Professional Documents

Culture Documents

010 - ITP For Hydro Test

Uploaded by

Sam JoseOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

010 - ITP For Hydro Test

Uploaded by

Sam JoseCopyright:

Available Formats

CLIENT CONSULTANT CONTRACTOR

EMP-TR-0163: CONSTRUCT, COMPLETE AND MAINTAIN, IN DEFECTS LIA

PERIOD, THE CHILLED WATER PIPING NETWORK AT BLUEWATERS IS

DISTRICT COOLING PROJECT

TBA

ITP for Pipe Line Hydrotesting

INSPECTION AND TEST PLAN

Inspection

REFERENCE

& Test DESCRIPTION Inspection Requirements ACCEPTANCE CRITERIA

Code DOCUMENT

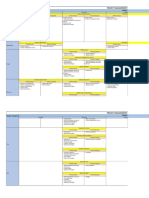

1 Submittals

1.1 Approval of Method Statement Approved Drawings Internal Review of Document before Submission Approved by Company

2 Air Blowing

1 Hrs Pnematic :leak Tightness Hold

Pneumatic Testing ,Air Blowing & Purging Pre Commissioning Checklist

Approved Drawings @ 1.5 bar

2.1 Chamber Inspection Checklist

Approved method Statement 0% DEW Point in all Lines

Pipe Line Completed ,Valve Installed, Bolt Tighten

No Leaks

3 Water Filling

Sweet water

sweet water Ensure all high point air

Approved Drawings Flow Meter reading

3.1 Filing of water in to the Pipe Line vents are open and all low points

Approved method Statement Allow the pressure to stabilize and carry

drains are closed.

out a visual inspection of all joints.

Air relased from the Line Ensure all

Approved Drawings

3.2 Water Filling and Venting G Venting of whole line high point air vents are open and all

Approved method Statement

low points drains are closed.

4 HydroTest

MSP051-PRC-002-PLN-001 1st Issue Dated 16/06/2013

CLIENT CONSULTANT CONTRACTOR

EMP-TR-0163: CONSTRUCT, COMPLETE AND MAINTAIN, IN DEFECTS LIA

PERIOD, THE CHILLED WATER PIPING NETWORK AT BLUEWATERS IS

DISTRICT COOLING PROJECT

TBA

ITP for Pipe Line Hydrotesting

INSPECTION AND TEST PLAN

Inspection

REFERENCE

& Test DESCRIPTION Inspection Requirements ACCEPTANCE CRITERIA

Code DOCUMENT

10 Bar Visual inspection shall occur

Approved Drawings

4.1 Pressurizing the Line on all pipe joints to ensure no

Approved method Statement 1.5 times of working Pressure

leakage

No Leaks and Pressure Drop

Approved Drawings

4.2 Hydro test 1.5 times of working Pressure -10 Bar Visual inspection shall occur on all

Approved Method Statement

pipe joints to ensure no leakage

5 Close out of ITP

All test code inspection & testing

5.1 ITP close out Registers Internal Review of Document before Submission

completed as per defined frequency

W - Witness: notified of the time & place of inspection or test and attend or witness the activity

H - Hold Point: notified of the time & place of inspection or test in order to inspect the activity

