is constructions, and one for traditional masonry

not provided with the system. The Schiedel Chimney construction. The flues from each chimney can be

Systems available are as follows: combined into one chimneystack at roof level. Figure 3

shows the Back to Back Chimney System used in timber

1. Schiedel Open Fire Internal Chimney System frame construction.

This is a single chimney system for use in timber and

steel frame construction along with traditional masonry 3. Schiedel Open Fire External Chimney System

construction. All components to the chimney stack from This system provides for the building of the chimney on

floor to chimney pot are included in the chimney pack. an external wall. The system fundamentally works on the

The standard chimney breast is 1640mm wide but this same principles as the Schiedel Open Fire Internal

can be reduced to 1220mm. The Schiedel Open Fire System. Figure 12 shows how the system is installed.

Internal Chimney System can accommodate both open

fire and room sealed appliances. 4. Schiedel Air System (Closed Appliances)

The Schiedel Air System is suitable for use with all

The system is suitable for all types of fuels such as gas, central heating boilers, pellet burners and stoves and

oil and solid fuel, which includes wood and peat. Figures inserts. The system has the added benefits of providing

1 and 2 show the Schiedel Open Fire Internal Chimney back ventilation, which makes it suitable for use with

System installed in timber frame and masonry condensing boilers. The back ventilation and the

construction respectively. specially made air shaft in the system provides optimum

air conditions within the chimney. Figures 4 & 5 show

these systems installed.

Concrete or brick coping

Concrete picture frame coping

Expansion plate

Chimney tray required Extendable expansion plate

Corbel to support external Double chimney tray required

finish

High grade ceramic liner jointed Galvanised steel

with high temperature sealant support for brickwork

High grade ceramic liner above party wall

jointed with high Holes to facilitate

temperature sealant reinforcement bars Special size corbel to support Timber frame wall

where necessary external finish (block or brick) attached to

chimney with

Standard gap of 40mm flexible timber

to be kept between frame stainless

Timber frame party wall

outer surface of steel ties

chimney and structural

Standard gap of 40mm to

timbers

be kept between outer Special size

Masonry wall surface of chimney and concrete blocks

structural timbers

Special size

concrete blocks

Chimney secured

to masonry wall

every metre Fire chamber formed

(expanded metal) with concrete lintel

Fire chamber formed with and hollow blocks

concrete lintel and hollow

blocks

Traditional foundation required

Traditional foundation

required

Fig 2: Open Fire Internal Chimney System (Masonry) Fig 3: Back to Back Chimney System

Certificate No. 01/0121 / Schiedel Chimney Systems 3

5. Schiedel Chimney Incorporating Bends 7. Schiedel Multi Chimney System

The Schiedel bend kits allow the chimney flue to be The concept of the multi chimney system is to allow up

offset. There are two types of bend kits: to 10 room sealed appliance to be connected to the one

- The Chimney Breast Bend Kit for use within the chimney. The profiled ceramic liners enable the chimney

chimney breast. The standard offset is 200mm. to work effectively at low temperatures. This is a

- The Standard Bend Kit which can be used concentric air-flue gas system whereby the waste gases

anywhere in the house and allows the chimney to are passed through the ceramic liner and combustion air

be offset as much as necessary. is delivered through an outer concrete casing. Figure 8

shows the concept of this system.

Figure 6 shows a schematic of the bend kit installed.

2.1.1 Typical List

Note: Bend kits are not available with the prefabricated A typical chimney system is composed of the following

chimney system. elements:

• Inner refractory clay flue liners manufactured to IS

6. Schiedel Prefabricated Chimney System EN 1457:1999 (2006)

The Schiedel Prefabricated Chimney is assembled in the • Ceramic chimney pot

factory in predetermined lengths. The first section • Rockwool insulation 91.5kg/m3

consists of a precast fireplace unit. The second and third • Outer lightweight chimney blocks

sections consist of the same lightweight concrete blocks, • Special ventilation outlets in outer chimney blocks

insulation and flue liners as other Schiedel Chimney for central heating installations

Systems, but are joined together to form variable lengths • Concrete corbels and capping

of chimney sections, to a max of 4m. Each assembly is • Fire lintel (lightweight concrete)

reinforced with steel rods and a series of special

• Hollow blocks (lightweight concrete)

connectors and anchors which are tightened together on

• Lead dpc trays

site. The different sections of the system can be hoisted

in by crane and joined together giving fast and efficient • Stainless steel movement plate

construction. Figure 7 gives an indication of how the • Stainless steel wall tie fixings

prefabricated system is installed. • High temperature ceramic sealant

Other ancillary products are listed in Table 2.

Ventilation pot

Concrete or brick coping

Expansion plate

Chimney tray required

Corbel to support

external finish

Ventilation shaft

incorporated within

the chimney block

High grade ceramic liner

jointed with high Holes to facilitate

temperature sealant reinforcement bars

where necessary

Standard gap of

40mm to be kept

between outer

surface of chimney

and structural timbers

Chimney block

400 x 400 x 330mm Chimney secured

to masonry wall

every metre with

expanded metal ties

Support block &

adaptor for

Insert or built-in connection to stove

appliance using air

from outside

Traditional foundation required

Fig 5: Chimney System for Stove appliances

Fig 4: Air, Room Sealed Appliance Chimney System

Certificate No. 01/0121 / Schiedel Chimney Systems 4

Component Size (mm) Weight (kg) Crushing Strength

2

Chimney Block Swift 20 400 x 400 x 330 23 11.3N/mm

2

Chimney Block Swift 25 480 x 480 x 330 45 11.3N/mm

2

Chimney Block Swift 30 550 x 550 x 330 62 11.3N/mm

2

Chimney Block Air 16 460 x 320 x 330 30 13.7N/mm

2

Chimney Block Air 18 500 x 360 x 330 35 13.7N/mm

Ceramic Flue Liner 15 Ø 150 x 400 6.8 120kN

Ceramic Flue Liner 18 Ø 180 x 330 7.2 120kN

Ceramic Flue Liner 20 Ø 200 x 330 8.6 120kN

Ceramic Flue Liner 25 Ø 250 x 330 15.4 120kN

Ceramic Flue Liner 30 Ø 300 x 330 22.6 120kN

2

Hollow Block 400 x 195 x 330 19 7.8N/mm

2

Concrete Block 400 x 200 x 100 17 7N/mm

830 x 200 (Back) 55

Lintel (Ext) 28.4kN

830 x 350 (Front) 75

Lintel (Int) 1220 x 200 x 400 60 29.4kN

Coping (Large) 760 x 760 x 70 96 N/A

Coping (Small) 550 x 550 x 70 28 N/A

Coping (Picture Frame) 830 x 780 x 70 101 N/A

Corbel (Large) 675 x 675 x 100 88 30kN

Corbel (Cut) 675 x 535 x 100 62 16kN

Chimney Block Bend 210 x 110 x 400 12 N/A

3

Insulation 480 x 35 x 330 100kg/m N/A

Table 1: Nominal Characteristics of the Schiedel 3 Layer Insulated Chimney System

