Professional Documents

Culture Documents

LTC135 DS en V04

Uploaded by

Nirmal mehtaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

LTC135 DS en V04

Uploaded by

Nirmal mehtaCopyright:

Available Formats

LTC135

Load Tap Changer Testing Power Supply

▪▪Winding Resistance Measurement

▪▪Dynamic Resistance Measurement

▪▪Switch sequence timing

▪▪Transition/resistor measurement

Description LTC135 is designed to be used together with the following Megger

instruments:

LTC135 is an accessory for circuit breaker analyzers to test Load Tap

Changers where it delivers test currents for the measurements. EGIL TM1600/MA61 TM1700 series TM1800

The load tap changer is the only moving part connected to the Together with the circuit-breaker analyzer (CBA) it becomes a a test

transformer windings. Taking a transformer off the system to setup for performing dynamic measurements on load tap-changers.

investigate an internal problem with a tap changer is an expensive The unit can also be used for winding resistance measurements

exercise; therefore it is in every utility’s interest to carry out condition and other applications where a constant DC current test signal is

assessments of their tap changers to help detect developing faults at requested. It is a power supply designed for DC current testing

an early stage. of inductive loads with provisions for discharging the transformer

winding when the test is finalized.

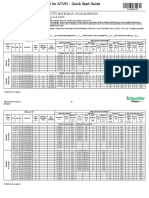

EGIL TM1600/ TM1700 TM1800

Supported

(with analog MA61 series

measurements

measurement)

Single-phase

Continuity test X X X X

Dynamic current/

X X X X

timing

Dynamic voltage/

X X X X

timing

Dynamic resistance

X1) X X X

and timing

Motor current

(external clamp-on)

Three-phase

Continuity test X X X

Dynamic voltage/

X X X

timing

Dynamic resistance

X X X

and timing

Motor current

X X

(external clamp-on)

LTC control X X X X

1) Resistance can be indicated/estimated by combining measured dynamic

LTC voltage and assumed/set test current

Application example Specifications LTC135

Dynamic resistance measurement (DRM) technique has been used Specifications are valid at an ambient temperature of +25°C,

extensively on high voltage circuit breakers to determine the condi- (77°F). Specifications are subject to change without notice.

tion and deterioration of arcing contacts inside the breaker. DRM Environment

is also an advanced diagnostic tool for LTCs to detect problems like Application field For use in high-voltage substations and

coking (creation of pyrolytic carbon and thick organic film on the industrial environments.

contacts), long term degradation of tap selector contacts and revers- Temperature

ing switch contacts, deviation in switching times, damaged transi- Operation -20ºC to +65°C (-4°F to +149°F)

tion resistors or reactors and excessive resistance increase of arcing Storage -40ºC to +85ºC (-40°F to +185°F)

and main contacts of LTC. DRM is measurement of resistance (or Relative humidity %RH 5%-95%, non condensing

voltage from a constant current source) trace while the tap changer

CE-marking

is switched from one extreme tap to the other and back. Since the

EMC 2004/108/EC

resistance changes dynamically as the LTC taps are changed, it is re-

LVD 2006/95/EC

corded with a high sampling rate and plotted as a function of time.

Dynamic change in resistance (or voltage) plot gives valuable infor- General

mation about the contact condition which cannot be determined by Mains voltage 100 - 250 V AC, 50 / 60 Hz

traditional static winding resistance measurements (WRM). Power consumption 300 W (max)

Dimensions 360 x 195 x 300 mm

Magnitude of test current for DRM test is very important. DRM

14.2 x 7.7 x 11.8 in.

response obtained at different test currents on same LTCs should

Weight 6.5 kg (14.3 lbs) instrument only

not be compared as DRM trace would vary depending upon the 10.9 kg (24 lbs) with accessories and

magnitude of test current selected. One of the major differences carrying case

between DRM and WRM setup, other than selection of test current, Outputs

is shorting the corresponding secondary winding. The reason for

Output current 3 x 0.1 A 3x1A 1x5A

shorting the secondary windings is twofold. First, by reducing the

Open circuit voltage 48 V 48 V 48 V

inductance it minimizes the L/R time constant of the circuit that al-

Output impedance 480 Ω 48 Ω 9.6 Ω

lows to measure and track fast variations in voltage/resistance as the

Shunt output 1 V / 0.1 A 1 V / 1 A 1 V / 5 A

taps are changed. The WRM test should use 1 and 5 A per tap and

Shunt inaccuracy 0.1% 0.1% 0.1%

the DRM test preferably a constant current source of 100 mA.

