Professional Documents

Culture Documents

MSS-SP-77-1995 - Guidelines For Pipe Support Contractual Relationships - 2000

Uploaded by

ecsuperalOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MSS-SP-77-1995 - Guidelines For Pipe Support Contractual Relationships - 2000

Uploaded by

ecsuperalCopyright:

Available Formats

Guidelines for Pipe Support

Contractual Relationships

Relationships and Responsibilitiesof the

Pipe Hanger Contractorwith the Purchaser's Engineer

or the Pipe Fabricatorand/or E W o r

Standard Practice

Developed and Approved by the

Manufacturers Standardization Society of the

Valve and Fittings Industry, Inc.

127 Park Street, NE

Vienna, Virginia 22180

(703) 281-6613

COPYRIGHT Manufacturers Standardization Society of the Valve and Fittings

Licensed by Information Handling Services

MSS STANDARD PRACTICE SP-77

An MSS Standard Practiceis intended as a basisfor common practice by

the manufacturer, the user, andthe general public. The existence of an

MSS Standard Practice does not initself precludethe manufacture, sale,

or use of productsnot conforming to the Standard Practice. Mandatory

conformance is established only by reference in a code, specification,

sales contract, or public law, as applicable.

Other standards documentsreferred to herein are identified by the date

of issue that was applicable to this standard at the date of issue of this

standard. See Annex A. This standard shall remain silent on the

applicability of those other standards of prior or subsequent dates of

issueeven though provisions of concernmay not havechanged.

References containedherein which arebibliographic in nature are noted

as “supplemental’ in the text.

Anypart of this standard may be quoted. Credit lines should read ‘EktractedfiomMSS SP-77,1995 reaflmed

2000 with permission of the publisher, the Manufaturers Standardization Sociev. ’ Reproduction prohibited

under copyright convention unlesswrittenpermission is granted by the Manufacturers Standardùation Society

of the Valve andFittings Industry, Inc.

Originally Approved September 1971

Copyright Q.1985 by

Manufacturers Standardization Society

of the

Valve and Fitting Industry, Inc.

Printed in U.S.A.

COPYRIGHT Manufacturers Standardization Society of the Valve and Fittings

Licensed by Information Handling Services

MSS STANDARD PRACTICE SP-77

FOREWORD

This standard was developed by a cooperative effort of representatives of the pipe hanger manufacturers in

response to a need to clarify the relationships which exist betweenthe purchaser’sengineer, pipe fabricator, pipe

erector, pipe hanger, designer,pipe hanger manufacturer and the client.

By clarifying these relationships, it is hoped that pipe hangers andsupports can be properly considered at thetime

of plant design; that the pipe hanger andsupport contract can be let early enough to allow for design, approval,

fabrication and delivery of pipe hangers and supports to satisfy customer requirements; that the purchaser’s

engineers can be aware of pipe the hanger contractor’s requirementswith regard to drawings and supplemental

data; that the pipe fabricator can be awareof the pipe hanger contractor’s requirements with regard to dimen-

sional and weight data; and that the pipe erector can be aware of how pipe hangers andsupports must be received,

stored and installed in order to perform as intended. A client’s hgnger requirements can be best served by having

all parties knowledgeable of each others needs and responsibilities.

There are three companion standards, SP-58, SP-69 and SP-89 relating to hanger design,selection, application,

fabrication and installation. In addition, the MSS Hanger Committee has developed a standard on hanger

terminology, as covered .in SP-90.

CONTENTS

SECTION PAGE

I Foreword ..................................... .................................................. II

Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ii

1. Scope .......................................................................................... 1

2. Objective . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

3. Functions of Pipe Hanger Contractor .............................................................. 1

4. Functions of Purchaser’s Engineer ................................................................ 3

5. Functions of Pipe Fabricator and/or Erector ........................................................ 4

Annex A - Referenced Documents ............................................................... 7

11

COPYRIGHT Manufacturers Standardization Society of the Valve and Fittings

Licensed by Information Handling Services

STD.MSS SP-77-ENGL 1975 5770bll0 0503397 399 D

MSS STANDARD PRACTICE SP-77

GUIDELINES FOR PIPE SUPPORTCONTRACTUAL RELATIONSHIPS

I. SCOPE a) When a formal stress and thermal analysis of

the pipingsystem is provided by the pur-

> 1.1 This standard establishes practical and chaser’s engineers,the hanger contractor shall

recognizable guidelines relative

to defining areas design a supporting system inaccordancewith

of responsibility for pipehanger contractors, that analysis.

purchaser’s engineers,and pipe fabricators and/

or erectors. b) In the absence of, or requirements for, a

formal stress and thermal analysis by the

1.2 This standard includes references to other purchaser’s engineers, the hanger contractor

MSS standardsfor the purpose ofprecisely may locate and providehangers to satisfy

defining theseareas of responsibility. movement and load conditions as determined

by approximate methods.

