Professional Documents

Culture Documents

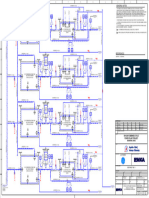

Alberta Infrastructure and Transportation Standard F Shape Barrier

Uploaded by

tylerlhsmithOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Alberta Infrastructure and Transportation Standard F Shape Barrier

Uploaded by

tylerlhsmithCopyright:

Available Formats

General Notes:

1. The barrier is based on a design that has been crash tested and meets

the requirements of NCHRP Test Level 3. The following deflecton

76 211 211 225 665 224 665 225 211 211 76 information is provided for guidance on the use of this barrier:

R2 60 200 125

5 A B

2000 kg pick-up truck test @ 100kph @ 25° Approx deflection

Unanchored 1800 mm

190

2-A1001G A1501G

76 152

APPENDIX B4

13x76x76mm Four 25 mm diameter by 1m long steel dowels

153

per segment driven through holes provided 75 mm

555

Square Washer (A36M)

102mm Ø A1001G

28mm Ø A1002G Three 19 diameter anchor bolts c/w drop-in 900 mm (anchor

810

432

SLEEVE

432

A307 Anchor Bolt R2

25 anchors in concrete slab on traffic side failure is expected)

w/Heavy Hex Nut Three 28 diameter A307 fully developed tension 300 mm (deflection

102

356

A1004G

76

32mm Ø x 90mm anchor bolts on traffic side on top edge only)

180

40

Slotted Hole

150

When using this barrier, it is the responsibility of the user to ensure

Bolt on Traffic Side 180 A1003G A1003G appropriate deflection room or anchoring commensurate with the risks

75

112

when required (see 648 (TYP) 305 305 305 based on traffic and site conditions.

75 50 general notes #1) 210

3000 Materials:

570 1. Reinforcing bars – Grade 400W.

See DETAIL "P" 2. 19 mm diameter loop bars – Minimum yield 420 MPa, minimum tensile

END VIEW ELEVATION VIEW strength 550 MPa, minimum 14% elongation in 203 mm, pass a 180

OPTIONAL ANCHOR BOLTS degree bend test using a 3.5D bend diameter.

3. 32 mm diameter pin – ASTM A36.

(Traffic Side Only) 4. All reinforcing bars and steel hardware to be hot-dip galvanized after

fabrication to the requirements of CSA G164.

610 890 890 610 5. Concrete strength shall be 40 MPa @ 28 days, and all requirements

of Section 7 -Precast Concrete Units of the Specifications for Bridge

Construction shall be met.

Handling and installation:

1. At no time shall the barriers be lifted, moved, etc. by the use of the

68

68

loop bars at the ends.

Cl

50

570 2. For barriers placed on a paved surface, all loose dirt and sand shall

be removed from the roadway just prior to placement of the barriers.

223

223

Barriers can also be placed on a compacted base material with a

minimum thickness of 150 mm and a minimum width of 1.2 m.

50 3. Calculated mass of one segment = 1.8 tonnes

Cl 102 (TYP) 32mm Ø x 90mm Slotted Hole (TYP)

222

222

810

810

86E3 (TYP)

in 102 Long Pocket BAR LIST : 3000 SEGMENT

PLAN VIEW Mark Size Shape No. Length Mass

See DETAIL "R"

222

222

NOTE: Remaining rebars are omitted for clarity A1001G 10 18 1820 26.0

Cl

50

50 122 50

102 A2001G 20 6 898 13.0

75

75

90 168 A1501G 15 1 2900 5.0

50

Cl

570 570 A1002G 10 4 2900 9.1

25

A1003G 10 4 790 2.0

75

A SECTION B SECTION D=102

A1004G 10 2 510 1.0

471

P LIFTING SLOT DETAIL

TOTAL Kg 55.0

710

R SLOTTED HOLE DETAIL ( 25mm Chamfer to prevent spalling)

SET WITH 92mm

0

13

WOODEN BLOCK

876 64

11

1

64

B1903G 6 D=76mm

114

406

13

394

305

B1901G 64 Vertical Stirrups

Approved:

BD1902G Top Plate A1001G Original signed by

838 Allan Kwan

857

711

35mm Ø Hole Executive Director,

102

Centred on Plate Technical Standards Branch

ELEVATION D=165 INFRASTRUCTURE AND

TRANSPORTATION

32mm Ø Date: NOVEMBER 23, 2004

205

108

D=70mm

13mm TOP PLATE DETAIL

25

For connection pin 406

PLAN 10mm & Retainer Hole

details see Detail "Q"

Retainer Bolt Optional A2001G

LOOP BAR ASSEMBLY

DETAILS OF BARRIER CONNECTION Q CONNECTION PIN DETAIL

Material as stated in General Notes

H-APP-B4-1

Prepared Checked Scale: Dwg No.:

By: M.T By: R.Y N.T.S. CB6 4.2 M 16

You might also like

- Sheet 3 03252019Document1 pageSheet 3 03252019Brylle De GuzmanNo ratings yet

- SI 5NB0A 001 00 Eng - v1 - m56577569830747488Document1 pageSI 5NB0A 001 00 Eng - v1 - m56577569830747488brassoyNo ratings yet

- Instructions and Cautions For Safe Use of AC Servos: General-Purpose AC Servo CautionDocument1 pageInstructions and Cautions For Safe Use of AC Servos: General-Purpose AC Servo CautiontadyNo ratings yet

- Reaffirmed 2004Document11 pagesReaffirmed 2004krixotNo ratings yet

- 01.MBT-RCC OHT-5 Lakh-DK-Model PDFDocument1 page01.MBT-RCC OHT-5 Lakh-DK-Model PDFArun NesamNo ratings yet

- Section of Pier: 42-25 MM Ø BarsDocument1 pageSection of Pier: 42-25 MM Ø Barsshekhar Nath chapagainNo ratings yet

- WW Product Catalogue 2019 07 Screen PDFDocument28 pagesWW Product Catalogue 2019 07 Screen PDFIoan BogdanNo ratings yet

- PWM DCDocument2 pagesPWM DCĐỗ Xuân BằngNo ratings yet

- Innovance H2U Data SheetDocument2 pagesInnovance H2U Data SheetAmr samir ShahinNo ratings yet

- 65 93 PR Pid 01090 - 0001 - BDocument1 page65 93 PR Pid 01090 - 0001 - BgeocaustasNo ratings yet

- Si 6uafa 003 EngDocument1 pageSi 6uafa 003 EngRodrigoMacedoNo ratings yet

- DMDCMDocument2 pagesDMDCMSupuran RichardoNo ratings yet

- Turk - New Turntable - Hydraulic JacksDocument2 pagesTurk - New Turntable - Hydraulic JacksEdward CelebreNo ratings yet

- 1 - STEEL STAIRCASE GA DRAWING1.dwgDocument1 page1 - STEEL STAIRCASE GA DRAWING1.dwgnimish.aquamarineNo ratings yet

- S001Document1 pageS001Yong Hui OngNo ratings yet

- MPRDC 02-ModelDocument1 pageMPRDC 02-Modelramthakurh12No ratings yet

- CUT ManualDocument7 pagesCUT ManualjannNo ratings yet

- Section Z-Z Section X-X: 8T12-150-T1 10T12-150-T1Document1 pageSection Z-Z Section X-X: 8T12-150-T1 10T12-150-T1inno musiimeNo ratings yet

- General NotesDocument1 pageGeneral Notesmustafa1989ocNo ratings yet

- Boundary Wall DrawingDocument1 pageBoundary Wall Drawingsandip wankhadeNo ratings yet

- TOEPC71061774Document4 pagesTOEPC71061774bejaouiNo ratings yet

- 1CB5:Elevation (Scale 1:25) : A B C D E A B C D E 7 7Document1 page1CB5:Elevation (Scale 1:25) : A B C D E A B C D E 7 7Rolly Marc G. SoteloNo ratings yet