Measurement range

EGIL and TM1600 (4 V) 0 - 44 Ω 0 - 4.4 Ω 0 - 850 mΩ

TM1700/1800 (15 V) 0 - 200 Ω 0 - 20 Ω 0-4Ω

Included accessories

Carrying bag

x3

Sets of test leads (x3) 20 m (65 ft)

General hook-up overview, in this case together with

TM1760. Ordering information

Item Art. No.

LTC135

Including carrying bag and cables CG-92100

Postal address Visiting address Registered to ISO 9001 and 14001

Megger Sweden AB Megger Sweden AB Subject to change without notice.

Box 724 Rinkebyvägen 19 Art.No. ZI-CG04E • Doc. CG2016DE • 2014

SE-182 17 DANDERYD SE-182 36 DANDERYD LTC135_DS_en_V04

SWEDEN SWEDEN www.megger.com

T +46 8 510 195 00 seinfo@megger.com Megger is a registered trademark

F +46 8 510 195 95 www.megger.com

You might also like

- Chapter 6 Predictive Maintenance Technologies: Table 6.1.1Document35 pagesChapter 6 Predictive Maintenance Technologies: Table 6.1.1carlosorizabaNo ratings yet

- FEAG Power Center Control PDFDocument20 pagesFEAG Power Center Control PDFEnriqueNo ratings yet

- IGBT Shovel Inverter ControlDocument11 pagesIGBT Shovel Inverter ControlGumercinda AlvizNo ratings yet

- Power Factor ControllersDocument2 pagesPower Factor Controllersmuhammad ahsanNo ratings yet

- CA 2016 RheologyDocument341 pagesCA 2016 Rheologybhardwaj.mitNo ratings yet

- P12x TechnicalDataSheet en 1EDocument31 pagesP12x TechnicalDataSheet en 1Ekvramanan_1No ratings yet

- FACTS/HVDC Solutions to Enhance Power DeliveryDocument5 pagesFACTS/HVDC Solutions to Enhance Power DeliveryslomczynskiNo ratings yet

- Nokian Capacitor NC12 Controller CutsheetsDocument2 pagesNokian Capacitor NC12 Controller CutsheetsTARIK PELITNo ratings yet

- Directional/Non-Directional Overcurrent Protection Technical Data SheetDocument30 pagesDirectional/Non-Directional Overcurrent Protection Technical Data SheetSyed UmerNo ratings yet

- Shimadzu AGX-V SeriesDocument28 pagesShimadzu AGX-V SeriesRepresentaciones y Distribuciones FAL100% (1)

- MICOM P12x-TechnicalDataSheetDocument28 pagesMICOM P12x-TechnicalDataSheetSeba GonzálezNo ratings yet

- Section VII.4 Pla Ns - Poste 225/30 KV de Ka Nka N 3Document28 pagesSection VII.4 Pla Ns - Poste 225/30 KV de Ka Nka N 3Haowei LiuNo ratings yet

- CT&WP Check ListDocument1 pageCT&WP Check ListDen OjNo ratings yet

- Adaptive Semi-Active Control of Suspension System With MR Damper Tomoaki Mori, Itthisek Nilkhamhang, Akira SanoDocument6 pagesAdaptive Semi-Active Control of Suspension System With MR Damper Tomoaki Mori, Itthisek Nilkhamhang, Akira Sanowwew20No ratings yet

- Micom 30 Series Transformer Differential Protection Application GuideDocument30 pagesMicom 30 Series Transformer Differential Protection Application Guide1981todurkarNo ratings yet