2. OBJECTIVE

3.3.2 The pipe hanger design shall include the

2.1 To beused, as a basis for contractual following:

requirements if agreeable to both parties,

where there is a lack of definition in the job a) Selection and sizing of hanger and support

specification. components to accommodate pipe movement

and loading conditions, and which are appro-

2.2 To furnish guidance and practical observa- priate for the piping system beingsupported.

tions in order to minimize common misunder-

standings which may occur between participat- b) In the absence of other requirements, supple-

ing groups. When usedin this context, the word mentary steel shall be designed in accordance

‘shall’ is to be interpreted as ‘should‘. with AISC specifications.

3. FUNCTIONS OF PIPE HANGER c) Selection of materials which are appropriate

CONTRACTOR for the intendedservice and specified

environment.

3.1 To design, detail-and furnish pipe hangers,

anchorsand guides as specifiedin the hanger d) Providing a designwhichprecludes any inter-

contract, and to comply with all provisions of the ferencewith the structure, equipment and

pipe hanger specification and applicable codes. appurtenances for which drawings and/or

details were furnished by the purchaser’s

3.2 To work in close cooperation with the engineers at the time that the hanger design

purchaser’s

engineer, the pipe fabricator and the was initiated.

pipe erector.

3.3.3 Specificrequirementsand recommenda-

3.3 Pipe Hanger Design is the development of tions.relative to pipe hanger design, are covered

a supporting system to properly support and in MSS SP-58 and MSS SP-69.

control each piping systemfor all conditions of

operation delineated by the purchaser’s engi- 3.4 Pipe

HangerAssemblyDrawings,when

neers. As it is not possible to anticipate location required, shall include the following:

and types of vibration which may occur during

operation of a pipingsystem, vibration control a) An illustration of the pipehangerassemblyin

devices are excluded from the basic hanger its

installed position, correctly oriented

with

contract unlessspecifically

defined and located.respect to piping and building structure. Ele-

vations of supporting structure and pipe shall

3.3. I The pipe hanger design shall be based on be shown.

the following:

COPYRIGHT Manufacturers Standardization Society of the Valve and Fittings

Licensed by Information Handling Services

MSS SP-77 STANDARD PRACTICE

b) Location of pipe hanger assembly with refer- d) Welded pipe attachments shall be shaped to

ence to building column lines. Where required contour, whenever practical. Welded attach-

to compensate for horizontal movements, ments for reducers, reducing ells, and fabri-

offsetlocations of attachments to building cated pipe bends, etc. should be shaped by the c

structure and/or pipe shall be shown. pipe fabricator or erector in order thatcenter

to end dimensions be met. For these situa- .

Complete bill of material. tions. the welded attachments should be pro-

vided with additional length for shaping.

d) Setting and installation data for specialty

products such as variable spring and constant 3.5.2 Coating,

support hangers, and snubbers, which require

either field adjustment or verification of the a) Unless otherwise noted, fabricated material,

installed position. specified to be painted, shall receive one shop

coat of fabricator’s standard primer.

e)Designload and, when applicable, special

loadings such as hydrostatic test. b) Unless otherwisenoted, material surfaces shall

be prepared for coating by removal of loose

f) Field weld sizes and, when required, special scale, loose weld spatter and other foreign

notations. material.

g) A unique hanger marknumber, including c) Applications of coating shall be in accordance

revision

level and, when required, other with the coatingmanufacturer’s recommenda-

identification information. tions.

h) Where job requirements permit, typical d) Rod threads forfield adjustment shall not be

details and approximate hanger locations may painted; bolt threads in assembliesmay be

be used in lieu of individual drawings. painted. When specified,external adjustment

threads shall recei1.e a coating of rust pre-

3.4.1 Detailed requirements and recommen- ventive compound.

dations relative to pipe hanger assembly draw-

ings are covered in MSS SP-89. Stainless steel orother corrosion resistant

material need not be painted.

3.5 PipeHanger Shop Fabrication,Coating,

Packaging. Marking and Shippingshall include Small items such as beam attachments which

the following: are to be welded to existing steel need not be

painted.

3.5.1 Shop Fabrication

3.5.3 Packaging!,Marking andShipping

a) Materials shall be cut to size, and shall be

formed,drilled,punched,threadedand a) Hangers should be assembled to the degree

welded in accordance with the requirements practical. taking into account shipping and

of the pipe hanger assembly drawings. handling limitations.

b) Dimensional tolerances shall be in accordance b) Hanger assemblies or subassemblies shall be

with MSS SP-89, Section 4. properlymarkedwithidentifying numbers.

Random material may be identified in bulk.

c) Formed componentsmay be furnished in the

‘as formed’ condition without any further

mechanical work.

