Professional Documents

Culture Documents

Design and Analysis of Pre Engineered in PDF

Uploaded by

ShashankSinghOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Design and Analysis of Pre Engineered in PDF

Uploaded by

ShashankSinghCopyright:

Available Formats

International Journal of Applied Sciences, Engineering and Management

ISSN 2320 – 3439, Vol. 03, No. 06, November 2014, pp. 26 – 29

Design and Analysis of Pre Engineered Industrial Buildings (PEB)

A. SRAVAN KUMAR1, SANJEEV RAO2, MADAN MOHAN3, DR. SREENATHA REDDY4

1

M. Tech Structural Engineering, Department of Civil Engineering, Guru Nanak Institute of Technology, JNTU, Hyderabad.

2

Professor, Department of Civil Engineering, Guru Nanak Institute of Technology, JNTU, Hyderabad.

3

Professor, Department of Civil Engineering, Guru Nanak Institute of Technology, JNTU, Hyderabad.

4

Principal, Guru Nanak Institute of Technology, JNTU, Hyderabad.

Abstract: Pre-engineeredbuildings (PEB) is the concept of steel structures introduce in early 1960’s the structure here uses

entire I sections and the beauty here in this concept is no welding process will be carried out in site entire structure will be

Designed and manufactured in shop and this will be brought to sit and assembles, the entire sectional properties will depends

just upon the moments at that specific locations so there won’t be any excess steel used in the thus it is economical. Here I

am designing such a PEB building by selecting a real time project consisting a 69m wide and 173m length textile building by

IS 800-2007 Design code using STAAD Pro and explaining its each and every parameters and design and detailing

procedures.

Keywords: Pre-Engineered-Buildings, IS: 800-2007.

INTRODUCTION TABLE 1

Pre engineering buildings are generally used for the Structure Configuration Details

Industries airports, Hanger building, power plants what not,

almost all the sectors where the conventional steel structures Location : Ahmedabad, India.

are used to be there the half portions of such buildings are Length : 173 m

replaced by these PEB’s. These PEB buildings can be Width : 67 m

constructed with all the requirement like cranes different Eave height : 6m (clear)

level floors and can be constructed up to higher heights. Bay spacing : 19 @ 8.0m C/C + 2 @

There are quite pretty uses with these structures we can go 10.5m C/C

up to higher clear spans horizontally and vertically. It is easy End Wall column : 2 @ 7.0m C/C + 1 @

in point of manufacturing and erection. As the entire spacing 9.5m C/C + 7 @ 6.5m

sections are built up sections the required thick plates as per C/C

design will be cut and welded to the design sectional Seismic zone : III

dimensions there will a max of 12m length pieces because Wind speed : 39 m/sec

of transportation restraint. These pieces will be brought to Wind terrain : 2

the site and connected with nut and bolt mechanism. Thus category

even the manufacturing process is easy when compared to Wind Class : C

regular conventional structures as in those buildings entire Life Span : 50 years

manufacturing i.e. welding process goes on site as it is so Slope of roof : 1:10

time taking and hazardous. Soil type : Medium

Importance factor : 1

I. Structure Configuration Response reduction : 5

factor

The structure which I considered now is a textile plant Purlin spacing : 1500 mm

located in Ahmedabad having its dimensions as 173m length Girt spacing : 1800 mm

and 67m width having a clear height of 6m with 2 no. of

internal column which is at a distance of 1 @ 14m C/C + 1

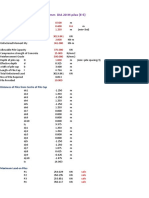

@ 29m C/C + 1 @ 26m C/C. As the building in Ahmedabad TABLE 2

is falls under seismic zone-III with a wind speed of 39m/s Calculation of Dead Load

i.e. 140Kmph. As the structure is having some irregular

intermediate column spacing the structure won’t be Sheeting unit : 4.44kg/m2(0.5mm Total Coat

symmetric to its ridge. The details of parameters are weight Thick(TCT) galvanized sheet)

provided in table 1 : 4.71 kg/m(spacing of purlin =

1.5m)

Purlin wt.

: 4.71/1.5

II. Dead Load Calculation : 3.14 kg/m2

Dear load consists of self-weight of the frame weight of : 1.2 kg/m

sheeting, weight of purlins, Sag angles and additional Sag rods wt.

components like insula : 1.2/1.5 :0.8 kg/m2

tion, Roof liners etc. if present Dead load considerations Insulation

: 1.6 kg/m2

are as per the IS:875 part 1. The loading calculation is as per material wt.

the table 2 : 4.44 + 3.14 + 0.8 + 1.6

Dead load

: 10kg/m2 : 0.1 KN/m2

IJAEM 030602 Copyright @ 2014 SRC. All rights reserved.

