Professional Documents

Culture Documents

Aci 318-14 RC-BM-001

Uploaded by

Bunkun15Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Aci 318-14 RC-BM-001

Uploaded by

Bunkun15Copyright:

Available Formats

Software Verification

PROGRAM NAME: SAFE

REVISION NO.: 0

EXAMPLE ACI 318-14 RC-BM-001

Flexural and Shear Beam Design

PROBLEM DESCRIPTION

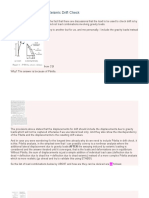

The purpose of this example is to verify the beam flexural design in SAFE. The

load level is adjusted for the case corresponding to the following conditions:

The stress-block extends below the flange but remains within the balanced

condition permitted by ACI 318-14.

The average shear stress in the beam falls below the maximum shear stress

allowed by ACI 318-14, requiring design shear reinforcement.

A simple-span, 20-foot-long, 12-inch-wide, and 18-inch-deep T beam with a

flange 4 inches thick and 24 inches wide is modeled using SAFE. The beam is

shown in Figure 1. The computational model uses a finite element mesh of frame

elements, automatically generated by SAFE. The maximum element size is

specified as 6 inches. The beam is supported by columns without rotational

stiffnesses and with very large vertical stiffness (1 × 1020 kip/in).

The beam is loaded with symmetric third-point loading. One dead load (DL02)

case and one live load (LL30) case, with only symmetric third-point loads of

magnitudes 3, and 30 kips, respectively, are defined in the model. One load

combination (COMB30) is defined using the ACI 318-14 load combination

factors of 1.2 for dead load and 1.6 for live load. The model is analyzed for both

of these load cases and the load combination.

The beam moment and shear force are computed analytically. The total factored

moment and shear force are compared with the SAFE results and found to be

identical. After completing the analysis, the design is performed using the ACI

318-14 code in SAFE and also by hand computation. Table 1 shows the

comparison of the design longitudinal reinforcement. Table 2 shows the

comparison of the design shear reinforcement.

EXAMPLE ACI 318-14 RC-BM-001 - 1

Software Verification

PROGRAM NAME: SAFE

REVISION NO.: 0

600 mm

75 mm 100 mm

500 mm

75 mm

300 mm

Beam Section

2000 mm 2000 mm 2000 mm

Shear Force

Bending Moment

Figure 1 The Model Beam for Flexural and Shear Design

EXAMPLE ACI 318-14 RC-BM-001 - 2

Software Verification

PROGRAM NAME: SAFE

REVISION NO.: 0

GEOMETRY, PROPERTIES AND LOADING

Clear span l = 240 in

Overall depth h = 18 in

Flange thickness ds = 4 in

Width of web bw = 12 in

Width of flange, bf = 24 in

Depth of tensile reinf. dc = 3 in

Effective depth d = 15 in

Depth of comp. reinf. d' = 3 in

Concrete strength f' c = 4,000 psi

Yield strength of steel fy = 60,000 psi

Concrete unit weight wc = 0 pcf

Modulus of elasticity Ec = 3,600 ksi

Modulus of elasticity Es = 29,000 ksi

Poisson’s ratio v = 0.2

Dead load Pd = 2 kips

Live load Pl = 30 kips

TECHNICAL FEATURES OF SAFE TESTED

Calculation of flexural and shear reinforcement

Application of minimum flexural and shear reinforcement

RESULTS COMPARISON

Table 1 shows the comparison of the SAFE total factored moments in the beam

with the moments obtained by the analytical method. They match exactly for this

problem. Table 1 also shows the comparison of the design reinforcement.

Table 1 Comparison of Moments and Flexural Reinforcements

Reinforcement Area (sq-in)

Moment

Method (k-in) As+

SAFE 4032 5.808

Calculated 4032 5.808

A +s ,min = 0.4752 sq-in

EXAMPLE ACI 318-14 RC-BM-001 - 3

Software Verification

PROGRAM NAME: SAFE

REVISION NO.: 0

Table 2 Comparison of Shear Reinforcements

Av

Reinforcement Area,

s

(sq-in/ft)

Shear Force (kip) SAFE Calculated

50.40 0.592 0.592

COMPUTER FILE: ACI 318-14 RC-BM-001.FDB

CONCLUSION

The SAFE results show an exact comparison with the independent results.