COPYRIGHT Manufacturers Standardization Society of the Valve and Fittings

Licensed by Information Handling Services

STD.MSS SP-77-ENGL 1995 œ 5770bllU 0503399 Tb7 œ

MSS STANDARD PRACTICE SP-77

c) Each hanger shipment shall contain a packing 4.4 Plant Design-Duringthe initial design

listidentifying the material included in the phase, consideration shall be given to the pipe

shipment, also noting the total number of hanger requirements. Some of the requirements

boxes, bundles, bags,etc. making up the are as follows:

shipment.

a) Piping shall be routed to provide ample space

d) Where possible, eachhanger assembly should around piping for installation of standard

be shipped complete. hanger products and toallow for both vertical

and horizontal pipe movement.

e) Constant supports, variable springs and sim-

ilar items may be packaged, skidded and b) Building structure shall be adequate for sup-

shipped separate from the rigid components porting piping loads, as generated by maxi-

of an assembly. mum recommended spans, including hydro-

static test loads.

3.5.4Detailed requirements and recommen-

dations relative to pipe hanger shop fabrication, c) Secondary systems, valves, cable trays, etc.,

coating, packaging, marking and shipping are should be located so as not to interfere with

covered in MSS SP-58 and SP-89. the accessibilityof principal structural mem-

bers which may be used for the support or

3.6 CoordinationandConsultationshall anchorage of primary systems.

include the following:

4.5 Scope ofWork-The scope of hanger

a) Information relative to engineering, fabri- support work required in any project shall be

cation and delivery shall beprovided as clearly defined inthe form of drawings covering

required. piping, equipment and structure; specifications

covering design and material; applicable codes;

b) Notification of material procurement delays and a statement defining design senices to be

and possible material substitutions. furnished by hanger contractor.

c) Notification to the purchaser’s engineers, any 4.5.1Any conditions whichmaynecessitate

questionable situations which may become special consideration or any operational pro-

apparent. cedure which may produceabnormal loading or

movement shall be specifically noted.

4. FUNCTIONS OF PURCHASERS 4.5.2 Other factors to be covered in the scope

ENGINEER are hanger design drawing requirements, ap-

proval procedures, quality assurance require-

4, I To delineate the scope of the hanger design ments,inspection requirements, construction

work, establish complete pipingsupport specifí- schedule and shipping stipulations.

cations and monitor the progress of the design

to insure compliance. 4.5.3 Drawings and

SupplementalData

should include, but not be limited to, the

4.2 To maintain a current working knowledge following:

of available hanger products and design criteria

in order to properly coordinate the pipe support a) Piping drawings and immediate notification

phase with all other phases of the plant design. of any intended revisions.

4.3 To retain responsibility for thepiping b) Piping composites, if available, for checking

design such that stresses generated by pressure clearances.

and thermal expansion are within the allowable

stress range.

3

COPYRIGHT Manufacturers Standardization Society of the Valve and Fittings

Licensed by Information Handling Services

c) Flow diagrams. c) Painting and protective coating requirements.

d) All structural drawings including plans and d) Identification of pipingsystemswhichwill

elevations, column and girder schedules, tur- undergo hydrostatic tests.’

bine foundation, concrete floor plans,

trenches, embedded plates, etc. e) Special material requirements.

e) Architecturalandgeneralarrangement f) Packing, marking and shipping instructions.

drawings.

4.6 Scheduling-Hangerdesigncontract

f) Cable tray drawings. should be awarded as soon as possible to provide

necessary lead timefor design, approval, fabrica-

g) H.V.A.C. and duct drawings. tion and delivery of hangers.

h) Equipmentdrawings, which may include 4.6.1 In order to coordinate hanger shipments

boiler, turbine, condenser, deaerator, heaters, with job requirements, the hanger contractor

etc., should be available on request. shall be provided with the following:

i) Piping flexibility analyses, when available, a) Erection schedule with immediate

notification

including pipe line deflections. of changes.

j) Movements and allowable loadings at temi- b) Piping arrangement drawing releasesche-

na1 points such as boiler headers, economizer dules.

inlets andother- equipment connections,

should be available on request. c) Time schedulefor approval of hanger details.

k) Piping specificatións, including piping sizes,

schedules, materials, temperatures and 5. FUNCTIONS OF PlPEFABRICATOR

pressures. AND/OR ERECTOR

1) Valve and Specialtylistincludingpressure 5.1 The pipe fabricator and/or erector shall

ratings, manufacturer and figure numbers, work in close cooperation with the pipe hanger

and weights. contractor andthe purchaser’s engineer to effect

a hanger installation that meets the purchaser’s

m) lnsulation specification including material, requirements.

thickness and density for pipe sizes and

temperatures. 5.2 Whenthe pipe fabricatororthe pipe

erector is also furnishing the hangers, he should

n) Seismic design requirements. serve as liaison between the pipe hanger con-

tractor andthe purchaser’s engineer.

