Professional Documents

Culture Documents

Water Quality in Engine Coolant PDF

Uploaded by

RasoolKhadibiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Water Quality in Engine Coolant PDF

Uploaded by

RasoolKhadibiCopyright:

Available Formats

Category: Coolants

Water Quality in Bulletin No. 99.023

Date: 09/20/99

Engine Coolant

Introduction:

Penray frequently is asked to recommend practices relative to water selection for the blending of engine coolant. ASTM

publishes the following recommendation, and a discussion follows.

ASTM Water Quality Recommendation (from D-4985):

ppm (max.) Grains Per Gallon

(max.)

Chlorides 40 2.5

Sulfates 100 5.8

Total Dissolved Solids 310 20

Total Hardness (calcium and magnesium) 170 10

Discussion:

Engine coolant is a mixture of antifreeze and water, usually 50% each. ASTM specs require the antifreeze be formu-

lated so that when it is mixed with water at 50%, the freeze point is no higher than -34°F (-37°C). A great deal of work

and expense goes into the formulation of quality antifreeze. Reputable companies use high quality ethylene glycol,

and purchase deionized water and chemicals that are certified to be low in contaminants, such as chloride, to blend

the anti corrosion properties into the finished product. Frequently, the effort seems somewhat wasted when the end

user indiscriminately uses water unsuitable for engine coolant to blend with the antifreeze.

Probably the poorest choice of blending water is well water. The minerals, when introduced into engine coolant are

the source of several concerns.

Calcium: combines in engine coolant to form scale on hot heat exchange surfaces. Scale is an efficient insulator,

and the result is localized engine overheating that can cause component failure.

Magnesium: Magnesium also can form scale, creating localized overheating and warped engine heads. It is the

second of the two components (with calcium) measured to determine the degree of "water hardness". Water that

contains calcium and magnesium is defined as "hard"; the concentration of the two chemicals combined determines

the level of hardness.

Silicate: In water, silicate would be detected as the result of sand, not sodium silicate inhibitor. Sand is frequently

found in cooling systems, and is associated with premature wear due to abrasion in various areas of the cooling

system.

Chloride: Municipal drinking water most often is, in fact, acceptable for engine coolant. A water test can determine

the quality of municipal water. Nevertheless, most municipal waters contain chlorine, resulting in the formation of

chlorides in the coolant. Chlorides are aggressive to aluminum.

Oxygen: Anyone who has tried deionized water knows it tastes nasty. This is due to its lack of oxygen. Oxygen

contributes tremendously to metal corrosion and depletion of inhibitors. City water is full of oxygen making it suitable

for drinking and keeping pet fish. Water with low oxygen levels is preferable for coolant.

Therefore, the argument for distilled or deionized water is made on the basis that such water contains fewer reactive

chemicals, resulting in optimum coolant life and performance. It is also true that Penray antifreeze chemistry is

formulated with certain safeguard additives chosen to address typical city water. This is another "good - better - best"

choice; relating city water, shop blending DI water, and prediluted coolant from a blending plant representing the

three quality choices. No one recommends using well water for engine coolant.

You might also like

- Cooling Water Treatment and Analysing: Operating InstructionDocument7 pagesCooling Water Treatment and Analysing: Operating Instructionamin32No ratings yet

- Astm TestingDocument7 pagesAstm TestingFallo SusiloNo ratings yet

- Diesel Engine Cooling Water TreatmentDocument3 pagesDiesel Engine Cooling Water TreatmentPraneel Kurhade0% (2)

- An Introduction To Coolants PDFDocument57 pagesAn Introduction To Coolants PDFPETER ADAMNo ratings yet

- Komatsu D575ADocument4 pagesKomatsu D575ARasoolKhadibiNo ratings yet

- Properties and Manufacture of Ammonium Perchlorate: September 2020Document11 pagesProperties and Manufacture of Ammonium Perchlorate: September 2020Aditya Pathak50% (2)

- Antifreeze ComponentsDocument8 pagesAntifreeze ComponentsOscar Rivera100% (1)

- Chrome PlatingDocument11 pagesChrome PlatingMahesh Babu100% (1)

- Coolant WriteupDocument8 pagesCoolant WriteupRajiv SrivastavaNo ratings yet

- Uniformity Tests Result of Concrete Admixture: Remark: T Denotes Manufacturer's Stated Value in % by MassDocument3 pagesUniformity Tests Result of Concrete Admixture: Remark: T Denotes Manufacturer's Stated Value in % by MassSudhir MishraNo ratings yet

- Amigurumi Toy «Bunny Anabel» Master class - Crochet toy: (с) 2016 Tkachenko Olga @amigurushkaDocument16 pagesAmigurumi Toy «Bunny Anabel» Master class - Crochet toy: (с) 2016 Tkachenko Olga @amigurushkaMáté MihályfiNo ratings yet

