Professional Documents

Culture Documents

RCD 2

Uploaded by

John Joshua DavantesCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

RCD 2

Uploaded by

John Joshua DavantesCopyright:

Available Formats

Reinforced Concrete Design – 2: ELASTIC BEHAVIOR OF BEAM SECTIONS

ENGR BIR

ELASTIC BEHAVIOR OF BEAM SECTIONS

In this section, it is assumed that a small transverse load is placed on a concrete beam with tensile reinforcing bars

and that the load is gradually increased in magnitude until the beam fails. Three distinct stages of beam before collapse

occurs: (1) the uncracked stage; (2) the concrete cracked-elastic stress stage; and (3) the ultimate-strength stage.

Uncracked Concrete Stage

At small loads when the tensile stress are less than the modulus of rupture (the bending tensile stress at which the

concrete begins to crack), the entire cross section of the beam resists bending, with compression on one side and

tension on the other.

Figure 1. Uncracked concrete stage

Concrete Cracked – Elastic Stresses Stage

As the load is increased after the modulus of rupture of the concrete is exceeded, cracks begin to develop in the bottom

of the beam. The moment at which these cracks begin to form is referred to as the cracking moment, M cr. As the load

is further increased, these cracks quickly spread up to the vicinity of the neutral axis, and then the neutral axis begins

to move upward. The cracks occur at those places along the beam where the actual moment is greater than the

cracking moment. Now that the bottom has cracked, another stage is present because the concrete in the cracked

zone obviously cannot resist tensile stresses. This stage will continue as long as the compression stress in the top

fibers is less than about one-half of the concrete’s compression strength and as long as the steel stress is less than its

yield stress. To compute the concrete and steel stresses in this range, the transformed-area method is used.

Figure 2. Concrete cracked – elastic stresses stage

Ultimate – Strength Stage

As the load is increased further so that the compressive stresses are greater than 0.50fc’, the tensile stress cracks

move farther upward, as does the neutral axis, and the concrete compression stresses begin to change appreciably

from a straight line.

NATIONAL UNIVERSITY – MANILA

2ND Semester AY 2017-2018

Reinforced Concrete Design – 2: ELASTIC BEHAVIOR OF BEAM SECTIONS

ENGR BIR

Figure 3. Ultimate – strength stage

Figure 4. Moment – curvature diagram for reinforced concrete beam with tensile reinforcement only

Cracking Moment

Cracking moment is the moment that causes the stress in the extreme fiber of unreinforced beam to reach the modulus

of rupture. T he moment curvature – relationship is linear and the section referred to as the uncracked section.

𝑓𝑟 = λ 0.62 √𝑓𝑐 ′ 𝑀𝑃𝑎

𝑓𝑟 𝐼𝑔

𝑀𝑐𝑟 =

𝑌𝑡

Transformed – Area Method

The basic concept of a transformed area is that the section of steel and concrete is transformed into a homogenous

section of concrete by replacing the actual steel area with an equivalent area of concrete. Two conditions must be

satisfied for the transformation process.

A. Equilibrium

- T he force in the steel must be equal to the force in the transformation concrete.

B. Strain Compatibility

- The unit strains must be the same.

𝐸𝑠

𝑛= (𝑚𝑜𝑑𝑢𝑙𝑎𝑟 𝑟𝑎𝑡𝑖𝑜)

𝐸𝑐

NATIONAL UNIVERSITY – MANILA

2ND Semester AY 2017-2018

Reinforced Concrete Design – 2: ELASTIC BEHAVIOR OF BEAM SECTIONS

ENGR BIR

𝐴 𝑐 = 𝑛𝐴 𝑠 (𝑡𝑟𝑎𝑛𝑠𝑓𝑜𝑟𝑚𝑒𝑑 𝑎𝑟𝑒𝑎)

Where:

n = is used for tension steel

2n = is used for compression steel

NOTE:

1. When the maximum tensile stress in the concrete is smaller than the modulus of rupture, the section is called

uncracked section with no tension cracks develop, the entire gross concrete area is used in the computation.

2. When the maximum tensile stress in concrete is greater than the modulus of rupture, the section is called the

cracked sections with or without compression steel.