Component Size (mm) Weight (kg) Specification

Expansion Plate 600 x 600 x 200 2.3 EN 11401

Damp Proof Tray (Ridge) 675 x 675 x 150 65 Code 5 Lead

Damp Proof Tray (Slope) 675 x 675 x 150 73 Code 5 Lead

Ø 200 x 300 12.7 Ceramic

Ø 200 x 375 14.5 Ceramic

Chimney Pots (Red, Black, Buff)

Ø 200 x 450 18.4 Ceramic

Ø 200 x 600 26.3 Ceramic

1.5 GRC Prefabricated Stack 490 x 490 x 1500 97 Fibre Concrete

1.5 GRP Prefabricated Stack 430 x 430 x 1500 22 Fibre Concrete

Refractory Cement 1 Litre Cartridges

Masonry Ties Expanded metal wall tie or L-shaped stainless steel wall bracket

Timber Frame Ties Stainless Steel flexible wall tie

Reinforcement Kit Galvanised bars, grout and plastic stoppers

Stabilising Kit Galvanised bars and angle irons to brace chimney to truss

Aluminium Bracket Especially for Prefabricated Stack

Damper To close off chimney when not in use

Inspection Door For easy access to cleaning

Table 2: Ancillary Items

Schiedel Chimney Stack No reinforcement Reinforcement Guidance from Schiedel

Chimney with corbel ≥1.2m 1.2m to 1.5m 1.5m<

Chimney plain N/A Up to 1.5m 1.5m above

Table 3: Maximum Heights of Chimney Stacks

Certificate No. 01/0121 / Schiedel Chimney Systems 5

GRC or GRF prefabricated

Purpose made aluminium straps chimney stack

Standard chimney blocks may are used to brace each chimney

be inserted to extend offset as section. The straps should be

shown in tables fixed as the chimney is being

erected, one strap per section of

chimney

The chimney must be

Traditional support required secured to the roof members Do not cut the yellow safety

using the truss bracket cord until the flue liners are

positioned centrally over the

rebate. The weight of the flue

liners will then be supported

by the primary safety cable.

Clean the end of the flue pipe

and apply the high temperature

ceramic sealant. Lay on even

bed of mortar around the outside

edges of the block

Tighten the anchor bolts to

level and plumb the stack

Fig 6: Bend Kits

Standard gap of 40mm to be

kept between outer surface

2.1.2 Description of Schiedel Chimney Block and structural timbers

The lightweight precast chimney blocks are available in

various sizes. Table 1 gives a list of the nominal

characteristics of the block, while Table 2 gives a list of Fig 7: Prefabricated Chimney System

the ancillary items with the chimney system.

2.2.4 Fire Lintels

2.2 MANUFACTURE OF SYSTEM ELEMENTS Fire lintels are made from expanded clay particles, size

2.2.1 Clay Flue Liner blended and bound with refractory cement.

The inner clay liner is manufactured from a blend of

suitable refractory clays, using normal heavy clay 2.2.5 Quality Control

working machinery, i.e. grinding, blending, add water, Quality control on manufactured items includes checks

de-airing and extruding, then through a drying process on weight, dimensions, crushing strength and density.

and finally through a kiln and fired to the required Schiedel Chimney Systems has a full in-house quality

temperature. All flue liners are manufactured and tested control system in operation.

to the requirements of IS EN 1457:1999 (2006).

2.3 DELIVERY, STORAGE AND MARKING

2.2.2 Insulation A Schiedel Chimney System is ordered by chimney

Mineral fibre insulation slabs or tubes with a nominal height. Each chimney system (pack), with the exception

3

apparent density of 100kg/m are supplied with each of the prefabricated chimney, is delivered to site on a

system. The insulation slabs or tubes are manufactured series of pallets and contains all the materials necessary

to comply with the Building Regulations 1997 to 2007. to construct a chimney from the base to chimney pot.

The pack for a standard chimney can be fitted on two

2.2.3 Accessories pallets. Pallets should be stored on a firm level base

Chimney corbel and copings are manufactured from until required. The pallets are shrink-wrapped and are

normal density mix. Other accessories, e.g. expansion labelled with a cardboard wrapper, which shows the

plates, inspection doors, are manufactured to Irish manufacturer’s name, flue size, chimney height,

Standards or equivalent European Standard. The steel production batch number and the IAB identification mark

used in these products has been assessed as being incorporating the number of this Certificate, and contains

suitably corrosion resistant for use in chimneys. The instructions on storage and installation.

high temperature sealant used in the joints between

liners is a proprietary product specially manufactured for When pallets are unwrapped, components should be

Schiedel. It is supplied in special disposable cartridges. carefully offloaded. They should be stored off the ground

Certificate No. 01/0121 / Schiedel Chimney Systems 6

and under cover in such a manner that they are 2.4.3 Constructional Hearths

protected from accidental damage and adverse effects A constructional hearth must be provided to all Schiedel

of weather. Chimney Systems. The constructional hearth should be

constructed in accordance with Section 2.18 and 2.19 of

The system has the advantage of being able to deliver a TGD to Part J of the Building Regulations 1997 to 2007.

full chimney to a specific building on pallets. This The installation of the constructional hearth is the

method of delivery allows for easy storage on site and responsibility of the main contractor.

avoids unnecessary breakage of flue liners and pots as

is common with traditional-built chimneys on 2.4.4 GRC Prefabricated Chimney Stack

construction sites. The Schiedel GRC Prefabricated Chimney Stack

consists of a glass fibre reinforced concrete (GRC)

2.4 INSTALLATION PROCEDURE sleeve which is fitted over the chimney system to negate

2.4.1 General the need for plastering.

Assembly of the Schiedel Chimney Systems is carried

out in accordance with the requirements of this 2.4.5 Height of Chimney Stacks

Certificate and the manufacturer’s instructions. Where it is required to clad the portion of an internal

Installation on site is carried out by the main contractor. chimney above the roofline with brickwork, a corbel unit

Installers of the system must be familiar with the system is incorporated in the construction just below the

and at least one operative installing the system must roofline. The opening in the roof must be suitably

have received formal training on the principals of trimmed by timber fixed to the roof member. Figures 9

installation. Schiedel Chimney Systems offer a full and 10 are two examples of finished chimney stacks.

technical back-up service to installation operatives.