- Caterpillar D11Document3 pagesCaterpillar D11RasoolKhadibiNo ratings yet

- Caterpillar D6Document3 pagesCaterpillar D6RasoolKhadibi100% (1)

- An Introduction To CoolantsDocument247 pagesAn Introduction To CoolantstollywhistleNo ratings yet

- Basics of Mining and Mineral Processing by W Scott Dunbar PDFDocument179 pagesBasics of Mining and Mineral Processing by W Scott Dunbar PDFFerudun Akyol100% (1)

- Coolant Requirement ASTMDocument5 pagesCoolant Requirement ASTMjeganNo ratings yet

- Variable Vane Pumps PV7Document32 pagesVariable Vane Pumps PV7RasoolKhadibi100% (1)

- Wartsila OEM Engine Manufacturer ApprovalsDocument8 pagesWartsila OEM Engine Manufacturer ApprovalsSivakumar SelvarajNo ratings yet

- Spare Parts List For Komatsu D355a-3 BulldozerDocument19 pagesSpare Parts List For Komatsu D355a-3 BulldozerRasoolKhadibiNo ratings yet

- Caterpillar D9Document4 pagesCaterpillar D9RasoolKhadibiNo ratings yet

- 2 5415941395045155907 PDFDocument19 pages2 5415941395045155907 PDFAlyelXNo ratings yet

- NEC Pipe Fill ChartDocument5 pagesNEC Pipe Fill ChartKenshin HimuraNo ratings yet

- Cooling Tower PresentationDocument44 pagesCooling Tower PresentationAmi Desai100% (1)

- Cooling Water Treatment and Analysing: Lmbo QFKD Fkpqor'qflkDocument7 pagesCooling Water Treatment and Analysing: Lmbo QFKD Fkpqor'qflkRonald Bienemi Paez100% (1)

- Water Treatment in ChillersDocument14 pagesWater Treatment in ChillersabmopalhvacNo ratings yet

- Demineralization and Condensate Polishing BasicsDocument16 pagesDemineralization and Condensate Polishing BasicsvenkeekuNo ratings yet

- Seismic Performance and Design of Precas PDFDocument13 pagesSeismic Performance and Design of Precas PDFCsongor BiroNo ratings yet

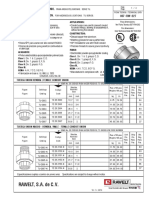

- Union Universal RAWELTDocument4 pagesUnion Universal RAWELTLuisDonairesNo ratings yet

- Mitsubishi Diesel Engine Technical Information: Coolant AdditivesDocument3 pagesMitsubishi Diesel Engine Technical Information: Coolant AdditivesMoniru islamNo ratings yet

- Havoline Extended Life Antifreeze CoolantDocument6 pagesHavoline Extended Life Antifreeze CoolantNegru P. PlantatieNo ratings yet

- Application Engineering Bulletin: Automotive Industrial Marine G-Drive Genset Powergen Antifreeze in Warm ClimatesDocument3 pagesApplication Engineering Bulletin: Automotive Industrial Marine G-Drive Genset Powergen Antifreeze in Warm ClimatesCesar G.No ratings yet

- R20 Applied Chemistry - UNIT-5Document19 pagesR20 Applied Chemistry - UNIT-5maheshbabugandupalli7No ratings yet

- Cooltech LLO CoolantDocument2 pagesCooltech LLO CoolantahmedalgaloNo ratings yet

- Caterpillar Coolant FluidsDocument52 pagesCaterpillar Coolant Fluidsbsantos9100% (1)

- Fact Sheet: Lime Terminology, Standards & PropertiesDocument10 pagesFact Sheet: Lime Terminology, Standards & PropertiesalexituuNo ratings yet

- Axel Elgi 2013Document18 pagesAxel Elgi 2013Virender KumarNo ratings yet

- Eastman 2197 Turbo-Oil TDS - SkySupplyUSADocument2 pagesEastman 2197 Turbo-Oil TDS - SkySupplyUSASkySupplyUSANo ratings yet

- Cooling System Maintenance For Heavy Duty Engines: Technical Service Bulletin 88-1Document3 pagesCooling System Maintenance For Heavy Duty Engines: Technical Service Bulletin 88-1Agus Setiawan Feat AvrNo ratings yet

- ES COMPLEAT™ AntifreezeCoolant - LT15548Document2 pagesES COMPLEAT™ AntifreezeCoolant - LT15548Cesar G.No ratings yet

- Water Requirements, Volvo CoolantsDocument1 pageWater Requirements, Volvo CoolantsmostafaNo ratings yet

