Professional Documents

Culture Documents

Tech Spec Ref Is 456 1343 CBC

Uploaded by

dsbishtOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Tech Spec Ref Is 456 1343 CBC

Uploaded by

dsbishtCopyright:

Available Formats

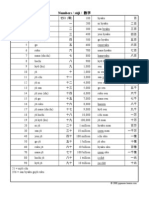

Technical Specification: Section: Materials, workmanship, I&T: Plain and RCC works (Indian standards)

IS 456- 2016 : SECTION 2 MATERIALS, WORKMANSHIP, INSPECTION ANDTESTING

5 MATERIALS

5.1 Cement

5.2 MineralAdmixtures

5.3 Aggregates

5.4 Water

5.5 Admixtures

5.6 Reinforcement

5.7 Storage of Materials

6 CONCRETE

6.1 Grades

6.2 Properties of Concrete

7 WORKABIUTY OF CONCRETE

8 DURABILITY OFCONCRETE

8.1 General

8.2 Requirements for Durability

9 CONCRETE MIX PROPORTIONING

9.1 Mix Proportion

9.2 Design MixConcrete

9.3 Nominal Mix Concrete

10 PRODUCTION OF CONCRETE

10.1 QualityAssuranceMeasures

10.2 Batching

10.3 Mixing

11 FORMWORK

1J.1 General

11.2 Cleaning and Treatment of Formwork

11.3 Stripping Time

12 ASSEMBLY OF REINFORCEMENT

13 TRANSPORTING, PLACING, COMPACTION AND CURING

13.1 Transporting and Handling

13.2 Placing

13.3 Compaction

13.4 Construction Joints and Cold Joints

Technical Specification: Section: Materials, workmanship, I&T: Plain and RCC works (Indian standards)

13.5 Curing

13.6 Supervision

14 CONCRETING UNDER SPECIALCONDITIONSs

14.1 Work in Extreme Weather Conditions

14.2 Under-Water Concreting

15 SAMPLING AND STRENGTH OFDESIGNED CONCRETEMIX

15.1 General

15.2 Frequency of Sampling

15.3 Test Specimen

15.4 Test Results of Sample

16 ACCEPTANCE CRITERIA

17 INSPECTION AND TESTING OF STRUCTURE

Technical Specification: Section: Materials, workmanship, I&T: Plain and RCC works (Indian standards)

IS 1343 : 2012 COP Prestressed concrete

SECTION 2 MATERIALS, WORKMANSHIP, INSPECTION AND TESTING

5 MATERIALS

5.1 Cement

5.2 Mineral Admixtures

5.3 Aggregates

5.4 Water

5.5 Chemical Admixtures

5.6 Prestressing and Untensioned Steel

5.7 Storage of Materials

6 CONCRETE

6.1 Grades

6.2 Properties of Concrete

7 WORKABILITY OF CONCRETE

8 DURABILITY OF CONCRETE

8.1 General

8.2 Requirements for Durability

9 CONCRETE MIX PROPORTIONING

9.1 Mix Proportion

9.2 Design Mix Concrete

10 PRODUCTION OF CONCRETE

10.1 Quality Assurance Measures

10.2 Batching

10.3 Mixing

11 FORMWORK

12 ASSEMBLY OF PRESTRESSING AND REINFORCING STEEL

12.1 Prestressing Steel

12.2 Sheathing Ducts

12.3 Untensioned Steel

13 PRESTRESSING

13.1 Prestressing Equipment

13.2 Procedure for Tensioning and Transfer

13.3 Grouting

13.4 Grouting Operations

14 TRANSPORTING, PLACING, COMPACTING AND CURING

15 CONCRETING UNDER SPECIAL CONDITIONS

15.1 Work in Extreme Weather Conditions

16 SAMPLING AND STRENGTH TEST OF CONCRETE MIX

17 ACCEPTANCE CRITERIA

18 INSPECTION AND TESTING OF STRUCTURES

Technical Specification: Section: Materials, workmanship, I&T: Plain and RCC works (Indian standards)