- 1AHA027592ODocument5 pages1AHA027592OAdetunji TaiwoNo ratings yet

- P120 P121 P122 P123 P125 P126 P127 Technical Data Sheet OverviewDocument29 pagesP120 P121 P122 P123 P125 P126 P127 Technical Data Sheet OverviewTheerat WongNo ratings yet

- DHR Rheology TheoryDocument341 pagesDHR Rheology TheoryMario StiflerNo ratings yet

- 004 - Tuning Guide (EDC17) - ModelDocument1 page004 - Tuning Guide (EDC17) - ModelMartin Hani100% (1)

- Feed motors for SINAMICS S110/S120 at line 380-480V 3 ACDocument6 pagesFeed motors for SINAMICS S110/S120 at line 380-480V 3 ACJosé Manuel GonzálezNo ratings yet

- P12x TechnicalDataSheet EN 03Document28 pagesP12x TechnicalDataSheet EN 03kartengenharia.nfeNo ratings yet

- MotorynkaDocument5 pagesMotorynkaJanNo ratings yet

- ITIG-III Brochure 021120 OnlineDocument9 pagesITIG-III Brochure 021120 OnlineAdli ZahidNo ratings yet

- Armd TorsionDocument1 pageArmd Torsionchetan_thakur4278No ratings yet

- 06 InstrumentationDocument41 pages06 InstrumentationChesca AguaNo ratings yet

- Transformer2016 SC en V02 DIGI PDFDocument24 pagesTransformer2016 SC en V02 DIGI PDFAndrés FelipeNo ratings yet

- Reverse Blocking Triode Thyristors: Semiconductor Technical DataDocument4 pagesReverse Blocking Triode Thyristors: Semiconductor Technical DataYoshiZHNo ratings yet

- 04a Lateral Dynamics and Stability 3 PDFDocument24 pages04a Lateral Dynamics and Stability 3 PDFAnonymous h74wgH0% (1)

- Component Models For Harmonic Analysis: ETAP Knowledge BaseDocument4 pagesComponent Models For Harmonic Analysis: ETAP Knowledge Basesyed Mujtaba hassanNo ratings yet

- How To Use MultimeterDocument31 pagesHow To Use MultimeterJuan Manuel Ortega PérezNo ratings yet

- Global Performance Of A Semi-submersible 5MW Wind-turbine Including Second-order Wave EffectsDocument15 pagesGlobal Performance Of A Semi-submersible 5MW Wind-turbine Including Second-order Wave EffectsAkhilaNo ratings yet

- Airfoil Surface Pressure and Wake Velocity ExperimentDocument24 pagesAirfoil Surface Pressure and Wake Velocity ExperimentAh WenNo ratings yet

- Eldro Thruster Brake CatalougeDocument11 pagesEldro Thruster Brake CatalougeAlphaNo ratings yet

- Automotive Power Relay: Technical Data For Contact SideDocument3 pagesAutomotive Power Relay: Technical Data For Contact SideStuxnetNo ratings yet

- Automotive Power Relay: Technical Data For Contact SideDocument3 pagesAutomotive Power Relay: Technical Data For Contact SideStuxnetNo ratings yet

- IPCG CG A3 Compatibility Chart EN Sep 2020Document1 pageIPCG CG A3 Compatibility Chart EN Sep 2020Kiplagat ChelelgoNo ratings yet

- VSEA Webinar FinalDocument49 pagesVSEA Webinar FinalJitendra ItankarNo ratings yet

- SynchroMax Technical Data OverviewDocument2 pagesSynchroMax Technical Data OverviewHedayatNo ratings yet

- Transformer2017 US en V03Document28 pagesTransformer2017 US en V03bharathNo ratings yet

- Air-Cooled Chiller Models and SpecsDocument99 pagesAir-Cooled Chiller Models and SpecsWeng Hoe ChooNo ratings yet

- LTBeamN Validation Report Compares Beam Analysis SoftwareDocument28 pagesLTBeamN Validation Report Compares Beam Analysis SoftwareIonescu PaulNo ratings yet