- How Much Do You Know About Heavy Duty CoolantDocument5 pagesHow Much Do You Know About Heavy Duty CoolantengrsurifNo ratings yet

- Keeper: Coolants and Cooling System MaintenanceDocument3 pagesKeeper: Coolants and Cooling System MaintenanceAung Myo ThantNo ratings yet

- Cooling SystemDocument12 pagesCooling SystemSakoraphob BanlengchitNo ratings yet

- Cooling SystemDocument81 pagesCooling SystemRipper KaunglayNo ratings yet

- Technical Service Bulletin Re-Print From Baldwin Filter CompanyDocument2 pagesTechnical Service Bulletin Re-Print From Baldwin Filter Companyvoyager1No ratings yet

- Accumulation Pressure Test, Corrosion of Boilers On ShipsDocument4 pagesAccumulation Pressure Test, Corrosion of Boilers On ShipsibnuharyNo ratings yet

- CTS-5 Cool Check® 3-Way Water Check Specifications & InstructionsDocument2 pagesCTS-5 Cool Check® 3-Way Water Check Specifications & InstructionsvNo ratings yet

- Water Reuse Strategies: Steel Industry Case StudiesDocument15 pagesWater Reuse Strategies: Steel Industry Case StudiesMashaelNo ratings yet

- Cooling Water Treatment and Periodical Test of The Cooling WaterDocument4 pagesCooling Water Treatment and Periodical Test of The Cooling WaterGaurav MaithilNo ratings yet

- Engine Coolants (Antifreeze) : Technical HandbookDocument16 pagesEngine Coolants (Antifreeze) : Technical Handbookanil73100% (1)

- Cat Deac: Prevents Freezing While Providing Superior Component ProtectionDocument2 pagesCat Deac: Prevents Freezing While Providing Superior Component ProtectionCarlos Indigoyen LimaymantaNo ratings yet

- Acumulation TestDocument5 pagesAcumulation TestNeeraj RahiNo ratings yet

- Automotive Coolant - General Information: Austech AC-10 Austech AC-9 Austech AC-2 Austech AC-1Document2 pagesAutomotive Coolant - General Information: Austech AC-10 Austech AC-9 Austech AC-2 Austech AC-1senthilkumar rangarajNo ratings yet

- Product Data: Antifreeze NFDocument5 pagesProduct Data: Antifreeze NFJaya PranataNo ratings yet

- ShellDocument4 pagesShellMaboodNo ratings yet

- ES Compleat NOAT Data SheetDocument3 pagesES Compleat NOAT Data SheetAntonio Tavara HernandezNo ratings yet

- Pressed 0Document12 pagesPressed 0Rath AsypadenNo ratings yet

- Fluid Recommendations ###Document5 pagesFluid Recommendations ###benjir shuvoNo ratings yet

- Color Changing Antifreeze/Coolant: Montreal Toronto Edmonton VancouverDocument2 pagesColor Changing Antifreeze/Coolant: Montreal Toronto Edmonton VancouverDarmawan Putranto0% (1)

- Aral Antifreeze Silikatfrei Global English PDB 456112Document2 pagesAral Antifreeze Silikatfrei Global English PDB 456112Техник СвязиNo ratings yet

- IWT Question Summary 01-02-15Document10 pagesIWT Question Summary 01-02-15jamaljamal20No ratings yet

- Fluid RecommendationsDocument6 pagesFluid RecommendationsAlfredoNo ratings yet

- Welcome To: Cooling Water Treatment in Power Plants Recent Trends & Case StudyDocument17 pagesWelcome To: Cooling Water Treatment in Power Plants Recent Trends & Case StudyrpshvjuNo ratings yet

- Calidad de Agua ReymsaDocument3 pagesCalidad de Agua Reymsacarmen hernandezNo ratings yet

- Calflo Heat Transfer FluidDocument4 pagesCalflo Heat Transfer FluidderekfisherNo ratings yet

- LT15108 GBDocument8 pagesLT15108 GBvNo ratings yet

- Rules of ThumbDocument35 pagesRules of ThumbIbrahim Al-HammadiNo ratings yet

- FL Course 7Document10 pagesFL Course 7Fianu AndreeaNo ratings yet

- Fluid Analysis for Mobile Equipment: Condition Monitoring and MaintenanceFrom EverandFluid Analysis for Mobile Equipment: Condition Monitoring and MaintenanceNo ratings yet

- Water Softening with Potassium Chloride: Process, Health, and Environmental BenefitsFrom EverandWater Softening with Potassium Chloride: Process, Health, and Environmental BenefitsNo ratings yet

- Transmission Glycol TestDocument1 pageTransmission Glycol TestRasoolKhadibiNo ratings yet

- Transmission Glycol TestDocument2 pagesTransmission Glycol TestRasoolKhadibiNo ratings yet