4.5.4 Pipehangerspecificationsshould

include the following when applicable: 5.3 The pipe fabricator shall provide prompt

information concerning any deviations or addi-

a) Reference to codes and standards, such as: tions to the engineer’s piping arrangement

ASME B31 Codes for Pressure Piping, drawings and erection schedules. For cold

ASME Boiler Codes, MSS SP-58, MSS sprung systems, he shall also provide drawings

SP-69 and MSS SP-89. which indicate “cut shorts” and the location of

finalfieldwelds from which the hanger con-

b) Customer standards. tractor may determine the proper pipe elevations

and provide the required amount of hanger

adjustment.

4

COPYRIGHT Manufacturers Standardization Society of the Valve and Fittings

Licensed by Information Handling Services

~~ ~ ~~

STD*MSS SP-77-ENGL L775 5770b40 050L40L 4 4 5

MSS STANDARD PRACTICE SP-77

5.4 The pipe fabricator shall provide actual recommended that within this periodof time,

weights and dimensions of specially fabricated the hangers be installed and finish coated, or

pipe, fittings and valves, so that pipe hangers that they be reprimed.

may be properly sized and loads accurately

calculated. In order to avoid delaysindesign 5.5.3 Hanger installation practices shall

and delivery, it is imperative that this informa- include the following:

mation be made availableas early as possible.

a) Installation in accordance with the pipe

5.5 The pipe erector, in order to insure that hanger assembly drawing.

pipe hangers are available when required and

function properly when installed, shall be b) Relocation and reorientation of any hangeror

responsible for the following: restraint from the specified location shall not

be permitted beyondthat which is established

5.5.1 Receiving of hanger assemblies and by the responsible hanger designer, without

components shall be in accordance with the his express permission.

following:

c) Installed hangersor hanger components shall

a) The receiving clerk should be responsible for be used only for their intended purpose. They

verifying agreement between the bill of lading shall not beused for rigging or erection

and the shipment as received. Any damageor purposes.

shortage should be noted on the bill of lading

and the shipper and carrier immediately d) Planned installation sequence

notified.

I) The hungerdesigner assumesresponsi-

b) Unloading should be done with reasonable bility for avoidinghangerinterference

care, taking note of any precautionary notices with all piping, electrical trays,ducts and

on the containers. Items of shipment should equipment specificallydimensioned on

not be dropped. drawingssupplied to him. Studies are

made to avoid such interferences during

5.5.2 Storage of hangerassembliesand the design phase of pre-engineered hang-

components shall be in accordance with the ers; however the designer cannot control

following: avoidance of interference caused by field

run piping, electricalconduits, instrumen-

a) It is recommended that containers be opened tation, added steel framing, etc. If modifi-

and contents verified against the packing list cations are made by the field, the hanger

before theyare placed in the storage area. Any designer shall be so advised in writing.

damage or shortage should be noted and the

pipe hanger contractor immediately notified. 2) The hunger installer should be cognizant

of the total amount of piping and equip-

b) Storage should be in a dry area and protected ment to be installed in any given area. He

from the direct effects of weather and dirt. should develop an installation sequence

giving priority to major components and

c) It is recommended that a system be estab- strata of piping closest to the supporting

lished to facilitate retrieval of material from structure. The installer also shouldreview

storage. routing offield run piping in order to

reserve space for known components to

d) It should be noted, that even with the best of be installed at somelater date in order to

storage conditions, hangers that receive a minimize revamp work. He should coor-

shop coat of rust inhibitive primer,may begin dinate erection of all piping with other

to deteriorate after six months. It is, therefore, trades to maintain erection clearancesand