Installation of the chimney does not present any undue Please note:

difficulty either in terms of their accommodation within • The height of a chimney stack to a Schiedel

traditional or system built dwellings or their compatibility Chimney System should be in accordance with

with accepted operational sequences. With the Table 3.

exception of the prefabricated chimney system, the • Where a chimney stack is built off a corbel, the

weights of the chimney components are such that stack should not exceed 1.2m above the roof line

mechanical handling equipment is not normally required unless it is reinforced (see Table 3).

(see Table 1). The Schiedel Chimney System affords • For a Schiedel Chimney without a corbel, the

appreciable saving in construction time when compared chimney stack must always be reinforced (see

with conventional masonry construction. Table 3).

• The chimney stacks in the Schiedel Chimney

2.4.2 Foundation Systems meet the requirements in all areas of the

The Schiedel Chimney Systems are constructed from Wind Zone Map of the TGD to Part A of the Building

lightweight concrete blocks and lintels. As these blocks Regulations 1997 to 2007, when installed in

are lighter than normal density blockwork, a accordance with this Certificate and the

conventional concrete foundation is adequate. Refer manufacturer’s guidance.

also to Section 3.3 of this Certificate.

Standard tapered pot (red)

Combustion air Supplied concrete coping

vented through

coping at the

top. Stainless steel expansion

plate to facilitate vertical

expansion and rear

ventilation

Preformed insulation

(mineral wool)

Wall weep required

Chimney tray required

Corbel to support external

finish (block or brick)

System allows for multiple

appliances (max. 10)

Inspection doors for easy cleaning

Condensates can be removed

and discharged as per local

environmental regulations

Fig 9: Chimney Stack

Fig 8: Multi System

Certificate No. 01/0121 / Schiedel Chimney Systems 7

dry-lining are fixed to the chimney breast using dabs of

Standard tapered pot (red) drywall adhesive at not greater than 600mm centres. For

the chimney breast design required, there is also the

Supplied concrete coping

option of studding out to the sides and slabbing as can

Stainless steel expansion be done for a traditional chimney. A 50mm wide dry wall

plate to facilitate vertical adhesive ribbon must be applied along all edges of the

expansion and rear dry-lining, e.g. around openings. Fire stopping at the

ventilation

junction of ceiling and chimney is achieved by using a

Preformed insulation continuous fillet of dry wall adhesive. Where the chimney

(mineral wool)

faces of a Schiedel Chimney System are left exposed in

an uninhabited attic, it is not necessary to plaster the

surfaces, however it is preferable that all exposed

chimney blockwork are rendered.

Chimney tray 2.4.9 Inspection

required

Once a Schiedel Chimney System has been installed,

the following should be inspected:

• All joints in blockwork have been checked

• All fire stops and spacers are properly located and

secured in accordance with this Certificate and the

manufacturer’s installation instructions.

The fitting of terminal and roof flashing above the corbel

should be inspected before scaffolding is removed.

Fig 10: Stack Protruding Through Roof

2.4.6 Installation of Reinforcement

The reinforcement bars must start below the lateral

Upper lead tray

support. Start by inserting the plastic stoppers into the

holes on the underside of the first block with bars. Screw

the bars together and insert equal lengths into two

opposite holes in the chimney block. The liquid grout

should be poured around the bars to ensure stability. Lower lead tray

Table 3 describes where and when reinforcement is

required.

Where the chimney block has a rendered finish, i.e. Timber frame party wall

where no corbel has been used, then reinforcement is

always required. The chimney rendering and flashing is

carried out as normal.

2.4.7 Bends and Chimneys

The Schiedel Chimney System offers two options for

bends in chimneys: Breast Bend Kit and Standard Bend Back apron

Kit, however the latter is more generally used. The

Chimney Breast Bend Kit shown in Figure 12 is an

example of the standard bend kits available. Chimneys

should be vertical where possible but where bends are

unavoidable, the angle of the bend should be no greater

o Stepped cavity trays Front apron

than 45 to the vertical for oil-burning appliances and

o

37.5 to the vertical for solid fuel appliances. There

should be no more than two bends in the length of the

chimney.

Where a Schiedel Swift Chimney System is completely Timber frame party wall

installed it should be allowed to cure for a minimum of

four to five days before the appliance is used.

2.4.8 Plastering of Chimneys

Chimneys exposed externally throughout their length

must be either clad in brickwork or rendered blockwork. Fig 11: Cavity Tray Detail

The internally exposed faces of the Schiedel Chimney

blocks can be plastered on the exposed faces or boxed

in with plasterboard and skim-coated.

The chimney breast to all chimney systems must be dry-

lined or plastered. The plasterboard sheets used in the

Certificate No. 01/0121 / Schiedel Chimney Systems 8

Brickwork on

external chimney

may be reduced

by tumbling in,

either on both

sides or one side

Bend kit

required when

tumbling in on

one side only

Figure 12: Brickwork for External Chimney System

Type of Fuel Type of Appliance Rated Output Schiedel Chimney Remarks

Open fire Coal

Solid 45kW 200mm diameter pipe

Roomheater Smokeless fuel

Coal

Independent boiler 45kW 200mm diameter pipe

Smokeless fuel

Not less than the outlet The flue size will be specified

Closed Appliance 45kW

diameter of the appliance by appliance manufacturer

Closed room heater

20kW for 120mm

Central heating boiler 120mm or 200mm The flue size will be specified

Oil of flue and 45kW

Warm air convector diameter pipe by appliance manufacturer

for 200mm of flue

Water heater

Fire

20kW for 120mm

Central heating boiler 120mm or 200mm The flue size will be specified

Gas of flue and 60kW

Warm air convector diameter pipe by appliance manufacturer

for 200mm of flue

Water heater

(1) These are minimum sizes. The actual size must not be smaller than the outlet diameter of the appliance.

