Professional Documents

Culture Documents

ESTA-OMEGA 2000 - Electrostatic Powder Coating Unit

Uploaded by

Renato AbalosOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ESTA-OMEGA 2000 - Electrostatic Powder Coating Unit

Uploaded by

Renato AbalosCopyright:

Available Formats

ESTA \ OMEGA

-CONTENTS-

SUBJECT............................................................................................................................................... PAGE

OMEGA 2000 COVER

CONTENTS........................................................................................................................................... 1

OPERATION AND CONTROL............................................................................................................ 2

ADVICE ON USE.................................................................................................................................. 3

OMEGA 2000 POWDER COATING CONSIST FOLLOWING COMPONENTS........................ 4

PUTTING INTO SERVICE................................................................................................................... 5

OMEGA 2000 CONSOLE GRUOP ASSEMBLY SKETCH.............................................................. 6

OMEGA 2000 POWDER COATING UNIT CONNECTION SKETCH.......................................... 7

OMEGA 2000 POWDER COATING UNIT FRONT VIEW............................................................ 8

OMEGA 2000 POWDER COATING UNIT REAR VIEW................................................................ 9

OMEGA 2000 POWDER COATING UNIT INSIDE VIEW............................................................. 10

OMEGA 2000 POWDER COATING UNIT ELECRICITY CONNECTION SKETCH.................. 11

OMEGA 2000 POWDER COLOUR GUN ASSEMBLY SKETCH.............................................. 12

INJECTOR GRUOP..................................................................................................... 13

OMEGA 2000 POWDER COATING UNIT PNEUMATIC CONNECTION SKETCH................... 14

35 Lt. POWDER HOPPER.......................................................................................... 15

TROUBLE SHOOTING....................................................................................................................... 16

PART LIST…………............................................................................................................................. 17-18

The caracteristics given in this instruction manual are not binding andESTA/OMEGA A.Ş.

Reserve the right to modify its models.

TEKNİK MAKİNA SANAYİİ TİCARET A.Ş.

HALİL RIFAT PAŞA MAH. AYDINLIK TEPE SOK. NO:14 34384 OKMEYDANI / İSTANBUL

PHONE: 00 90 ( 212 ) 222 71 75 ( Pbx ) FAX: 00 90 (212) 220 24 07

EDITION : E - 11.01.2010 -1- OM 2000 - CODE : 6070-1

ESTA\ OMEGA

OPERATION AND CONTROL

The powder in the powder hopper is fluidised by the admission of air under the fluidised bed

plate.

The turbulence air regulator , above which the control manometer is positioned, allows

fluidisation control. ( Page 8 )

Suction plunger (Injector) fitted to the top of the hopper sucks in the turbulence powder and

transfer it to the gun.

- Air regulator for the plunger injection air. This air controls the quantity of powder

projected. ( Page 8 )

- Air regulator for the plunger dilution air. This air enables the powder transported

correctly.( Page 8 )

- Each air regulator is fitted with a control manometer.

When switching on the power pack the high voltage in the OMEGA 2000 gun is activated at

the same time the powder and air supply to the gun are set free. The high voltage builds up on

electrical field between the gun and the earthed work piece.

The outcoming powder / air mixture is electrostatically charged by the high electrical

potential at the electrode . The deflector plate and the atomizing air produce an adjustable

powder cloud.

Power pack the mains supplies 220 V 50 Hz an input transformer which is connected to a

medium frequency oscillator.

The Low Voltage cable from the power pack 0-12 V connected to the gun.

OMEGA 2000 apowder coating installations are built according to the highest safety

requirements. There is a short – circuit protection when the electrode approaches the work

piece, the control module automatically reduces the amount of high voltage to a nondangerous

valve

EDITION : E – 11.01.2010 -2- OM 2000 – CODE : 6070-1

ESTA\ OMEGA

ADVICE ON USE

*Earthing

Perfect earthing of the work pieces is premise for perfect powder coating incorrect earthing

leads to:

- Very lean wrap-around

- Non - uniform coating

- Back - spraying of powder on gun operator.

- Dangerous electrical charging

*Premises for perfect earthing and coating

- The works-pieces to be coated should be connected to the earth terminal of the electrotatic

generator. It is therefore advisable to clean the hangers for the parts regularly so as the

assure good contact.

- The earthing resistance of the work-piece must not exceed 1 MegaOhm.