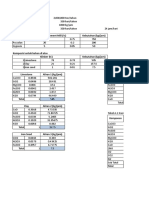

IRS Concrete Bridge Code: 1997

Contents

1. SCOPE

2. TERMINOLOGY

3. SYMBOLS

4. MATERIALS

4.1 Cement

4.2 Aggregtes

4.3 Water

4.4 Admixtures

4.5 Reinforcement

4.6 Prestressing steel

4.7 Handling and storage of materials

5. CONCRETE

5.1 Grades

5.2 Properties of concrete

5.3 Workability of concrete

5.4 Durability

5.5 Concrete mix proportioning

5.6 Production and control of concrete

5.7 Ready Mixed Concrete

6. FALSEWORK AND FORM WORK

6.1 Falsework

6.2 Formwork

6.3 Cleaning and treatment of forms

6.4 Stripping time

6.5 Tolerances for finished concrete bridge structure

7. REINFORCEMENT & PRESTRESSING TENDONS

7.1 Ordinary reinforcement

7.2 Prestressing tendons

8. TRANSPORTATION, PLACEMENT, COMPACTION & CURING OF CONCRETE

8.1 Transportation

8.2 Placing

8.3 Compaction

8.4 Curing of concrete

8.5 Construction joints

8.6 Concreting under special conditions

8.7 Sampling, strength tests and acceptance criteria

8.8 Supervision

8.9 Pumpable concrete

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Wood Substitutes - Industrial Products As Substitutes ForDocument19 pagesWood Substitutes - Industrial Products As Substitutes ForkunjuvavuNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Concrete TestDocument9 pagesConcrete TestVelmurugan BalasubramanianNo ratings yet

- Pile Cap DesignDocument16 pagesPile Cap DesignAnton_Young_1962100% (1)

- Cmqoe Sample ExamDocument23 pagesCmqoe Sample Examibrahimgomaa100% (2)

- Astm C1260 PDFDocument5 pagesAstm C1260 PDFanant11235No ratings yet

- Plan de Trabajos: Cash FlowDocument3 pagesPlan de Trabajos: Cash FlowAriel IsaackNo ratings yet

- 10 - Internal Audit Manual For Construction CompaniesDocument4 pages10 - Internal Audit Manual For Construction Companiesdsbisht100% (1)

- Hydration of CementDocument39 pagesHydration of Cementatul_kolhe100% (2)

- As 3972-2010Document29 pagesAs 3972-2010Yuvaraj Dhandapani100% (2)

- Clinker Reactivity Presentation - Sept 2012 - LafargeDocument33 pagesClinker Reactivity Presentation - Sept 2012 - LafargeTin Nguyen100% (5)

- Systems Assurance Management in Railway Through The Project Life CycleDocument6 pagesSystems Assurance Management in Railway Through The Project Life CycleJasmine TsoNo ratings yet

- Building Insulation BulletinDocument4 pagesBuilding Insulation BulletinSarath ChukkapalliNo ratings yet

- Haryana issues COVID-19 regulations to prevent spreadDocument2 pagesHaryana issues COVID-19 regulations to prevent spreaddsbishtNo ratings yet

- Nabcb BCB201Document40 pagesNabcb BCB201dsbishtNo ratings yet

- DP 201423Document43 pagesDP 201423dsbishtNo ratings yet

- NTA 2019 GuidelinesDocument2 pagesNTA 2019 GuidelinesRishit ShiveshNo ratings yet

- What Is 3D Printing?Document1 pageWhat Is 3D Printing?dsbishtNo ratings yet

- BudherDocument1 pageBudherdsbishtNo ratings yet

- Gujarat Navratri Rituals: Durga Mahishsura Garba RaasDocument3 pagesGujarat Navratri Rituals: Durga Mahishsura Garba RaasdsbishtNo ratings yet

- Japanese Numbers PDFDocument1 pageJapanese Numbers PDFchvsuneelNo ratings yet

- 214646Document3 pages214646Aliza Noor100% (1)

- Inter Sector Shifting (ISS) Form May 2018Document2 pagesInter Sector Shifting (ISS) Form May 2018dsbisht50% (2)

- Total Kjeldahl Nitrogen (TKN) analysis guideDocument4 pagesTotal Kjeldahl Nitrogen (TKN) analysis guidedsbishtNo ratings yet

- Notice MOSTDocument7 pagesNotice MOSTdsbishtNo ratings yet

- CMQOE Fact SheetDocument2 pagesCMQOE Fact SheetcsteeeeNo ratings yet

- Brochure M Tech Design Hc30Document11 pagesBrochure M Tech Design Hc30dsbishtNo ratings yet

- ISO 14001 2004plain Eng PraxionDocument22 pagesISO 14001 2004plain Eng PraxiondsbishtNo ratings yet

- Best Practices Guide On State Level Solar Rooftop Photovoltaic ProgramsDocument60 pagesBest Practices Guide On State Level Solar Rooftop Photovoltaic ProgramsharishrajendraNo ratings yet