- 2293 - Automatic Transformer Winding Analyser - HAEFELY - Brochure - V2109Document9 pages2293 - Automatic Transformer Winding Analyser - HAEFELY - Brochure - V2109זיו קלייןNo ratings yet

- MeggerDocument23 pagesMeggerbertovalen100% (1)

- ATV61 Quick Start Annex S1B86981 03Document8 pagesATV61 Quick Start Annex S1B86981 03GALIH ZULFIKAR LASMANANo ratings yet

- E-P Control Valve InstructionsDocument25 pagesE-P Control Valve InstructionsYuriiNo ratings yet

- Multi - Digital Arrester Tester ALCL-80X DatasheetDocument2 pagesMulti - Digital Arrester Tester ALCL-80X DatasheetJaringan SamarindaNo ratings yet

- Multicomponent Dynamometer: ForceDocument4 pagesMulticomponent Dynamometer: ForceIrina BancescuNo ratings yet

- 00-Basic VibrationDocument91 pages00-Basic VibrationMohamed Al-OdatNo ratings yet

- A Robust Hybrid Current Control For Permanent Magnet Synchronous Motor DriveDocument8 pagesA Robust Hybrid Current Control For Permanent Magnet Synchronous Motor DriveAnonymous 3z8oE1KWTNo ratings yet

- ModulosDocument39 pagesModulosRafael EstradaNo ratings yet

- 2117R Data SheetDocument1 page2117R Data SheetKh TurmunkhNo ratings yet

- Multi-Vehicle Adaptive Cruise Control With Collision Avoidance in Various TransitionsDocument18 pagesMulti-Vehicle Adaptive Cruise Control With Collision Avoidance in Various TransitionsmecharoNo ratings yet

- High-Performance Adaptive Torque Control For An IPMSM With Real-Time MTPA OperationDocument11 pagesHigh-Performance Adaptive Torque Control For An IPMSM With Real-Time MTPA Operationalaref elhajNo ratings yet

- Civil Engineering November 2021 Review Innovations Concrete 4 AnalysisDocument3 pagesCivil Engineering November 2021 Review Innovations Concrete 4 AnalysisLemuel TeopeNo ratings yet

- FCS/W Portable Test Kit ManualDocument21 pagesFCS/W Portable Test Kit ManualNguyen Vu Nhat HaNo ratings yet

- Feedback Control BasicsDocument34 pagesFeedback Control BasicsChesca AguaNo ratings yet

- Aparatus MV Indoor Breaker BrochureDocument24 pagesAparatus MV Indoor Breaker BrochureNurul MukhlisiahNo ratings yet

- Air-Cooled Chiller (R410A Inverter Series) : M5ACV 030 CR M5ACV 055 CR M5ACV 075 CRDocument98 pagesAir-Cooled Chiller (R410A Inverter Series) : M5ACV 030 CR M5ACV 055 CR M5ACV 075 CRRicardo Molina SánchezNo ratings yet

- CLKT, Clkto, CLV: Infrared WindowDocument4 pagesCLKT, Clkto, CLV: Infrared WindowkoushkiNo ratings yet

- LM-100 Light MeterDocument2 pagesLM-100 Light MeterNirmal mehtaNo ratings yet

- PLC Intro PDFDocument16 pagesPLC Intro PDFNirmal mehtaNo ratings yet

- 110 V Systems RCD TestingDocument1 page110 V Systems RCD TestingNirmal mehtaNo ratings yet

- Et214 2005 PDFDocument17 pagesEt214 2005 PDFNirmal mehtaNo ratings yet

- Measurement of Overall Power Loss For Different Three Phase 100kVA Transformer Core MaterialDocument3 pagesMeasurement of Overall Power Loss For Different Three Phase 100kVA Transformer Core MaterialNirmal mehtaNo ratings yet

- Appendix D Power Electronics Journals Conferences WorkshopsDocument2 pagesAppendix D Power Electronics Journals Conferences WorkshopsNirmal mehtaNo ratings yet

- 309a Engineering Data SheetDocument17 pages309a Engineering Data SheetKarwai CHNo ratings yet