A. Transformed Area for uncracked section

fc < fr = 0.62 √fc

Note: Whole concrete area is used and equivalent concrete area (n-1) As is used.

B. Transformed Area for cracked section

fc > fr = 0.62 √fc

Note: Only the shaded area of concrete is used and equivalent concrete area nAs is used.

Where:

𝑓𝑐

𝑘=

𝑓𝑠

𝑓𝑐 +

𝑛

NATIONAL UNIVERSITY – MANILA

2ND Semester AY 2017-2018

Reinforced Concrete Design – 2: ELASTIC BEHAVIOR OF BEAM SECTIONS

ENGR BIR

C. Cracked section reinforced for both tension and compression

Note: Modular ratio for compression steel is 2n

Convert As’ to equivalent concrete area, 2nAs’ – As’ = (2n-1) As’

1. Cracked Section

Ac = bx + (2n-1) As’ (equivalent concrete area in compression)

Ac = nAs (equivalent concrete area in tension)

2. Uncracked Section

Ac = bh + As (n-1)

Steps in analysis of uncracked section:

1. Neutral axis at a distance x from the top

2. Solve for x

3. Concrete stress if moment M is known

4. Stress of steel

Steps in analysis of cracked section:

1. Locate NA

2. Moment of inertia at NA

3. Stress of concrete

4. Stress of steel

Sample Problems:

1. A rectangular beam has dimensions of 250mm by 625mm with an effective depth of 575mm and is reinforced

with three 25mm. The concrete cylinder strength is 27.6MPa and the tensile strength in bending (modulus of

rupture) is 3.28MPa. The yield point of the steel is 414.7MPa. The beam carries a bending moment of 61kN-

m. Use uncracked, transformed section method. Determine the following:

A. Concrete compression stress at the top

B. Concrete tensions stress at the bottom

C. Stress in steel

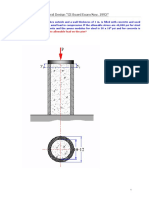

2. A rectangular reinforced concrete beam with a width of 299mm and an effective depth 0f 500mm is subjected

to a service moment of 120kN-m. The beam is reinforced with 4-25mm bars with a modular ratio of 8. Use

cracked, transformed section method.

A. Distance of the neutral axis from the top of the beam

B. Maximum stress of concrete

C. Maximum stress of steel

NATIONAL UNIVERSITY – MANILA

2ND Semester AY 2017-2018

You might also like

- 2.2 - Concrete Cracked Elastic Stresses StageDocument12 pages2.2 - Concrete Cracked Elastic Stresses StageMarcelo AbreraNo ratings yet

- Lecture 4 DamsDocument18 pagesLecture 4 DamsKristine D. SanchezNo ratings yet

- 2019 - May (Mste With Solutions)Document17 pages2019 - May (Mste With Solutions)Angelique VeteNo ratings yet

- T-Beam DesignDocument5 pagesT-Beam DesignPrince Arc MiguelNo ratings yet

- Torsion of Rolled Sections in Building StructuresDocument27 pagesTorsion of Rolled Sections in Building StructuresrilopiyNo ratings yet

- Problems in RCD - MARCELO T. ABRERA JR.Document16 pagesProblems in RCD - MARCELO T. ABRERA JR.Marcelo AbreraNo ratings yet

- 2) Introduction To WSD, Rectangular BeamsDocument10 pages2) Introduction To WSD, Rectangular BeamsVanessa Rosal PalerNo ratings yet

- Problems in Statistical PhysicsDocument14 pagesProblems in Statistical PhysicsJulian Rey100% (1)

- Chapter 4 - Soil Compaction-1Document5 pagesChapter 4 - Soil Compaction-1Yandi TVNo ratings yet

- Ce0061 Professional Course 4 - (Specialized 2) Ste Track: Prestressed Concrete DesignDocument40 pagesCe0061 Professional Course 4 - (Specialized 2) Ste Track: Prestressed Concrete DesignjerichoNo ratings yet

