Professional Documents

Culture Documents

Loadbearingpads PDF

Uploaded by

diolanaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Loadbearingpads PDF

Uploaded by

diolanaCopyright:

Available Formats

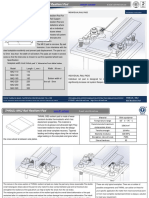

LOAD BEARING PADS Symar Load Bearing

Symar® Load Bearing Pads are used extensively in standard construction

Pads are available in

applications, precast and prestressed concrete bridges, buildings and structural steel two grades:

bearings applications, as well as machinery, equipment foundation, railway tie pads,

SYMAR SP ELASTOMERIC

and shock and vibration isolation. LOAD BEARING PADS

Compressive design

Symar Load Bearing Pads are made from Symar masticated rubber which is a fully loads up to 10.3 N/mm2

cured fibre reinforced rubber made from a proprietary blend of recycled rubbers. (1500 psi) and ultimate

During the manufacturing process synthetic fibres are added to the base rubber compressive strength of

compounds to create an internal stiffening much like steel reinforced concrete. This 69.8 N/mm2 (10,000

mesh structure delivers enhanced tensile and psi)

compressive strength, stiffness, tear resistance,

Symar elastomeric bearing SYMAR XP ELASTOMERIC

durability, and superior ozone and weather

resistance. The combination of these properties

pads have been used in: LOAD BEARING PADS

Compressive design

cannot be achieved using only virgin materials. Bridge bearing masonry pads loads up to 13.8 N/mm2

Lighting standard pad seats (2000 psi) and ultimate

Symar XP

Handrail bearing pads compressive strength of

Our premium grade Symar XP Elastomeric Load

Pads between steel beams, 103.4 N/mm2 (15,000

Bearing Pads are constructed in a unique cross ply girders, and columns psi)

manufacturing process, giving uniform physical

Pads between bridge and

roof beams and

properties in all directions. These premium grade

® Symar is a registered trademark of KN Rubber LLC. © 2008-2010 KN Rubber LLC. All Rights Reserved.

substructures.

load bearing pads are designed for more

Shock and vibration isolation

demanding structural applications with greater

Railway tie pad applications

load requirements.

Symar® Load Bearing Pads are manufactured in continuous cure presses,

not batch presses, which allows us to economically produce custom

shapes and sizes and meet the demands of large scale construction Made with

projects. Load bearing pads can be supplied to specified dimensions

ready for installation, including required cut outs and holes, or in sheet

form for later sizing.

rubber

Stock sheets are available in 1.219m x 1.219m (48” x 48”)

and 3.17mm to 25.4 mm (1/8” to 1”) thickness.

Custom sizes can be made to suit your application.

National Rubber Technologies Corp., A KN Rubber company,

NATIONAL RUBBER

T E C H N O L O G I E S

is one of the largest manufacturers of premium grade bearing CUSTOMER SERVICE:

pads in the construction industry. We are a vertically integrated

A KN Rubber company

manufacturer and annually ship over 100 million pounds (45

1-800-387-8501

million kg) of rubber products annually to distributors and end info@nrtna.com

users in North America, Europe, and the Middle East.

LOAD BEARING PADS

Technical Data

PHYSICAL PROPERTIES SPECIFICATION OF SPECIFICATION OF

TEST METHOD

(ORIGINAL) SYMAR SP LOAD BEARING PADS SYMAR XP LOAD BEARING PADS

Tensile Strength, Min. ASTM D412, Die C MD: 5.2 Mpa MD: 754 PSI MD: 7.0 Mpa 1000 PSI

Tear Strength, Min. ASTM D624, Die B MD: 26.4 kN/m MD: 150 PI MD: 35 kN/m 200 PI

TD: 52.5 kN/m TD: 300 PI TD: 70 kN/m 400 PI

Elongation, %, Min. ASTM D412, Die C MD: 15 MD: 15

TD: 40 TD: 40

Hardness, Shore A ASTM D2240 80 ±5 75 ±5

Specific Gravity ASTM D297 sec. 16.3 N/A 1.18

Ozone Resistance ASTM D518 "B" Application specific Application specific

Low Temperature Resistance ASTM D2137 @ –40°C Pass Pass

Coefficient of Friction ASTM D1894 >0.8 >0.8

PHYSICAL PROPERTIES TEST METHOD

(HEAT AGED) A STM D573, 70H @ 70°C

Tensile Strength, Change % Max. ASTM D412, Die C ±25 ±25

Elongation, Change %, Max. ASTM D412, Die C ±25 ±25

Hardness, Change Pts. Max. ASTM D2240 ±10 ±10

MD = Machine Direction; TD = Transverse Direction

Load Deflection 14 (2030)

