Professional Documents

Culture Documents

2

Uploaded by

kkkprot0 ratings0% found this document useful (0 votes)

16 views1 pageaspen

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentaspen

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

16 views1 page2

Uploaded by

kkkprotaspen

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

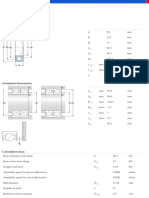

Aspen Exchanger Design and Rating Shell & Tube V9.

1

File: C:\Users\AY\Desktop\HW.EDR Printed: 1/8/2018 at 10:26:40 PM

Overall Summary

1 Size 248 X 5000 mm Type AEL Hor Connected in 1 parallel 1 series

2 Surf/Unit (gross/eff/finned) 0.6 / 0.6 / m² Shells/unit 1

3 Surf/Shell (gross/eff/finned) 0.6 / 0.6 / m²

4 Rating / Checking PERFORMANCE OF ONE UNIT

5 Shell Side Tube Side Heat Transfer Parameters

6 Process Data In Out In Out Total heat load kW 669.9

7 Total flow kg/s 8 8 Eff. MTD/ 1 pass MTD °C 42.51 / 42.57

8 Vapor kg/s 0 0 0 0 Actual/Reqd area ratio - fouled/clean 0.1 / 0.1

9 Liquid kg/s 8 8 8 8

10 Noncondensable kg/s 0 0 Coef./Resist. W/(m²-K) m²-K/W %

11 Cond./Evap. kg/s 0 0 Overall fouled 2756.5 0.00036

12 Temperature °C 25 49.94 100 60 Overall clean 2756.5 0.00036

13 Dew / Bubble point °C 78.09 78.09 Tube side film 10457.7 0.0001 26.36

14 Vapor mass fraction 0 0 0 0 Tube side fouling 0 0

15 Pressure (abs) bar 1.01 0.44995 1.01 0.44995 Tube wall 303611.6 0 0.91

16 DeltaP allow/cal bar 0.2 2.20032 0.1101 10.09048 Outside fouling 0 0

17 Velocity m/s 3.33 3.43 19.26 18.55 Outside film 3789.9 0.00026 72.73

18 Liquid Properties Shell Side Pressure Drop bar %

19 Density kg/m³ 787.62 764.15 953.99 990.16 Inlet nozzle 0.01036 0.47

20 Viscosity mPa-s 0.9626 0.6363 0.8946 1.7622 InletspaceXflow 0.02682 1.22

21 Specific heat kJ/(kg-K) 3.457 3.496 2.165 2.015 Baffle Xflow 1.16686 53.17

22 Therm. cond. W/(m-K) 0.1574 0.1482 0.134 0.1426 Baffle window 0.95444 43.49

23 Surface tension N/m OutletspaceXflow 0.02881 1.31

24 Molecular weight 46.07 46.07 93.13 93.13 Outlet nozzle 0.00748 0.34

25 Vapor Properties Intermediate nozzles

26 Density kg/m³ Tube Side Pressure Drop bar %

27 Viscosity mPa-s Inlet nozzle 0.00497 0.05

28 Specific heat kJ/(kg-K) Entering tubes 0.86524 8.47

29 Therm. cond. W/(m-K) Inside tubes 8.10388 79.3

30 Molecular weight Exiting tubes 1.23879 12.12

31 Two-Phase Properties Outlet nozzle 0.00686 0.07

32 Latent heat kJ/kg Intermediate nozzles

33 Heat Transfer Parameters Velocity / Rho*V2 m/s kg/(m-s²)

34 Reynolds No. vapor Shell nozzle inlet 1.25 1231

35 Reynolds No. liquid 51918.75 78533.2 341907.6 173584.4 Shell bundle Xflow 3.33 3.43

36 Prandtl No. vapor Shell baffle window 2.74 2.83

37 Prandtl No. liquid 21.15 15.01 14.46 24.91 Shell nozzle outlet 1.29 1269

38 Heat Load kW kW Shell nozzle interm

39 Vapor only 0 0 m/s kg/(m-s²)

40 2-Phase vapor 0 0 Tube nozzle inlet 1.03 1017

41 Latent heat 0 0 Tubes 19.26 18.55

42 2-Phase liquid 0 0 Tube nozzle outlet 1.69 2816

43 Liquid only 669.9 -669.9 Tube nozzle interm

44 Tubes Baffles Nozzles: (No./OD)

45 Type Plain Type Single segmental Shell Side Tube Side

46 ID/OD mm 16.65 / 19.05 Number 67 Inlet mm 1 / 114.3 1 / 114.3

47 Length act/eff mm 5000 / 4935 Cut(%d) 15.99 Outlet 1 / 114.3 1 / 88.9

48 Tube passes 1 Cut orientation H Intermediate / /

49 Tube No. 2 Spacing: c/c m 0.067 Impingement protection None

50 Tube pattern 90 Spacing at inlet mm 256.48

51 Tube pitch m 0.0238 Spacing at outlet mm 256.48

52 Insert None

53 Vibration problem (HTFS / TEMA) No / RhoV2 violation No