- Perfect earthing of the coating booth with 10 mm2+ copper line.

*Powder booth

The OMEGA 2000 powder unit is used with a powder with a suction system and a powder

recovery system.

Ventilation of the spraying booth ensure correct air throughput:

The powder / air mixture concentration of 10 g/m3 for unproved powder may not exceeded in

any part of booth.

- The floor of working area must be electrostatically conductive. (5 m) around of booth

must be earthed)

- All persons within the working range must wear electrostatically conductive shoes.

- If the person use gloves ensure that the palm areas are cut out.

*Powder

A powder which binds causes blocking up take sample of powder and compress it in the palm

of hand. If it binds together tightly, the powder is likely to block the pipe the or the nozzle.

So concern humidy in powder and ensure recovery powder should be sieved.

*The plunger, hose and gun should be cleared with blowing air after each shift.

*The venturi pieces of injector may wear out after a certain time owing to abrasion by the

powder. The wear depends on the powder used. Change the venturi once the wear obvious to

the eye.

*Inspect the compressed air filter daily In particular verify that the elimination of water is

carried out correctly If water appears in the hoses we recommend using an air dryer.

EDITION : E – 11.01..2010 -3- OM 2000 – CODE : 6070-1

ESTA\ OMEGA

OMEGA 2000 POWDER COATING

CONSIST FOLLOWING COMPONENTS

1- OMEGA 2000 CONTROL MODULE

2- CONSOLE ASSEMBLY

3- GROUP OF INJECTOR PUMP

4- MANUAL POWDER GUN

5- POWDER HOPPER 35Lt.

6- POWDER HOSE

7- PNEUMATIC HOSES

8- SPARE PARTS SET

8.1- Small size deflector Ø 17 - 1 pcs

8.2- Big size Deflector Ø 26 - 1 pcs

8.3- Injector venturi (o-rıng) - 1 pcs

8.4- Fuse 1A - 2 pcs

8.5- Fuse 3A - 2 pcs

8.6- Hose clamp Ø 19 - 1 pcs

EDITION : E – 11.01.2010 -4- OM 2000 – CODE : 6070-1

ESTA\ OMEGA

PUTTING INTO SERVICE

-The following should be carried out;

-Compressed air connection should be done with inside diameter 8 mm air hose to main air

regulator inlet.

-Compressed air inlet pressure should be min. 4 bar max.6 bar, dry , oil free .

-Main electrical connection 220 V - 50 Hz single phase + earth mains +/- 7,5 V change from

main is acceptable otherwise extra voltage regulator should be recommended.

-Set the main air regulator max. 5 bar.

-Connect the earthing cable to earthing main.

-Before open main air supply pull regulator 05, 06, 07 (Page8)and turn anti clockwise set zero

-Start main switch on from rear of the control module. Pull the trigger and adjust

HV (high voltage). It should be max. 80 kV (duty of supply voltage change digital display

should give +/- 10 kV difference.)

-Adjust the turbulence air, using air regulator to a pressure 0,3-1 bar.

-Please concern humidity and foreign material inside of powder.

-Turbulence air connected main trigger so put the gun direction to powder booth and pull

the trigger, meanwhile put the lid on the hopper.

-Adjust injection air 1 to 2,5 bar to give powder output requested level.

-Adjust dilution air 0,3 to 1,5 bar to prevent the powder from arriving in bursts when the

powder flow is low.

-You should spray the powder the distance is about 10-20 cm between gun and work pieces.

you should set (HV) High Voltage max. level.

-If you make repaint of rejected work pieces, adjust HV 30-40 kV

EDITION : E – 11.01.2010 -5- TRN – OM 2000 – CODE : 6070-1

ESTA\ OMEGA

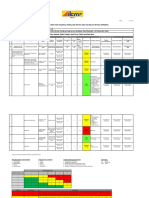

TROUBLE SHOOTING

SYMPTOM PROBABLE CAUSE

AND REMEDY

Main switch-on but indicator -Check the fuses 14,16 from rear

display doesn’t light on part of power pack.

-Check the mains supply if electricity

is exist.

When pulling trigger, indicator -Check the gun cable plug sockets.

display on, but there is no increase -Check the fuses 14(3A)

on High Voltage -Ifit still doesn’t work call the our

technical service

When pulling trigger, indicator -Electro valve connection socket should

display on, but air regulator gauge be checked.

doesn’t work. -Electronic control module repaired.