6.35mm 9.53mm 12.7mm 25.4mm

Load Range: N/mm^2 (psi)

12 (1740)

0.25” 0.375” 0.5” 19.05mm 1”

10 (1450) 0.75”

SYMAR SP 8 (1160)

LOAD BEARING PADS 6 (870)

4 (580)

2 (290)

0 1 2 3 4 5 6 7 8 9 10

(0.04) (0.08) (0.12) (0.16) (0.2) (0.24) (0.28) (0.32) (0.35) (0.39)

Deflection: mm (inches)

16 (2320)

6.35mm 9.53mm 12.7mm 19.05mm 25.4mm

14 (2030)

0.25” 0.375” 0.5” 0.75” 1”

Load Range: N/mm^2 (psi)

12 (1740)

10 (1450)

SYMAR XP

8 (1160)

LOAD BEARING PADS

6 (870)

4 (580)

2 (290)

0 1 2 3 4 5 6 7 8 9 10 11 12

(0.04) (0.08) (0.12) (0.16) (0.2) (0.24) (0.28) (0.32) (0.35) (0.39) (0.43) (0.47)

Deflection: mm (inches)

National Rubber Technologies makes no representations or warranties with respect to the suitability of materials for a particular purpose. Buyers and users must determine the safety and suitability of National

Rubber Technologies’ products for their own purposes and assume all risk, responsibility, and liability for all injuries, losses, or damages arising from the application of the information or use of National Rubber

Technologies' products, whether or not occasioned by National Rubber Technologies' negligence or based on strict product liability.

NATIONAL RUBBER 35 Cawthra Avenue, Toronto, ON M6N 5B3

T E C H N O L O G I E S Telephone 416.657.1111 Toll-Free 1.800.387.8501

Fax 416.656.1231 info@nrtna.com www.knrubber.com

A KN Rubber company

You might also like

- IBS - SP Setia PDFDocument32 pagesIBS - SP Setia PDFzeroicesnowNo ratings yet

- PUYAT STEEL-RoofDocument2 pagesPUYAT STEEL-RoofMARK DANIEL DAGALENo ratings yet

- MBrace Fibre PDFDocument4 pagesMBrace Fibre PDFFrancois-No ratings yet

- Bomag PDFDocument12 pagesBomag PDFm arif pNo ratings yet

- 1 - SubmittalSupportDocument Primus LineDocument34 pages1 - SubmittalSupportDocument Primus Linezeroicesnow100% (1)

- JKR Scale of FeeDocument43 pagesJKR Scale of Feezeroicesnow100% (2)

- Operating and Maintenance Manual: (Project Name)Document75 pagesOperating and Maintenance Manual: (Project Name)Bob MorrisNo ratings yet

- Dramix 4D 6560BG-6560BGDocument1 pageDramix 4D 6560BG-6560BGAndrew Jr. ZapantaNo ratings yet

- AusFlex AC AR StripSeal Brochure LOW RES 221108Document8 pagesAusFlex AC AR StripSeal Brochure LOW RES 221108aileensambranoNo ratings yet

- Kinds of Conveyor Belts Pipe Conveyor Belt Conveyo 5ad270867f8b9acc4a8b4583Document19 pagesKinds of Conveyor Belts Pipe Conveyor Belt Conveyo 5ad270867f8b9acc4a8b4583nicolasNo ratings yet

- HammacatalogueDocument20 pagesHammacataloguegilea stefanNo ratings yet

- 2023 Wiawis Archery Web-7-9Document3 pages2023 Wiawis Archery Web-7-9duque107No ratings yet

- 3D 8030BGP-8030BGPDocument1 page3D 8030BGP-8030BGPcsillag janosNo ratings yet

- Sikawrap - 300 CDocument4 pagesSikawrap - 300 CJhune UrabaNo ratings yet

- Bridon Oil and Gas Catalogue SplitDocument25 pagesBridon Oil and Gas Catalogue SplithshobeyriNo ratings yet

- Sika PDS - E - Sikadur - 42 MP SlowDocument5 pagesSika PDS - E - Sikadur - 42 MP Slowlwin_oo2435No ratings yet