EXAMPLE ACI 318-14 RC-BM-001 - 4

Software Verification

PROGRAM NAME: SAFE

REVISION NO.: 0

HAND CALCULATION

Flexural Design

The following quantities are computed for all the load combinations:

ϕ = 0.9

Ag = 264 sq-in

As,min = 0.0018Ag = 0.4752 sq-in

f c′ − 4000

β1 =

0.85 − 0.05 =0.85

1000

0.003

=cmax = d 5.625 in

0.003 + 0.005

amax = β1cmax = 4.78125 in

As = min[As,min, (4/3) As,required] = min[0.4752, (4/3)5.804] = 0.4752 sq-in

COMB30

Pu = (1.2Pd + 1.6Pt) = 50.4 k

Pu l

Mu = = 4032 k-in

3

The depth of the compression block is given by:

2 Mu

a =−

d d2 − = 4.2671 in (a > ds)

0.85 f c'ϕ b f

Calculation for As is performed in two parts. The first part is for balancing the

compressive force from the flange, Cf, and the second part is for balancing the

compressive force from the web, Cw. Cf is given by:

Cf = 0.85fc' (bf − bw) ds = 163.2 k

The portion of Mu that is resisted by the flange is given by:

d

Muf = Cf d − s ϕ = 1909.44 k-in

2

EXAMPLE ACI 318-14 RC-BM-001 - 5

Software Verification

PROGRAM NAME: SAFE

REVISION NO.: 0

Therefore, the area of tensile steel reinforcement to balance flange compression

is:

M uf

As1 = = 2.7200 sq-in

f y (d − d s 2 ) ϕ

The balance of the moment to be carried by the web is given by:

Muw = Mu − Muf = 2122.56 k-in

The web is a rectangular section with dimensions bw and d, for which the design

depth of the compression block is recalculated as

2 M uw

a1 = d− d2 − = 4.5409 in (a1 ≤ amax)

0.85 f c′ ϕ bw

The area of tensile steel reinforcement to balance the web compression is then

given by:

M uw

As2 = = 3.0878 sq-in

a1

ϕ fy d − ϕ

2

The area of total tensile steel reinforcement is then given by:

As = As1 + As2 = 5.808 sq-in

Shear Design

The following quantities are computed for all of the load combinations:

ϕ = 0.75

Check the limit of f c′ :

f c′ = 63.246 psi < 100 psi

The concrete shear capacity is given by:

ϕ Vc = ϕ2 f c′ bwd = 17.076 k

The maximum shear that can be carried by reinforcement is given by:

EXAMPLE ACI 318-14 RC-BM-001 - 6

Software Verification

PROGRAM NAME: SAFE

REVISION NO.: 0

ϕ Vs = ϕ8 f c′ bwd = 68.305 k

The following limits are required in the determination of the reinforcement:

(ϕ Vc/2) = 8.538 k

(ϕ Vc + ϕ 50 bwd) = 23.826 k

Vmax = ϕ Vc + ϕ Vs = 85.381 k

Given Vu, Vc and Vmax, the required shear reinforcement in area/unit length for

any load combination is calculated as follows:

If Vu ≤ (Vc/2) ϕ,

Av

= 0,

s

else if (Vc/2) ϕ < Vu ≤ (ϕVc + ϕ 50 bwd),

Av 50 bw

= ,

s fy

else if (ϕVc + ϕ 50 bwd) < Vu ≤ ϕ Vmax

Av (V − ϕVc )

= u

s ϕ f ys d

else if Vu > ϕ Vmax,

a failure condition is declared.

For each load combination, the Pu and Vu are calculated as follows:

Pu = 1.2Pd + 1.6P1

Vu = Pu

(COMB30)

Pd = 2 k

Pl = 30 k

Pu = 50.4 k

Vu = 50.4 k, (ϕVc + ϕ 50 bwd) < Vu ≤ ϕ Vmax

Av (Vu − ϕVc )

= = 0.04937 sq-in/in or 0.592 sq-in/ft

s ϕf ys d

EXAMPLE ACI 318-14 RC-BM-001 - 7

You might also like

- Swimming Pool Details Structures SampleDocument1 pageSwimming Pool Details Structures SampleBunkun15100% (3)