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- dSPACE ASM Product Information 2018-01 English PDFDocument40 pagesdSPACE ASM Product Information 2018-01 English PDFkkkprotNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- 3.design in Z Using Root Locus 2016 17Document8 pages3.design in Z Using Root Locus 2016 17kkkprotNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- SiS7PID ControllerDocument15 pagesSiS7PID ControllerkkkprotNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- 1Document1 page1kkkprotNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Mother ToguerDocument3 pagesMother Togueryolic91No ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Solver ModificationDocument4 pagesSolver ModificationkkkprotNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- YTU Cascaded First-Order Filters Introduce Second-Order Transfer FunctionsDocument58 pagesYTU Cascaded First-Order Filters Introduce Second-Order Transfer FunctionskkkprotNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Ballbot: A Low-Cost Robot For Tennis Ball Retrieval: John WangDocument12 pagesBallbot: A Low-Cost Robot For Tennis Ball Retrieval: John WangkkkprotNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- 1011049635Document250 pages1011049635muce01122917No ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- Week1 NotesDocument53 pagesWeek1 NoteskkkprotNo ratings yet

- Luk Fail Diag Zms de enDocument48 pagesLuk Fail Diag Zms de enIndranil BhattacharyyaNo ratings yet

- IMQDocument2 pagesIMQkkkprotNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- FVM Witch OpenFOAM-MatlabDocument817 pagesFVM Witch OpenFOAM-MatlabDavid Mestanza100% (1)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Elbow Mixture Analysis: ISSN (PRINT) :2394-6202, (ONLINE) :2394-6210, VOLUME-1, ISSUE-2,2015Document14 pagesElbow Mixture Analysis: ISSN (PRINT) :2394-6202, (ONLINE) :2394-6210, VOLUME-1, ISSUE-2,2015kkkprotNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Angular Contact Ball Bearings Super-Precision-71818 ACD/HCDocument2 pagesAngular Contact Ball Bearings Super-Precision-71818 ACD/HCkkkprotNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Self Aligning Ball Bearings BD 1205 EKTN9 H 205Document2 pagesSelf Aligning Ball Bearings BD 1205 EKTN9 H 205kkkprotNo ratings yet

- Intelligent Powertrain Design: Jimmy C. Mathews Advisors: Dr. Joseph Picone Dr. David GaoDocument44 pagesIntelligent Powertrain Design: Jimmy C. Mathews Advisors: Dr. Joseph Picone Dr. David GaokkkprotNo ratings yet

- Research Article: CFD Analysis of The Effect of Elbow Radius On Pressure Drop in Multiphase FlowDocument9 pagesResearch Article: CFD Analysis of The Effect of Elbow Radius On Pressure Drop in Multiphase FlowkkkprotNo ratings yet

- Deep Groove Ball Bearings-61910-2RS1Document1 pageDeep Groove Ball Bearings-61910-2RS1kkkprotNo ratings yet

- Max 3500N: DimensionsDocument1 pageMax 3500N: DimensionskkkprotNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- 11 Sliding Mode ControlDocument9 pages11 Sliding Mode ControlKgotsofalang Kayson NqhwakiNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Bondgraph To Transfer FunctionsDocument19 pagesBondgraph To Transfer FunctionskkkprotNo ratings yet

- NLSC Lecture Notes 2017Document212 pagesNLSC Lecture Notes 2017kkkprotNo ratings yet

- A025 PaperDocument9 pagesA025 PaperkkkprotNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- NLSC Lecture Notes 2017Document212 pagesNLSC Lecture Notes 2017kkkprotNo ratings yet

- FulltextDocument85 pagesFulltextkkkprotNo ratings yet

- Hybrid Dynamic Systems Tutorial PDFDocument66 pagesHybrid Dynamic Systems Tutorial PDFkkkprot100% (1)

- Seminario 3Document47 pagesSeminario 3kkkprotNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Particle Swarm Optimization With Area Extension (AEPSO) : A Macroscopic Model of PSO in Robotic SwarmDocument50 pagesParticle Swarm Optimization With Area Extension (AEPSO) : A Macroscopic Model of PSO in Robotic SwarmkkkprotNo ratings yet

- BTP2B-EPCIC-BTJTB-B-DES-0008 - Rev 0 - Safeguarding MemorandumDocument59 pagesBTP2B-EPCIC-BTJTB-B-DES-0008 - Rev 0 - Safeguarding MemorandumSesep Sianturi100% (1)

