Professional Documents

Culture Documents

Elrad Pa600 Power Ampl SCH PDF

Uploaded by

SATBRAIN0 ratings0% found this document useful (0 votes)

402 views3 pagesOriginal Title

elrad_pa600_power_ampl_sch.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

402 views3 pagesElrad Pa600 Power Ampl SCH PDF

Uploaded by

SATBRAINCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 3

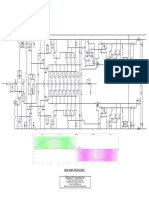

PA Power Amplifier

PA-600

Attached is the schematic of a PA or subwoofer power amplifier capable of delivering about

650W RMS into 4Ω loads. The original design was called ’PA 600’ and was first published in

the German magazine ’Elrad’ in 1990.

Towards the end of 1995, a scaled-down version of this circuit appeared in ’Elektor’ as ’PA 300’.

It is virtually the same circuit except for a less powerful output stage (now two complementary

pairs instead of five with additional driver stage) and minor changes in component selection and

values. However, as ’Elektor’ is much more popular, many people built a ’PA 300’ without

knowing it was scaled down from a bigger amplifier.

Since there have been several requests for easy-to-build and simple high power amplifiers for

DJing, subwoofers or PA on the forum recently, I tried to re-draw the schematic of the more

powerful version from memory and from looking at some of my old boards in the junk box.

Note that this is a working circuit and not a simulated design. I’ve built several of these. There

might be an error or two in the drawing or parts list, however. Although it is a comparatively

simple circuit, it is not recommended for beginners. The power supply is capable of delivering

high voltage at high currents, and if something goes wrong, it will seriously go wrong. Feed the

input with a 60Hz sinewave and connect your toaster to the output to see what I mean.

Suggested rail voltage is ± 80V, so a 2×60V 1200VA transformer for each channel is what you

need. Add a 35A bridge rectifier and at least 40mF / 100V worth of capacitance per rail. A

soft start circuit for the transformer, primary and secondary fuses and last not least a protection

circuit is needed. You may use the protection circuit published in the ’Elektor PA 300’ article

– it’s simple and it works. You might have to change R42 and R43 because of the higher rail

voltage.

There are 12 TO-3 devices that need to be cooled properly. In my opinion, the best way is to

get 4 extrusions with vertical fins, mount 3 devices on each and mount them with L-shaped bars

to form a tunnel. A (quiet but powerful) fan should be added to enforce airflow. The output

devices and emitter resistors can be wired p2p on the heatsinks whereas the driver circuit should

be built on a small board. Diodes D103..D106 are a temperature sensor and should be mounted

on the heatsink (using a small board). Bias can be adjusted using VR118, recommended value is

250mA. R121 and R122 should be chosen to limit maximum output current to a save value.

R114, R115, R119, R120, R123, R124 Metal Film or similar, 1.1W, 5%

R106, R109, R125..R137 Metal Oxide or similar, 5W, 5%

VR118 Variable Resistor, 0.25W

All other resistors Metal Film, 0.5W, 1%

C101, C103..C105, C107, C109, C111..C115 Film 160V

C106, C110 Electrolytic, 25V

C116, C117 Electrolytic, 100V

D101, D102 Zener 15V, 1.5W

D103..D110 1N4002

D111, D112 BY500-4

T101, T105 MJE350

T103, T104 MJE340

T102 BD139

T106 TIP35F

T107 TIP36F

T108..T113 MJ15022

T114..T119 MJ15023

IC101 NE5534

No rants please. This is not high end – simplicity and power were primary goals. I did not design

the circuit, but I built several and all are still working. There are better sounding designs now,

but they are more complicated and much more expensive. Decide yourself.

Feel free to contact me with questions, but please do a search on the forums first. Probably

someone else already asked the same question. I’m registered at www.diyaudio.com as

’AMT-Freak’.

If you find errors in this document, please drop me a note.

Have fun!

Oliver.

