Professional Documents

Culture Documents

Valvula Solenoide VML

Uploaded by

René Rocha MolinaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Valvula Solenoide VML

Uploaded by

René Rocha MolinaCopyright:

Available Formats

VML

Solenoid safety valves for Air and Gas

Slow opening and fast closing type

DN10 … DN80

www.elektrogas.com

VML2 - VML4

Certified Quality System

Printed in Italy - EE162/0704

VML

Slow safety solenoid valve

Class A – Group 2

The VML type valve is a slow opening single-stage

solenoid valve, normally closed.

This type of device is suitable for air or gas blocking and

releasing controls, required in gas power burners,

atmospheric gas boilers, furnaces and others gas

consuming appliances.

The VML type valves are made in accordance with

EN161 standard (EC type examination certificate no.

0063AQ1350).

1- Features

Large range for inlet/outlet connections, from 3/8” to

3" pipes sizing.

Provided with G1/4” pressure gauge on two sides in

the inlet pressure chamber. Others gauge points on

request.

Optional G1/8” connection for closed position

indicator micro switch (on request from 3/4" to 3").

Fig. 1

Fine mesh filter incorporated prevents dirty

contamination of the seal seat.

Maximum operating pressure 200 mbar or 360 2- Technical specifications

mbar.

Suitable for air and non-aggressive gases (EN 437, Connections ……………….. Gas threaded ISO 7/1

1, 2 and 3 families). from Rp3/8 to Rp2

Flanged PN16 - ISO 7005

Easy adjustable flow rate, rapid stroke and opening DN 40, DN 80

time.

Voltage rating ……………… 230 VAC 50/60 Hz

Qualified for continuous service (100% ED) and Voltage on request …………110 VAC 50/60 Hz

endless ON/OFF cycles.

Voltage tolerance …………. -15% / +10%

Coil insulation is class H (180°C).

Power consumption ………. see charts

Terminal box with PG connector.

Environment temperature … -15°C / +60°C

The large models are provided with a power saving

electronic device, to reduce power consumption and Max. working pressure …….200 / 360 mbar

working temperature. Flow capacity ……………… see charts

Valves are 100% tested by computerized testing Disc sealing …..…………… NBR

machineries and are fully warranted.

Closing time ………………. < 1 second

For valve identification see the following charts.

Opening time …………….... adjustable from 4 to 25 s

Protection class …………… IP 54 (EN 60529)

WARNING Cable gland ………………... PG09

- This control must be installed in compliance with Overall dimensions ……….. see charts

the laws in force.

- Read instructions before use.

- Elettromeccanica Delta S.p.a. reserves the right

to update or make technical changes without

prior notice.

2 Printed in Italy - EE162/0704

3- Operation

The VML type valve is a safety shutting device using

auxiliary power supply.

When it is de-energized, the spring pushes on the seal

disc, keeping the gas passage closed. Now, the inlet

chamber is under the gas line pressure, and it forces on

the disc too, improving the seal.

When the coil is powered the valve opens rapidly or

slowly, against the strength of the spring and gas

pressure. The rapid stroke may be adjusted using the

regulating screw on the top (see the Service Instruction

Section), to adjust the initial gas flow. Main flow and

opening time can be adjusted also.

If the power supply is shut off, the valve rapidly closes,

interrupting the gas flow.

4- Accessories

A fine mesh filter is provided, to prevent dirty

contamination of the seal seat. However, an external

strainer must be installed upstream of the valve.

Inlet pressure area is provided with bilateral G1/4"

gauges, to connect min/max adjustable pressure

switches, leakage tester or other gas equipments. Fig. 2

Flanged models are provided with gauges in the outlet

chamber too

On request, valves are supplied with a G1/8” connection 6- General information

on the bottom, to installed a closed position indicator

micro switch (from 3/4" to 3"). An adapting rod is Backpressure sealing is compliant with the Class A:

provided too. the maximum backpressure admitted, with leakage

within the EN161 requirements, is 150mbar.