- Si 6ngfa 004 EngDocument1 pageSi 6ngfa 004 EnglgsmartNo ratings yet

- SD.20 Structural Concrete Standards Anchor Bolt DetailsDocument1 pageSD.20 Structural Concrete Standards Anchor Bolt DetailsajmainNo ratings yet

- Cable Diagram Cutter Drive 271195900 - LP - D - 090917Document1 pageCable Diagram Cutter Drive 271195900 - LP - D - 090917Mohamed Noor AhamedNo ratings yet

- Drawing Limit E 3733.500Document1 pageDrawing Limit E 3733.500JonathanSaucedoNo ratings yet

- BbomercitoDocument5 pagesBbomercitoOmar Espinoza sanchezNo ratings yet

- ABB - AF - Contactor - 4poleDocument6 pagesABB - AF - Contactor - 4poleAhmad HamdanNo ratings yet

- CNC 104 Rim Vent: DatasheetDocument1 pageCNC 104 Rim Vent: DatasheetAs'adNo ratings yet

- TD803 BEAVER SeriesDocument2 pagesTD803 BEAVER SeriesDwi UlleNo ratings yet

- LDS - Permanent - Magnet - Shakers - Brochure - LR 2Document3 pagesLDS - Permanent - Magnet - Shakers - Brochure - LR 2snowflakefiat121No ratings yet

- Shimano Deore XT 770 Chainset InstructionsDocument1 pageShimano Deore XT 770 Chainset InstructionsLuis SalavinNo ratings yet

- Top of Wall: +2370 MM RL 260Document7 pagesTop of Wall: +2370 MM RL 260ascdfgNo ratings yet

- Block 3 - Courtyard North: H.MclarnonDocument1 pageBlock 3 - Courtyard North: H.MclarnonCosmin CosminNo ratings yet

- Designer Portfolio-7Document29 pagesDesigner Portfolio-7andalibNo ratings yet

- Uc600 Manual de InstalacionDocument2 pagesUc600 Manual de Instalacionm.cortezNo ratings yet

- Sizes of Different Motor FramesDocument2 pagesSizes of Different Motor FramesVijay Raghavan0% (1)

- BSD-C Plain: Manual Push Up OperatedDocument1 pageBSD-C Plain: Manual Push Up OperatedLordM00nNo ratings yet

- 0310212-TD-000042-01 Boiler Aux Steel Structure - Column Beam and Bracing (Is Standard)Document1 page0310212-TD-000042-01 Boiler Aux Steel Structure - Column Beam and Bracing (Is Standard)Rizwan AhmadNo ratings yet

- Farwestern University School of Engineering Project:-Seismic Analysis and Design of 5 Storey BuildingDocument1 pageFarwestern University School of Engineering Project:-Seismic Analysis and Design of 5 Storey BuildingRooking Ewondo SfuutNo ratings yet

- R0404-MT - Rev - 0 DF Da Bateria de CicloneDocument2 pagesR0404-MT - Rev - 0 DF Da Bateria de CiclonecaapasaNo ratings yet

- General NotesDocument1 pageGeneral Notesmustafa1989ocNo ratings yet

- Power Supply Aoc 715G5654-P03-001-002H схемаDocument5 pagesPower Supply Aoc 715G5654-P03-001-002H схемаALEXISNo ratings yet

- Allorde - P1Document1 pageAllorde - P1flor johnNo ratings yet

- Instrument Hookup 6Document1 pageInstrument Hookup 6Wael ZakariaNo ratings yet

- General Notes:: Type "D" BearingsDocument1 pageGeneral Notes:: Type "D" BearingsMiguel Angel Montaña PeñaNo ratings yet

- LCD Inverter - 715t2266-1 - Oz9938gnDocument2 pagesLCD Inverter - 715t2266-1 - Oz9938gntavi100% (1)

- Frame Nema Iec Motores w22 Weg CompressDocument1 pageFrame Nema Iec Motores w22 Weg CompressRogelio FloresNo ratings yet

- Sharp LC 90le745uDocument54 pagesSharp LC 90le745uYAMIR SANDOVALNo ratings yet

- Shimano Deore Crankset User ManualDocument1 pageShimano Deore Crankset User ManualJose Luis GutierrezNo ratings yet