When pulling trigger, indicator -Run out of powder in the hopper.

display on, air regulator gauge -Adjust fluidisation air.

on, but there is no powder -Clean plunger and plunger air circuit.

-Check plunger suction pipe.

-Check if plunger is properly fixed.

-Clogged hose or gun inside section

(Clean or change)

There is no fluidisation -Check the fluidising air regulator

-Check the connection fluidisation air hose

if it is broken

-Fluidising bed should be clogged duty of

humidity and oil contamination

The gun is powder spraying, -Trigger should be remained open

without triggering (Clean with air)

-Electro valve remained open

Powder doesn’t stick to object -Unit main connection earth should be checked

static shocked on user -Check earthing cable of unit.

-Check hangers cleaning.

EDITION : E – 11.01.2010 -16- OM 2000 – CODE : 6070-1

TEKNİK MAKİNA SAN.VE TİC. A.Ş.

PART LIST

PRODUCT NO :

FOR..........................DATE ..................................

PREPARED EQUIPMENT LIST

PACK NO DESCRIPTION PIECE CONFIRM

OM-2000 POWDER COATING EQUIPMENT ( DEMONTED )

1. COMPLETE UNIT PACK

1.1. POWDER COATING EQUIPMENT 1

1.2. CONSOLE GROUP 1

2.1 REGULATOR GROUP WITH GLASS 1

2.2 PERPENDICULAR CONSOLE 1

2.3 TRAY UPPER 1

2.4 CARRIER CAR 1

1.3. MANUAL COATING GUN PACK 1

3.1 MANUAL COATING GUN 1

3.2 POWDER HOSE (5m) 1

3.3 4-6 PNEUMATIC HOSE (5m) 2

3.4 6-8 PNEUMATIC HOSE (5m) 1

3.5 INJECTION GROUP 1

3.6 AUTOMATIC SOCKET 1

3.7 GUN HANGER 1

3.8 PRODUCT GUIDE 1

1.4. SPARE PARTS OF POWDER COATING SYSTEM

4.1 BIG SIZE DEFLECTOR ( Ø26 mm ) 1

4.2 SMALL SIZE DEFLECTOR ( Ø17 mm ) 1

4.3 INJECTION VENTURI ( WITH - O-RING ) 1

4.4 FUSE (3 Amper) 2

4.5 FUSE (1 Amper) 2

1.5. CONNECTION PARTS

5.1 HOSE CONNECTOR ( 13 x 19 mm ) 1

5.2 BOLT ( YSB ) M6 x 15 mm 8

5.3 STAMP M6 12

5.4 BOLT ( YSB ) M6 x 25 mm 4

5.5 CABLE CONNECTION ( 2,5 x 100 mm ) 20

5.6 BOLT ( YSB ) M5 x 100 mm 2

2. HUPPER PACK ( 35 Lt ) 1

THE EQUIPMENTS THAT ARE WRITTEN ABOVE HAVE BEEN PACKED AND CONTROLED BY OUR SIDE

EXPORT STICKER

HOMELAND STICKER

INSTALLED BY : MANUFACTURE EXECUTIVE :

EDITION : E – 11.01.2010 -17- OM 2000 – CODE : 6070

TEKNİK MAKİNA SAN.VE TİC. A.Ş.

PART LIST

PRODUCT NO :

FOR..........................DATE ..................................

PREPARED EQUIPMENT LIST

PACK NO DESCRIPTION PIECE CONFIRM

OM-2000 POWDER COATING EQUIPMENT ( COMPLETE)