You might also like

- NS-BP112/NS-BP102 CRX-B370/CRX-B370D: MCR-B370/MCR-B270/ MCR-B370D/MCR-B270DDocument65 pagesNS-BP112/NS-BP102 CRX-B370/CRX-B370D: MCR-B370/MCR-B270/ MCR-B370D/MCR-B270DVicente Fernandez100% (1)

- ft857-897 Squelch PDFDocument0 pagesft857-897 Squelch PDFSandro FreireNo ratings yet

- D2KFB VER.2a.REV.1 PDFDocument2 pagesD2KFB VER.2a.REV.1 PDFDevelop with AcelogicNo ratings yet

- E515 IO Mixer PDFDocument2 pagesE515 IO Mixer PDFalexnder gallego100% (3)

- Yorkville AM100 Service ManualDocument10 pagesYorkville AM100 Service Manualcaimanater100% (1)

- Wireless World 1995 06 S OCRDocument92 pagesWireless World 1995 06 S OCRMilton Nast100% (2)

- Audiocenter VA Series PDFDocument4 pagesAudiocenter VA Series PDFarthurcraigNo ratings yet

- Ecler Pam1400 1000 600 300Document183 pagesEcler Pam1400 1000 600 300Lluis Reparacion ElectronicaNo ratings yet

- MH-083 Ecomaster Comfort User ManualDocument17 pagesMH-083 Ecomaster Comfort User ManualSATBRAIN100% (2)

- Tram 2 PreampDocument30 pagesTram 2 Preampdecky999100% (1)

- Falcon 7X CommunicationsDocument105 pagesFalcon 7X Communicationsjunmech-1No ratings yet

- Audio Power AmpDocument6 pagesAudio Power AmpAudi MirantiNo ratings yet

- Bader-451 04511530english - v114 PDFDocument37 pagesBader-451 04511530english - v114 PDFkumbrovNo ratings yet

- JLH 1985 HeadphoneDocument5 pagesJLH 1985 HeadphoneDave LeeNo ratings yet

- 8210-Service Manual (070525)Document31 pages8210-Service Manual (070525)Douglas AtkinsNo ratings yet

- Kathrein 80010292 V 03 Antenna DatasheetDocument2 pagesKathrein 80010292 V 03 Antenna DatasheetRadu Stan100% (1)

- DIYAudio DIYAB Honey Badger Build Guide v1.0Document30 pagesDIYAudio DIYAB Honey Badger Build Guide v1.0Danh Pro100% (1)

- Ampl 12AU7Document6 pagesAmpl 12AU7Adinei HamradioNo ratings yet

- X-Altra Moving Coil/Moving Magnet RIAA EQ Preamplifier RIAA EQ PreamplifierDocument7 pagesX-Altra Moving Coil/Moving Magnet RIAA EQ Preamplifier RIAA EQ PreamplifierbobannesicNo ratings yet

- JLH 2001 DesignDocument4 pagesJLH 2001 DesignDaniel ScardiniNo ratings yet

- 50W Hi-Fi Power Audio Amplifier TDA7294 PDFDocument5 pages50W Hi-Fi Power Audio Amplifier TDA7294 PDFciamponi1959100% (1)

- Loudspeaker Protector: Elektor Electronics 12/96Document1 pageLoudspeaker Protector: Elektor Electronics 12/96Kalinga Jayatilake0% (1)

- Dual High Slew Rate, Low Noise Operational Amplifier: BA15218 / BA15218F / BA15218NDocument5 pagesDual High Slew Rate, Low Noise Operational Amplifier: BA15218 / BA15218F / BA15218NAnonymous vKD3FG6RkNo ratings yet

- D:/Mydata/Ltspice/Blameless 1500V2.AscDocument1 pageD:/Mydata/Ltspice/Blameless 1500V2.AscrudiNo ratings yet

- 10" ARRAY 2560 M: Fabulous Series by ACR - 10 Inch - WooferDocument2 pages10" ARRAY 2560 M: Fabulous Series by ACR - 10 Inch - WooferIrsyadi 86No ratings yet