Maximum torsional stresses admitted are compliant

5- Coil features with the Group 2 of the EN161 standard.

Recommended testing pressure is 1500 mbar Max.

All components are design to withstand any

The continuous service (100% ED) causes inevitable coil

mechanical, chemical and thermal condition

heating, depending of working environment. This

occurring during typical service.

situation is absolutely normal and has not to worry. To

improve the coil cooling, install the valve allowing free air Effective impregnation and surface treatments has

circulation. been used to improve mechanical sturdiness,

sealing and resistance to corrosion of the

The models from 1"¼ up to 3" are provided with a power components.

saving electronic device. It has two stages of operation:

full power is supplied to the coil while the valve is Valves are suitable for use with air and non-

opening; low power is supplied while the valve is aggressive gases included in the 1, 2 and 3 families

opened. (EN 437).

Coil and terminal box are provided with suitable gaskets, Materials in contact with gas:

to avoid water and dirty contamination (see the Service • Aluminium

Instruction Section). • Brass

• Stainless steel

• Plated steel

• Anaerobic adhesive

• Nitrile rubber (NBR)

• Polytetrafluoroethylene (PTFE)

3 Printed in Italy - EE162/0704

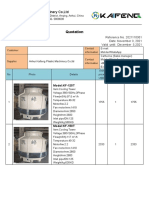

7- Valve identification

Connections type 230V AC 110V AC 24V AC/DC 12V AC/DC

Threaded Flanged 360 mbar 200 mbar 360 mbar 200 mbar 200 mbar 130 mbar 200 mbar 130 mbar

Rp 3/8 VML0 VML0B

Rp 1/2 VML1 VML1B

Rp 3/4 VML2 VML2B

Rp 1 VML3 VML3B

Rp 1¼ VML35 VML35B

1

Rp 1½ DN 40 ( ) VML4 VML4B

1

Rp 2 DN 50 ( ) VML6 VML6B

2

DN 65 ( ) VML7 VML72 VML7B VML72B

2

DN 80 ( ) VML8 VML82 VML8B VML82B

Fig. 3

Model Connections Maximum Power Overall Dimensions Weight

Pressure Consump.

@230VAC (mm)

Threaded Flanged (mbar) (W) A B C D Int h (Kg)

VML0 Rp 3/8 360 20 88 77 180 196 - - 1,8

VML1 Rp 1/2 360 20 88 77 180 196 - - 1,8

VML2 Rp 3/4 360 45 88 96 200 222 - - 2,7

VML3 Rp 1 360 45 88 96 200 222 - - 2,7

3

VML35 Rp 1¼ 360 45/180 ( ) 120 153 258 290 - - 6

1 3

VML4 Rp 1½ DN 40 ( ) 360 45/180 ( ) 120 153 258 290 110 4x18 6

1 3

VML6 Rp 2 DN 50 ( ) 360 45/180 ( ) 106 156 264 302 125 4x18 6,3

2 3

VML7 DN 65 ( ) 200/360 60/240 ( ) 200 305 335 424 145 4x18 14,5

2 3

VML8 DN 80 ( ) 200/360 60/240 ( ) 200 305 335 424 160 8x18 14,5

1 2 3

( ) Optional kit ( ) Vstart =3 mm minimum ( ) Working/Opening

4 Printed in Italy - EE162/0704

8- Loss of pressure

Natural gas

Town gas

mmH2O

Air

DN 80

DN 65

m³/h

2"

1"½

1"¼

1"

3/4"

1/2"

3/8"

mbar

Formula of conversion from air

to other gases

Gas type Specific gravity K

(kg/m³)

Natural Gas 0.80 1.25

Town Gas 0.57 1.48

Liquid Gas 2.08 0.77

Air 1.25 1.00

+15°C, 1013 mbar, dry

5 Printed in Italy - EE162/0704

9- Valve installation 10- Electrical connections (IEC 730-1)

Verify the line pressure is lower of the maximum working Check correspondence between valve voltage rating and

pressure admitted to the valve. line power supply, before making any electrical

Check correspondence of flow direction with arrow connections.

printed on valve body.