(2) Larger sized chimneys can be used above oil and gas applications, provided they are lined with the appropriate and correctly

sized liner.

Table 4: Schiedel Chimney Sizes Recommended for Various Types of Appliance

Certificate No. 01/0121 / Schiedel Chimney Systems 9

Part Three / Design Data 3

3.1 GENERAL be tied to the structure using the specified stainless steel

Schiedel chimneys, when installed in accordance with wall ties at three unit intervals; the necessary support

this Certificate, will perform in a safe and satisfactory must be provided during and after construction by the

manner when used internally or externally in domestic intermediate floors and by the timber trimming at roof

housing or commercial/industrial buildings. The chimney level.

systems can be used in conjunction with gas, oil or solid

fuel burning appliances, as described in Section 4 of this 3.5 FLOOR DETAIL

Certificate. The term ‘solid fuel’ relates to those fuels Where the chimney system passes through concrete

listed in Appendix A of BS 1846-1:1994 Glossary of floors, a sliding joint must be made using mineral wool or

terms relating to solid fuel burning equipment – similar non-combustible material. Bonding between the

Domestic appliances. chimneys and the floor or structure must be avoided. A

minimum clearance of 40mm must be maintained

3.2 DESIGN REQUIREMENTS between the outer surface of the chimney block and

Schiedel have designed several chimney systems which timber structural members such as joists and rafters.

can be adapted to suit open fire IAB room sealed After the units have been positioned, the gap must be

heating appliances that might be installed during the filled with mineral wool having a minimum density of 25

2

lifetime of the dwelling. The size and formation of fire – 30kg/m .

openings must be in accordance with BS 1251:1987

Specification for open fireplace components and BS 3.6 CAVITY WALLS

8303-1:1994 Installation of domestic heating and When an external chimney is erected the design and

cooking appliances curing solid mineral fuels – installation of the flue connection to the appliance must

Specification for the design of installation. Appliances be in accordance with BS 6461-1:1984. Particular care

must allow access to the chimney for cleaning. must be taken to comply with the weather details for the

connection flue where it passes through the cavity wall.

The design of the chimney must be in accordance with Details of cavity trays are shown in Figures 11 and 12.

normal good practice. For example, the chimney must

be terminated so as to prevent discharge gases from re- 3.7 AIR SUPPLY

entering the building, or entering any other adjacent Heat producing appliances are required to be provided

building. The structure to which the chimney system is with an adequate supply of air for combustion of fuel and

attached must be in accordance with the relevant Codes for efficient operation of the chimney or flue. For this

of Practice. With the exception of the Multi system, reason a Schiedel Chimney System must be located

only one appliance or open fire per chimney is to be where the chimney has adequate air supply (ventilation).

used. The chimney system can be used with solid fuel, oil and

gas burning appliances. For appliances that require

The Schiedel block units comply with the general combustion air from outside the dwelling, the Schiedel

recommendations for materials for flue block chimneys Air System can be installed.

contained in BS 6461-1:1984 Installation of chimneys

and flues for domestic appliances burning solid fuel The following are the ventilation requirements for the

(including wood and peat) – Code of practice for respected fuels.

masonry chimneys and flue pipes.

(i) Air Supply for Solid Fuel Burning Appliances

Completed chimneys should be left to cure for 4 to 5 with output rating not more than 45kW

days before the appliance is used. The ventilation requirements must comply with

Table 2.1, Diagram 3.2 and Diagram 4.3 of Section

3.3 FOUNDATION 2, 3 and 4 respectively of TGD to Part J of the

Where a chimney is built up from foundation level, it Building Regulations 1997 to 2007.

must be supported on a concrete foundation designed in

accordance with normal good practice. This foundation (ii) Air Supply for Individually Fuelled (Non-Fan

must reach a frost-free depth i.e. approximately 1m Assisted) Gas Burning Appliances with Rated

below ground level if the chimney system is installed Input up to 60kW and for Gas Burning Cooking

externally or approximately 400mm below floor level if Appliances

the chimney is internal. The performance requirements for air supply should

comply with Clause 3.4 and 3.5 of TGD to Part J of

3.4 CONNECTION TO STRUCTURE the Building Regulations 1997 to 2007.

The chimney units should not be bonded into the

building structure, but external chimneys must be tied to (iii) Oil Burning Appliances with a Rated Output up

the structure at not more than three block unit intervals to 45kW

and at the point of departure from the roofline, using the The ventilation requirements should comply with

specified stainless steel ties. Consideration must be Clause 4.1 of TGD to Part J of the Building

given to the effects on the adjacent structure of the loads Regulations 1997 to 2007.

imposed by the chimney fixings. Internal chimneys must

Certificate No. 01/0121 / Schiedel Chimney Systems 10

(iv) Air Supply for Room Sealed Appliances

The ventilation requirements must comply with

Table 2.1, Diagram 3.2 and Diagram 4.3 of Section

2, 3 and 4 respectively of TGD to Part J of the

Building Regulations 1997 to 2007.

Certificate No. 01/0121 / Schiedel Chimney Systems 11

Part Four / Technical Investigations 4

4.1 DOMESTIC APPLIANCES 4.4 PROXIMITY OF COMBUSTIBLE MATERIAL

Schiedel Chimney Systems are suitable for use with The requirement of J3 of the Building Regulations 1997

solid fuel (coal, wood logs, chips and pellets), oil and to 2007 can be met by ensuring that hearths, fireplaces,

gas burning appliances. Before installing a chimney chimneys and flue pipes are:

system, the following guidance should be given on the • Of sufficient size (ref Table 4);

respected fuel-burning appliance. • Constructed of suitable materials (ref Section 2 and

3 of this Certificate);

4.1.1 Solid Fuel Burning Appliance • Suitably isolated from any adjacent combustible

Guidance should be either sought from Schiedel material (ref 4.4.1 of this Certificate).