- SMW 3 0Document1 pageSMW 3 0Zoran Poštin0% (1)

- EEEngine G77 - Internal Bias Ver.1 Full SchematicDocument3 pagesEEEngine G77 - Internal Bias Ver.1 Full SchematicRaWaNo ratings yet

- Speaker Protection CircuitDocument3 pagesSpeaker Protection Circuitsontuyet820% (2)

- 4PRO 3003A 4003A ManualDocument11 pages4PRO 3003A 4003A ManualCarlo Bianco100% (1)

- P3A - 60-100W Hi-Fi PowerAmp - Dual OutputDocument13 pagesP3A - 60-100W Hi-Fi PowerAmp - Dual OutputEdvaldo CostaNo ratings yet

- NC2k R4Document16 pagesNC2k R4AlNo ratings yet

- K 4700Document16 pagesK 4700EvangelistaNo ratings yet

- 2 Band Onboard PreampDocument7 pages2 Band Onboard PreampDanny RachmanNo ratings yet

- Power Amp Super Bridge 120W by IC TDA2030 - EleccircuitDocument7 pagesPower Amp Super Bridge 120W by IC TDA2030 - EleccircuitmarcioulguimNo ratings yet

- 4d4fe32593743 - SiA 208RDocument8 pages4d4fe32593743 - SiA 208RManoj VattavilaNo ratings yet

- SRX725/SRX725F: Dual 15" High-Power Two-Way SpeakerDocument2 pagesSRX725/SRX725F: Dual 15" High-Power Two-Way SpeakerulissesNo ratings yet

- Yamaha psr550 Sevicemanual PDFDocument50 pagesYamaha psr550 Sevicemanual PDFAnand s100% (1)

- 869 SingleDocument1 page869 Singleapi-3833673No ratings yet

- Sony HCD Rv222 Ver 1.1Document86 pagesSony HCD Rv222 Ver 1.1Carlos Raul100% (2)

- 25 Watt Mosfet AmplifierDocument4 pages25 Watt Mosfet AmplifierCarlos Alberto NetoNo ratings yet

- Quad 303 SetupDocument2 pagesQuad 303 SetupdimitrijbNo ratings yet

- Power Amplifier Schematics: MODELS 3B, 4B, 5B, 7B, 8B, 9B & 14B September 2001Document13 pagesPower Amplifier Schematics: MODELS 3B, 4B, 5B, 7B, 8B, 9B & 14B September 2001Hiển AmplierNo ratings yet

- 7 Tone Control Stereo Preamplifier Circuits With PCB Low NoiseDocument48 pages7 Tone Control Stereo Preamplifier Circuits With PCB Low Noisesameerato100% (1)

- 8 Catalogue - 2021 22Document152 pages8 Catalogue - 2021 22Yazhisai SelviNo ratings yet

- VOXDocument2 pagesVOXDevendra NamdeoNo ratings yet

- Parts List From Pacific SemicondutorsDocument7 pagesParts List From Pacific SemicondutorsNeville McBeanNo ratings yet

- WR - DA7 Manual de ServicioDocument86 pagesWR - DA7 Manual de ServicioDanielNo ratings yet

- Audio Amplifier 200-500WDocument4 pagesAudio Amplifier 200-500WIndonesiaKan AgungNo ratings yet

- Class D AmplifierDocument5 pagesClass D AmplifierkothuraNo ratings yet

- Quad405 Service DataDocument0 pagesQuad405 Service DataDoco_manNo ratings yet

- Quad 33 303 PDFDocument25 pagesQuad 33 303 PDFKevin Kober100% (1)

- ISIS Professional AMPLIFICADOR - Zener 200W Yiroshi.Document1 pageISIS Professional AMPLIFICADOR - Zener 200W Yiroshi.Rafael MendozaNo ratings yet

- Deez Nuts Bass Treble Booster R2P1Document1 pageDeez Nuts Bass Treble Booster R2P1Samuel Verdeflor100% (1)