A. Sravan Kumar, Sanjeev Rao, Madan Mohan, Dr. Sreenatha Reddy

III. Live Load Calculation

Live load is considered as per the IS: 875 part 2. And as

per the code IS: 875 part 2 the live load of anon-accessible

roof will be 75 kg/sqm i.e. 0.75kN/Sqm.

IV. Wind Load Calculation

Wind pressure calculation is done as per IS: 875part-2.

After once we arrive the wind pressure the pressure

coefficients of roof and wall are from table 4 and table 5

from IS 875 part 3 those parameters are as follows in Fig. 1 Main frame

Table3.

TABLE 3

Calculation of Wind Load

Wind speed

: 39 m/sec

(Vb)

Risk coefficient

:1

(K1)

Probability factor (K2) : 0.93

Topography factor

: 1.0

(K3)

: K1*K2*K3*Vb

Design wind speed

: 1*0.93*1*39

(VZ)

: 36.27 m/sec

:0.6*(Vz)2

Design wind pressure : 0.6*36.272

(PZ) : 789.3 N/m2 Fig. 2 Internal frame with changedwidth

: 0.789 KN/m2

V. Pre-Engineered Buildings by STAAD Pro

Structural Analysis and Design program (STAAD) is the

most popular structural engineering software which is

widely used for design of both Reinforced Concrete

Structures and all kinds of steel structures. This software is

developed by Bentley Corporation. This tool helps us to

design the entire structure in 2 Dimensional format or the

entire structure can be done in 3 Dimensional format. It is

equipped with almost all the renowned codes globally. To

design this building we need to do is modeling the structure

with tentative section properties applying load to it and

assigning the required design parameters then the structure

will be analyzed by stiffness matrix method. Then this

analysis will give the result of its stress ratios i.e. actual /

allowable stress ratios and moments of each members and

the deflections the members going, by observing the ratios

and the moments it’s having we can assign the section

properties accordingly. Thus this program will be reducing

the time consumption and that is how it has become a most Fig. 3 End frame with wind columns

adorable software all over.

VII. Load Combinations

VI. Drawings Load combinations include different combinations of

Following drawings includes drawings of frames which loads according to different codes (AISC-89/MBMA-86,

are selected for analysis IS800-1984, IS800-2007) by considering serviceability and

strength criteria as follows in TableV [4]-[7].

International Journal of Applied Sciences, Engineering and Management

ISSN 2320 – 3439, Vol. 03, No. 06, November 2014, pp. 26 – 29

Design and Analysis of Pre Engineered Industrial Buildings (PEB)

TABLE 4

Load Combinations According to Different Codes VIII. Design Specifications

IS 800-2007

Serviceability Combinations: These design specifications includes the limiting ratios of

(DL+LL) the sections i.e. like web depth/ web thickness, flange width /

(DL+WL/EL) flange thickness. The class selection will be depended upon

(DL+LL+CL) the seismic zone and building importance factor accordance to

(DL+0.8*LL+0.8*WL/EL+0.8*CL) that the class selection will be done.

Design combinations:

1.5*(DL+LL)

1.5*(DL+WL/EL)

(0.9*DL+1.5 WL/EL)

(1.5*DL+1.5*LL+1.05*CL)

(1.5*DL+1.05*LL+1.5*CL)

(1.2*DL+1.2*LL+0.6*WL/EL+1.05*CL)

(1.2*DL+1.05*LL+0.6*WL/EL+1.2*CL)

(1.2*DL+1.2*LL+1.2 *WL/EL+0.53*CL)

(1.2*DL+1.2*LL+1.2*WL/EL+0.53*CL)

TABLE 5

Limiting Width to Thickness Ratio According to IS 800 -2007-Table-2

Compression Ratio Class of section

Class 1 Class 2 Class 3(Semi-

(Plastic) (Compact) Compact)

Outstanding element of Rolled section b/tf 9.4ε 10.5ε 15.7ε

compression flange Welded section b/tf 8.4ε 9.4ε 13.6ε

Internal element of Compression due to bending b/tf 29.3ε 33.5ε 42ε

compression flange Axial compression b/tf Not applicable

Web of an I,H or box section Neutral axis at mid-depth d/tw 84ε 105ε 126ε

d/tw (84ε)/(1+r1) (105ε)/(1+r1) (126ε)/(1+2r2)