Chimney Systems or a chartered heating engineer

experienced in the use of solid fuel appliances to ensure 4.4.1 Isolation from Combustible Material

that the correct size of flue and ventilation is selected in Arrangements for spacing and packing between the

each case. chimney and any structural timber have been assessed

as being adequate to prevent excessive drying out of the

4.1.2 Oil Burning Appliance timber of the occurrence of any fire hazard. The spacing

Advice on the correct size of chimney flue should be must be maintained throughout the chimney height but

provided by the appliance manufacturer or registered the requirement does not apply to skirting boards or

boiler installer. floorboards: direct contact between these and the face

of the chimney is permissible.

4.1.3 Gas Burning Appliance

Guidance for the installation of gas burning appliances is Fig 1, 2 and 3 illustrate examples of how a standard gap

available from Bord Gáis. of 40mm is kept between outer surface of chimney and

structural timbers.

Sizes for the Schiedel Chimneys suitable for use with

open fires and appliances for domestic use are shown in It is generally unnecessary to box in the chimney, except

Table 4. to maintain the specified 40mm clearance between the

chimney and any loose combustible material, e.g. in an

4.2 STRENGTH AND STABILITY airing cupboard or insulated roof space.

The chimney components are sufficiently strong to

withstand normal site handling and accidental impacts 4.5 DURABILITY

associated with normal conditions of use. Stability of the The materials used in Schiedel Chimney Systems are

externally or internally installed chimney is adequate durable in terms of their resistance both to natural

with the lateral restraint provided by the interlocking weathering and flue conditions. Provided the chimney is

units. In addition further restraint is provided for external correctly used, e.g. the chimney size is matched to the

chimneys by the stainless steel ties used every meter. type and rating of the heating appliance, and the

For internal chimneys expanded metal ties are used for appliance is maintained in good working order and not

additional restraint. Where the chimneystack projects misused, the chimneys will have a minimum life of 30

above the roof it will remain stable under the action of years with an expected life of 60 years.

normal wind forces provided the stack heights do not

exceed the limits given in Table 3. Where the 4.6 INSPECTION, CLEANING AND MAINTENANCE

chimneystack is brick-clad, this cladding must be The Schiedel Chimney Systems are designed to allow

supported on the appropriate corbel supplied by access for inspection, cleaning and maintenance. The

Schiedel Chimney Systems. If brick cladding is required chimney can be swept throughout its length without

from foundation level it can be considered self- difficulty or without causing damage to any part of the

supporting. chimney once proper sweeping equipment is used. On

the Schiedel Open Fire System cleaning if achieved by

When the Schiedel Chimney Systems are correctly passing the brush head from the firebox to the flue

installed in a properly design chimney, they will not through the appliance, therefore no separate access to

collapse or cause danger to a building’s occupants in the the chimney is required. The Schiedel Central Heating

event of an accidental chimney fire caused by soot System comes with an inspection door and preformed

burnout or gaseous explosions of the kind which may inspection pipe to allow for easy cleaning and

occur through malfunctioning of the heating appliance. maintenance.

4.3 HEIGHT OF CHIMNEYS The frequency of chimney sweeping will depend on

The maximum permissible chimney height above the many factors, i.e. type of fuel and quantity used and

roofline must comply with Table 3 of this Certificate. method of operation of appliance. The interval of

inspection and cleaning will be determined by user

In addition to Table 3, the height of the chimneystack experience but under no circumstances should this be

above the roofline for a particular installation must be in less frequent than once a year.

accordance with the Building Regulations 1997 to 2007.

Certificate No. 01/0121 / Schiedel Chimney Systems 12

4.7 TESTS AND ASSESSMENTS WERE CARRIED

OUT TO DETERMINE THE FOLLOWING:

Tests by Ceram Building Technology were examined to

determine:

o

• Effect of thermal shock at 1000 C.

• Adequacy of thermal insulation.

• Effect of sweeping leakage rate before and after

thermal tests.

4.8 OTHER INVESTIGATIONS

(i) An examination was made of existing date to

determine:

- relevance of Ceram Building Technology test

results to Irish usage

- structural stability

- durability

(ii) A computer analysis was carried out to investigate

the thermal behaviour of the chimney.

(iii) Visits were carried out to existing sites to assess

practicability of installation and performance in use.

(iv) Reports of visits to the factory were examined and

an assessment made of the adequacy of quality

control procedures. Details were obtained of the

quality and composition of the materials used.

(v) Visits to sites in progress were carried out to assess

the practicability of installation.

(vi) No failure of the product in use has been reported to

the IAB.

(vii) On site smoke test has been carried out.

Certificate No. 01/0121 / Schiedel Chimney Systems 13

Part Five / Conditions of Certification 5

5.1 National Standards Authority of Ireland ("NSAI")

following consultation with the Irish Agrément Board 5.5 Any recommendations contained in this Certificate

("IAB") has assessed the performance and method of relating to the safe use of the certified product/process

installation of the product/process and the quality of the are preconditions to the validity of the Certificate.

materials used in its manufacture and certifies the However the NSAI does not certify that the manufacture

product/process to be fit for the use for which it is or installation of the certified product or process in

certified provided that it is manufactured, installed, used accordance with the descriptions and specifications set

and maintained in accordance with the descriptions and out in this Certificate will satisfy the requirements of the

specifications set out in this Certificate and in Safety, Health and Welfare at Work Act 2005, or of any

accordance with the manufacturer's instructions and other current or future common law duty of care owed by

usual trade practice. This Certificate shall remain valid the manufacturer or by the Certificate holder.

for five years from date of issue so long as:

5.6 The NSAI is not responsible to any person or body

(a) the specification of the product is unchanged. for loss or damage including personal injury arising as a

direct or indirect result of the use of this product or

(b) the Building Regulations 1997 to 2007 and any process.

other regulation or standard applicable to the

product/process, its use or installation remains 5.7 Where reference is made in this Certificate to any

unchanged. Act of the Oireachtas, Regulation made thereunder,

Statutory Instrument, Code of Practice, National

(c) the product continues to be assessed for the quality Standards, manufacturer's instructions, or similar

of its manufacture and marking by NSAI. publication, it shall be construed as reference to such

publication in the form in which it is in force at the date of

(d) no new information becomes available which in the this Certification.

opinion of the NSAI, would preclude the granting of the

Certificate.