Check correct alignment of connecting pipes and allow 1. Switch off power supply and remove protection

enough space from the walls to allow free air circulation. cover.

2. Connect power cables to rectifier circuit terminal

Remove the end caps and make sure no foreign board.

body is entered into the valve during handling. 3. Should cables pass through originally closed

Install in an area that is protected from rain and opening, use the rubber disc placed underneath the

water splashes or drops. box plug to close any other opening.

Threaded models: 4. Screw back the box cover, taking care to use all

gaskets properly, because this could condition the

1. Put sealing agent onto the pipe thread (avoid valve life duration.

excessive quantities of fittings glue which could

enter in the valve and damage the seal seat).

2. Screw the pipes using proper tools only. Do not use

unit as lever because damage to the valve stem

could result.

Flanged models:

1. Position the gasket and insert the bolts.

2. Screw the nuts tightening them crosswise and using

proper tools only.

Avoid overtightening and mount tension free.

Following chart shows the maximum values of bending

moment (Fmax), torque (Tmax) and screws driving torque

(Cmax), according with EN13611.

Connections Fmax Tmax Cmax

(Nm) t<10 s (Nm) (Nm)

Rp 3/8 70 35 -

Rp 1/2 105 50 -

Rp 3/4 225 85 -

Rp 1 340 125 -

Rp 1¼ 475 160 -

Rp 1½ 610 200 50 Fig. 5

Rp 2 1100 250 50

DN 65 1600 - 50

DN 80 2400 - 50 WARNING

• To prevent product damage and dangerous

situations, read the Installation and Service

Instructions carefully.

Fmax

• Turn off all power before servicing any part of

Tmax the system.

• Perform leak and functional tests after mounting.

A gas leak detection spray may be used also.

Fig. 4 • Coil and terminal box must be replaced with

identical spare parts only.

• If the coil is turned, make sure the brake is

Valve may be mounted with coil in horizontal or vertical

properly tightened and the coil is locked.

position. Coil may be oriented 360 degrees in any

direction. • Use all gaskets properly (void warranty).

• All wiring must be in compliance with local and

national codes.

• Make sure all works are performed by qualified

technicians only.

6 Printed in Italy - EE162/0704

11- Fast stroke adjustment (Vstart)

Fast flow section may be adjusted:

1. Remove plastic cap.

2. Using an hexagonal wrench, turn the outer screw

clockwise to decrease or counter-clockwise to

increase the initial fast stroke.

3. When adjustment is completed, screw back the

plastic cap.

NOTE: in the DN65 and DN80 models the minimum

adjustable stroke is 3 mm.

12- Flow rate adjustment (Vmax)

Flow rate may be adjusted from 0 cubic meters/h up to

the maximum admitted:

1. Remove plastic cap.

2. Keeping the outer screw fixed, use a screw driver to

turn the internal screw clockwise to decrease or

counter-clockwise to increase flow rate (factory

setting is max. flow rate).

3. When adjustment is completed, screw back the

plastic cap.

NOTE: the flow rate regulation can not be lower than the

fast flow section.

13- Opening time adjustment (T)

To regulate opening time, turn the screw located on the

side of the brake. One fourth of a turn clockwise

increases opening time by 2÷3 s, up to a maximum of

about 25 s (slow run).

Factory setting is about 12÷14 s. Fig. 6

14- Coil replacement

Before to start with coil replacement, make sure it is the

WARNING cause of failure.

• Perform the fast stroke adjustment before of the To perform coil replacement do the following:

flow rate adjustment. 1. Make sure an identical one spare part is available.

• Make sure that capacity adjustments are made 2. Switch off power supply and remove the box cover.

while burner is working. 3. Disconnect the wires from terminal board.

• Check the regulation is not changed during 4. To remove brake, turn it counter clockwise.

reassembly.