- 9946Z - 0657-SP-SL-DE-C-G77-452-P3 - Typical Sections Through Permeable Block PavingDocument1 page9946Z - 0657-SP-SL-DE-C-G77-452-P3 - Typical Sections Through Permeable Block Pavingjmdavies.isNo ratings yet

- Sikawrap - 230 CDocument4 pagesSikawrap - 230 CNyein ZawNo ratings yet

- CemFIL AntiCrak HP 6736 Product Sheet WW 10-2014 Rev8 en FinalDocument2 pagesCemFIL AntiCrak HP 6736 Product Sheet WW 10-2014 Rev8 en FinalvliegenkristofNo ratings yet

- Buchas - GGB - Ozyska - Slizgowe - GAR-MAX - Zwijane - Z - WoknaDocument6 pagesBuchas - GGB - Ozyska - Slizgowe - GAR-MAX - Zwijane - Z - WoknaEdson FelixNo ratings yet

- PT Foundations-2Document5 pagesPT Foundations-2YNNo ratings yet

- Top Features: Team Yamaha Blue/WhiteDocument2 pagesTop Features: Team Yamaha Blue/WhitecenterbladeNo ratings yet

- Crane Rail Pads MK2Document2 pagesCrane Rail Pads MK2Mukty BaktiarNo ratings yet

- Johnson Demountable Bearing BrochureDocument20 pagesJohnson Demountable Bearing BrochureJulio FerrerNo ratings yet

- CRIFI SRL - Sand Production PlantsDocument15 pagesCRIFI SRL - Sand Production PlantsGiacomo SimoncelliNo ratings yet

- 115 ComBAR - Techical Info PDFDocument28 pages115 ComBAR - Techical Info PDFRaquel RochaNo ratings yet

- Testing of NEOPRENE Bearings SKGDocument61 pagesTesting of NEOPRENE Bearings SKGkl Rahul locationNo ratings yet

- Vibration Pads: Mason Industries, IncDocument2 pagesVibration Pads: Mason Industries, Incbman0051401No ratings yet

- Sikawrap - 300 CDocument4 pagesSikawrap - 300 CAlexis KarampasNo ratings yet

- Dock BumperDocument40 pagesDock BumperdannysuryaNo ratings yet

- When It Matters: Malarkey ShinglesDocument2 pagesWhen It Matters: Malarkey ShinglesHoeNo ratings yet

- SS Engineered BearingsDocument2 pagesSS Engineered BearingsVictor ElizondoNo ratings yet

- Sikawrap - 600 C WVDocument4 pagesSikawrap - 600 C WVIndra KusumaNo ratings yet

- Tds Armo Grid SR Eu en Ver202301Document2 pagesTds Armo Grid SR Eu en Ver202301abdo abjNo ratings yet

- Sikawrap 301 C Pds enDocument4 pagesSikawrap 301 C Pds enjohanes b muda100% (1)

- Mci - 2241/mci - 2242 Watertight Coat: Typical Applications and FeaturesDocument2 pagesMci - 2241/mci - 2242 Watertight Coat: Typical Applications and FeaturesAdrian EspinosaNo ratings yet

- Glass Fibre Grid v1Document13 pagesGlass Fibre Grid v1Anirudh SabooNo ratings yet

- Smith Bit GF30BDODVDocument1 pageSmith Bit GF30BDODVJosê Fêlix Rivas CaballeroNo ratings yet

- Sikawrap 300 CDocument5 pagesSikawrap 300 CAkram ShakirNo ratings yet

- Michelin X Tweel Airless Radial Tire BrochureDocument8 pagesMichelin X Tweel Airless Radial Tire BrochureArup DeyNo ratings yet

- Acl 2020Document40 pagesAcl 2020Romel SomarNo ratings yet

- Finite Element Analysis of Natural Rubber Isolator : Mineo T and Keiko MDocument7 pagesFinite Element Analysis of Natural Rubber Isolator : Mineo T and Keiko Modzew1826No ratings yet

- Membrane Lined Insulated Gutter - BrochureDocument8 pagesMembrane Lined Insulated Gutter - BrochureAThaddeusAntonioNo ratings yet

- Tracks Full Line Canada 01-22-2016Document15 pagesTracks Full Line Canada 01-22-2016gurcayhidayetNo ratings yet

- Brake Discs Pads P 1264 EN PDFDocument4 pagesBrake Discs Pads P 1264 EN PDFNanda Kishore ReddyNo ratings yet