- Mahbuba Mam All Slides PDFDocument189 pagesMahbuba Mam All Slides PDFRubayet AlamNo ratings yet

- Building Girt CalcDocument2 pagesBuilding Girt Calcwudongxiao3953No ratings yet

- DSM CalculatorDocument5 pagesDSM CalculatorVengatesh HariNo ratings yet

- How To Construct A Concrete Swimming Pool - (PDF) - The ConstructorDocument13 pagesHow To Construct A Concrete Swimming Pool - (PDF) - The ConstructorBunkun15No ratings yet

- Annexure 4.7 - IIT PAVE OutputDocument22 pagesAnnexure 4.7 - IIT PAVE OutputTanmoy Das0% (2)

- CE Pre-Board Structural Engineering and ConstructionDocument13 pagesCE Pre-Board Structural Engineering and ConstructionpppppNo ratings yet

- Advanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionFrom EverandAdvanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionNo ratings yet

- Temperature Loads in Saudi Arabia - Structural Engineering Other Technical Topics - Eng-TipsDocument2 pagesTemperature Loads in Saudi Arabia - Structural Engineering Other Technical Topics - Eng-TipsMohammad AasimuddinNo ratings yet

- Seismic Design of Cast-in-Place Concrete Diaphragms, Chords and CollectorsDocument71 pagesSeismic Design of Cast-in-Place Concrete Diaphragms, Chords and CollectorsMd Abdur RasidNo ratings yet

- Chapter 3 Direct Displacement Based DesignDocument68 pagesChapter 3 Direct Displacement Based DesignMuhammadNomanKNo ratings yet

- Concrete Column Design Based On ACI 318-19: Input Data & Design SummaryDocument3 pagesConcrete Column Design Based On ACI 318-19: Input Data & Design Summaryجميل عبد الله الحماطيNo ratings yet

- 4.3 Design of Base Plate W STIFFENER (Feb 21 2015)Document27 pages4.3 Design of Base Plate W STIFFENER (Feb 21 2015)Jair llacuachaqui villalvaNo ratings yet

- Load Combinations For Seismic DriftDocument4 pagesLoad Combinations For Seismic DriftErwin ObenzaNo ratings yet

- L3 Lateral ForceDocument75 pagesL3 Lateral Forceapirakq100% (1)

- Advanced Steel Composite BeamsDocument68 pagesAdvanced Steel Composite BeamsMert SarıNo ratings yet

- Probabilistic Seismic Hazard Analysis Nepal (Solukhumbu) Complete ReportDocument74 pagesProbabilistic Seismic Hazard Analysis Nepal (Solukhumbu) Complete ReportSabin AcharyaNo ratings yet

- İsrail Deprem Yönetmeliği EkiDocument18 pagesİsrail Deprem Yönetmeliği EkiErol Eylemci KaplanNo ratings yet

- Seismic design of concrete structuresDocument38 pagesSeismic design of concrete structuresBeammanNo ratings yet

- CE 809 - Lecture 3 - Response of SDF Systems To Harmonic LoadingDocument54 pagesCE 809 - Lecture 3 - Response of SDF Systems To Harmonic LoadingArslan UmarNo ratings yet

- Cie 525 - Reinforced Concrete Structures: Thursday SEPTEMBER 22, 2016Document10 pagesCie 525 - Reinforced Concrete Structures: Thursday SEPTEMBER 22, 2016Bodhi RudraNo ratings yet

- BUETDocument128 pagesBUETMD. ABDUL MUEED FAHIMNo ratings yet

- Eurocodes Presentation 1Document51 pagesEurocodes Presentation 1Nemanja MilekicNo ratings yet

- Long Term Deflection in Concrete BeamsDocument6 pagesLong Term Deflection in Concrete BeamsRenganayagi BalajiNo ratings yet

- Timber Joist Design BS5268Document3 pagesTimber Joist Design BS5268Zheny FortinNo ratings yet

- Design of Advanced Reinforced Concrete MembersDocument226 pagesDesign of Advanced Reinforced Concrete MembersĐỗ Nguyên KhôiNo ratings yet

- Asce 41-13 PDFDocument1 pageAsce 41-13 PDFVAIBHAVNo ratings yet

- Accelerated Brideg Construction in Washington StateDocument16 pagesAccelerated Brideg Construction in Washington StatesyedabdulhannanNo ratings yet