(e) the product or process continues to be

manufactured, installed, used and maintained in

accordance with the description, specifications and

safety recommendations set out in this certificate.

(f) the registration and/or surveillance fees due to IAB

are paid.

5.2 The IAB mark and certification number may only be

used on or in relation to product/processes in respect of

which a valid Certificate exists. If the Certificate

becomes invalid the Certificate holder must not use the

IAB mark and certification number, and must remove

them from the products already marked.

5.3 In granting Certification, the NSAI makes no

representation as to;

(a) the absence or presence of patent rights subsisting

in the product/process; or

(b) the legal right of the Certificate holder to market,

install or maintain the product/process; or

(c) whether individual products have been

manufactured or installed by the Certificate holder in

accordance with the descriptions and specifications set

out in this Certificate.

5.4 This Certificate does not comprise installation

instructions and does not replace the manufacturer's

directions or any professional or trade advice relating to

use and installation which may be appropriate.

Certificate No. 01/0121 / Schiedel Chimney Systems 14

The Irish Agrément Board

This Certificate No. 01/0121 is accordingly granted by the NSAI to Schiedel Chimney Systems on behalf

of The Irish Agrément Board.

Date of Issue: April 2001

Signed

Seán Balfe

Director of the Irish Agrément Board

Readers may check that the status of this Certificate has not changed by contacting the Irish Agrément

Board, NSAI, Glasnevin, Dublin 9, Ireland. Telephone: (01) 807 3800. Fax: (01) 807 3842. www.nsai.ie

Revisions: September 2007

• Inclusion of the Schiedel Prefabricated Chimney and Chimney Stack.

Certificate No. 01/0121 / Schiedel Chimney Systems 15

You might also like

- Anatomy of A Boiler FailureDocument14 pagesAnatomy of A Boiler FailureIlker CetinNo ratings yet

- Double Drum Sawdust StoveDocument9 pagesDouble Drum Sawdust StovejnesslerNo ratings yet

- Typical Physical Properties of Vermiculite ConcreteDocument6 pagesTypical Physical Properties of Vermiculite ConcreteUmeshchandra PatilNo ratings yet

- Monolithic refractory solutions for cement industryDocument16 pagesMonolithic refractory solutions for cement industryhisemNo ratings yet

- Materials in Industrial Furnace ConstructionDocument28 pagesMaterials in Industrial Furnace ConstructionAlexander TabaresNo ratings yet

- AGC YourGlassDocument404 pagesAGC YourGlassRufee AlphansoNo ratings yet

- Resistance Furnaces: Main Parts of A Resistance FurnaceDocument51 pagesResistance Furnaces: Main Parts of A Resistance Furnacehussein hajNo ratings yet

- Physical Properties Classification: The Siam Refractory Industry Co., LTDDocument23 pagesPhysical Properties Classification: The Siam Refractory Industry Co., LTDManekGorisNo ratings yet

- StovesDocument5 pagesStovesElsa LaminNo ratings yet

- BF Cast House Product & DesignDocument50 pagesBF Cast House Product & DesignHara Prasad MurtyNo ratings yet

- Launder Channel RevBDocument5 pagesLaunder Channel RevBAriadnaNo ratings yet

- REFERENCES OF BLAST FURNACE REPAIRDocument6 pagesREFERENCES OF BLAST FURNACE REPAIRNishant BandaruNo ratings yet

- Cvs General Presantation 09Document69 pagesCvs General Presantation 09dertas6641100% (1)

- Flue and Chimney SystemDocument60 pagesFlue and Chimney Systemgalih permanaNo ratings yet

- Insulating Fire Brick ProductsDocument3 pagesInsulating Fire Brick Productsshuyang zhang100% (1)

- 2023 Enerack Solar Mounting System CatalogDocument29 pages2023 Enerack Solar Mounting System CatalogIan CarvalhoNo ratings yet

- Ggbs in Cement Paste and MortarDocument6 pagesGgbs in Cement Paste and MortarsaiNo ratings yet

- Aluminum Furnace-Resco PDFDocument4 pagesAluminum Furnace-Resco PDFmanuel CairesNo ratings yet

- Glass 4 - 5 11 - 2015Document70 pagesGlass 4 - 5 11 - 2015Laxman KumarNo ratings yet

- Grindability of Solid BiocarbonDocument8 pagesGrindability of Solid BiocarbonJJNo ratings yet

- ICON (IPX-3200) IPSTAR Satellite Terminal Release 1.1Document18 pagesICON (IPX-3200) IPSTAR Satellite Terminal Release 1.1030929No ratings yet

- Glass RefractoryDocument52 pagesGlass RefractorySans Sen0% (1)

- Machine Design Vol 12-2Document26 pagesMachine Design Vol 12-2CikamaksaNo ratings yet

- Ankral RNTDocument1 pageAnkral RNTmahreza189No ratings yet

- Manual Vulcan en InglesDocument12 pagesManual Vulcan en InglesingegusNo ratings yet

- Urcast Shac Ev 0 3 CLDocument1 pageUrcast Shac Ev 0 3 CLmahreza189No ratings yet

- Gypwall 3.2: General Purpose Metal Stud Partition SystemDocument20 pagesGypwall 3.2: General Purpose Metal Stud Partition SystemA CNo ratings yet

- Alsiflex®-1260 Blankets - Technical Data Sheet - English PDFDocument2 pagesAlsiflex®-1260 Blankets - Technical Data Sheet - English PDFTanmay GorNo ratings yet

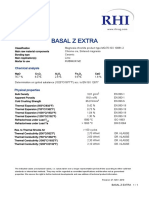

- Basal Z Extra: Chemical AnalysisDocument1 pageBasal Z Extra: Chemical Analysismahreza189No ratings yet

- Thermocouples and Resistance ThermometersDocument44 pagesThermocouples and Resistance ThermometersmihailiuhaszNo ratings yet

- Perillex Bricks PDFDocument3 pagesPerillex Bricks PDFMuntandwe georgeNo ratings yet