R- Review: review relevant documents and quality records

DEFINITIONS

A- Approval: relevant documents or test results shall be approved

I - Inspection: Inspect the activity

M- Monitoring: visit any work to inspect the activity during the process

Prepared by Arvind Pai, QA/QC Engineer

MSP051-PRC-002-PLN-001 1st Issue Dated 16/06/2013

COMPLETE AND MAINTAIN, IN DEFECTS LIABILITY Doc.No: 1396-ITP-010

ATER PIPING NETWORK AT BLUEWATERS ISLAND

TRICT COOLING PROJECT

Revision : 00

or Pipe Line Hydrotesting Pages : 3

CTION AND TEST PLAN Title: Pipeline Hydrotesting

FREQUENCY OF INSP. / VERIFYING Overseas Overseas

Consultant EMPOWER

TEST DOCUMENT AST S/C AST

Once before the work starts and Approved Method Statement

H H R&A R&A

revisions if required Method Statement register

Whole Line Pneumatic Test report NA H I&A I&A

Whole Line Approved Request for H H I&A A

Inspection

All Vent Chambers Physical Inspection H H W&A A

MSP051-PRC-002-PLN-001 1st Issue Dated 16/06/2013

COMPLETE AND MAINTAIN, IN DEFECTS LIABILITY Doc.No: 1396-ITP-010

ATER PIPING NETWORK AT BLUEWATERS ISLAND

TRICT COOLING PROJECT

Revision : 00

or Pipe Line Hydrotesting Pages : 3

CTION AND TEST PLAN Title: Pipeline Hydrotesting

FREQUENCY OF INSP. / VERIFYING Overseas Overseas

Consultant EMPOWER

TEST DOCUMENT AST S/C AST

Pressure test Chart

Whole Line H H I&A I&A

Pressure Test report

Pressure test Chart

Whole Line H H I&A I&A

Pressure Test report

Check sheets &

Each code to verify H H R&A R&A

Registers/Reports

Approved BY

MSP051-PRC-002-PLN-001 1st Issue Dated 16/06/2013

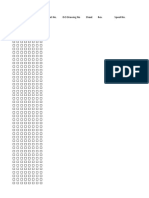

HYDROTESTING - CHECKLIST

EMP-TR-0163: CONSTRUCT, COMPLETE AND MAINTAIN, IN DEFECTS LIABILITY PERIOD, THE CHILLED

Project Name: WATER PIPING NETWORK AT BLUEWATERS ISLAND DISTRICT COOLING PROJECT ITR No.:

Consultant Ref. ITP: 1396-ITP-010

Client: ITP Test Code:

Main Contractor Date:

Sub Contractor:

Location:

Inspection Party

Item

Main Activity Acceptance Criteria AST - AST - Remarks

No. AST -QA/QC Consultant EMPOWER

Foreman Engineer

Ensure that the material inward

inspection is completed and approved for

1.0 Approved Material inward

Pipes and Fittings ( free issued by

inspection

Empower) .

2.0 Ensure Approved Shop drawing is used. Approved Shop drawing

Is Method Statement / ITP / Risk

Approved Submittals

3.0 Assessment approved and being followed

Briefing Card

and briefed.

Ensure Pnuematic test caried out and No pressure drop /Leaks in

4.0

Approved the Pipeline

Ensure Only Sweet water is Filled in the

5.0 DEWA Drinking Water

pipeline

Visual inspection of Water

6.0 Ensure Water is Fully Filled in the Line

overflow on Open Vents

Visual inspection of Water

7.0 Ensure all air enterapments Relased overflow without air onOpen

Vents

Allow the pressure to

The system pressure shall be increased stabilize and carry

8.0

initially to 5 bar out a visual inspection of all

joints.

Carry

Continue to increase pressure slowly by 2

9.0 out a visual inspection of all

bar at every 30 minutes.

joints.No leaks

Ensure the pressure reached for Monitor Pressure gauge

10.0

HydroTesting reading every half an hour

Monitor Pressure gauge

11.0 Pressure hold for Six hours

reading every half an hour

12.0 Pressure Reading for Six Hours No Pressure Drop

Ensure Hydrotest Completed and Signed

13.0 Accepted HydroTest report

by Client/Consultant

14.0 Release for Flushing . Accepted HydroTest report

Overseas AST Engineer/Foreman Overseas AST QA/QC Engineer Consultant EMPOWER

Name & Signature Name & Signature Name & Signature Name & Signature

1396-ITP010-FORM/01

You might also like

- Piping Pressure Test, Flushing & Air Blowing ProcedureDocument17 pagesPiping Pressure Test, Flushing & Air Blowing Proceduresoumaya yahyaoui100% (8)

- Contract Administration 1st Edition RicsDocument36 pagesContract Administration 1st Edition RicsNuwantha UduwageNo ratings yet

- ITP For Structural Steel WorkDocument3 pagesITP For Structural Steel WorkAbdullah Al JubayerNo ratings yet

- ITP For Pipeline Construction Table 1Document3 pagesITP For Pipeline Construction Table 1wahyu100% (2)

- Itp For InsulationDocument14 pagesItp For InsulationHytham El-NoubyNo ratings yet