- FORMPREDocument8 pagesFORMPREFouquetNo ratings yet

- Roland TD-8 ManualDocument224 pagesRoland TD-8 ManualAnonymous cdQSIU03AQNo ratings yet

- Pa-9312 9324 9336Document2 pagesPa-9312 9324 9336cadatiNo ratings yet

- Circuit Adjustable Bass Filter From 50 HZ To 150 HZ NE5532Document4 pagesCircuit Adjustable Bass Filter From 50 HZ To 150 HZ NE5532Javier Castellanos BarrazaNo ratings yet

- MaxAmp 11/45 Manual and SchematicDocument23 pagesMaxAmp 11/45 Manual and Schematicoldradioguy2100% (1)

- Skema Box Speaker LAVOCE - Sistema-F153.14NDocument23 pagesSkema Box Speaker LAVOCE - Sistema-F153.14NZaid DenieNo ratings yet

- Audio Note Feed Forward Shunt RegulatorDocument6 pagesAudio Note Feed Forward Shunt RegulatorMario CaneverNo ratings yet

- Tektronix 2710 Spectrum Analyzer SM PDFDocument402 pagesTektronix 2710 Spectrum Analyzer SM PDFJpaul RodriguezNo ratings yet

- Circuit Power Audio Amplifier With TDA2030 2.1 Chanell - 3 X 18 Watts - Subwoofer - Complete With PCDocument8 pagesCircuit Power Audio Amplifier With TDA2030 2.1 Chanell - 3 X 18 Watts - Subwoofer - Complete With PCDominik StaffNo ratings yet

- 150 Watt Amplifier CircuitDocument4 pages150 Watt Amplifier CircuitKarsadi SaminNo ratings yet

- Class D Audio-Power Amplifiers - Interactive SimulationsDocument5 pagesClass D Audio-Power Amplifiers - Interactive SimulationsJUNIOR700No ratings yet

- Transistor Circuit Diagram of 2sa1943 and 2sc5200Document68 pagesTransistor Circuit Diagram of 2sa1943 and 2sc5200Eliecer GonzalezNo ratings yet

- Modification To AMP REV1Document14 pagesModification To AMP REV1augustinetezNo ratings yet

- Curso de Fotografia DigitalDocument14 pagesCurso de Fotografia DigitaldavidNo ratings yet

- User Manual 3984818Document23 pagesUser Manual 3984818SATBRAINNo ratings yet

- Rcrit 14V369 4509Document17 pagesRcrit 14V369 4509SATBRAINNo ratings yet

- Alex Original Digital ControllerDocument3 pagesAlex Original Digital ControllerSATBRAINNo ratings yet

- Ps 132kibes Zr32a Mux2b enDocument20 pagesPs 132kibes Zr32a Mux2b enSATBRAINNo ratings yet

- Emufdd EngDocument5 pagesEmufdd EngSATBRAINNo ratings yet

- ST vn450Document9 pagesST vn450SATBRAINNo ratings yet

- 0 - 30 V Adjustable Voltage, Current Stabilized VoltageDocument2 pages0 - 30 V Adjustable Voltage, Current Stabilized VoltageAPLCTNNo ratings yet

- 17IPS06Document3 pages17IPS06SATBRAINNo ratings yet

- 1313 Manual Consola Curtis PDFDocument46 pages1313 Manual Consola Curtis PDFsergioNo ratings yet

- 1204 051 PDFDocument49 pages1204 051 PDFEdison David OrtizNo ratings yet

- 1310 ManualDocument51 pages1310 Manual0101 HanafiNo ratings yet

- Sony Str-ks1200 Ver1.1Document104 pagesSony Str-ks1200 Ver1.1SATBRAINNo ratings yet

- Using The Memory Card ExplorerDocument18 pagesUsing The Memory Card ExplorerSATBRAINNo ratings yet

- SBC8360VEA: Socket 370 Embedded SBC With Multi-Media & Mechanical Backward Compatible SolutionsDocument1 pageSBC8360VEA: Socket 370 Embedded SBC With Multi-Media & Mechanical Backward Compatible SolutionsSATBRAINNo ratings yet