- Gun Burner. Materi 1Document10 pagesGun Burner. Materi 1DwiIndraswariNo ratings yet

- Arco Solar Inc.: Case Analysis OnDocument12 pagesArco Solar Inc.: Case Analysis OnAnish RajNo ratings yet

- Range of Wood Burning StovesDocument7 pagesRange of Wood Burning Stovesglynis100% (1)

- Foster Wheeler - CFB BrochureDocument20 pagesFoster Wheeler - CFB Brochureank_mehraNo ratings yet

- FIRE Compendium Series: Refractory Castable EngineeringDocument2 pagesFIRE Compendium Series: Refractory Castable EngineeringKhaled BOUALINo ratings yet

- Cement and RefractoriesDocument24 pagesCement and Refractorieshimanshuchawla654No ratings yet

- Pro Wearflex2000ht UkDocument1 pagePro Wearflex2000ht UkJagadeesh GuttiNo ratings yet

- VEGA - Indonesia PresentationDocument62 pagesVEGA - Indonesia PresentationSteve WanNo ratings yet

- Design and Operating Features of New 27.6 Mva Furnace at Nava Bharat Ventures Limited, PalonchaDocument4 pagesDesign and Operating Features of New 27.6 Mva Furnace at Nava Bharat Ventures Limited, PalonchaKvvPrasadNo ratings yet

- Rescocast 8 PDSDocument2 pagesRescocast 8 PDSaamirsaddiqNo ratings yet

- Manual of Metal Roofing Sheet Roll Forming MachineDocument8 pagesManual of Metal Roofing Sheet Roll Forming Machinenovo orderNo ratings yet

- Refractories en Web PDFDocument24 pagesRefractories en Web PDFMarsNo ratings yet

- The Ultimate Wood StoveDocument34 pagesThe Ultimate Wood StoveUmbisa Moses GwehonaNo ratings yet

- Aeroflex Metric Catalogue and SubmittalDocument8 pagesAeroflex Metric Catalogue and SubmittalZeeshanNo ratings yet

- Cones and Buller RingsDocument6 pagesCones and Buller RingsTravis WoodNo ratings yet

- Neoram Super 70 (Ramming Plastic Castable)Document1 pageNeoram Super 70 (Ramming Plastic Castable)muhammad abidinNo ratings yet

- Brazilian Green Pig Iron IndustryDocument18 pagesBrazilian Green Pig Iron IndustryJorge MadiasNo ratings yet

- LENTON Furnaces BrochureDocument20 pagesLENTON Furnaces Brochureantho_lombokNo ratings yet

- Ceramic Tile Properties and Deterioration FactorsDocument3 pagesCeramic Tile Properties and Deterioration Factorsمحمد محمود مهديNo ratings yet

- Thermo and Mechanical Stress Modelling Kiln Outlet DesignDocument5 pagesThermo and Mechanical Stress Modelling Kiln Outlet Designjoe_kudoNo ratings yet

- BS 3958-2 1982 (E)Document8 pagesBS 3958-2 1982 (E)Danny BiermansNo ratings yet

- Energy and Buildings - Laboratory01 - Thermal Bridges - 2017 PDFDocument55 pagesEnergy and Buildings - Laboratory01 - Thermal Bridges - 2017 PDFSamantha GraciNo ratings yet

- Ladle Refractory Monitoring WebDocument6 pagesLadle Refractory Monitoring WebsusantaNo ratings yet

- Vibradamp DC30 122IPMDocument3 pagesVibradamp DC30 122IPMtrublu260112No ratings yet

- External Wall Insulation Irish CertificationDocument19 pagesExternal Wall Insulation Irish CertificationTj GilliganNo ratings yet

- Porcelain InsulatorsDocument6 pagesPorcelain InsulatorsCeramiatNo ratings yet

- 14492Document7 pages14492sbpatil8808No ratings yet

- Jeremias Brochure DW-ECO2.0Document24 pagesJeremias Brochure DW-ECO2.0Vasilije MituNo ratings yet

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsFrom EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsRating: 5 out of 5 stars5/5 (1)

- En 20471-EngDocument20 pagesEn 20471-EngDean WilyNo ratings yet

- An Apprach en 20471-2013Document20 pagesAn Apprach en 20471-2013Ali ÖzgençNo ratings yet

- En 20471-EngDocument20 pagesEn 20471-EngDean WilyNo ratings yet

- Ilac P10Document10 pagesIlac P10BellbrujaNo ratings yet

- EN16001 Implementation GuideDocument36 pagesEN16001 Implementation GuideSeenivasagam SeenuNo ratings yet

- CEN-CENELEC approach for hazardous substances in PPE standardsDocument3 pagesCEN-CENELEC approach for hazardous substances in PPE standardsAli ÖzgençNo ratings yet

- En 20471-EngDocument20 pagesEn 20471-EngDean WilyNo ratings yet

- Beer Brewing Pfmea Aiag-FormatDocument128 pagesBeer Brewing Pfmea Aiag-FormatAli ÖzgençNo ratings yet

- Risk Assessment - Hot Water BoilersDocument4 pagesRisk Assessment - Hot Water BoilersAli ÖzgençNo ratings yet

- NFPA 10 - InspectionDocument2 pagesNFPA 10 - InspectionAli ÖzgençNo ratings yet

- LogicalReasoningTest1 QuestionsssDocument6 pagesLogicalReasoningTest1 QuestionsssMc Vharn Catre100% (1)

- Chapter 7pressure DesignDocument11 pagesChapter 7pressure DesignAli ÖzgençNo ratings yet

- OGP Energy Management GuidelinesDocument24 pagesOGP Energy Management GuidelinesTissa19690% (1)

- Ts Condensing TechnologyDocument32 pagesTs Condensing TechnologyAli ÖzgençNo ratings yet

- Material and Energy Balance in Industrial PlantDocument26 pagesMaterial and Energy Balance in Industrial Plantconan45No ratings yet

- DeaerationDocument5 pagesDeaerationEffy SaifulNo ratings yet

- Ayvaz Kondenstop Kitabi TR ENGDocument122 pagesAyvaz Kondenstop Kitabi TR ENGAli ÖzgençNo ratings yet