1. COMPLETE UNIT PACK

1.1. POWDER COATING EQUIPMENT 1

1.2. PERPENDICULAR CONSOLE 1

1.3. REGULATOR GROUP WITH GLASS 1

1.4. TRAY UPPER 1

1.5. CARRIER CAR 1

1.6. GUN HANGER 1

1.7. SPARE PARTS OF SYSTEM AND MANUAL COATING GUN PACK

7.1 MANUAL COATING GUN 1

7.2 POWDER HOSE (5m) 1

73 4-6 PNEUMATIC HOSE (5m) 2

7.4 6-8 PNEUMATIC HOSE (5m) 1

7.5 INJECTION GROUP 1

7.6 AUTOMATIC SOCKET 1

7.7 PRODUCT GUIDE 1

7.8 SPARE PARTS OF POWDER COATING SYSTEM

8.1 BIG SIZE DEFLECTOR ( Ø26 mm ) 1

8.2 SMALL SIZE DEFLECTOR ( Ø17 mm ) 1

8.3 INJECTION VENTURI ( WITH - O-RING ) 1

8.4 FUSE (3 Amper) 2

8.5 FUSE (1 Amper) 2

8.6 HOSE CONNECTOR ( 13 x 19 mm ) 1

8.7 CABLE CONNECTION ( 2,5 x 100 mm ) 20

2. HUPPER PACK ( 35 Lt ) 1

THE EQUIPMENTS THAT ARE WRITTEN ABOVE HAVE BEEN PACKED AND CONTROLED BY OUR SIDE

EXPORT STICKER

HOMELAND STICKER

INSTALLED BY : MANUFACTURE EXECUTIVE :

EDITION : E – 11.01.2010 -18- OM 2000 – CODE : 6070-1

You might also like

- NCR AG I 055 With Vendors ReplyDocument12 pagesNCR AG I 055 With Vendors ReplymuhammedemraanNo ratings yet

- WIWA Airless Spray GunsDocument52 pagesWIWA Airless Spray Gunsosvaldo lopezNo ratings yet

- Kit 138 New Bresle Salt PDFDocument2 pagesKit 138 New Bresle Salt PDFDian FaraNo ratings yet

- Nya 8896 PDFDocument1 pageNya 8896 PDFSaor PakpahanNo ratings yet

- Bright Annealing Process of Stainless S Teel TubeDocument2 pagesBright Annealing Process of Stainless S Teel TubeViraj ShiroleNo ratings yet

- Bright Annealing Copper and Its AlloysDocument4 pagesBright Annealing Copper and Its Alloysmp87_ingNo ratings yet

- Humade Msds MaDocument5 pagesHumade Msds MadchyNo ratings yet

- Floor Oven Fe50 Fe1000msss NewDocument1 pageFloor Oven Fe50 Fe1000msss Newtekstep7No ratings yet

- Diamatre Teava - PEDDocument72 pagesDiamatre Teava - PEDAlin TomozeiNo ratings yet

- Techsonic EZ III Rev 4 092010 PDFDocument70 pagesTechsonic EZ III Rev 4 092010 PDFandresgomez10No ratings yet

- 1-Piece Instrumentation, 40G and 40 Series: Part NoDocument2 pages1-Piece Instrumentation, 40G and 40 Series: Part Nozidanejason8No ratings yet

- 13 Samss 003 PDFDocument7 pages13 Samss 003 PDFMohamed SolimanNo ratings yet

- MESC SPE 74-018 - 2010 - Nickel Alloy Pipe To Astm b167Document7 pagesMESC SPE 74-018 - 2010 - Nickel Alloy Pipe To Astm b167sathi11189No ratings yet

- Carbon Arc Cutting PDFDocument44 pagesCarbon Arc Cutting PDFMark InnesNo ratings yet

- HIRARC FORM 2023 - Tugasan Start Up and Shut Down OPPDocument4 pagesHIRARC FORM 2023 - Tugasan Start Up and Shut Down OPPMuhammad 'Aizat PaimanNo ratings yet

- Iwe Mig Welding MachineDocument2 pagesIwe Mig Welding Machinem ramakrishna reddyNo ratings yet

- Basic Welding ProgrammeDocument104 pagesBasic Welding ProgrammeAmit SharmaNo ratings yet

- Swagelok Magnehelic Gauge InstructionsDocument4 pagesSwagelok Magnehelic Gauge InstructionsAnonymous vF4wgBTdSbNo ratings yet

- ST 37Document7 pagesST 37rendra.farisrNo ratings yet

- Coke Crusher - Lubrication Pumps Run in TestDocument26 pagesCoke Crusher - Lubrication Pumps Run in TestsayedNo ratings yet

- Purging Brochure PDFDocument19 pagesPurging Brochure PDFjustinctlNo ratings yet

- Actuation Product Catalogue - OneSteelDocument65 pagesActuation Product Catalogue - OneSteelJOHN100% (1)

- Welding and Fabrication TechnologyDocument2 pagesWelding and Fabrication TechnologyLeonicia MarquinezNo ratings yet

- CWRVC-1 2nd Edition 15085Document10 pagesCWRVC-1 2nd Edition 15085Cristi OgaruNo ratings yet