- Alesis RA500 Power AmplifierDocument32 pagesAlesis RA500 Power AmplifierputitibiNo ratings yet

- Wide Low Input Voltage DMX512 Decoder: DMX512 Color Perfect SolutionDocument5 pagesWide Low Input Voltage DMX512 Decoder: DMX512 Color Perfect SolutionSATBRAINNo ratings yet

- LabDocument9 pagesLabZuru Raya EthioNo ratings yet

- Electrical Symbols & Electronic SymbolsDocument6 pagesElectrical Symbols & Electronic SymbolsJeric Gader BriosoNo ratings yet

- TecsisDocument1 pageTecsisguna8825No ratings yet

- ADF4110/ADF4111/ADF4112/ADF4113 RF PLL Frequency SynthesizersDocument24 pagesADF4110/ADF4111/ADF4112/ADF4113 RF PLL Frequency SynthesizersMichael LiuNo ratings yet

- 05940586Document21 pages05940586ohenri100No ratings yet

- Z600EDocument2 pagesZ600Esaleemut3No ratings yet

- Pioneer dvr-530h-s (ET)Document144 pagesPioneer dvr-530h-s (ET)Jamal JardelNo ratings yet

- Bhoj Reddy Engineering College For Women: Microwave and Digital Communications Laboratory ManualDocument52 pagesBhoj Reddy Engineering College For Women: Microwave and Digital Communications Laboratory Manuallakshmipriya94No ratings yet

- Gps Anti Jammer Gpsdome - Effective Protection Against JammingDocument2 pagesGps Anti Jammer Gpsdome - Effective Protection Against JammingCarlos VillegasNo ratings yet

- RF Based Automatic Speed Limiter For VehiclesDocument35 pagesRF Based Automatic Speed Limiter For Vehiclesv3rajasekarNo ratings yet

- HWXX 6516DS1 VTM PDFDocument4 pagesHWXX 6516DS1 VTM PDFnguyentraihdNo ratings yet

- IC 74XX SeriesDocument34 pagesIC 74XX SeriesSandeep MishraNo ratings yet

- Cubic - CDR (3250-3280) (Manual)Document132 pagesCubic - CDR (3250-3280) (Manual)donboxNo ratings yet

- AdmitCard PDFDocument1 pageAdmitCard PDFMadhur GuptaNo ratings yet

- Apple Watch Series 2Document8 pagesApple Watch Series 2dorian451No ratings yet

- 8ryston .58 Preamplifier Operating InstructionsDocument5 pages8ryston .58 Preamplifier Operating InstructionsciohaniNo ratings yet

- Report On Radio Systems - 06122013 - FinalDocument22 pagesReport On Radio Systems - 06122013 - FinalDaryl JonesNo ratings yet

- THERMISTOR ProtectionDocument3 pagesTHERMISTOR Protectionjay shahNo ratings yet

- Opamp Desiging Project ReportDocument6 pagesOpamp Desiging Project ReportTarun PrakashNo ratings yet

- Teenagers and Smartphones Reading Comprehension Exercises 89545Document2 pagesTeenagers and Smartphones Reading Comprehension Exercises 89545Laura Salvatierra Monfort83% (6)

- OFDMADocument14 pagesOFDMAMaharshi RindaniNo ratings yet

- Keyes - Funduino Uno and Nano Multi Purpose Shield V3Document5 pagesKeyes - Funduino Uno and Nano Multi Purpose Shield V3David FernándezNo ratings yet

- Service Manual: CD Radio Cassette-CorderDocument42 pagesService Manual: CD Radio Cassette-Corderpepe3214No ratings yet

- IC-7000 Product BrochureDocument4 pagesIC-7000 Product BrochurerdeagleNo ratings yet

- Linear CircuitDocument6 pagesLinear CircuitLilySolaimanNo ratings yet

- RFX2402Document8 pagesRFX2402Tim HarveyNo ratings yet