Generally If r1 is negative but ≤ 42ε but ≤ 42ε

If r1 is positive d/tw (105ε)/(1+1.5r1)

Axial compression but ≤ 42ε

d/tw Not applicable 42ε

Web of a channel d/tw 42ε 42ε 42ε

Angle, compression due to bending (Both criteria should be b/t 9.4ε 10.5ε 15.7ε

satisfied) d/t 9.4ε 10.5ε 15.7ε

Single angle, or double angles with the components separated, b/t 15.7ε

axial compression (All three criteria should be satisfied) d/t Not applicable 15.7ε

(b+d)/t 25ε

Outstanding leg of an angle in contact back-to-back in a double d/t 9.4ε 10.5ε 15.7ε

angle member

outstanding leg of an angle with its back in continuous contact d/t 9.4ε 10.5ε 15.7ε

with another component

Stem of a T-section, rolled or cut from a rolled I-or H- section D/tf 8.4ε 9.4ε 18.9ε

Circular hollow tube, including welded tube subjected to:

a) Moment D/t 42ε2 52ε2 146ε2

b) Axial compression D/t Not applicable 88ε2

NOTES

1. Elements which exceed semi-compact limits are to be taken as of slender cross-section.

2. ε= (250 /fy) 1/2.

3. The stress ratio r1 and r2are defined as:

r1 = (Actual average axial stress(negative if tensile)/(Design compressive stress of web alone)

r2 = (Actual average axial stress(negative if tensile)/(Design compressive stress of overall section)\

International Journal of Applied Sciences, Engineering and Management

ISSN 2320 – 3439, Vol. 03, No. 06, November 2014, pp. 26 – 29

A. Sravan Kumar, Sanjeev Rao, Madan Mohan, Dr. Sreenatha Reddy

TABLE 6

Deflection Limits According to IS 800-2007

S.No Description

Vertical Lateral

Main frame L/180 H/150

1 Main frame with crane (pendent) L/180 H/200

Main frame with crane (cab operated) L/180 H/400

Crane Electric<50t L/750

2

beam Electric>50t L/1000

3 Wind column H/150

4 Mezzanine beam L/240

5 Under slung crane L/750

6 Purlin L/150

7 Girt L/150

8 Primary Minimum thickness 5mm

9 Secondary Minimum thickness 2mm

IX. Considerations

1) Wind Load application as per IS 875 (Part-3) -1987 [4] Indian Standard: 800 – 2007; General Construction in

(reaffirmed 1997), internal Pressure Coefficient is Steel — Code of Practice; 3rd S Revision, New Delhi:

considered as +/-0.2. (Since %of opening<5%). BIS.

2) External column base considered as fixed support. (Sway [5] Indian Standard: 800 – 1984; Code of Practice for

is not controlling with pinned connection).Internal column General Construction, In Steel; 1st Revision, New Delhi:

base considered as fixed support. BIS.

3) Wall cover is full height sheeted all around the building. [6] Syed Firoz (2012), “Design Concept of Pre-engineered

4) Rod bracing considered for Roof and wall for longitudinal Building”, International Journal of Engineering Research

and Applications (IJERA), Vol. 2, Issue 2, 267-272.

restrainment.

[7] C. M. Meera (2013),”Pre-Engineered Building Design of

an Industrial Warehouse”, international journal of

X. Conclusion

engineering sciences & emerging technologies, volume 5,

Following are the conclusions which are observed: issue 2, pp: 75-82.

1) The structure Designed in this has consumed a final [8] Indian Standard: 807 – 1976; Code Of Practice For

weight of 590MT Design, Manufacture, Erection And Testing (Structural

2) If the structure designed here is not a PEB if it is a Portion) Of Cranes and Hoists, 1st Revision, New Delhi:

conventional the weights would have gone higher by 30% BIS.

[9] Technical Manual, Zamil Steel, Saudi Arabia, Pre-

References Engineered Buildings Division.

[10] Design Manual, Zamin Steel, Saudi Arabia.

[1] Indian Standard: 1893 (Part1); 2002. Criteria for

[11] Technical Hand Book, Kirby Building Systems-

Earthquake Resistant Design Structures: New Delhi: BIS;

INDIA.LTD.

2002.