- Formulas and Tables Shear Torsion Serviceability Development LengthsDocument5 pagesFormulas and Tables Shear Torsion Serviceability Development LengthsWilkenn TuazonNo ratings yet

- Reviewer RCDDocument3 pagesReviewer RCDShadowiw KulitNo ratings yet

- P5 3B Bernardo KathryneDocument5 pagesP5 3B Bernardo KathryneKATHRYNE BERNARDONo ratings yet

- 10 Relative EquilibriumDocument35 pages10 Relative EquilibriumTrixia DuazoNo ratings yet

- Lesson 3 and 4Document10 pagesLesson 3 and 4Mark MarkNo ratings yet

- HydraulicsDocument12 pagesHydraulicsMugiwara Sparrow0% (1)

- Gis Located Above B)Document10 pagesGis Located Above B)Apple AterradoNo ratings yet

- Pamantasan NG Lungsod NG ValenzuelaDocument2 pagesPamantasan NG Lungsod NG ValenzuelaDiane de OcampoNo ratings yet

- 4 BuoyancyDocument5 pages4 BuoyancyDaniel Vasquez0% (1)

- Cap 8 Bending Strength of Compact and Noncompact ShapesDocument13 pagesCap 8 Bending Strength of Compact and Noncompact Shapescarlomonsalve1No ratings yet

- 7 8soil PDFDocument2 pages7 8soil PDFAnnerose GaleraNo ratings yet

- HYDRAULICSDocument33 pagesHYDRAULICSSamNo ratings yet

- Problem 1 Structural Design Ce Board Exam Nov 1992 PDF FreeDocument2 pagesProblem 1 Structural Design Ce Board Exam Nov 1992 PDF FreeRachel Delosreyes0% (1)

- 11 - Design of One-Way Slabs PDFDocument23 pages11 - Design of One-Way Slabs PDFAndrea Sochayseng SolijonNo ratings yet

- Gabion Chapter 2 and 3Document10 pagesGabion Chapter 2 and 3Patrick Ray TanNo ratings yet

- Moren - MODULE 3 - Beams-ColumnDocument18 pagesMoren - MODULE 3 - Beams-ColumnJoshua Espanto MorenNo ratings yet

- Bautista, Allan C Bsce-4ADocument1 pageBautista, Allan C Bsce-4AJohn Taylor BernasNo ratings yet

- 14 Making and Curing Concrete Test Specimens in The FieldDocument6 pages14 Making and Curing Concrete Test Specimens in The FieldJohn MarkNo ratings yet

- Design of Doubly Reinf and - T-BeamsDocument13 pagesDesign of Doubly Reinf and - T-BeamsGrace Ann CabanbanNo ratings yet

- Ce6702 DecDocument57 pagesCe6702 Decpmali2No ratings yet

- Highway and Railroad Engineering: Reversed CurvesDocument8 pagesHighway and Railroad Engineering: Reversed CurvesDirect XNo ratings yet

- Properties of Concrete With Coconut Husk and Dried Banana Leaffibers As Aggregate ReplacementintroductionrationaleDocument3 pagesProperties of Concrete With Coconut Husk and Dried Banana Leaffibers As Aggregate Replacementintroductionrationalejohn philip s garciaNo ratings yet

- Ce Review Nov 2021: (310mm) (155mm) (220mm) (7.21 In.)Document2 pagesCe Review Nov 2021: (310mm) (155mm) (220mm) (7.21 In.)Ice DelevingneNo ratings yet

- Subject 1 Algebra Trigonometry Plane Geometry Solid Geometry Analytic Geometry Probability PhysicsDocument49 pagesSubject 1 Algebra Trigonometry Plane Geometry Solid Geometry Analytic Geometry Probability PhysicsDani LubosNo ratings yet

- Mathalino - Double Integration MethodDocument38 pagesMathalino - Double Integration Methodanjibee100% (1)

- Module 2 SW4 PDFDocument11 pagesModule 2 SW4 PDFhgfhfghfghgNo ratings yet

- Connections 1Document26 pagesConnections 1Nicole ReyesNo ratings yet

- Item 1018Document5 pagesItem 1018Ester MarianNo ratings yet

- Comprehensive Exam - Mste (Solve Again)Document3 pagesComprehensive Exam - Mste (Solve Again)Ag OribianaNo ratings yet