- Structure Design of Foundation of Light Pole IS 875Document8 pagesStructure Design of Foundation of Light Pole IS 875YashwantRajVermaNo ratings yet

- Cours - Temperature Gradient PDFDocument2 pagesCours - Temperature Gradient PDFtarekhocineNo ratings yet

- Shear Wall With Boundary ElementDocument4 pagesShear Wall With Boundary ElementArnel DodongNo ratings yet

- Simplified Procedures For Calculation of Instantaneous and Long-Term Deflections of Reinforced Concrete BeamsDocument12 pagesSimplified Procedures For Calculation of Instantaneous and Long-Term Deflections of Reinforced Concrete BeamssukolikNo ratings yet

- Moment Redistribution in BeamsDocument12 pagesMoment Redistribution in BeamsChukwuka WayemeruNo ratings yet

- Stiffness of Concrete SlabsDocument61 pagesStiffness of Concrete SlabsfaumijkNo ratings yet

- Reinforced Concrete Design On ACI - Part 1 PDFDocument45 pagesReinforced Concrete Design On ACI - Part 1 PDFshahrol905No ratings yet

- Design of Oneway SlabsDocument5 pagesDesign of Oneway SlabsOsama TamariNo ratings yet

- Relating Seismic Design Level and Seismic Performance: Fragility-Based Investigation of RC Moment-Resisting Frame Buildings in ChinaDocument13 pagesRelating Seismic Design Level and Seismic Performance: Fragility-Based Investigation of RC Moment-Resisting Frame Buildings in ChinaAniket DubeNo ratings yet

- Retrofitting of Reinforced Concrete Column by Steel JacketingDocument5 pagesRetrofitting of Reinforced Concrete Column by Steel JacketingAhsan RafiqNo ratings yet

- Chapter 1Document33 pagesChapter 1Divya V SNo ratings yet

- Seismic Hazard Assessment PDFDocument77 pagesSeismic Hazard Assessment PDFparamieNo ratings yet

- Aci Rectangular Tanks2010 PDF FreeDocument18 pagesAci Rectangular Tanks2010 PDF FreeArchieNo ratings yet

- Evaluation of Seismic Performance of RC Frame Structures by Pushover and Time History Analyses - Part-2Document15 pagesEvaluation of Seismic Performance of RC Frame Structures by Pushover and Time History Analyses - Part-2Adam Michael GreenNo ratings yet

- Wood - ArmerDocument6 pagesWood - ArmerNovak Novaković100% (1)

- Lec 1 Design of RC Structures For Lateral LoadsDocument49 pagesLec 1 Design of RC Structures For Lateral Loadsamin alzuraiki100% (1)

- 2003 Ibc Diaphragm DesignDocument100 pages2003 Ibc Diaphragm Designer_zaheer100% (2)

- 16.seismic Design 1Document73 pages16.seismic Design 1Shantonu DeyNo ratings yet

- OutputDocument5 pagesOutputMoch Raka RizkiNo ratings yet

- Design of Concrete Corbel/bracketDocument5 pagesDesign of Concrete Corbel/bracketThomas John Doblas AgrabioNo ratings yet

- TB Lecture10 Braced Frame StructuresDocument33 pagesTB Lecture10 Braced Frame StructuresSaeed Khawam100% (2)

- Fitsum Abebe PDFDocument87 pagesFitsum Abebe PDFbernice el mazeNo ratings yet

- 3 Michael Salmon Seismic Ysis of Safety-Related Nuclear Structures Tuesday 18 2016 5B1 5DDocument14 pages3 Michael Salmon Seismic Ysis of Safety-Related Nuclear Structures Tuesday 18 2016 5B1 5Dpezhmankhan100% (1)

- Changes in ACI 318M-19Document31 pagesChanges in ACI 318M-19amr mohanadNo ratings yet

- Analysis of Tank 2 PDFDocument11 pagesAnalysis of Tank 2 PDFBALRAJNo ratings yet

- Design check of BRBF systems using pushover analysisDocument14 pagesDesign check of BRBF systems using pushover analysisHectoreRodriguezlNo ratings yet