- Makalah Lengkap Word H.nasaruddin Salam RevisiDocument7 pagesMakalah Lengkap Word H.nasaruddin Salam RevisiAhmad SuzaqiNo ratings yet

- LIFESAVER Jerrycan Quick User GuideDocument2 pagesLIFESAVER Jerrycan Quick User GuideIdan AwaludinNo ratings yet

- Hydraulics Lab Manual - PandemicDocument12 pagesHydraulics Lab Manual - PandemichghvtfNo ratings yet

- AGA3 1990 AlgorithmDocument3 pagesAGA3 1990 Algorithmyan2huaNo ratings yet

- PHD Thesis, J SinhaDocument163 pagesPHD Thesis, J SinhaDr. Jiweshwar SinhaNo ratings yet

- NPSH CalculationDocument8 pagesNPSH Calculationagung sudarsonoNo ratings yet

- Montana (Short Parshall) Flume Users ManualDocument14 pagesMontana (Short Parshall) Flume Users ManualJabulani2010No ratings yet

- Sizing of Relief Valves (Critical and Two-Phase Flow) With Isentropic Nozzle Model (HEM)Document2 pagesSizing of Relief Valves (Critical and Two-Phase Flow) With Isentropic Nozzle Model (HEM)Nadia BahloulNo ratings yet

- Developmental Lesson PlanDocument13 pagesDevelopmental Lesson PlanEmma RissingerNo ratings yet

- MANUAL de PARTES SIST - Lubrication Oil StationDocument1 pageMANUAL de PARTES SIST - Lubrication Oil StationKasjdkasd AksdjasdjNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Introduction to NODAL AnalysisDocument47 pagesIntroduction to NODAL AnalysisAmin Elfatih100% (2)

- m3rp Addmanual 3gzf500730 - 82 10 - 2008Document12 pagesm3rp Addmanual 3gzf500730 - 82 10 - 2008Dimas_pradethaNo ratings yet

- Assignment#7 (PB 1, Case2, N 0.5) .ReportDocument10 pagesAssignment#7 (PB 1, Case2, N 0.5) .Reportseraj ibramemNo ratings yet

- Procees Design of Centrifugal Pumps - Sizing and Specification SpreadsheetDocument17 pagesProcees Design of Centrifugal Pumps - Sizing and Specification SpreadsheetMagesh leoNo ratings yet

- Unit 1 - Introduction To Hydraulics & Pneumatics Marks - 06Document8 pagesUnit 1 - Introduction To Hydraulics & Pneumatics Marks - 06Akshay KhangreNo ratings yet

- Chapter 9: Rheological and Mechanical Properties of PolymersDocument71 pagesChapter 9: Rheological and Mechanical Properties of PolymersJonatas SilvaNo ratings yet

- Tutorial 4 - BMCG 2613 - Hydrostatic Force PDFDocument2 pagesTutorial 4 - BMCG 2613 - Hydrostatic Force PDFmege1105No ratings yet

- Exercise Lec-23 DfdhyDocument4 pagesExercise Lec-23 DfdhyDev RajyaguruNo ratings yet

- USM Process Heat Transfer ExamDocument11 pagesUSM Process Heat Transfer ExamSaiful MunirNo ratings yet

- Momentum Equation in Cylindrical Coordinate: Appendix BDocument8 pagesMomentum Equation in Cylindrical Coordinate: Appendix BAbdul Rauf AttariNo ratings yet

- Linear Momentum Equations Practice ProblemsDocument49 pagesLinear Momentum Equations Practice Problemsyana22No ratings yet

- What Is Membrane FiltrationDocument7 pagesWhat Is Membrane FiltrationRobinBrittoNo ratings yet

- Chapter 7 Permeability Hydraulic ConductivityDocument73 pagesChapter 7 Permeability Hydraulic Conductivityjoemer cabayaoNo ratings yet

- Regulator SizingDocument29 pagesRegulator SizingDương HoàngNo ratings yet

- Hydrodynamic Calculation Gate Valve (Through-Conduit)Document23 pagesHydrodynamic Calculation Gate Valve (Through-Conduit)met-calcNo ratings yet

- Spe 1382 GDocument9 pagesSpe 1382 GIsrael Arias GonzálezNo ratings yet

- 1 s2.0 S0142727X17310354 MainDocument21 pages1 s2.0 S0142727X17310354 MainYash Sanjay ShewaleNo ratings yet

- FM 3e SI Chap11 LectureDocument71 pagesFM 3e SI Chap11 LecturemohdrashdansaadNo ratings yet

- Ministry of Higher Education And Scientific Research Al-Muthanna University College of Engineering Department of Chemical Engineering Taylor-prandtl modification mass transferDocument16 pagesMinistry of Higher Education And Scientific Research Al-Muthanna University College of Engineering Department of Chemical Engineering Taylor-prandtl modification mass transferعبدالمحسن علي ENo ratings yet