- Inspection and Test Plan For Piping (PP/FRP Piping)Document2 pagesInspection and Test Plan For Piping (PP/FRP Piping)Anonymous EyK4vt6Y100% (1)

- QUALITY ASSURANCE PROTOCOLDocument2 pagesQUALITY ASSURANCE PROTOCOLShah Newaz KabirNo ratings yet

- 1.13 Inspection & Test PlansDocument1 page1.13 Inspection & Test Plansabimanyubawono100% (2)

- Piping Reinstatement: Inspection Test Report Form NoDocument2 pagesPiping Reinstatement: Inspection Test Report Form NoFrancisco75% (4)

- Inspection & Test Plan for HVAC Duct InstallationDocument1 pageInspection & Test Plan for HVAC Duct InstallationDong VanraNo ratings yet

- DSM-xxx-0xxx-xx, Checklist For HDPE Piping InstallationDocument1 pageDSM-xxx-0xxx-xx, Checklist For HDPE Piping Installationkadir tanzania100% (4)

- ESR00550 - Cold Field Bending-revBDocument12 pagesESR00550 - Cold Field Bending-revBSam Jose67% (3)

- Inspector General's Report On Chicago's Buildings DepartmentDocument43 pagesInspector General's Report On Chicago's Buildings DepartmentMitch ArmentroutNo ratings yet

- COP of Safe Use of Mobile CraneDocument9 pagesCOP of Safe Use of Mobile Cranekhabbab hussainNo ratings yet

- INSPECTION & TEST PLAN FOR FLUE GAS AND AIR DUCTSDocument1 pageINSPECTION & TEST PLAN FOR FLUE GAS AND AIR DUCTStreyNo ratings yet

- ITP-P-001 ITP For Above Ground Piping Rev. ADocument9 pagesITP-P-001 ITP For Above Ground Piping Rev. APhong Đỗ100% (1)

- 08572-Trht-Egcb-Qc-Aq-012 Itp - Pipeline Construction Rev0 PDFDocument34 pages08572-Trht-Egcb-Qc-Aq-012 Itp - Pipeline Construction Rev0 PDFbelhaska100% (2)

- WPS - Smaw - 2Document6 pagesWPS - Smaw - 2Harkesh RajputNo ratings yet

- ITP - (Pressure Testing Piping) PDFDocument3 pagesITP - (Pressure Testing Piping) PDFSUNNY BOSS100% (1)

- UG PIPING COATINGDocument10 pagesUG PIPING COATINGcloud23No ratings yet

- Steel TankDocument4 pagesSteel TankRanu JanuarNo ratings yet

- Hindustan Petroleum Standard Piping Inspection Test PlanDocument6 pagesHindustan Petroleum Standard Piping Inspection Test Planمحمد أزها نو الدينNo ratings yet

- Itp For Ug PipelineDocument3 pagesItp For Ug PipelineJustin Alwar100% (1)

- Test Pack Format: Contents of Hydrostatic Test PackagesDocument2 pagesTest Pack Format: Contents of Hydrostatic Test PackagesmiteshNo ratings yet

- Hydrostatic Test Report SummaryDocument1 pageHydrostatic Test Report SummaryCipta AdikaryaNo ratings yet

- Duties of Tank InspectorDocument1 pageDuties of Tank InspectorJawed AlamNo ratings yet

- 30-99!90!1619-Rev.0-Method Statement For Pipeline WeldingDocument21 pages30-99!90!1619-Rev.0-Method Statement For Pipeline WeldingkilioNo ratings yet

- ARCC Hydrotest Packages Summary ReportDocument4 pagesARCC Hydrotest Packages Summary ReportSiddiqui Abdul KhaliqNo ratings yet

- 2.FIT-UP & 3. Welding ReportDocument2 pages2.FIT-UP & 3. Welding Reportkhurshid alam Khan100% (1)

- ITP SampleDocument2 pagesITP Sampleeiman_zerep50% (2)

- Inspection, Flushing & Testing of Piping-21Document6 pagesInspection, Flushing & Testing of Piping-21Saurabh Kumar VermaNo ratings yet

- ITP For Flow MeterDocument4 pagesITP For Flow MeterSayee KrishnanNo ratings yet