- Topic 4 - Precast Concrete Connections For Framed Buildings - 2Document90 pagesTopic 4 - Precast Concrete Connections For Framed Buildings - 2Abdullah RamziNo ratings yet

- Steel Bridge DesignDocument9 pagesSteel Bridge DesignĴetzaa Barragán ChávezNo ratings yet

- Poroelastic StructuresFrom EverandPoroelastic StructuresG. CederbaumNo ratings yet

- Flexural and Shear Design VerificationDocument7 pagesFlexural and Shear Design VerificationKhuất Trần ThanhNo ratings yet

- Software Verification: Example Hong Kong Cp-04 Rc-Bm-001Document7 pagesSoftware Verification: Example Hong Kong Cp-04 Rc-Bm-001renzo1221No ratings yet

- NZS 3101-06 RC-BM-001Document7 pagesNZS 3101-06 RC-BM-001renzo1221No ratings yet

- KBC 2009 Example 001Document6 pagesKBC 2009 Example 001yudhi putraNo ratings yet

- Guide To Standards-Pools and SpasDocument15 pagesGuide To Standards-Pools and SpasMIguel HazNo ratings yet

- HealthcareDocument3 pagesHealthcareBunkun15No ratings yet

- Intake Tower Existing DamDocument3 pagesIntake Tower Existing DamBunkun15No ratings yet

- EducationDocument3 pagesEducationBunkun15No ratings yet

- Basic Requirements in Swimming Pool Construction - The ConstructorDocument10 pagesBasic Requirements in Swimming Pool Construction - The ConstructorBunkun15No ratings yet

- Design and Construction of Swimming Pools-Ib-P-Bc2017 014Document10 pagesDesign and Construction of Swimming Pools-Ib-P-Bc2017 014Luffy11No ratings yet

- Checklist ResPoolsDocument7 pagesChecklist ResPoolsBunkun15No ratings yet

- Swimming Pool Sample LayoutsDocument1 pageSwimming Pool Sample LayoutsBunkun15No ratings yet

- Swimming Pool Site PlanDocument1 pageSwimming Pool Site PlanBunkun15No ratings yet

- CommercialDocument3 pagesCommercialBunkun15No ratings yet

- Title - Section 6-1.29 - Swimming Pool Design Standards - New York Codes, Rules and RegulationsDocument24 pagesTitle - Section 6-1.29 - Swimming Pool Design Standards - New York Codes, Rules and RegulationsBunkun15No ratings yet

- Swimming Pool Roofing OptionsDocument2 pagesSwimming Pool Roofing OptionsBunkun15100% (1)

- Swimming Pool & Spa Safety: PurposeDocument12 pagesSwimming Pool & Spa Safety: PurposekenNo ratings yet

- Industrial BuildingsDocument2 pagesIndustrial BuildingsBunkun15No ratings yet

- Starting A Bookstore BusinessDocument11 pagesStarting A Bookstore BusinessBunkun15No ratings yet

- HotelsDocument2 pagesHotelsBunkun15No ratings yet

- 4 Ways To Book PublishingDocument7 pages4 Ways To Book PublishingBunkun15No ratings yet

- How To Start A Bookstore BusinessDocument5 pagesHow To Start A Bookstore BusinessBunkun15No ratings yet

- Basements For HousingDocument2 pagesBasements For HousingBunkun15No ratings yet

- Designing Resilient HomesDocument2 pagesDesigning Resilient HomesBunkun15No ratings yet

- Residential - Low-RiseDocument4 pagesResidential - Low-RiseBunkun15No ratings yet

- Pc-I (Infrastructure-Proforma For Development Projects)Document12 pagesPc-I (Infrastructure-Proforma For Development Projects)Haider IqbalNo ratings yet

- University OrganogramDocument1 pageUniversity OrganogramBunkun15No ratings yet

- Stable Sprayed ConcreteDocument2 pagesStable Sprayed ConcreteBunkun15No ratings yet

- Anchorage Detail of Column at Top FloorDocument5 pagesAnchorage Detail of Column at Top FloorBunkun15No ratings yet

- ICBS Faculty Positions in Engineering, Business, SciencesDocument1 pageICBS Faculty Positions in Engineering, Business, SciencesBunkun15No ratings yet

- Imperial College of Business Studies Employment Application FormDocument3 pagesImperial College of Business Studies Employment Application FormBunkun15No ratings yet