- ASP Procedures For Testing Characteristics of Automotive Sheet Steel LubricantsDocument31 pagesASP Procedures For Testing Characteristics of Automotive Sheet Steel LubricantsSamsudin AhmadNo ratings yet

- 1.5 APS Powder Insert: Parts List PL 41001 EN 13Document18 pages1.5 APS Powder Insert: Parts List PL 41001 EN 13Alexandre VecaNo ratings yet

- Holiday Detector Voltage SettingsDocument1 pageHoliday Detector Voltage Settingsrizviabbas2012No ratings yet

- MS 2571 PDFDocument1 pageMS 2571 PDFnd_teng0% (1)

- Safety and Operating Manual: Pipe Threading MachineDocument19 pagesSafety and Operating Manual: Pipe Threading MachineNalina S. Bala KumarNo ratings yet

- 1-Manual Horizontal Stand CTS670 ST7H PDFDocument121 pages1-Manual Horizontal Stand CTS670 ST7H PDFManikandaprabhu ManickamNo ratings yet

- NDT Training Syllabus PDFDocument8 pagesNDT Training Syllabus PDFNkwor AndersonNo ratings yet

- Siemens Ihm Pxm50.e A6v11211557 enDocument71 pagesSiemens Ihm Pxm50.e A6v11211557 enMatheus PraseresNo ratings yet

- 800D SeriesDocument3 pages800D Seriesvkeie0206No ratings yet

- Manual de Monitoramento de Condições LCM20 - EN PDFDocument41 pagesManual de Monitoramento de Condições LCM20 - EN PDFRafael G OliveiraNo ratings yet

- EM-SRC-0005-Marking Packaging Preservation and Shipping Requirements PDFDocument37 pagesEM-SRC-0005-Marking Packaging Preservation and Shipping Requirements PDFdang2172014No ratings yet

- p999999 100zd11 000 zd0001 - 0 Welding StandardDocument25 pagesp999999 100zd11 000 zd0001 - 0 Welding StandardJennyNo ratings yet

- MaxiFlo MU HA C M ManualDocument43 pagesMaxiFlo MU HA C M ManualRameez IrfanNo ratings yet

- PC 2569 Apcomin Industrial Rozc PrimerDocument3 pagesPC 2569 Apcomin Industrial Rozc PrimerAshishKumar RavalNo ratings yet

- Dynamic and Static Balancing of Rolls - How, Why and WhenDocument2 pagesDynamic and Static Balancing of Rolls - How, Why and WhenAbolfazl KhakiNo ratings yet

- Specification For FlangesDocument16 pagesSpecification For FlangesMehdi NouriNo ratings yet

- Stack Emissions Monitoring Report: Your Contact at ESGDocument26 pagesStack Emissions Monitoring Report: Your Contact at ESGMohamed Irfan Z H100% (1)

- Rigaku Radioflex RF-EGM2 Series Brochure - VISCODocument4 pagesRigaku Radioflex RF-EGM2 Series Brochure - VISCOrhinemineNo ratings yet

- Hydro Aluminium - AlSi7Mg0.6Document2 pagesHydro Aluminium - AlSi7Mg0.6Raj PrasanthNo ratings yet

- Thermo Fisher Scientific XL3 XL2 Hardware OverviewDocument37 pagesThermo Fisher Scientific XL3 XL2 Hardware OverviewMAmar100% (1)

- Advantage & Disadv of Bellow & Slip JointDocument2 pagesAdvantage & Disadv of Bellow & Slip JointSharun Suresh0% (1)

- Wfp291338 For Quality and Quantity Inspection of FoodsDocument14 pagesWfp291338 For Quality and Quantity Inspection of FoodsOzlem MepNo ratings yet

- dpvc-09 Petrobras PDFDocument47 pagesdpvc-09 Petrobras PDFBilly TanNo ratings yet

- Thermax Limited: Inspection Procedure For GalvanizingDocument14 pagesThermax Limited: Inspection Procedure For GalvanizingNsidibe Michael EtimNo ratings yet

- BS 1724 (Bronze Welding by Gas)Document24 pagesBS 1724 (Bronze Welding by Gas)nandi_scrNo ratings yet

- Welder Qualification Record: CODE: AS/NZS 1554.5-2014 WMS-WPS-30Document2 pagesWelder Qualification Record: CODE: AS/NZS 1554.5-2014 WMS-WPS-30Ali TalebiNo ratings yet