- NVC LED Exterior Lighting ISSUE 1 PDFDocument104 pagesNVC LED Exterior Lighting ISSUE 1 PDFmaheshNo ratings yet

- Celpac: Solid State Relays & ContactorsDocument5 pagesCelpac: Solid State Relays & ContactorsOmarAlirioSuarezCañareteNo ratings yet

- BTI PlanosDocument18 pagesBTI PlanosHache Reyk KhanNo ratings yet

- Motor Lincoln 286 TSCDocument5 pagesMotor Lincoln 286 TSCJose BarreroNo ratings yet

- Notes:: Surf. TreatmentDocument1 pageNotes:: Surf. Treatmentberliani navitasNo ratings yet

- Kingspan - Kingzip - Roof - KS500 1000 ZIP IP Installation Guide - 032017 - UKDocument1 pageKingspan - Kingzip - Roof - KS500 1000 ZIP IP Installation Guide - 032017 - UKGeorgios PNo ratings yet

- Tubing Cutter Replacement WheelsDocument1 pageTubing Cutter Replacement WheelsKTNo ratings yet

- Boundary Boundary: Builder CellarDocument1 pageBoundary Boundary: Builder CellarAnde BhanuNo ratings yet

- TMCo Single ChamberDocument4 pagesTMCo Single ChamberamcodocontNo ratings yet

- Foamular 400 600 1000 Xps Product Data SheetDocument2 pagesFoamular 400 600 1000 Xps Product Data SheettylerlhsmithNo ratings yet

- Layfield Geomembrane Anchor Trench Calc'sDocument10 pagesLayfield Geomembrane Anchor Trench Calc'stylerlhsmithNo ratings yet

- SPR-3906 Technical SummaryDocument2 pagesSPR-3906 Technical SummarytylerlhsmithNo ratings yet

- Xypex Technology PDFDocument6 pagesXypex Technology PDFtylerlhsmithNo ratings yet

- Hydrovac SafetyDocument1 pageHydrovac SafetytylerlhsmithNo ratings yet

- Steel Body - Lever Hoists: A e B A e B A e BDocument1 pageSteel Body - Lever Hoists: A e B A e B A e BtylerlhsmithNo ratings yet

- Tank Environmental Protection - Environment CanadaDocument4 pagesTank Environmental Protection - Environment CanadatylerlhsmithNo ratings yet

- Historicalsteels PDFDocument1 pageHistoricalsteels PDFtylerlhsmithNo ratings yet

- SonoTube Cost ComparisonDocument2 pagesSonoTube Cost ComparisontylerlhsmithNo ratings yet

- Welding Washers For Steel DeckDocument2 pagesWelding Washers For Steel DecktylerlhsmithNo ratings yet

- Registered Bolt Manufacturer List PDFDocument120 pagesRegistered Bolt Manufacturer List PDFtylerlhsmithNo ratings yet

- Price List For Alberta Transportation DocumentsDocument10 pagesPrice List For Alberta Transportation DocumentstylerlhsmithNo ratings yet

- Atlantic Industries Product BrochureDocument28 pagesAtlantic Industries Product BrochuretylerlhsmithNo ratings yet

- Russel Metals CatalogueDocument6 pagesRussel Metals Cataloguetylerlhsmith0% (1)

- NBC 2015 Commentary L Seismic Upgrading Provisions, and Heritage Building Case-StudyDocument1 pageNBC 2015 Commentary L Seismic Upgrading Provisions, and Heritage Building Case-StudytylerlhsmithNo ratings yet

- AGS Flexible Coupling: WarningDocument4 pagesAGS Flexible Coupling: WarningtylerlhsmithNo ratings yet

- Gradation of Granular MaterialsDocument2 pagesGradation of Granular MaterialstylerlhsmithNo ratings yet

- QSK45-60G 4021359 GDocument6 pagesQSK45-60G 4021359 GHamilton mirandaNo ratings yet