[12] Comparison of Design procedures for Pre Engineered

[2] IS 875: Part 1 to 3 Code Of Practice For Design Loads

Buildings (PEB): A Casy study, Authors: G Sai kiran, A

(Other Than Earthquake) For Buildings and Structures,

Kailasa Rao, R. Pradeep kumar.

1st Revision, New Delhi: BIS..

[3] Indian Standard: 801 – 1975; Code Of Practice For Use

Of Cold-Formed Light Gauge Steel Structural Member’s

In General Building Construction, 1st Revision, New

Delhi: BIS.

International Journal of Applied Sciences, Engineering and Management

ISSN 2320 – 3439, Vol. 03, No. 06, November 2014, pp. 26 – 29

You might also like

- Thesis DR SureshDocument101 pagesThesis DR SureshShashankSinghNo ratings yet

- DNIT/Tender Document Name of Work: As Per List of Press Note. Index Section Description Page NoDocument25 pagesDNIT/Tender Document Name of Work: As Per List of Press Note. Index Section Description Page NoShashankSinghNo ratings yet

- Pump Foundation Design Calculations ReportDocument8 pagesPump Foundation Design Calculations ReportShashankSinghNo ratings yet

- J 217 Column Base Reactions r6Document66 pagesJ 217 Column Base Reactions r6ShashankSinghNo ratings yet

- Jowi Soil TestDocument44 pagesJowi Soil TestShashankSinghNo ratings yet

- Two Pile GroupDocument12 pagesTwo Pile GroupJammy KingNo ratings yet

- IS 1893 Part 1 - 2016 PDFDocument49 pagesIS 1893 Part 1 - 2016 PDFpoojaNo ratings yet

- Tipl 19 20 J 219 Barabanki Column Base ReactionsDocument32 pagesTipl 19 20 J 219 Barabanki Column Base ReactionsShashankSinghNo ratings yet

- Energies 12 02593 PDFDocument26 pagesEnergies 12 02593 PDFKiran 007No ratings yet

- Exceptions To ACI 318Document45 pagesExceptions To ACI 318Albert FernandezNo ratings yet

- Lumped Mass Method Example PDFDocument10 pagesLumped Mass Method Example PDFSujan GhimireNo ratings yet

- Causes and Etiological Profile of Short Stature in Pediatric PatientsDocument5 pagesCauses and Etiological Profile of Short Stature in Pediatric PatientsShashankSinghNo ratings yet

- Comparing Design Procedures for Pre-Engineered BuildingsDocument6 pagesComparing Design Procedures for Pre-Engineered BuildingsPrem KumarNo ratings yet

- Schedule of Quantity For Industrial BuildingDocument4 pagesSchedule of Quantity For Industrial BuildingShashankSinghNo ratings yet

- Column Overlap On 9TH Floor (PDF01) PDFDocument1 pageColumn Overlap On 9TH Floor (PDF01) PDFShashankSinghNo ratings yet

- Foundation Design ReportDocument5 pagesFoundation Design ReportShashankSinghNo ratings yet

- Bamboo Construction Source BookDocument99 pagesBamboo Construction Source BookDeo DoktorNo ratings yet

- Technical Bid FormatDocument4 pagesTechnical Bid FormatShashankSinghNo ratings yet

- Figure Drawing BasicsDocument23 pagesFigure Drawing BasicsBlueseagrain894% (119)

- L 183201517314Document3 pagesL 183201517314ShashankSinghNo ratings yet

- Earthquake Behaviour of BuildingsDocument268 pagesEarthquake Behaviour of BuildingsChristian PintoNo ratings yet

- Pile Cap 10 PileDocument3 pagesPile Cap 10 PileShashankSinghNo ratings yet

- Framecad Technical Gypsum Guide PDFDocument24 pagesFramecad Technical Gypsum Guide PDFShashankSinghNo ratings yet

- DETAILS OF RCC GUTTER AT+122.10m LVL. - R1Document1 pageDETAILS OF RCC GUTTER AT+122.10m LVL. - R1ShashankSinghNo ratings yet

- ΣΕΖΑΝDocument166 pagesΣΕΖΑΝanimalismsNo ratings yet

- Soil Liquefacation Check (18.11.17)Document8 pagesSoil Liquefacation Check (18.11.17)ShashankSinghNo ratings yet

- New Doc 2018-08-05 PDFDocument3 pagesNew Doc 2018-08-05 PDFShashankSinghNo ratings yet