- Sikawrap®-300 C: Product Data SheetDocument4 pagesSikawrap®-300 C: Product Data SheetHenri DormoyNo ratings yet

- Architectural Shingles Booklet OK MalarkeyDocument12 pagesArchitectural Shingles Booklet OK MalarkeyHoeNo ratings yet

- Brochure Optimisation of Turnouts enDocument8 pagesBrochure Optimisation of Turnouts ensorinarseneNo ratings yet

- GRANOR AC-AR Expansion JointDocument5 pagesGRANOR AC-AR Expansion JointscribdarellNo ratings yet

- Dramix 3d 6535bg-6535bgDocument1 pageDramix 3d 6535bg-6535bgmanish_mokalNo ratings yet

- 192 eDocument4 pages192 eGuilherme AugustoNo ratings yet

- 4D 6560BG 1 PDFDocument1 page4D 6560BG 1 PDFNavneet NarayanNo ratings yet

- Form Active Tent Structure Denver International AirportDocument5 pagesForm Active Tent Structure Denver International AirportNishika AgrawalNo ratings yet

- EE Imanes de Levantamiento (MB-2300D) PDFDocument20 pagesEE Imanes de Levantamiento (MB-2300D) PDFangelsiddhartaNo ratings yet

- Plaquette-Radial 2021 Exe LDDocument3 pagesPlaquette-Radial 2021 Exe LDfabrizioNo ratings yet

- DS3 Series PDFDocument4 pagesDS3 Series PDFNikolasCarsaNo ratings yet

- Description: Unifrax India Private LimitedDocument2 pagesDescription: Unifrax India Private LimitedAbdel HamidNo ratings yet

- KEMROC New Products (EN)Document5 pagesKEMROC New Products (EN)mani_208eeNo ratings yet

- Steel Wire RopeDocument2 pagesSteel Wire RopePIEC ElevatorsNo ratings yet

- Fact Sheet Elastic Transport Protection For Steel Coils On Freight Cars enDocument4 pagesFact Sheet Elastic Transport Protection For Steel Coils On Freight Cars ensorinarseneNo ratings yet

- Tehnički List - WALLMESH MRDocument3 pagesTehnički List - WALLMESH MRMARKO MATUHANo ratings yet

- DSGDocument2 pagesDSGAnonymous YW5mvpNo ratings yet

- MALAY (Foreign Language) : Section 1Document5 pagesMALAY (Foreign Language) : Section 1zeroicesnowNo ratings yet

- Scale of Fee (SOF) : What Is The Purpose of The BEM SOF ?Document17 pagesScale of Fee (SOF) : What Is The Purpose of The BEM SOF ?zeroicesnowNo ratings yet

- MALAY (Foreign Language) : Paper 0546/02 Reading and Directed WritingDocument6 pagesMALAY (Foreign Language) : Paper 0546/02 Reading and Directed WritingzeroicesnowNo ratings yet

- MediSaversVIP Prime Pricing Table 1Document15 pagesMediSaversVIP Prime Pricing Table 1zeroicesnowNo ratings yet

- Plastiseal : Rubber-Bitumen Cold Applied Joint SealantDocument4 pagesPlastiseal : Rubber-Bitumen Cold Applied Joint SealantzeroicesnowNo ratings yet

- 2 - PrimusLine - flyer-water-GBDocument4 pages2 - PrimusLine - flyer-water-GBzeroicesnowNo ratings yet

- PlastijointDocument2 pagesPlastijointzeroicesnowNo ratings yet

- How To Unlock A Word Document Under Windows: Seth Teller EmailDocument2 pagesHow To Unlock A Word Document Under Windows: Seth Teller EmailzeroicesnowNo ratings yet

- Route Location Data Collection: Road Design Check ListDocument2 pagesRoute Location Data Collection: Road Design Check Listzeroicesnow100% (1)

- Culvert Design Checklist 2019Document5 pagesCulvert Design Checklist 2019zeroicesnowNo ratings yet

- Drainage Drawing Check ListDocument2 pagesDrainage Drawing Check ListzeroicesnowNo ratings yet

- SUTS-IEM Evening Talk Series 20210421 v3 (1) - EditedDocument1 pageSUTS-IEM Evening Talk Series 20210421 v3 (1) - EditedzeroicesnowNo ratings yet

- BEM Scale of FeeDocument43 pagesBEM Scale of FeezeroicesnowNo ratings yet

- Conceptual Structural Design Methods of Reinforced Concrete Buildings Rev 2Document16 pagesConceptual Structural Design Methods of Reinforced Concrete Buildings Rev 2Dawit SolomonNo ratings yet