- Itp PipingDocument4 pagesItp PipingkennethNo ratings yet

- Tins-Gen-Itp-M-001 To 005-r00 - Mechanical Works (Logo 2)Document4 pagesTins-Gen-Itp-M-001 To 005-r00 - Mechanical Works (Logo 2)achusanachuNo ratings yet

- Site Inspection Test PlanDocument24 pagesSite Inspection Test Planprabu palaniswamyNo ratings yet

- AGC-TR-414 (Revised Tie-In Package For 4'' - KALCIP-TR-510)Document49 pagesAGC-TR-414 (Revised Tie-In Package For 4'' - KALCIP-TR-510)Dilshad Ahemad100% (2)

- Itp For Piping QPDocument4 pagesItp For Piping QPRejoy baby100% (2)

- Material Inspection Report: Project Name Date InspDocument22 pagesMaterial Inspection Report: Project Name Date InspRafiqKuNo ratings yet

- ItpDocument7 pagesItpJose Sherin100% (1)

- Hydrotest Procedure For PipingDocument4 pagesHydrotest Procedure For Pipingsuria qaqcNo ratings yet

- Inspection & Test Plan for Chilled Water Expansion TanksDocument1 pageInspection & Test Plan for Chilled Water Expansion TanksvictorNo ratings yet

- Welding Procedure Specification For Storage Tank & Piping SystemDocument3 pagesWelding Procedure Specification For Storage Tank & Piping SystemAhmad MohammadNo ratings yet

- Piping Fabrication Installation QCP On SiteDocument1 pagePiping Fabrication Installation QCP On SiteTarun PatelNo ratings yet

- Pt-bm-g00-Dc-00101 Inspection and Test Plan For Piping Fabriction and ErectionDocument5 pagesPt-bm-g00-Dc-00101 Inspection and Test Plan For Piping Fabriction and Erectioneldobie3100% (1)

- WELD SUMMARY TRACKINGDocument30 pagesWELD SUMMARY TRACKINGThamaraikani Mani100% (1)

- Ayari Maher: Qualified Welder I.D.CardDocument10 pagesAyari Maher: Qualified Welder I.D.CardZouhair BenmabroukNo ratings yet

- ITP For Steel Structure1Document3 pagesITP For Steel Structure1吴兴泊No ratings yet

- Hydrotest Procedure for Reinforced Thermosetting Epoxy-Resin PipesDocument13 pagesHydrotest Procedure for Reinforced Thermosetting Epoxy-Resin PipesMohammad Rizwan0% (1)

- F07-Visual Inspection Report NEWDocument1 pageF07-Visual Inspection Report NEWmohd as shahiddin jafriNo ratings yet

- Hydrotest QI304-sampleDocument3 pagesHydrotest QI304-sampleHanuman Rao100% (1)

- Wps For Smaw06-001 (Pipe 6g CS)Document10 pagesWps For Smaw06-001 (Pipe 6g CS)walitedisonNo ratings yet

- Itr Ew 01a - EngDocument2 pagesItr Ew 01a - Engwassim nasriNo ratings yet

- Vacuum Box Testing ProcedureDocument6 pagesVacuum Box Testing ProcedureKandula Raju100% (1)

- Larsen & Toubro underground piping inspection planDocument4 pagesLarsen & Toubro underground piping inspection planBhavani PrasadNo ratings yet

- Inspection Test Plan (Itp) at Shop: Remark No DescriptionDocument2 pagesInspection Test Plan (Itp) at Shop: Remark No Descriptionanang_pri100% (1)

- Itp - Tanks - 01Document10 pagesItp - Tanks - 01ravigurajapuNo ratings yet

- Fit Up Report Format-1Document1 pageFit Up Report Format-1BalkishanDyavanapellyNo ratings yet

- SA04C2-T-MET-AAG-00037 Hydrotest Method StatementDocument25 pagesSA04C2-T-MET-AAG-00037 Hydrotest Method StatementABAID ULLAH100% (2)

- NRP QapDocument10 pagesNRP QapKevin Mathew100% (1)

- JIMT Fire Fighting System Pre Commissioning Punch List (Piping)Document9 pagesJIMT Fire Fighting System Pre Commissioning Punch List (Piping)Gomathyselvi100% (1)