- Ci33 1112 Pernos de AnclajeDocument10 pagesCi33 1112 Pernos de AnclajeShadin Asari ArabaniNo ratings yet

- 40M GBT DGNDocument7 pages40M GBT DGNShashankSinghNo ratings yet

- AB 01 ModelDocument1 pageAB 01 ModelShashankSinghNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Base Detector b710lpDocument4 pagesBase Detector b710lpTai KucingNo ratings yet

- CJ70Document116 pagesCJ70FlexartNo ratings yet

- JacketIngDocument28 pagesJacketIngVelmurugan Balasubramanian0% (1)

- Contractors: Company - Address - PhoneDocument2 pagesContractors: Company - Address - PhoneMohammad Anwar HossainNo ratings yet

- Jar TestDocument7 pagesJar TestWanShanuzieNo ratings yet

- OferDinamarca16feb - Graduate Talent Programme Novo NordiskDocument6 pagesOferDinamarca16feb - Graduate Talent Programme Novo NordiskClásico MovieNo ratings yet

- Hot Rolling TesisDocument284 pagesHot Rolling TesisJoselo HR100% (1)

- IRTracer 100 Brochure C103 E091Document28 pagesIRTracer 100 Brochure C103 E091Mariela VeraNo ratings yet

- Consul PDF 25777Document2 pagesConsul PDF 25777Eben OforiNo ratings yet

- Continuity Testing Procedure-Nota Utk PelajarDocument8 pagesContinuity Testing Procedure-Nota Utk PelajarFairos ZakariahNo ratings yet

- Chapter 3Document3 pagesChapter 3Quennie Dhea AdanzaNo ratings yet

- Barangay Ordinance On Open Burning 2022Document4 pagesBarangay Ordinance On Open Burning 2022Catherine Parinas100% (4)

- 60.30-069 - 1994specification For Differential PressureDocument5 pages60.30-069 - 1994specification For Differential PressurepradeepNo ratings yet

- Machine Glass Thermometers Model 32, V-Form: ApplicationsDocument5 pagesMachine Glass Thermometers Model 32, V-Form: ApplicationschauNo ratings yet

- Guided Wave and WeldingDocument44 pagesGuided Wave and Weldingharoub_nas100% (1)

- Signature Series Component Installation ManualDocument106 pagesSignature Series Component Installation Manualjavierchapa75100% (1)

- Compact Repeater 972-0RB12 3Document16 pagesCompact Repeater 972-0RB12 3Kelly Perez LopezNo ratings yet

- Paper, 49th Annual Syp, ADDocument12 pagesPaper, 49th Annual Syp, ADPhilNo ratings yet

- TERHAD document physical properties states matter identification reactionsDocument2 pagesTERHAD document physical properties states matter identification reactionsjanizanNo ratings yet

- 32316Document3 pages32316egaliNo ratings yet

- Isorod Guide SpecDocument8 pagesIsorod Guide SpecmarkicivanNo ratings yet

- Icold Committe On Cemented Materail Dams Rock-Filled Concrete DamsDocument123 pagesIcold Committe On Cemented Materail Dams Rock-Filled Concrete DamsMarcelo ProtzNo ratings yet

- Annexure C Cost EstimateDocument35 pagesAnnexure C Cost EstimateAnonymous WaXq9sYSQNo ratings yet

- Automated Guided Vehicle Systems: Style and FunctionDocument16 pagesAutomated Guided Vehicle Systems: Style and FunctionJayant DeshmukhNo ratings yet

- Safety and Handling of Organic PeroxidesDocument26 pagesSafety and Handling of Organic PeroxidesМаксим ХилоNo ratings yet

- Ropaque™ Ultra E: Technical Data Sheet For Europe, Middle East and AfricaDocument3 pagesRopaque™ Ultra E: Technical Data Sheet For Europe, Middle East and AfricahongducxxxNo ratings yet

- Multi-point fastening system for bottom-hung windowsDocument8 pagesMulti-point fastening system for bottom-hung windowsna1111No ratings yet

- A Review of The Present and Future Utilisation of FRP Composites in The Civil Infrastructure With Reference To Their Important In-Service PropertiesDocument27 pagesA Review of The Present and Future Utilisation of FRP Composites in The Civil Infrastructure With Reference To Their Important In-Service PropertiesalbertofgvNo ratings yet

- Catalogo de Filtros Separador de Aire (Parker)Document112 pagesCatalogo de Filtros Separador de Aire (Parker)Mikel1020No ratings yet