- PRES TIG Hot Wire Narrow Gap Welding enDocument25 pagesPRES TIG Hot Wire Narrow Gap Welding enRavishankarNo ratings yet

- Cswip 3.1Document2 pagesCswip 3.1Anna PariniNo ratings yet

- CHG 55B2Document1 pageCHG 55B2Nhien ManNo ratings yet

- Product Data: Hempadur Multi-Strength 35530Document2 pagesProduct Data: Hempadur Multi-Strength 35530Vijayaraj KumarNo ratings yet

- SS Pipe Welding ProcedureDocument5 pagesSS Pipe Welding Procedureamit rajputNo ratings yet

- A34 020 R7 Manual 500FWD MaintenanceDocument19 pagesA34 020 R7 Manual 500FWD MaintenanceVladimirNo ratings yet

- FX Desiccant Dryer ManualDocument56 pagesFX Desiccant Dryer Manualx6kvdvffp2No ratings yet

- en 3706Document22 pagesen 3706Thanh XuanNo ratings yet

- en 3706 PDFDocument22 pagesen 3706 PDFThanh Xuan NguyenNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Switch Industrial Sales Corp - 3M Products CATALOGDocument48 pagesSwitch Industrial Sales Corp - 3M Products CATALOGRenato AbalosNo ratings yet

- BDO Manager's Check Application FormDocument2 pagesBDO Manager's Check Application FormRenato AbalosNo ratings yet

- Panasonic LED Lighting PricelistDocument11 pagesPanasonic LED Lighting PricelistRenato Abalos100% (2)

- Zoom Phone Product OverviewDocument2 pagesZoom Phone Product OverviewRenato AbalosNo ratings yet

- CONTI's Bakeshop Brochure - May 2021Document8 pagesCONTI's Bakeshop Brochure - May 2021Renato AbalosNo ratings yet

- Permatex 81158 TDSDocument2 pagesPermatex 81158 TDSRenato AbalosNo ratings yet

- Safety Data Sheet: 1. IdentificationDocument8 pagesSafety Data Sheet: 1. IdentificationRenato AbalosNo ratings yet

- Flyer Royu OCT 2018 V1Document8 pagesFlyer Royu OCT 2018 V1Renato AbalosNo ratings yet

- FIREFLY EcoLum PriceList - November 2018Document2 pagesFIREFLY EcoLum PriceList - November 2018Renato AbalosNo ratings yet

- 3M Heat Shrink Tubing & Sleeving CatalogueDocument9 pages3M Heat Shrink Tubing & Sleeving CatalogueRenato AbalosNo ratings yet

- 2018 Calendar - Saudi ArabiaDocument1 page2018 Calendar - Saudi ArabiaRenato AbalosNo ratings yet

- Bacoor SolidarityDocument1 pageBacoor SolidarityRenato AbalosNo ratings yet

- LMB Application FormDocument2 pagesLMB Application FormRenato AbalosNo ratings yet

- Sartorious PR6143 PDFDocument4 pagesSartorious PR6143 PDFRenato AbalosNo ratings yet

- Sartorious Pr6143Document4 pagesSartorious Pr6143Renato AbalosNo ratings yet

- Serpentine Belt Replacement Etc - Chevy Traverse 2008-2016Document4 pagesSerpentine Belt Replacement Etc - Chevy Traverse 2008-2016Renato Abalos50% (2)

- Handy Electrical Calculator - IEC & BSDocument5 pagesHandy Electrical Calculator - IEC & BSRenato AbalosNo ratings yet

- Quotation: Jumo GMBH & Co. KG "Dubai Branch"Document2 pagesQuotation: Jumo GMBH & Co. KG "Dubai Branch"Renato AbalosNo ratings yet

- Ajay Syscon Manual 529Document28 pagesAjay Syscon Manual 529Renato Abalos100% (1)

- Safety Guidlines e F DDocument8 pagesSafety Guidlines e F DRenato AbalosNo ratings yet

- Engineering Application Guide: Fluor Daniel - Electrical/Control SystemsDocument2 pagesEngineering Application Guide: Fluor Daniel - Electrical/Control SystemsRenato AbalosNo ratings yet

- N163S AC/DC Power Supply: Dimensions and Drilling PlanDocument2 pagesN163S AC/DC Power Supply: Dimensions and Drilling PlanVariya DharmeshNo ratings yet