- 0.hydro Test Package Index - 1Document13 pages0.hydro Test Package Index - 1VISHNUPRASAD ARAKKAL MOHANDASNo ratings yet

- Method Statement For CPFII Pipe Cleaning&Flushing With Air Works Rev1Document9 pagesMethod Statement For CPFII Pipe Cleaning&Flushing With Air Works Rev1Delil OzanNo ratings yet

- 022 Itp For Fence Gate PDFDocument5 pages022 Itp For Fence Gate PDFJithesh.k.sNo ratings yet

- DSM-xxx-0xxx-xx, Checklist For HDPE Piping InstallationDocument1 pageDSM-xxx-0xxx-xx, Checklist For HDPE Piping Installationkadir tanzaniaNo ratings yet

- Hydrostatic and Pneumatic TestingDocument32 pagesHydrostatic and Pneumatic TestingRahmat BasukiNo ratings yet

- Managing Safely v5 Course SyllabusDocument5 pagesManaging Safely v5 Course SyllabusMohammad AshrafNo ratings yet

- SQF 681 Rev 004 Internal Audit Checklist Project ManagementDocument6 pagesSQF 681 Rev 004 Internal Audit Checklist Project ManagementSam JoseNo ratings yet

- Managing Safely v5 Course SyllabusDocument5 pagesManaging Safely v5 Course SyllabusMohammad AshrafNo ratings yet

- SQF 681 Rev 004 Internal Audit Checklist Project ManagementDocument6 pagesSQF 681 Rev 004 Internal Audit Checklist Project ManagementSam JoseNo ratings yet

- Joint Welder ID1 Welder ID2 DD MX TV 1Document1 pageJoint Welder ID1 Welder ID2 DD MX TV 1Sam JoseNo ratings yet

- Guideline To Machinery Directive 2006 - 42 - ECDocument457 pagesGuideline To Machinery Directive 2006 - 42 - ECSam JoseNo ratings yet

- Job Description For Hse AdvisorDocument2 pagesJob Description For Hse AdvisorSam JoseNo ratings yet

- Welcome To WordDocument8 pagesWelcome To WordMuhammad FajriNo ratings yet

- Study Guide: Course: IOSH Managing Safely Recommended Study Hours: 18 HoursDocument2 pagesStudy Guide: Course: IOSH Managing Safely Recommended Study Hours: 18 HoursRiyaz Ur Rahaman CiNo ratings yet

- Project management process overviewDocument6 pagesProject management process overviewSam JoseNo ratings yet

- Management ChartDocument1 pageManagement ChartSam JoseNo ratings yet

- Internal Audit ReportDocument21 pagesInternal Audit ReportSam JoseNo ratings yet

- Alcohol Textbook 4th EdDocument448 pagesAlcohol Textbook 4th Edres06suc94% (16)

- Alcohol Textbook 4th EdDocument448 pagesAlcohol Textbook 4th Edres06suc94% (16)

- Weld Details For QsDocument1 pageWeld Details For QsSam JoseNo ratings yet

- Accepted With Comments: By: Aneeshraj Baburaj Santhamma (ABS) Date: January 29, 2018Document12 pagesAccepted With Comments: By: Aneeshraj Baburaj Santhamma (ABS) Date: January 29, 2018Sam JoseNo ratings yet

- CV Spirited GuideDocument41 pagesCV Spirited GuideSam JoseNo ratings yet

- File 1493039491Document36 pagesFile 1493039491Sam JoseNo ratings yet

- 20mm Plate MTCDocument2 pages20mm Plate MTCSam JoseNo ratings yet

- Yemen Crisis FinalDocument5 pagesYemen Crisis FinalSam JoseNo ratings yet

- Paint system for above ground pipe field weldsDocument2 pagesPaint system for above ground pipe field weldsSam JoseNo ratings yet

- API Specification Seat TestDocument3 pagesAPI Specification Seat TestSam JoseNo ratings yet

- To Do List For Projects1Document3 pagesTo Do List For Projects1Sam JoseNo ratings yet

- Joint No. ISO Drawing No Sheet Rev. Spool NoDocument9 pagesJoint No. ISO Drawing No Sheet Rev. Spool NoSam JoseNo ratings yet