- Unifrom Load Partially Distributed at Left EndDocument1 pageUnifrom Load Partially Distributed at Left EndBunkun15No ratings yet

- Padeye Check SttandardDocument36 pagesPadeye Check SttandardRiandi HartartoNo ratings yet

- TSwift CometDocument63 pagesTSwift CometRoberto LopezNo ratings yet

- Som Syllabus (Ce2252)Document1 pageSom Syllabus (Ce2252)rajapratyNo ratings yet

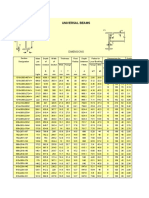

- UNIVERSAL BEAM DIMENSIONSDocument241 pagesUNIVERSAL BEAM DIMENSIONSeng_muhammad88No ratings yet

- Lec 6 Flexure Theory - Laterally Supported BeamsDocument64 pagesLec 6 Flexure Theory - Laterally Supported BeamsChristian LeobreraNo ratings yet

- CMT Lab1Document5 pagesCMT Lab1Jeneza Alma BalogoNo ratings yet

- Part B: Stress Analysis of A Rectangular Plate With A Circular HoleDocument2 pagesPart B: Stress Analysis of A Rectangular Plate With A Circular HoleAkhil KumarNo ratings yet

- ASD-Insert Plate CheckDocument12 pagesASD-Insert Plate CheckJvv GudboyNo ratings yet

- Calculation of Pipe SupportDocument6 pagesCalculation of Pipe Supportnaveen_86No ratings yet

- CH 11 Energy MethodsDocument31 pagesCH 11 Energy MethodsLuis Fer Baeza100% (2)

- Binquet and LeeDocument1 pageBinquet and LeeLoukit KhemkaNo ratings yet

- American Wide Flange Steel Beams W Beam LetterDocument7 pagesAmerican Wide Flange Steel Beams W Beam LetterzafarbadalNo ratings yet

- Ce2404 Pcs NotesDocument49 pagesCe2404 Pcs NotesChockalingamNo ratings yet

- Soil Nail Stability Analysis Tingo Maria-Aguaytia HighwayDocument5 pagesSoil Nail Stability Analysis Tingo Maria-Aguaytia HighwayAl_catrazNo ratings yet

- Flexural Strength Masonry PrismsDocument10 pagesFlexural Strength Masonry PrismsMuhammadAboubakarFarooqNo ratings yet

- CE 6705 Analysis & Design of Buildings Against Hazards: Professor T. BalendraDocument29 pagesCE 6705 Analysis & Design of Buildings Against Hazards: Professor T. BalendraThet Naing WinNo ratings yet

- Comparing seismic codes of Japan, USA and IranDocument11 pagesComparing seismic codes of Japan, USA and IranhazelfidNo ratings yet

- Bend Steel in Steel BarDocument3 pagesBend Steel in Steel BarMir Masood ShahNo ratings yet

- 2 67 1599883408 1170ijmperdjun20201170Document12 pages2 67 1599883408 1170ijmperdjun20201170Hamza RehmanNo ratings yet

- TEKNIK MATERIAL FTMD ITBDocument71 pagesTEKNIK MATERIAL FTMD ITBemiaNo ratings yet

- EDU Detailed Drawings Exercises 2017Document51 pagesEDU Detailed Drawings Exercises 2017SmrileNo ratings yet

- Shot PeeningDocument12 pagesShot PeeningAyrton PabloNo ratings yet

- Brinch Hansen Lateral CapacityDocument18 pagesBrinch Hansen Lateral CapacityDhimas Surya NegaraNo ratings yet

- Sai Srinivas JonnaDocument12 pagesSai Srinivas Jonnasai srinivasNo ratings yet

- 1-Intro GFRP-RC 08102020Document74 pages1-Intro GFRP-RC 08102020Mustufa F KanjetaNo ratings yet

- Earthquake QuizDocument1 pageEarthquake QuizGwapo SeptimoNo ratings yet

- Faliures in Steel StructuresDocument15 pagesFaliures in Steel StructuresVindula RanawakaNo ratings yet

- I Would Love Some Help With This Materials Problem... - Chegg - Com1Document2 pagesI Would Love Some Help With This Materials Problem... - Chegg - Com1Shahnewaz BhuiyanNo ratings yet