COPYRIGHT Manufacturers Standardization Society of the Valve and Fittings

Licensed by Information Handling Services

~~~ ~~~~~ ~

~

STD.MSS SP-77-ENGL L995 M 5770b40 0501402 381 m

PRACTICE STANDARD SP-77

availability of building structure for sup- 6) Hangers for certain piping systems may

porting functions. be required to be checked for adjustment

during initial run at operating tempera-

e) Hanger adiustment ture. Particular attention should be given

to spring hangers and spring supports.

To compensatefor pipe elevation dis-

crepancies, hangers are usually provided f) Inspection

with means to permit vertical adjustment

during and after installation. Threaded Each installed hanger should be verified

devicesusing turnbuckles, clevises, etc. against the hanger drawing to assure that

provide this feature or the adjustment is all components are undamaged and have '

inherently available in the hanger design. been properly installed prior to startup.

No adjustment shall be made that will

result in less than full usable thread Threadedcomponents used for adjust-

engagement. ment of each hanger should be checked

for operability and inspected for possible

For smallsizepiping, the necessity for damage. Damaged components shall be

adjusting can be detected visually. For replaced.

large or heavypiping, the necessity for

adjustment may not be as obvious and the Lock nuts on threaded components, cot-

installer mustdetermine that each hanger ter pins, temporary lockingdevices(travel

or supportsubstantially carries its proper stops) and otherlocking means furnished

load. Hanger drawings usually denote the with springunitsshould be properly

operating and hydrostatic test loads. engaged.

Adjustment devices or features are usually Restraint devices utilizinghydraulic fluids

providedwith meansfor locking;lock should be checked for proper amount of

nuts being the most common means. fluid. If it is found necessary to addfluid,

Upon completion of hanger adjustment, it must be of the type specifiedby the

adjustment features should be locked or restraint supplier.

lock nuts should be properly tightened. It

is not recommended to break threads or Verify that spring locking devices and any

tack weld as a means of locking unless so temporary hangers and supportsrequired

specified on hanger drawings. for hydrostatic testing are removed and

stored.

Hydrostatictesting,whenrequired,

should not be performed until all hanger Spring hangers should be checked in both

assemblies have been properly installed, the cold and hot position to insure that

adjusted and loaded in accordance with their load/ travel indicators are approxi-

the hanger drawings. mately where the pipe hanger assembly

drawings indicate that they should be and

After completion of hydrostatic tests of that the pipe is at theproper elevation.

the piping system, any devices (e.g.,spring

travel stops, temporary supports, etc.) Detailed requirements and recommen-

furnished for hydrostatic test purposes dations relative to receiving, storage and

must be removed. installation of pipe hangerassemblies

are covered in MSS SP-89.

COPYRIGHT Manufacturers Standardization Society of the Valve and Fittings

Licensed by Information Handling Services

MSS PRACTICE SP-77

ANNEX A

REFERENCED DOCUMENTS

This annex is an integral part of this Standard Practice which is placed after the main text for convenience.

AISC - 1989 American Institute of Steel Construction "Manual of Steel Construction

ASMEB31.1 - 1998 Code for Pressure Piping

ASME - 1998 Boiler and Pressure Codes

MSS SP-58-1993 Pipe Hangers and Supports - Materials, Design and Manufacture

MSS SP-69- 1996 Pipe Hangers andSupports - Selection and Application

MSS SP-89-1998 Pipe Hangers and Supports - Fabrication and Installation Practices

Publications of the following organizations appear on the list.

AISC American Institute of Steel Construction, Inc.

One E. Wacker Drive, Suite 3 100

Chicago, Illinois 6060 1-2001

Phone: (3 12) 670-2400

ANSI American National Standards Institute

11 West 42nd Street, 13th Floor

New York, NY 10036-8002

Phone: (2 12) 642-4900

ASME The American Society of Mechanical Engineers

Three Park Avenue

New York, NY 1O0 16-5990

Phone: (2 12) 59 1-7000

MSS Manufacturers Standardization Society ofthe Valve and Fittings Industry, Inc.

127 Park Street, N.E.

Vienna, VA 22 180-4602

Phone: (703) 281-6613

COPYRIGHT Manufacturers Standardization Society of the Valve and Fittings