5. Extract and replace coil.

• Adjustments below 40% of capacity are

unadvisable because they may cause 6. Reassemble following the inverse sequence.

turbulence.

WARNING

• When reassemble, use all gaskets properly.

• Perform functional test after mounting.

• All works must be executed by qualified

technicians only and in compliance with local

and national codes.

7 Printed in Italy - EE162/0704

15- Maintenance

To maintain a good performance of the system, almost Cap

once a year, an inspection of the valve is recommended.

Brake

External inspection

Turn off all power before servicing any part of the

system.

O-ring

Check the conditions of the terminal board gasket. If

gasket is deteriorated, replace it with a new one.

Check the electrical connections are clean, dry and

correctly tightened. Coil assembly

Check the conditions of pipe connections: cover them

with a soap solution and check for leakages. O-ring

Stem

Internal inspection

To make an internal inspection of the valve, do the Screw

following:

Upper flange

1. Close ball valve upstream the system.

Main O-ring

2. Remove the coil like shown in the section 14.

3. Using an Allen key, remove the screws on the upper Spring

flange, in cross way. The gas in the valve will come

out during this step.

4. Check the hydraulic brake is free of oil leakages

(small leakages are admitted). If it’s necessary,

Sliding ring

replace it with a new one.

5. Check the main O-ring and, if it’s necessary, replace Plunger

it with a new one.

6. Clean the internal side of the stem with a clean cloth Disc + gasket

and compressed air. Filter

7. Remove the spring and blow it with compressed air.

Check the spring is corrosion free. Take attention to

the assembly direction of the spring. G1/4” plug

8. Check the wear conditions of the sliding rings and, if

it’s necessary, replace them. Valve body

9. Clean the sealing disc assembly with a clean cloth

and compressed air. Fig. 8

10. Check the conditions of the sealing gasket. If gasket

is deteriorated, replace it with a new one.

When the reassembly is finished, verify the correct

11. Clean the sealing lip with a clean cloth. Do not use sealing between the upper flange and the valve body:

tools, because a lip damage could result.

1. Open ball valve to restore pressure into the valve.

12. Remove the filter and blow it with compressed air.

2. Apply a soap solution between the upper flange and

13. Check the O-ring on the top of stem and, if it’s the valve body and check for leakages.

necessary, replace it.

3. Remove the soap solution with a clean cloth, before

14. Reassemble the valve following the inverse to reassemble the coil.

sequence.

To assemble the sliding rings, wind them onto a lower WARNING

diameter (ex. Screw driver), then insert them from the • When reassemble, use all gaskets properly.

top.

• Perform functional test after mounting.

When reassembling, take attention to the correct

position of the sliding rings and spring. • All works must be executed by qualified

technicians only and in compliance with local

and national codes.

8 Printed in Italy - EE162/0704

You might also like

- 440T4 4T60 4t60e 4t65eDocument24 pages440T4 4T60 4t60e 4t65eFTompkins73100% (4)

- A Guide to Vintage Audio Equipment for the Hobbyist and AudiophileFrom EverandA Guide to Vintage Audio Equipment for the Hobbyist and AudiophileNo ratings yet

- Caterpillar XQ100 Towable Diesel Generator SetDocument5 pagesCaterpillar XQ100 Towable Diesel Generator SetMacAllister MachineryNo ratings yet

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsFrom EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsRating: 5 out of 5 stars5/5 (1)

- TRIHALDocument32 pagesTRIHALangelcepedasantosNo ratings yet

- Hospital Management Information SystemDocument47 pagesHospital Management Information SystemNisarg100% (1)

- Pocket PDFDocument437 pagesPocket PDFFranko MilovanNo ratings yet

- Assault RiflesDocument203 pagesAssault Riflessadfafgdsg100% (1)

- Solenoid Valve Data SheetDocument14 pagesSolenoid Valve Data SheetGuido Moreno PeredoNo ratings yet

- Cedaspe Buchholz RelayDocument22 pagesCedaspe Buchholz RelayRichard Sy100% (2)