- Sample2 PVEliteDocument45 pagesSample2 PVEliteRam MurtyNo ratings yet

- Machinery Safety Guide Sponsored by TÜV SÜD Product ServiceDocument52 pagesMachinery Safety Guide Sponsored by TÜV SÜD Product ServiceAli ÖzgençNo ratings yet

- Energy Efficiency Technical TrainingDocument13 pagesEnergy Efficiency Technical TrainingAli ÖzgençNo ratings yet

- How To Do Value Stream MappingDocument10 pagesHow To Do Value Stream MappingAnuj SrivastavaNo ratings yet

- The Performance Indicator DelusionDocument6 pagesThe Performance Indicator DelusionAli ÖzgençNo ratings yet

- EA-4-16 G-2003. EA Guidelines On The Expression of Uncertainty in Quantitative TestingDocument28 pagesEA-4-16 G-2003. EA Guidelines On The Expression of Uncertainty in Quantitative Testingcolve87No ratings yet

- Safedesign: Machine Risk Assessment: Insert Photo HereDocument48 pagesSafedesign: Machine Risk Assessment: Insert Photo HereAli ÖzgençNo ratings yet

- Ect149 EMC Electromagnetic CompatibilityDocument36 pagesEct149 EMC Electromagnetic CompatibilitytjnoonNo ratings yet

- Decision No 768 2008 EC enDocument47 pagesDecision No 768 2008 EC enDebreteni FlorinNo ratings yet

- Testing and Commissioning Procedure: 2007 EDITIONDocument47 pagesTesting and Commissioning Procedure: 2007 EDITIONAli Özgenç100% (1)

- Regulation (Ec) No 765-2008 of The European Parliament and of The CouncilDocument18 pagesRegulation (Ec) No 765-2008 of The European Parliament and of The CouncilAli ÖzgençNo ratings yet

- Underwater Restaurant: A Tribute to Norway's CoastDocument9 pagesUnderwater Restaurant: A Tribute to Norway's CoastNiyandha PupNo ratings yet

- HornBricks Company ProfileDocument7 pagesHornBricks Company ProfileBarkhad MohamudNo ratings yet

- RCC54 Circular Column ChartingDocument1 pageRCC54 Circular Column ChartingBunheng LonNo ratings yet

- 09-28-2018 Architectural Plans and ExhibitsDocument55 pages09-28-2018 Architectural Plans and ExhibitsNone None NoneNo ratings yet

- LEED v4 For Building Design and Construction: Homes and Multifamily Low-RiseDocument6 pagesLEED v4 For Building Design and Construction: Homes and Multifamily Low-Riseapi-395468565No ratings yet

- Updated SP-511Document7 pagesUpdated SP-511Feroz GullNo ratings yet

- External Prestressing in BavariaDocument10 pagesExternal Prestressing in BavariaAna CastroNo ratings yet

- Civil Dissertation TopicDocument8 pagesCivil Dissertation TopicVishal PatelNo ratings yet

- Glulam Connection Detail PDFDocument19 pagesGlulam Connection Detail PDFAbdurrahman CinarNo ratings yet

- Ruukki Sandwich PanelsDocument48 pagesRuukki Sandwich PanelsPrabu RengarajanNo ratings yet

- SRV Engineering College Lecture Notes on Prefabricated StructuresDocument57 pagesSRV Engineering College Lecture Notes on Prefabricated Structuresg.rajaNo ratings yet

- HCB Manual GTZ 2008Document14 pagesHCB Manual GTZ 2008suvajjit RoyNo ratings yet

- Vertical Subsystems and Rigid Frame AnalysisDocument20 pagesVertical Subsystems and Rigid Frame Analysisarif_rubinNo ratings yet

- Quantity Take Off: Applied Science UniversityDocument25 pagesQuantity Take Off: Applied Science UniversityMarlon Arvin Marmita83% (6)

- Standard Const. Labor Works OutputDocument2 pagesStandard Const. Labor Works OutputAnton_Young_1962No ratings yet

- Final TEC Report 2 PDFDocument124 pagesFinal TEC Report 2 PDFrisingrishuNo ratings yet

- Summary of Land Development Accomplishment: Project Title: Project Location: Sub-Project: DateDocument19 pagesSummary of Land Development Accomplishment: Project Title: Project Location: Sub-Project: Dateabegailmarasigan100% (1)

- Ubc 1982Document778 pagesUbc 1982ilavarasant100% (4)

- ConcreteCentre - EC2 Bridges ExtractDocument6 pagesConcreteCentre - EC2 Bridges Extractmrzap500713% (8)

- Product Data: Beam Lintels LengthsDocument2 pagesProduct Data: Beam Lintels LengthsRakesh ParaliyaNo ratings yet

- Otter Tail County, Henning Transfer Station Designs, FOTH Engineering, Feb. 2023Document4 pagesOtter Tail County, Henning Transfer Station Designs, FOTH Engineering, Feb. 2023Michael AchterlingNo ratings yet

- Modular Water Cooled Water Chiller - (With PLC French)Document22 pagesModular Water Cooled Water Chiller - (With PLC French)HENRYNo ratings yet

- Roofmate PDFDocument29 pagesRoofmate PDFFadi HNo ratings yet

- Chemdrain Chemical Waste Drainage System Recommended Short Form SpecificationDocument2 pagesChemdrain Chemical Waste Drainage System Recommended Short Form SpecificationGreg FarzettaNo ratings yet

- Ebanks, Peta-Gaye PDFDocument156 pagesEbanks, Peta-Gaye PDFDiomede PidrancoNo ratings yet

- UntitledDocument28 pagesUntitledESON LOHNo ratings yet

- Toll Plaza ADocument54 pagesToll Plaza Akhraieric16No ratings yet

- GenieMat FF Brochure NA ENG DigitalDocument16 pagesGenieMat FF Brochure NA ENG DigitalSK C&T - KEO ỐP LÁT, CHỐNG THẤM.No ratings yet

- Earthquake Resistant Building: Iqra Javed 3 ADocument16 pagesEarthquake Resistant Building: Iqra Javed 3 AIqRa JaVedNo ratings yet

- Index For Safe Work Method Statements (CIVIL/FIT-OUT WORK)Document2 pagesIndex For Safe Work Method Statements (CIVIL/FIT-OUT WORK)Ranjan KumarNo ratings yet