Licensed by Information Handling Services

~~

List of MSS Standard Practices

(Price List Available Upon Request)

Number

SP-6-I gag Standard Finishesfor Contact Facesof Pipe Flangesand Connecting-End Flangesof Valves and Fittings

SP-9-1997 Spot Fadng for B m e , Iron and Steel Flanges

SP-25-1998 Standard MarkingSystem For Valves. Fittings. Flanges and Unions

SP422-1999 Class 150 Conusion Resistant Gats. Glove.Angle and Check Valveswith Flanged and Butt weld Ends

SP-43-I991 (R 96) Wrought Stainless Steel Butt-welding FWngs

S P 4 - I 996 Steel Pipeline Flanges

SP-45-I998 Bypass and DrainConnedons

SP-51-2000 Class 15OLW Comion Resistant Cast Flanges and Flanged Fittings

SP"lQ99 Quality Standard forSteel Castings and Forgings for Valves. Flanges and Fittings and Other Piping Componets - Magnetic Partide

ExaminationMethod

SP-54-I999 -

Quality Standard for Steel Castingsfor Valves, Flanges, and Fittings and Other Piping Components Radiographic ExaminationMethod

SP-55-1996 -

Quality Standard fa Steel Castings for Valves. Flanges and Fangs and Other Piping Components VisualMethod for Evaluation Of

surfaœ IrregldaritieS

SP-58-1993 Pipe Hangers andSuppork - Materials. Design and Manufacture

SP-60-1999 Connecting Flanga Joint Between Tapping Sleeves and Tapping Valves

SP-61-1999 Pressure Testingof Steel Valves

SP55-I999 High Pressure ChemicalIndustry Flanges and Threaded Stubs for Usewith Lens Gaskets

SP-67-1995 Butterffy Valves

SP-68-1997 High Pressure Buttw?y Valves with Offset Design

SP-69-1996 -

Pipe Hangers and SupportsSelaction andA p p l i i

SP-70-1998 Cast Iron Gate Valves, Flanged and Threáded Ends

SP-71-1997 Gray Iron Swing Ch& Valves, Flanged and Threaded Ends

SP-72-1999 Ball Valves with Flanged01 Butt Welding Ends for GeneralServiœ

SP-73-1991 (R 96)Brazing Joints for Wmught and Cast Copper Alloy Solder Joint Pressure Fittings

SP-75-1998 Specitication for High Test Wrought Butt Welding Fittings

SP-77- I995 (R 00) Guidelines for Pipe Support Contractual Relatianships

SP-78-1998 Cast Iron Plug Valves, Flanged and Threaded Ends

SP-79-19QW Socket-Welding Reducer Inserts

SP-80-1997 Bronze Gate, Globe. Angle and Check Valves

SP-81-2OOO Stainless Steel, Bonnetless, Flanged, Knife Gate Valves

SP-82-1992 Valve Pressure Testing Methods

SP-83-1995 Class 3000 Steel Pipe Unions. Sodcet-Welding and Threaded

SP-85-1994 Cast Iron Globe&Angle Valves, Flanged and Threaded Ends

SP-86-1997 Guidelines for Metric Data in Standards for Valves, Flanges, Fittings and Actuators

SP-87-1991 (R 96) Factory-Made Butt-welding Fittings for Class 1 Nudear Piping Applications

SP-88-1993 Diaphragm Type Valves

SP-69-1998 Pipe Hangars andSupports - Fabrication and Installation Prdcticeg

SP-90-2000 Guidelines on Terminologyfor Pipe Hangers and Supports

SP-91-1992 (R 0 6 ) Guidelines for Manual Operationsof Valves

SP-92-1999 MSS Valve User Guide

SP-93-1999 Quality Standard forSteel Castings and Forgings for Valves, Flanges, and Fittings and Other Piping Components-Liquid Penetrant

ExaminationMethod

SP-94-1999 Quality Std for Ferritic and MarteMitlc Steel Castings for Valves, Flanges, and Fittings and Other Piping Components-Ultrasonic

ExaminationMethod

SP-95-2ooO Swage(d) Nipples andBull Plugs

SP-96-1996 Guidelines on Terminology for Valves and Fittings

SP-97-1995 Integrally Reinforced Forged BranchOutlet FittingsSoCket Welding, Threaded and Buttwelding Ends

SP-98-1996 Protective Coatingsfor the Interior @Valves, Hydrants. and Fittings

SP-99-1994 Instrumant Valves

SP-100-1997 Qualification Requirements for Elastomer Diaphragms for Nuclear Diaphragm Type Valves

SP-101-1989 Part-Turn Valve Actuator Attachment-Flange and Driving Component Dimensions and-performance Characteristics

SP-102-1989 -

Multi-Turn ValveAduator Attachment Flange and Driving Camponent Dimensions and Performance Characteristics

SP-103-1995 (R 00) Wrought Copper and Copp$rAlloy Insert Fittings for Polybutylene System

SP-104-1995 Wrought Copper Solder Joint Pressure Fittings

SP-I 05-1 996 Instrument Valves for Code Applications

SP-I 06-1 990 (R 96) Cast Copper Alloy Flangessad Flanged Fittings, Class 125, 150 and 300

SP-107-1991 (R 00) Transition Union Fittings for Joining Metal and Plastic Products

SP-106-1996 Resillent-Seated Cast Iron-Eccentric Plug Valves

SP-109-1997 Welded Fabricated Copper Solder Joint Pressure Fittings

SP-110-1996 Ball Valves Threaded, Socket-wekling, Solder Joint, Gmoved and Flared Ends