- Elektrogas VMRDocument8 pagesElektrogas VMRthiago_juliao1984No ratings yet

- Parker Lucifer SolenoidsDocument8 pagesParker Lucifer SolenoidsAmet koko TaroNo ratings yet

- Bard UP03Document12 pagesBard UP03Alan VazquezNo ratings yet

- RIS DGPTDocument6 pagesRIS DGPTKarin Aca OviNo ratings yet

- Catalog Functional Safety Solutions Asco en 5084612Document16 pagesCatalog Functional Safety Solutions Asco en 5084612alejomariana03No ratings yet

- Coaxial ValvesDocument4 pagesCoaxial ValvesvishadkapadiaNo ratings yet

- PEE 1560-ACMV SpecDocument97 pagesPEE 1560-ACMV SpecjimiNo ratings yet

- Cedaspe Gas AnalyserDocument20 pagesCedaspe Gas AnalyserokyNo ratings yet

- ÉSECÈ Group - Steam Boiler - Mar12 ENGDocument4 pagesÉSECÈ Group - Steam Boiler - Mar12 ENGDiego Otero RodríguezNo ratings yet

- 1595a Bul 7-04 PDFDocument2 pages1595a Bul 7-04 PDFBogdan Laurențiu LingurariuNo ratings yet

- Pressure Relief Valve 3/4" - 1"Document5 pagesPressure Relief Valve 3/4" - 1"Gisella Mariel RubilarNo ratings yet

- VMR enDocument11 pagesVMR enCarlosNo ratings yet

- The Wall-Mount™ Air Conditioners - 9.0 Eer, (60Hz) : G R R-410ADocument12 pagesThe Wall-Mount™ Air Conditioners - 9.0 Eer, (60Hz) : G R R-410AcarlosNo ratings yet

- Ee Full Catalogue PDFDocument19 pagesEe Full Catalogue PDFDaya SagarNo ratings yet

- Asco Temperature SeriesDocument4 pagesAsco Temperature SeriesJhon PaulNo ratings yet

- RNP Actuator Metso NewDocument11 pagesRNP Actuator Metso NewOGPE-AMC1No ratings yet

- Hot-Air Generator: Operation ManualDocument13 pagesHot-Air Generator: Operation ManualNur HidayatNo ratings yet

- European Instruction Manual Series 215 Solenoid Valve Gas Shut Off de de 5288058Document4 pagesEuropean Instruction Manual Series 215 Solenoid Valve Gas Shut Off de de 5288058Sergio RodriguezNo ratings yet

- AC Bard Wall MountedS3502Document24 pagesAC Bard Wall MountedS3502Ricardo Dardon100% (1)

- Manual Zaf-Zdaf EngDocument20 pagesManual Zaf-Zdaf EngIulian TitaNo ratings yet

- VMR enDocument11 pagesVMR enFernando Paiva De PaulaNo ratings yet

- FunctionalSafety V7666Document12 pagesFunctionalSafety V7666rufino.perea.2No ratings yet

- Buccholtz Atus CatalogDocument4 pagesBuccholtz Atus Catalogindrajit mondalNo ratings yet

- As 7703 Iso Fe Serie enDocument8 pagesAs 7703 Iso Fe Serie enprihartono_diasNo ratings yet

- Data Sheets 1301 Series High Pressure Regulators Bulletin Fisher en en 6106236Document8 pagesData Sheets 1301 Series High Pressure Regulators Bulletin Fisher en en 6106236Abdeldjalil AchourNo ratings yet

- Transformercare Unit Tcu Series: Technical Specifications DescriptionDocument2 pagesTransformercare Unit Tcu Series: Technical Specifications DescriptionJoão Paulo SacramentoNo ratings yet

- EMO-T EN Low-1Document8 pagesEMO-T EN Low-1pusicantonijeNo ratings yet

- OEM En3-222Document4 pagesOEM En3-222chandushar1604No ratings yet

- Asco P SeriesDocument9 pagesAsco P SeriesjiseobNo ratings yet

- Irrigation Solenoid ValveDocument1 pageIrrigation Solenoid ValveAtul KalaskarNo ratings yet