- Sikawrap®-900 C: Carbon Fibre Fabric For Structural StrengtheningDocument2 pagesSikawrap®-900 C: Carbon Fibre Fabric For Structural StrengtheningRoberto Jimenez PerezNo ratings yet

- Electrical Specs KsaDocument75 pagesElectrical Specs KsaMEP299 MAPUANo ratings yet

- Types of Joints in Concrete ConstructionsDocument7 pagesTypes of Joints in Concrete ConstructionsbotchNo ratings yet

- Case Study On Ground Improvement by High Pressure Jet GroutingDocument6 pagesCase Study On Ground Improvement by High Pressure Jet Groutingnagy_andor_csongorNo ratings yet

- Design and Analysis of G+3 Building by Using Staad Pro: Mini ProjectDocument10 pagesDesign and Analysis of G+3 Building by Using Staad Pro: Mini ProjectsaikirankasivojjulaNo ratings yet

- 2013 Soil Mechanics II and Exercises Midterm Exam: e With Respect To The Initial Void Ratio. For This GroundDocument7 pages2013 Soil Mechanics II and Exercises Midterm Exam: e With Respect To The Initial Void Ratio. For This GroundAbera MamoNo ratings yet

- Cs Anil Piping Design ResumeDocument9 pagesCs Anil Piping Design ResumeANIL KUMARNo ratings yet

- Katalog Vers 2 ReprintDocument52 pagesKatalog Vers 2 ReprintfernandoNo ratings yet

- Mortar Analysis Part 3 - L SchnabelDocument4 pagesMortar Analysis Part 3 - L SchnabelSugarPOP666No ratings yet

- Peppers A2LCF GlandDocument2 pagesPeppers A2LCF GlandBob JohnsonNo ratings yet

- V5329A TWDocument4 pagesV5329A TWS M NaveedNo ratings yet

- UPVC Price List - LDocument4 pagesUPVC Price List - LPardeep Parashar100% (1)

- ELECTRICAL WIRING PLAN DemoDocument24 pagesELECTRICAL WIRING PLAN DemoTommy Dela CruzNo ratings yet

- Report Water Resources - Spillways, Crest Gates, and Outlet WorksDocument13 pagesReport Water Resources - Spillways, Crest Gates, and Outlet WorksChristian BaldoNo ratings yet

- 01 Suspension Bridge DrawingsDocument11 pages01 Suspension Bridge DrawingsNurali Mamen100% (1)

- Rain Water Harvesting Seminar Report PDFDocument16 pagesRain Water Harvesting Seminar Report PDFHarveen Sai75% (8)

- Eurocode 3 PDF ScribdDocument2 pagesEurocode 3 PDF ScribdAna0% (1)

- Rodajes Miniatura NSKDocument41 pagesRodajes Miniatura NSKenicolas2No ratings yet

- Foundation For Civil EngineeringDocument2 pagesFoundation For Civil Engineeringmudassir2640No ratings yet

- Design of Doble Angle For TrussDocument10 pagesDesign of Doble Angle For TrussUmesh ChamaraNo ratings yet

- Al Alloys Chemicals MechanicalsDocument1 pageAl Alloys Chemicals MechanicalsFactory FactoryNo ratings yet

- Conpipe - CementlingDocument43 pagesConpipe - Cementlingויליאם סן מרמיגיוס50% (2)

- FEA Basics To UploadDocument20 pagesFEA Basics To Uploadatul patilNo ratings yet

- Course Outline UpdatedDocument1 pageCourse Outline UpdatedAddisu AyeleNo ratings yet

- 4330V Nickel-Molybdenum-Vanadium Through Hardening Steel - Hillfoot Multi MetalsDocument1 page4330V Nickel-Molybdenum-Vanadium Through Hardening Steel - Hillfoot Multi MetalsidontlikeebooksNo ratings yet

- Corrigendummno 3 Withannexures Ito IVDocument72 pagesCorrigendummno 3 Withannexures Ito IVProject Manager IIT Kanpur CPWDNo ratings yet

- Powell Hydraulic Hose Catalogue Price List 2017Document20 pagesPowell Hydraulic Hose Catalogue Price List 2017Anonymous VRspXsmNo ratings yet

- L CR 002r1 PDFDocument19 pagesL CR 002r1 PDFDhakshina KNo ratings yet