- TACH-10: Contact / Non-Contact TachometerDocument2 pagesTACH-10: Contact / Non-Contact TachometeraNo ratings yet

- Special Considerations PLCDocument32 pagesSpecial Considerations PLCdilipelineNo ratings yet

- Aaaa PDFDocument1 pageAaaa PDFNirmal mehtaNo ratings yet

- Kijk PDFDocument1 pageKijk PDFNirmal mehtaNo ratings yet

- Gujarat Technological University (Established Under Gujarat Act No. 20 of 2007)Document1 pageGujarat Technological University (Established Under Gujarat Act No. 20 of 2007)Nirmal mehtaNo ratings yet

- DET14C DET24C 2001 644 - QS - en FR de Es NL - V04Document8 pagesDET14C DET24C 2001 644 - QS - en FR de Es NL - V04Nirmal mehtaNo ratings yet

- RCDT300 Series Residual Current Device TestersDocument4 pagesRCDT300 Series Residual Current Device TestersNirmal mehtaNo ratings yet

- CNDocument2 pagesCNNirmal mehtaNo ratings yet

- VAX 020 High Voltage Amplifier Expands IDAX Range to 2 kVDocument2 pagesVAX 020 High Voltage Amplifier Expands IDAX Range to 2 kVNirmal mehtaNo ratings yet

- The Seven Types of Power Problems: White Paper 18Document21 pagesThe Seven Types of Power Problems: White Paper 18FELIXDEJNo ratings yet

- Delta4000 Ds Us V12aDocument4 pagesDelta4000 Ds Us V12aNirmal mehtaNo ratings yet

- Mto210 Ds Us V09aDocument2 pagesMto210 Ds Us V09aNirmal mehtaNo ratings yet

- Bba B0118 2 PDFDocument2 pagesBba B0118 2 PDFNirmal mehtaNo ratings yet

- User Login: You Are Currently Logged Out. Please Enter Your User ID and Password To Log inDocument1 pageUser Login: You Are Currently Logged Out. Please Enter Your User ID and Password To Log inNirmal mehtaNo ratings yet

- How To Write The Methods Section of A Research PaperDocument4 pagesHow To Write The Methods Section of A Research PaperManish Chandra Prabhakar0% (1)

- Perspectives and Results On The Stability and Stabilizability of Hybrid SystemsDocument14 pagesPerspectives and Results On The Stability and Stabilizability of Hybrid SystemsNirmal mehtaNo ratings yet

- Lopes 2006Document10 pagesLopes 2006Nirmal mehtaNo ratings yet

- Asst Eng Civi Eng Advt 08 2014 15 PDFDocument3 pagesAsst Eng Civi Eng Advt 08 2014 15 PDFNirmal mehtaNo ratings yet

- Improvement of Dynamic Stability of A Single Machine Infinite-Bus Power System Using Fuzzy Logic Based Power System StabilizerDocument11 pagesImprovement of Dynamic Stability of A Single Machine Infinite-Bus Power System Using Fuzzy Logic Based Power System StabilizerNirmal mehtaNo ratings yet

- M.Tech.: Subject Code Paper ID: (E0602)Document2 pagesM.Tech.: Subject Code Paper ID: (E0602)Nirmal mehtaNo ratings yet

- B0118Document2 pagesB0118Nirmal mehtaNo ratings yet

- The Effects of Lane Position in A Swimming Race (Cont)Document17 pagesThe Effects of Lane Position in A Swimming Race (Cont)leonardocascallarNo ratings yet

- Mains Supply: Noadswood Science, 2012Document16 pagesMains Supply: Noadswood Science, 2012LailaNo ratings yet

- Mil HDBK 978B PDFDocument1,224 pagesMil HDBK 978B PDFjsadachiNo ratings yet

- 4 Standards For AC Motors PDFDocument37 pages4 Standards For AC Motors PDFEdú BrizuelaNo ratings yet

- Phy ChemDocument2 pagesPhy Chemanon_632542580No ratings yet

- Rfic Unit IIDocument36 pagesRfic Unit IIBlessina PreethiNo ratings yet

- 2660 Thomas Medical Grade Compressor For Ventilator Oxygen ConcentratorDocument1 page2660 Thomas Medical Grade Compressor For Ventilator Oxygen ConcentratorAiman HashmiNo ratings yet