SP-111-1996 Gray-Iron and Ductile-lron Tapping SJeeves

SP-I 12-1999 -

Quality Standard for Evaluation of Cast Sutfaœ Finishes Visual.and

, e Tactile

c a Method.

f This

r umusts be sold

SP - with

O aI three

dimensional Cast Surface Comparabr, which b a necessary p a ~ W the Standard.

Additional Compamtors may be solil separately at $25.00 each. Same quantity discounts apply on total order.

SP-113-1994 Connecting Joint between Tapping Machines and Tapping .Valves

SP-114-1995 Corrosion Resistant Pipe Fittings Threaded and Socket Welding, Class 150 and 1000 '

SP-I 15-1999 Excess Flow Valves for Natural GasService

SP-I 16-1996 Serviœ Line Valves and Fittings for Drinking Water Systems

SP-117-1996 Bellows Seals for Globe and Gate Valves

SP-116-1996 Compact Steel Globe Check V a W - Flanged, Flangèless, Threaded& Welding Ends (Chemical 8 Petroleum ReRnery Serviœ)

SP-119-1996 Belled End Socket WeldingFittings-StainlessSteel and Copper Nlckel

SP-120-1997 Flexible Graphite Packing System for Rising Stem Steel Valves (Design Requirements)

SP-121-1997 Qualification TestingMethods for Stem Packing for Rising StemSteel Valves

SP-122-1997 Plastic Industrial Ball Valves

SP-123-lm8 N o n - F e w Threaded and Solder-Joint Unions for Use wlth Copper Water Tube

SP-124-2ooo F a m t e d Tapping Sleeves

SP-125-2ooo Gray Iron and Dudile Iron In-line, Spring-Loaded. Center-Guided Check Valves

(R YEAR) Indicates year standard reaffirmed without substantbe changes

A large number of f o m r MSS Practicaa have been approvedby the ANSI or ANSI Standards, published by others. In order to maintain a single SourCe

of authoritative information,the MSS withdraws its Standard Practice in such cases.

Manufacturers Standardization Society of the Valve and Fittings Industry, Inc.

N.E.,Vienna, VA221804620 (703) 281-6613Fax# (703) 281-6671

127 Park Street,

COPYRIGHT Manufacturers Standardization Society of the Valve and Fittings

Licensed by Information Handling Services

You might also like

- Penstock ManualDocument159 pagesPenstock Manualstudent_bl95% (21)

- Darcy WeisbachDocument11 pagesDarcy WeisbachSudip SardarNo ratings yet

- Power House 1Document1 pagePower House 1ecsuperalNo ratings yet

- Rubber Tires Racking SchemeDocument22 pagesRubber Tires Racking SchemeecsuperalNo ratings yet

- Env Dao 2000-81Document105 pagesEnv Dao 2000-81Francis Ruther IcaoNo ratings yet

- Hydro Sample Site PlanDocument1 pageHydro Sample Site PlanecsuperalNo ratings yet

- Power HouseDocument1 pagePower HouseecsuperalNo ratings yet

- Carrier Optima (42CSH) - Wall MountedDocument8 pagesCarrier Optima (42CSH) - Wall MountedErwin Maldo50% (2)

- Dam & DesanderDocument1 pageDam & DesanderecsuperalNo ratings yet

- Dao05 10 Cwa IrrDocument50 pagesDao05 10 Cwa IrrecsuperalNo ratings yet

- DAO 2007-22 - Guidelines On The Requirements For Continuous Emission Monitoring Systems (CEMS) and Other Acceptable Protocols, Thereby Modifying and Clarifying Certain ProvisiDocument6 pagesDAO 2007-22 - Guidelines On The Requirements For Continuous Emission Monitoring Systems (CEMS) and Other Acceptable Protocols, Thereby Modifying and Clarifying Certain ProvisiPacific SpectrumNo ratings yet

- WellpointDocument2 pagesWellpointecsuperalNo ratings yet

- Alstom HP 1103 PerformanceDocument2 pagesAlstom HP 1103 PerformanceecsuperalNo ratings yet

- Dao05 10 Cwa IrrDocument50 pagesDao05 10 Cwa IrrecsuperalNo ratings yet

- DAO 90-34 - Revised Water Usage and Classification Water Quality Criteria Amending Section Nos 68 and 69, Chapter III of The 1978 NPCC Rules and RegulationsDocument11 pagesDAO 90-34 - Revised Water Usage and Classification Water Quality Criteria Amending Section Nos 68 and 69, Chapter III of The 1978 NPCC Rules and RegulationsPacific Spectrum100% (4)

- BS4504 PN 16 Flange DimensionsDocument3 pagesBS4504 PN 16 Flange DimensionsecsuperalNo ratings yet

- Ambient Noise Level Std.Document1 pageAmbient Noise Level Std.ecsuperalNo ratings yet

- Ambient Noise Level Std.Document1 pageAmbient Noise Level Std.ecsuperalNo ratings yet

- Commissioning Test Results for Oil-Immersed TransformerDocument18 pagesCommissioning Test Results for Oil-Immersed TransformerecsuperalNo ratings yet

- ASTM B88 Copper TubesDocument3 pagesASTM B88 Copper TubesecsuperalNo ratings yet

- RSCDocument3 pagesRSCecsuperalNo ratings yet