- List of Jsce Stands 2010Document3 pagesList of Jsce Stands 2010dsbisht100% (1)

- HCC IMS Self-Assessment QuestionsDocument5 pagesHCC IMS Self-Assessment QuestionsdsbishtNo ratings yet

- OHSAS 18001 2007 PraxionDocument26 pagesOHSAS 18001 2007 PraxiondsbishtNo ratings yet

- OHSAS 18001 2007 PraxionDocument26 pagesOHSAS 18001 2007 PraxiondsbishtNo ratings yet

- CIDC Faridabad TrainingDocument1 pageCIDC Faridabad TrainingdsbishtNo ratings yet

- Signi AttachDocument30 pagesSigni AttachdsbishtNo ratings yet

- OILES Stopper - Bridges - Seismic VibratnDocument1 pageOILES Stopper - Bridges - Seismic VibratndsbishtNo ratings yet

- SC On BOCWDocument2 pagesSC On BOCWdsbishtNo ratings yet

- Bocw Vs FactoriesDocument2 pagesBocw Vs FactoriesdsbishtNo ratings yet

- Mix DesignDocument27 pagesMix DesignSoni Mishra TiwariNo ratings yet

- 6 Slides Per Page Introduction To ConcreteDocument7 pages6 Slides Per Page Introduction To Concreteaksh007No ratings yet

- Vo 2021Document10 pagesVo 2021Remcy Mae LinghonNo ratings yet

- Standard STD 423-0007: Plastics - Determination of Tensile Properties Plast - Bestämning Av DraghållfasthetDocument1 pageStandard STD 423-0007: Plastics - Determination of Tensile Properties Plast - Bestämning Av DraghållfasthetRobertoNo ratings yet

- Contoh Neraca MassaDocument36 pagesContoh Neraca MassaSanji SagaNo ratings yet

- Mass ConcreteDocument4 pagesMass ConcreteTufan Kırık0% (1)

- Drainage design detailsDocument1 pageDrainage design detailsAnal BiswasNo ratings yet

- Self-Compacting Concrete: Theoretical and Experimental StudyDocument23 pagesSelf-Compacting Concrete: Theoretical and Experimental StudyPritha DasNo ratings yet

- ICI Concrete Cube Strength Competition Test ReportDocument18 pagesICI Concrete Cube Strength Competition Test ReportRonyJoyNo ratings yet

- Spesifikasi Tiang Pancang by Pt. Tripalindo PersadaDocument8 pagesSpesifikasi Tiang Pancang by Pt. Tripalindo Persadasugiarto budiNo ratings yet

- University of Engineering and Technology LHR, (NWL Campus) Lab Manual Subject: Plain Reinforcement ConcreteDocument57 pagesUniversity of Engineering and Technology LHR, (NWL Campus) Lab Manual Subject: Plain Reinforcement ConcreteNoman AliNo ratings yet

- Unit 05 - Lseeon 04 - Curtailment TheoryDocument10 pagesUnit 05 - Lseeon 04 - Curtailment TheoryMohamed AbdNo ratings yet

- Innovations in Chemical Admixture Technology As Related To SustainabilityDocument6 pagesInnovations in Chemical Admixture Technology As Related To SustainabilitymasteriragaNo ratings yet

- Advanced Concrete Technology Past Paper Questions 1Document11 pagesAdvanced Concrete Technology Past Paper Questions 1Asad QaziNo ratings yet

- Concrete Cold JointDocument4 pagesConcrete Cold JointAjayvidyanand SharmaNo ratings yet

- C & D WasteDocument9 pagesC & D WasteHarpreet SinghNo ratings yet

- Portland Cement Setting TimeDocument1 pagePortland Cement Setting TimemuhanadNo ratings yet

- Precast Concrete Frame With Moment ConnectionDocument32 pagesPrecast Concrete Frame With Moment ConnectionmaizansofiaNo ratings yet

- Rab Structure Precast Pretsress - Blok Gabungan Pasar Semarapura, Klungkung 2 Maret 2023Document3 pagesRab Structure Precast Pretsress - Blok Gabungan Pasar Semarapura, Klungkung 2 Maret 2023Komang SemadiNo ratings yet

- BEAM DESIGN TABLE FROM STAADDocument4 pagesBEAM DESIGN TABLE FROM STAADliezelNo ratings yet

- Penebar BrochureDocument4 pagesPenebar BrochureBhavish SeejoreNo ratings yet

- GRCDocument3 pagesGRCAristo OnanNo ratings yet