- 2-CE 305 MOD 2 Singly RCFDocument10 pages2-CE 305 MOD 2 Singly RCFLester Khiets RoaNo ratings yet

- NCESQ 2018 QuestionsDocument3 pagesNCESQ 2018 QuestionsKhent Alfred B. DerechoNo ratings yet

- Doubly Reinforced Beams: F F F F C D CDocument17 pagesDoubly Reinforced Beams: F F F F C D CEly ReyesNo ratings yet

- 2 Principles of HyrdostataicsDocument18 pages2 Principles of HyrdostataicsBillie Ian. Salamante JrNo ratings yet

- CE 45-Hydraulics SyllabusDocument2 pagesCE 45-Hydraulics SyllabuspicefeatiNo ratings yet

- Module 1 - Les #1 Analysis of Loads 1Document14 pagesModule 1 - Les #1 Analysis of Loads 1cutie4everrNo ratings yet

- Review of Related LiteratureDocument12 pagesReview of Related LiteratureJohn Clyde Agayao100% (1)

- M2 03 Constant and Falling Head TestDocument13 pagesM2 03 Constant and Falling Head TestPzynae FlorentinoNo ratings yet

- Volume 1Document15 pagesVolume 1Bhong LucenecioNo ratings yet

- X Tan G : CE Review For Nov 2022 - Hydraulics 7Document1 pageX Tan G : CE Review For Nov 2022 - Hydraulics 7JuDeNo ratings yet

- Example 1: Including The Weight of The Beam The Beam Has Continuous Lateral Support Isa W30x116 Adequate?Document6 pagesExample 1: Including The Weight of The Beam The Beam Has Continuous Lateral Support Isa W30x116 Adequate?Yousif alhassankoNo ratings yet

- Design of Columns Subject To Axial Load and BendingDocument10 pagesDesign of Columns Subject To Axial Load and BendingWilbert ReuyanNo ratings yet

- U 1.2 D+1.6 L+0.5 (LR R) : Section 405: Loads Table 405.3.1 Load CombinationsDocument4 pagesU 1.2 D+1.6 L+0.5 (LR R) : Section 405: Loads Table 405.3.1 Load CombinationsMary Joy DelgadoNo ratings yet

- Mathematics and Surveying May 2013Document8 pagesMathematics and Surveying May 2013Bernie RomeroNo ratings yet

- Problem 7. Structural Design "CE Board Exam Nov. 1992Document1 pageProblem 7. Structural Design "CE Board Exam Nov. 1992AlvinNo ratings yet

- FraceDocument12 pagesFraceIra MejiaNo ratings yet

- Ce353 Part 3 HydrologyDocument24 pagesCe353 Part 3 HydrologyAnnie TheExplorerNo ratings yet

- Soil Lec SoilCompositionDocument4 pagesSoil Lec SoilCompositionMikaela LorescaNo ratings yet

- Chapter-7 Shear DesignDocument14 pagesChapter-7 Shear DesignAngelo RosNo ratings yet

- 620PT4032007 2008 2009 2010Document4 pages620PT4032007 2008 2009 2010Mona fabrigarNo ratings yet

- C1609-Flex Test For GFRCDocument9 pagesC1609-Flex Test For GFRCBrinder DhanoaNo ratings yet

- RCD Module 11 Length Development Elefante OchoaDocument28 pagesRCD Module 11 Length Development Elefante OchoaJemson VictorioNo ratings yet

- Ce133p 2 WSD NSCP 2015Document2 pagesCe133p 2 WSD NSCP 2015RapNo ratings yet

- Dekton K&B ROADocument24 pagesDekton K&B ROABoraNo ratings yet

- Datasheet Diodo SB360Document2 pagesDatasheet Diodo SB360Gonzalo RojasNo ratings yet

- Mumax: A New High-Performance Micromagnetic Simulation ToolDocument9 pagesMumax: A New High-Performance Micromagnetic Simulation ToolArnab PattanayakNo ratings yet