- Fuel Injection Systems Diesel Fuel InjecDocument39 pagesFuel Injection Systems Diesel Fuel InjecRasoolKhadibiNo ratings yet

- Fluid Analysis Services: Call 131 228Document1 pageFluid Analysis Services: Call 131 228RasoolKhadibiNo ratings yet

- Mercaptans in Crude Oil: Larry Kremer & Weldon Cappel Baker HughesDocument11 pagesMercaptans in Crude Oil: Larry Kremer & Weldon Cappel Baker HughesRasoolKhadibiNo ratings yet

- M EthanethiolDocument4 pagesM EthanethiolRasoolKhadibiNo ratings yet

- EthanethiolDocument3 pagesEthanethiolRasoolKhadibiNo ratings yet

- Paver (Vehicle)Document3 pagesPaver (Vehicle)RasoolKhadibiNo ratings yet

- Wheel Tractor ScraperDocument2 pagesWheel Tractor ScraperRasoolKhadibi0% (1)

- Kepler's EquationDocument4 pagesKepler's EquationRasoolKhadibiNo ratings yet

- Circular MotionDocument6 pagesCircular MotionRasoolKhadibiNo ratings yet

- Claas Kgaa MBHDocument3 pagesClaas Kgaa MBHRasoolKhadibiNo ratings yet

- Content ServerDocument3 pagesContent ServerLINA KATHERIN ESPINOSA OSPINANo ratings yet

- Comprhensive Industry Document On Vertical Shaft Kiln Based Mini Cement PlantsDocument72 pagesComprhensive Industry Document On Vertical Shaft Kiln Based Mini Cement PlantsTuan Nguyen BaNo ratings yet

- Respirator Cartridge ChartDocument2 pagesRespirator Cartridge ChartRanto GunawanNo ratings yet

- 04 Psi Pikotek R 2018 enDocument14 pages04 Psi Pikotek R 2018 enAlejandro MartinezNo ratings yet

- NRS 103 - R27499 - Engl.Document1 pageNRS 103 - R27499 - Engl.Buluc GheorgheNo ratings yet

- Golongan I A - Iv A - Kelompok 1 - Xii Ipa 1Document42 pagesGolongan I A - Iv A - Kelompok 1 - Xii Ipa 1Anisa AyuNo ratings yet

- Fire Escape DoorDocument25 pagesFire Escape DoorAhtesham KhanNo ratings yet

- SelectionGuide UKDocument32 pagesSelectionGuide UKMichael TadrosNo ratings yet

- 10 129 139 PDF 13423Document11 pages10 129 139 PDF 13423Sinan YıldızNo ratings yet

- Consumer and Industrial Specialties: Rohm and Haas Water Treatment Product Selection Guide For North AmericaDocument5 pagesConsumer and Industrial Specialties: Rohm and Haas Water Treatment Product Selection Guide For North AmericaChoice OrganoNo ratings yet

- Chempart 29 (R)Document9 pagesChempart 29 (R)CanchindoNo ratings yet

- Transformer Aircel PDFDocument2 pagesTransformer Aircel PDFMuthukumar SivaramanNo ratings yet

- Catálogo Accesorios PTFE DINDocument100 pagesCatálogo Accesorios PTFE DINdepinfor lusofabrilNo ratings yet

- 1.1 CC Civil BrochureDocument4 pages1.1 CC Civil BrochureLuis Larry Bocanegra GomezNo ratings yet

- Ahmad MuhsenDocument10 pagesAhmad MuhsenAya SaheliNo ratings yet

- H40 Rebar Welding CalculationDocument1 pageH40 Rebar Welding CalculationcheeseonglawNo ratings yet

- Flat Multi Layer Microwave Absorber - FU-MLDocument2 pagesFlat Multi Layer Microwave Absorber - FU-MLtarun_sheladiyaNo ratings yet

- Hydrolycs QN and Ans.Document10 pagesHydrolycs QN and Ans.AyebareNo ratings yet

- Nav Composites 02-Flexture Concrete CompositesDocument29 pagesNav Composites 02-Flexture Concrete Compositesendah anggraeniNo ratings yet

- Neyriz Grey Cement Co.: Date: 02.05.30Document1 pageNeyriz Grey Cement Co.: Date: 02.05.30alishahsavarNo ratings yet

- Harmonized CODEDocument7 pagesHarmonized CODEvinayak.khorate2707No ratings yet

- Saponification - Kate SaradorDocument4 pagesSaponification - Kate Saradorkate saradorNo ratings yet

- MasterCast 141Document68 pagesMasterCast 141WES QingNo ratings yet

- Glass Art (Assignment)Document14 pagesGlass Art (Assignment)Noveed Tahsin AminNo ratings yet