- Torque ValuesDocument1 pageTorque ValuesImran IshakNo ratings yet

- MT75 OverhaulDocument31 pagesMT75 OverhaulfrodarturNo ratings yet

- Conmet Manual Hub Service ManualDocument25 pagesConmet Manual Hub Service ManualGeoff AndrewNo ratings yet

- Brilliance CT 6-64, Big Bore, iCT & Dual v.EXP Patient Support Repair and Replacement PDFDocument719 pagesBrilliance CT 6-64, Big Bore, iCT & Dual v.EXP Patient Support Repair and Replacement PDFAndrey100% (2)

- Hancock Series 5505Document8 pagesHancock Series 5505Ricardo CastroNo ratings yet

- Working Instructions DOC15 ACN6x4 Nxr12i RevfDocument45 pagesWorking Instructions DOC15 ACN6x4 Nxr12i RevfJezer LugoNo ratings yet

- Paint Application Guide No. 11: SSPC: The Society For Protective CoatingsDocument6 pagesPaint Application Guide No. 11: SSPC: The Society For Protective CoatingsaRiTo!No ratings yet

- Komatsu D65PX-0C K0210-0201 PageDocument2 pagesKomatsu D65PX-0C K0210-0201 PageGégé di TPNo ratings yet

- 3.2 Screws and NutsDocument133 pages3.2 Screws and NutsAndrew YauNo ratings yet

- NPCC P-3Document2 pagesNPCC P-3soumodip SahaNo ratings yet

- Mecanismo de Valvulas D7EDocument7 pagesMecanismo de Valvulas D7ELizandro Brito100% (1)

- Repair Procedures HandbookDocument72 pagesRepair Procedures HandbookJoãoFerreiraNo ratings yet

- MDSP - February 2022Document7 pagesMDSP - February 2022Joshua Gagate100% (1)

- 46-630 Boiler Controls - Liquid Level SwitchesDocument36 pages46-630 Boiler Controls - Liquid Level SwitchesDaniel Camargo PérezNo ratings yet

- Ajin SMT - Parts ListDocument78 pagesAjin SMT - Parts ListSerhidra SASNo ratings yet

- Ium Logik Oruday Out Romania 07 18 GB PDFDocument98 pagesIum Logik Oruday Out Romania 07 18 GB PDFBaciu Nicolae100% (1)

- TRIOCATALDocument13 pagesTRIOCATALVladimir Illich Pinzon100% (1)

- 2002 Seadoo Shop Manual 1Document557 pages2002 Seadoo Shop Manual 1Anthony Windover100% (1)

- Chapter 2 Cutting ToolsDocument33 pagesChapter 2 Cutting Toolskaleab hintsaNo ratings yet

- Manual: Original InstructionsDocument118 pagesManual: Original InstructionsMelanie GerdesNo ratings yet

- Watson - WC-1-1000 - Suspension ManualDocument34 pagesWatson - WC-1-1000 - Suspension Manualابراهيم حافظNo ratings yet

- E - C Manual - R1 - 28.8.18Document86 pagesE - C Manual - R1 - 28.8.18Bruno LopezNo ratings yet

- 12 Boom and Bucket HydraulicsDocument46 pages12 Boom and Bucket Hydraulicsmanuel eduardo pomahuali liñan0% (1)

- Six Axis Force / Torque Transducer FT Transducer: Assembly and Operating ManualDocument176 pagesSix Axis Force / Torque Transducer FT Transducer: Assembly and Operating Manualserban_elNo ratings yet

- Honda C70 Parts Manual PDFDocument78 pagesHonda C70 Parts Manual PDFArdy Robert100% (1)

- Eota TR 068 Design Structural Connections Column ShoesDocument13 pagesEota TR 068 Design Structural Connections Column ShoesthaibinhkxNo ratings yet

- Manual TV Series Iom Topworx en 82532Document36 pagesManual TV Series Iom Topworx en 82532wilbervizaareNo ratings yet

- Testing and Adjusting Adjusting Valve ClearanceDocument8 pagesTesting and Adjusting Adjusting Valve ClearanceJose Cruz Martinez MedinaNo ratings yet

- Viking Automatic 21Document11 pagesViking Automatic 21knulla din mammaNo ratings yet