- Fit-up, welding, and inspection report templateDocument9 pagesFit-up, welding, and inspection report templateSam JoseNo ratings yet

- Bending Procedure (3.2°)Document1 pageBending Procedure (3.2°)Sam JoseNo ratings yet

- TCG 0394 DT Aga 001Document3 pagesTCG 0394 DT Aga 001Sam JoseNo ratings yet

- AE-QA-01 - Incoming Inspection ReportDocument1 pageAE-QA-01 - Incoming Inspection ReportKarthi ThiyagarajanNo ratings yet

- KMM Suplier Quality Manual 2018Document23 pagesKMM Suplier Quality Manual 2018Jesus Cardona RezaNo ratings yet

- Quality Control PlanDocument7 pagesQuality Control PlaneliiiiiiNo ratings yet

- Sap - Quality Management With Real Time ExampleDocument10 pagesSap - Quality Management With Real Time ExampleJagadish JaganNo ratings yet

- 1662969136979-1PR009208 SowDocument14 pages1662969136979-1PR009208 SowNithin MathaiNo ratings yet

- Experienced Site Engineer Seeking New OpportunitiesDocument3 pagesExperienced Site Engineer Seeking New OpportunitiesShergul KhanNo ratings yet

- SIRE Inspection Preparation DocumentDocument4 pagesSIRE Inspection Preparation DocumentBacker Muhammed100% (1)

- Flow Chart of Garments Manufacturing Process / Technology:: Pattern MakingDocument3 pagesFlow Chart of Garments Manufacturing Process / Technology:: Pattern MakingMohammed ĹukmanNo ratings yet

- Hydrotest Test FormatDocument27 pagesHydrotest Test FormatRähûl Prätäp SïnghNo ratings yet

- 23-063-HENAKIYAH-CTC Offer - (17.04.2023)Document7 pages23-063-HENAKIYAH-CTC Offer - (17.04.2023)WORK WORKNo ratings yet

- Inoculation and HarvestingwebDocument7 pagesInoculation and HarvestingwebLeBinhNo ratings yet

- Weld Quality: Level 1-Chap 6Document102 pagesWeld Quality: Level 1-Chap 6joehodohNo ratings yet

- SPJ S1Document63 pagesSPJ S1SUHAIMINo ratings yet

- The Propose of Training Program For Welding Inspectors 2021Document5 pagesThe Propose of Training Program For Welding Inspectors 2021adelNo ratings yet

- Iso 3834-2Document16 pagesIso 3834-2NONNE NaineNo ratings yet

- Mil DTL 15024GDocument15 pagesMil DTL 15024GLogo SkyNo ratings yet

- 2.method Statement For Installation of Cable Tray & Cable LayingDocument14 pages2.method Statement For Installation of Cable Tray & Cable LayingMD AbdullahNo ratings yet

- POCKET GUIDE - Wire Rope For Oil FieldDocument2 pagesPOCKET GUIDE - Wire Rope For Oil Field刘 建No ratings yet

- Materials Inspection ManualDocument280 pagesMaterials Inspection ManualSreedhar Patnaik.MNo ratings yet

- Mil PRF 5606hDocument25 pagesMil PRF 5606hApanreza VitalyNo ratings yet

- Incoming Goods Inspection ChecklistDocument4 pagesIncoming Goods Inspection ChecklistRiyu RathodNo ratings yet

- Tripode VortexDocument69 pagesTripode VortexALEJANDRANo ratings yet

- Performance Measurement & MonitoringDocument7 pagesPerformance Measurement & MonitoringvladNo ratings yet

- Activity Hazard AnalysisDocument23 pagesActivity Hazard AnalysisHari UtamaNo ratings yet

- Is 802Document16 pagesIs 802Sourav DeyNo ratings yet

- Ahsan Rasheed Resume CB 15 Jan 021Document6 pagesAhsan Rasheed Resume CB 15 Jan 021Ahsan RasheedNo ratings yet

- Comments : 437AL, 438AR, 451AL, 452AR 460Document9 pagesComments : 437AL, 438AR, 451AL, 452AR 460Suman BajracharyaNo ratings yet