- General Physics 1 Week 12Document56 pagesGeneral Physics 1 Week 12Harold LimboNo ratings yet

- 2 Recycling and Formulation of Aluminum Scrap Via Mass Balance Die Casting and FormingDocument7 pages2 Recycling and Formulation of Aluminum Scrap Via Mass Balance Die Casting and FormingRobby AnugrahNo ratings yet

- Chapter 5Document7 pagesChapter 5syakirah iwanaNo ratings yet

- Summative Test in Sci. Q1-M4Document2 pagesSummative Test in Sci. Q1-M4SoraNo ratings yet

- Complex Refractive IndexDocument8 pagesComplex Refractive Indexashutosh pandeyNo ratings yet

- Hydrometer TestDocument2 pagesHydrometer Testshikar marmarNo ratings yet

- Skymap Diciembre NorteDocument2 pagesSkymap Diciembre NorteRobdaniel KoloNo ratings yet

- Tensor Intro PDFDocument2 pagesTensor Intro PDFMayank MittalNo ratings yet

- Apr May 2021 Final IalDocument18 pagesApr May 2021 Final Ialnew yearNo ratings yet

- Pte Apeuni 20230109 Weekly Kdij42 enDocument250 pagesPte Apeuni 20230109 Weekly Kdij42 enAarogyam AyurvedNo ratings yet

- Electro-Thermal Model of Lithium-Ion Batteries For Electrified Vehicles ApplicationsDocument5 pagesElectro-Thermal Model of Lithium-Ion Batteries For Electrified Vehicles ApplicationsTamil SelvanNo ratings yet

- Evsjv ' Ki F Vu e e 'VQ Ms V II Cö Íve: 2021-22 A - ©-Eq II Ev RU KVH© GDocument112 pagesEvsjv ' Ki F Vu e e 'VQ Ms V II Cö Íve: 2021-22 A - ©-Eq II Ev RU KVH© GDaud FaraizyNo ratings yet

- Figure 1 LP02 Second Class PyranometerDocument2 pagesFigure 1 LP02 Second Class PyranometerKaren Juliana Espinosa ValeroNo ratings yet

- FTS-1 (Code-B) - 21!03!2023 Home Assignment With Answer Keys PDFDocument46 pagesFTS-1 (Code-B) - 21!03!2023 Home Assignment With Answer Keys PDFXembergNo ratings yet

- 2.2 Linear Algebra & GeometryDocument16 pages2.2 Linear Algebra & GeometryRajaNo ratings yet

- Mathematics 7 3 Quarter: Learning Area Grade Level Quarter DateDocument4 pagesMathematics 7 3 Quarter: Learning Area Grade Level Quarter Datealdrin sabinoNo ratings yet

- Optics Assessment 2019 With AnswersDocument10 pagesOptics Assessment 2019 With AnswersBenjamin NgNo ratings yet

- Precision Metal Film Fixed Resistor Axial Leaded: FeaturesDocument21 pagesPrecision Metal Film Fixed Resistor Axial Leaded: FeaturesJonathan Llewellyn AndradaNo ratings yet

- Biaxial Interference Figures F12Document20 pagesBiaxial Interference Figures F12dcegarciamapuaNo ratings yet

- CE322 Assignment 3Document5 pagesCE322 Assignment 3PARAN, DIOSCURANo ratings yet

- DAV CAE CLASS XI Syllabus 2021-2022Document30 pagesDAV CAE CLASS XI Syllabus 2021-2022Prabhat Kumar MishraNo ratings yet

- Board Question Paper: July 2019: PhysicsDocument3 pagesBoard Question Paper: July 2019: PhysicsMahendra ShahNo ratings yet

- Continuous Nanofluids Jet Impingement Heat Transfer and FlowDocument9 pagesContinuous Nanofluids Jet Impingement Heat Transfer and FlowTahmid SadiNo ratings yet

- Electrical and Electronics EngineeringDocument5 pagesElectrical and Electronics EngineeringKharinandan D NNo ratings yet

- 09-10 Reversible Processes and Open System Energy BalanceDocument42 pages09-10 Reversible Processes and Open System Energy BalanceNomun BatunNo ratings yet