- 10 Ex-Safety and Main Current Switches PDFDocument91 pages10 Ex-Safety and Main Current Switches PDFrocket-vtNo ratings yet

- Foxboro RTDDocument12 pagesFoxboro RTDJonathanGonzalezDiazNo ratings yet

- BRAHMA Gas Sol Valve EG12....Document5 pagesBRAHMA Gas Sol Valve EG12....Efril DIlen FranciscoNo ratings yet

- Supape Solare RomstalDocument1 pageSupape Solare RomstalCraciun DanielNo ratings yet

- 3/2-Way Solenoid Valve, Direct-Acting: Type 744Document4 pages3/2-Way Solenoid Valve, Direct-Acting: Type 744Francisco Mones RuizNo ratings yet

- The Wall-Mount™ Air Conditioners - 9.0 Eer, (60Hz) : G R R-410aDocument16 pagesThe Wall-Mount™ Air Conditioners - 9.0 Eer, (60Hz) : G R R-410aYhonny OviedoNo ratings yet

- Dorma FloorspringsDocument28 pagesDorma FloorspringsanilNo ratings yet

- Buchholz Relays EB Series: The Most Popular Buchholz Relay For Oil-Immersed Power TransformersDocument20 pagesBuchholz Relays EB Series: The Most Popular Buchholz Relay For Oil-Immersed Power TransformersbharathNo ratings yet

- B&M Series 1000 SwitchesDocument12 pagesB&M Series 1000 SwitchesscribdkhatnNo ratings yet

- tmg740 3Document6 pagestmg740 3tespakNo ratings yet

- Wall Mount Aire AcondicionadoDocument8 pagesWall Mount Aire AcondicionadoJose SaldarriagaNo ratings yet

- Tender Doc Vol 3 Page No 827 To 830Document4 pagesTender Doc Vol 3 Page No 827 To 830Saurabh ChaudhariNo ratings yet

- 1098 EgrDocument44 pages1098 EgrPat AuffretNo ratings yet

- Ris PDFDocument9 pagesRis PDFcornel.irina9308No ratings yet

- Water Source HeatpumpDocument4 pagesWater Source HeatpumpgokulNo ratings yet

- 3/2-Way Solenoid Valve, Direct-Acting: Type 743Document4 pages3/2-Way Solenoid Valve, Direct-Acting: Type 743Francisco Mones RuizNo ratings yet

- BURKERT Inf Tecnica 8692Document8 pagesBURKERT Inf Tecnica 8692luisNo ratings yet

- Buchholz RelayDocument23 pagesBuchholz RelayMukesh KumarNo ratings yet

- Gas Burned Siemens Landis LGA41Document11 pagesGas Burned Siemens Landis LGA41Abelardo PeironeNo ratings yet

- Super Safety ValveDocument1 pageSuper Safety ValvePaul Ticona SNo ratings yet

- TLL13X Fozmula Liquid Level Sensor Data 8-6-33R2Document1 pageTLL13X Fozmula Liquid Level Sensor Data 8-6-33R2moisesNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Influence of System Parameters Using Fuse Protection of Regenerative DC DrivesFrom EverandInfluence of System Parameters Using Fuse Protection of Regenerative DC DrivesNo ratings yet

- Boat Maintenance Companions: Electrics & Diesel Companions at SeaFrom EverandBoat Maintenance Companions: Electrics & Diesel Companions at SeaNo ratings yet

- Catalogo Comercial Power Plus Box 1000Document100 pagesCatalogo Comercial Power Plus Box 1000René Rocha MolinaNo ratings yet

- Seakoo CatalogoDocument52 pagesSeakoo CatalogoRené Rocha MolinaNo ratings yet

- Leaflet GVPF 750 - 1000M Mec-EnDocument2 pagesLeaflet GVPF 750 - 1000M Mec-EnRené Rocha MolinaNo ratings yet