- DAO 2007-22 - Guidelines On The Requirements For Continuous Emission Monitoring Systems (CEMS) and Other Acceptable Protocols, Thereby Modifying and Clarifying Certain ProvisiDocument6 pagesDAO 2007-22 - Guidelines On The Requirements For Continuous Emission Monitoring Systems (CEMS) and Other Acceptable Protocols, Thereby Modifying and Clarifying Certain ProvisiPacific SpectrumNo ratings yet

- Pressure Relief Valve Engineering HandbookDocument93 pagesPressure Relief Valve Engineering Handbookakrouti92% (12)

- Flocon Flange Tables GuideDocument5 pagesFlocon Flange Tables GuideAngel AngeleyeNo ratings yet

- Electrical Test Sheet: Standard For Combined Cycle Power PlantDocument26 pagesElectrical Test Sheet: Standard For Combined Cycle Power PlantecsuperalNo ratings yet

- Central Philippine University College of Engineering SECOND SEMESTER S.Y. 2005-2006 Work Term ReportDocument17 pagesCentral Philippine University College of Engineering SECOND SEMESTER S.Y. 2005-2006 Work Term ReportecsuperalNo ratings yet

- El STD08Document34 pagesEl STD08ecsuperalNo ratings yet

- AC Induction Motor FundamentalsDocument24 pagesAC Induction Motor Fundamentalsrohtahir100% (3)

- FLANGE DIMENSIONS - DIN PN 6-40Document7 pagesFLANGE DIMENSIONS - DIN PN 6-40Dave DonohueNo ratings yet

- Air Preheater BasicsDocument1 pageAir Preheater Basics112dharmeshNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Asme B18.2.6 2003Document11 pagesAsme B18.2.6 2003Jesse ChenNo ratings yet

- SPLE - Plumbing Code No. 02 - Answer KeyDocument4 pagesSPLE - Plumbing Code No. 02 - Answer KeyAlexander Nuevo San AndresNo ratings yet

- Trelleborg Seapile & SeatimberDocument6 pagesTrelleborg Seapile & SeatimbersivakumarNo ratings yet

- Alsina Mecanoconcept Experience 2017 LowDocument24 pagesAlsina Mecanoconcept Experience 2017 LowMiguel AngelNo ratings yet

- Coge Foil 504Document4 pagesCoge Foil 504Saba AhmedNo ratings yet

- Dubo Worldwide: DUBO and KORREX Products Maryland MetricsDocument26 pagesDubo Worldwide: DUBO and KORREX Products Maryland MetricsSuresh Kumar MittapalliNo ratings yet

- Astm A178 A178m-02 PDFDocument4 pagesAstm A178 A178m-02 PDFZaida Isadora Torres Vera100% (1)

- Selective LeachingDocument13 pagesSelective Leachingarslanjaved690100% (1)

- Product Data Sheet: Astm Grade 2 Babbitt MetalDocument1 pageProduct Data Sheet: Astm Grade 2 Babbitt MetalAshutosh PandeyNo ratings yet

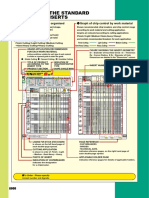

- Lecture 11 MasonryDocument26 pagesLecture 11 MasonrySunny LeungNo ratings yet

- List of Items and Corresponding Test For QCPDocument4 pagesList of Items and Corresponding Test For QCPSheila Marie Menes OmegaNo ratings yet

- Proper Use of The Rebound HammerDocument5 pagesProper Use of The Rebound HammerJan BooysenNo ratings yet

- Antivibradores Castel 1Document4 pagesAntivibradores Castel 1charly541No ratings yet

- BT Silfos 15 ENDocument1 pageBT Silfos 15 ENIonutCiobanuNo ratings yet

- Wabocrete IIDocument3 pagesWabocrete IIprasadNo ratings yet

- 04 MASONRY HandoutDocument9 pages04 MASONRY HandoutZabeth villalonNo ratings yet

- Specification - Tunnel Shotcrete LiningDocument43 pagesSpecification - Tunnel Shotcrete LiningAlhad Panwalkar100% (1)

- Tender MaterialsDocument8 pagesTender MaterialsJampani HymavathiNo ratings yet

- Residential Building Construction Training ReportDocument40 pagesResidential Building Construction Training ReportRaj Verma63% (8)

- ISO 2768 Machining Tolerance StandardDocument2 pagesISO 2768 Machining Tolerance Standardlohith.raviNo ratings yet

- Mitsu Turning Tools Insert GuideDocument110 pagesMitsu Turning Tools Insert GuideJeka MazurovskyNo ratings yet

- ASTERITE® Ice Technical-Data-Sheet.1569415465Document2 pagesASTERITE® Ice Technical-Data-Sheet.1569415465Mamoon ShahidNo ratings yet

- DSI ALWAG Systems - Mechanical Anchors and Rebar Rock Bolts PDFDocument16 pagesDSI ALWAG Systems - Mechanical Anchors and Rebar Rock Bolts PDFxenNo ratings yet

- Design Report of Retaining WallDocument37 pagesDesign Report of Retaining WallShivsagar yadav100% (1)

- Build retaining walls and prevent erosionDocument2 pagesBuild retaining walls and prevent erosionEdsun CaraleNo ratings yet

- Daily Report - 1Document6 pagesDaily Report - 1Akli Ale ManNo ratings yet

- Assumptions For RCC Structure Quantity CalculationDocument1 pageAssumptions For RCC Structure Quantity CalculationmustafazahmedNo ratings yet

- Kkatalog Veflopdf PDFDocument82 pagesKkatalog Veflopdf PDFPeroJurevicNo ratings yet

- Damp ProofingDocument15 pagesDamp ProofingKhushboo PriyaNo ratings yet

- Foreva - Historic BuildingsDocument4 pagesForeva - Historic BuildingsHuy Nguyen VanNo ratings yet