- Leading The Industry In: Solar Microinverter TechnologyDocument2 pagesLeading The Industry In: Solar Microinverter TechnologysukirajNo ratings yet

- CL5000J Series: Service ManualDocument84 pagesCL5000J Series: Service ManualSergiy FedotovNo ratings yet

- 6.4.TEC100IndoorNew ComplianceDocument51 pages6.4.TEC100IndoorNew CompliancesumanNo ratings yet

- TC Coolant Pump Userguide - 2020 - V2Document10 pagesTC Coolant Pump Userguide - 2020 - V2Luc DuchesneNo ratings yet

- Omsnoeringsmachines - TP 202 OmsnoeringsmachineDocument4 pagesOmsnoeringsmachines - TP 202 OmsnoeringsmachineArafat MiahNo ratings yet

- Amplivox240 User ManualDocument39 pagesAmplivox240 User ManualMaria AlejandraNo ratings yet

- PITE Ground Fault Locator GFL3836-User-manualDocument33 pagesPITE Ground Fault Locator GFL3836-User-manualMarinda FebriNo ratings yet

- Specification-206kva Cummins Gensets4896548274189506958Document9 pagesSpecification-206kva Cummins Gensets4896548274189506958Ariel CaparroNo ratings yet

- Voltage Drop GuidelinesDocument4 pagesVoltage Drop Guidelinesindira_tungNo ratings yet

- Operating Instructions and Installation Information Mettler Toledo Multirange ID7xx-Base Weighing TerminalDocument116 pagesOperating Instructions and Installation Information Mettler Toledo Multirange ID7xx-Base Weighing Terminalmariusz sNo ratings yet

- GEMPAC UserManual Appendix1 Ver 8Document40 pagesGEMPAC UserManual Appendix1 Ver 8Roberto Carlos Alvarez Vidal0% (1)

- AQUA Drive FC 202: Programming GuideDocument294 pagesAQUA Drive FC 202: Programming Guiderony sheekNo ratings yet

- Easy UPS On-Line - SRV2KI - APCDocument2 pagesEasy UPS On-Line - SRV2KI - APCSỹ TháiNo ratings yet

- 05solenoid CoilsDocument8 pages05solenoid CoilsLuis Fernando Juchani MoralesNo ratings yet

- Bee LabDocument5 pagesBee Labanitha paramasivamNo ratings yet

- CL100D (6-10kVA) Service Manuel - English PDFDocument64 pagesCL100D (6-10kVA) Service Manuel - English PDFAbdulrhmanNo ratings yet

- 100 td013 - en P PDFDocument80 pages100 td013 - en P PDFWILLYNo ratings yet

- 3RT20371AN20 Datasheet enDocument8 pages3RT20371AN20 Datasheet enDavid RubioNo ratings yet

- Grand Cru-Pjt Training Manual: " Add Your Company Slogan "Document106 pagesGrand Cru-Pjt Training Manual: " Add Your Company Slogan "Николай ЧупринаNo ratings yet

- Atmoscope: Self-Contained SMD Hot Air Work StationDocument12 pagesAtmoscope: Self-Contained SMD Hot Air Work StationFabian ZambranoNo ratings yet

- Siemens Lfs1.21a2 ManualDocument40 pagesSiemens Lfs1.21a2 ManualVicente Bonifatti CedeñoNo ratings yet

- Controller HAT600NBDocument24 pagesController HAT600NBOrlando David Zeña SandovalNo ratings yet

- HYGECO - Notice SB 0MAN052 H - ENGDocument20 pagesHYGECO - Notice SB 0MAN052 H - ENGmarius tothNo ratings yet

- Dry TransDocument31 pagesDry Transjroyal69No ratings yet

- jf5054 00Document7 pagesjf5054 00eduardo pinedaNo ratings yet

- Mainspro: Installation and Operation Guide Application Guide Reference GuideDocument55 pagesMainspro: Installation and Operation Guide Application Guide Reference GuidegealifeNo ratings yet

- Easy UPS 3M - E3MUPS80KHB1SDocument3 pagesEasy UPS 3M - E3MUPS80KHB1Smesssaoudi faresNo ratings yet

- Ccum 21 High ResDocument4 pagesCcum 21 High ResAshish ChughNo ratings yet

- PAC 2000 E: Operating ManualDocument19 pagesPAC 2000 E: Operating ManualcarrierNo ratings yet