- S LT LinoflameDocument26 pagesS LT LinoflameRené Rocha MolinaNo ratings yet

- Advant Controller 4050series eDocument124 pagesAdvant Controller 4050series eABVSAINo ratings yet

- WRO 2018 WeDo RegularDocument14 pagesWRO 2018 WeDo RegularAlaas AlvcaszaNo ratings yet

- Data Structures OutlineDocument5 pagesData Structures Outlineshahzad jalbaniNo ratings yet

- Theory: Figure 1: The Exit Age Distribution Curve E For Fluid Flowing Through A Vessel Also Called The Residence TimeDocument5 pagesTheory: Figure 1: The Exit Age Distribution Curve E For Fluid Flowing Through A Vessel Also Called The Residence Timeiko856No ratings yet

- Abu Dhabi Certification Scheme For Assistant EngineerDocument12 pagesAbu Dhabi Certification Scheme For Assistant EngineersureshNo ratings yet

- MARTA: 2012 KPMG Phase II Final DraftDocument114 pagesMARTA: 2012 KPMG Phase II Final DraftthomaswheatleyNo ratings yet

- LennoxDocument32 pagesLennoxCharly ColumbNo ratings yet

- Solucionario Libro Infotech 4th EditionDocument32 pagesSolucionario Libro Infotech 4th EditionGisella Espinoza BarberenaNo ratings yet

- Training Form PDFDocument2 pagesTraining Form PDFZurika WarniNo ratings yet

- NDT NablDocument3 pagesNDT NablPrabir KumarNo ratings yet

- Ductle Iron Spec1Document8 pagesDuctle Iron Spec1윤병택No ratings yet

- Overboard Dump ValveDocument3 pagesOverboard Dump ValveekabudiartiNo ratings yet

- Split Panasonic Cspc18dkqDocument16 pagesSplit Panasonic Cspc18dkqMaria de VillalobosNo ratings yet

- Glenair Connector Terms - SummaryDocument4 pagesGlenair Connector Terms - SummarybenNo ratings yet

- Ref: Bboneblk - SRM Beaglebone Black System Reference Manual Rev BDocument125 pagesRef: Bboneblk - SRM Beaglebone Black System Reference Manual Rev BhernangycNo ratings yet

- Commercial Vehicles BrochureDocument20 pagesCommercial Vehicles Brochurebinhtb14No ratings yet

- Original Instructions Alkuperäiset Ohjeet Αρχικýj Οδηγßεj: Rev. 4 5/31/11 BrwDocument32 pagesOriginal Instructions Alkuperäiset Ohjeet Αρχικýj Οδηγßεj: Rev. 4 5/31/11 BrwnikosvitalNo ratings yet

- KAIFENG Quotation For 150T Cooling TowerDocument13 pagesKAIFENG Quotation For 150T Cooling TowerEslam A. FahmyNo ratings yet

- Cardox-Blockage Removal SystemDocument5 pagesCardox-Blockage Removal SystemNaelNo ratings yet

- Instalación Sensor RPM TurboDocument13 pagesInstalación Sensor RPM TurboLuis Herrera MarinNo ratings yet

- Interr ModifDocument180 pagesInterr ModifJoaquin CampitiNo ratings yet

- PC Platform Compilers For PSS®E - Smart Grid Solutions - SiemensDocument2 pagesPC Platform Compilers For PSS®E - Smart Grid Solutions - SiemensSarah JenkinsNo ratings yet

- Plunger Pump Service Manual: Installation and Start-Up InformationDocument6 pagesPlunger Pump Service Manual: Installation and Start-Up InformationDark CenobiteNo ratings yet

- NFC Reader LibrarayDocument63 pagesNFC Reader Libraraysekhar479No ratings yet

- Lista Preturi Linhai 300 2014 PDFDocument25 pagesLista Preturi Linhai 300 2014 PDFSimonaVătafuNo ratings yet