- BLDC COMPRESSOR TCC DA HORIZONTAL r1.0Document18 pagesBLDC COMPRESSOR TCC DA HORIZONTAL r1.0Bruno Souza100% (2)

- IEC - 60243 Electric Strength of Insulating Materials - Test Methods - Part 2: Additional Requirements For Tests Using Direct VoltageDocument22 pagesIEC - 60243 Electric Strength of Insulating Materials - Test Methods - Part 2: Additional Requirements For Tests Using Direct VoltageAglieglie BrazorNo ratings yet

- Generator Write UpDocument14 pagesGenerator Write UpJerome B. PioNo ratings yet

- Scale up Hydrogenation CalculationsDocument8 pagesScale up Hydrogenation CalculationsFarah AnjumNo ratings yet

- Plugin GetPDFServlet 2Document4 pagesPlugin GetPDFServlet 2Pikir HatiNo ratings yet

- Subject Code/name: EE 2306-Flexible AC Transmission Systems: Facts 8 Kce/Eee/Qb/Ivyr/FactsDocument26 pagesSubject Code/name: EE 2306-Flexible AC Transmission Systems: Facts 8 Kce/Eee/Qb/Ivyr/FactssivakumarsarvananNo ratings yet

- FTS-3 (CODE-B) - QP - Solution 30-03-2020 - E - 0 PDFDocument26 pagesFTS-3 (CODE-B) - QP - Solution 30-03-2020 - E - 0 PDFaleemhakNo ratings yet

- Ongc Hazira Plant A Techno Commercial Insight'Document21 pagesOngc Hazira Plant A Techno Commercial Insight'Bhavesh PatelNo ratings yet

- Protection Relays General Electrical Tests ChecklistDocument6 pagesProtection Relays General Electrical Tests ChecklistMohamed NasrNo ratings yet

- Datasheet HiE SXXXKNDocument2 pagesDatasheet HiE SXXXKNpal rajNo ratings yet

- Relief Valve Case Study Loads Stresses PASSDocument11 pagesRelief Valve Case Study Loads Stresses PASSJafer SayedNo ratings yet

- A Level Physics 22 June2013Document16 pagesA Level Physics 22 June2013Inhamul HassanNo ratings yet

- ZUCCHINI Busbar SCP Series Technical Catalog PDFDocument77 pagesZUCCHINI Busbar SCP Series Technical Catalog PDFJahnValjahnNo ratings yet

- SS-AEPF Goodman Air ConditionerDocument8 pagesSS-AEPF Goodman Air ConditionerArmando EnriquezNo ratings yet

- IEC PublishesDocument3 pagesIEC Publishesashumishra007No ratings yet

- Syllabus Assigned For Term I (Theory) : Biology at EaseDocument19 pagesSyllabus Assigned For Term I (Theory) : Biology at EaseDILSHAD AYJNISHDNo ratings yet

- 300/500ma Low Dropout Linear Voltage Regulator: General Description FeaturesDocument11 pages300/500ma Low Dropout Linear Voltage Regulator: General Description FeaturesPedro RodriguezNo ratings yet

- Sites For Research Part ThreeDocument10 pagesSites For Research Part ThreeJayrine MonteroNo ratings yet

- PTCDocument4 pagesPTCHellena LaNo ratings yet

- Determination of Chezy's Constant and Friction FactorDocument15 pagesDetermination of Chezy's Constant and Friction FactorKuldeep MalNo ratings yet

- Lab 10: Frequency Relationships in Standing WavesDocument5 pagesLab 10: Frequency Relationships in Standing WavesKonstantinos FilippakosNo ratings yet

- Dcmotors601 0241Document42 pagesDcmotors601 0241Afrida Fazira MNo ratings yet

- Modeling of Advanced Alkaline ElectrolyzersDocument11 pagesModeling of Advanced Alkaline ElectrolyzersAhmedNo ratings yet