Professional Documents

Culture Documents

Belzona 1821: Product Specification Sheet

Uploaded by

Alex BravoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Belzona 1821: Product Specification Sheet

Uploaded by

Alex BravoCopyright:

Available Formats

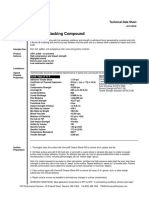

PRODUCT

World leaders in the conservation of man-made

SPECIFICATION

resources and the environment SHEET

®

BELZONA 1821

1. PRODUCT NAME Solidifier Component 5. PHYSICAL / MECHANICAL

Appearance Mobile liquid PROPERTIES

Belzona® 1821 Color Amber

(Fluid Metal) Determined after 7 days cure at

Density 1.06 - 1.0 g/cm3 77oF (25oC).

Fluid grade repair system for creating

positive grip surfaces and for casting Mixed Properties

components where machining is required. Mixing Ratio by Weight • Abrasion Resistance:

(Base : Solidifier) 5.3 : 1 Taber

Mixing Ratio by Volume The Taber abrasion resistance with 1 kg

2. MANUFACTURER (Base : Solidifier) 2:1 load is typically:

Belzona Inc., Mixed Form Viscous liquid CS17 Wheels (Dry) 40 mm3

2000 N.W. 88th Court Peak Exotherm loss per 1000 cycles

Miami, Florida 33172 Temperature 212 - 239oF

(100 -115oC)

Belzona Polymerics Ltd., Time to Peak Exotherm 22 - 28 mins • Adhesion:

Claro Road, Harrogate, Mixed Density 2.23 g/cm3 Tensile Shear

HG1 4AY, England. When tested in accordance with ASTM

D1002 using degreased strips, grit blasted

• Shelf Life: to a 3 - 4 mil profile typical values will be:

3. PRODUCT DESCRIPTION Separate base and solidifier components Aluminum 2,180 psi (153 kgs/cm2)

A two component machineable grade should have a shelf life of at least 5 years Brass 2,400 psi (169 kgs/cm2)

material based on silicone steel alloy when stored between 32oF (0oC) and Copper 2,600 psi (183 kgs/cm2)

blended within high molecular weight 86oF (30oC). Mild steel 3,600 psi (253 kgs/cm2)

reactive polymers and oligomers. The Stainless steel 3,600 psi (253 kgs/cm2)

system is designed for creating positive

grip surfaces on machinery and equipment • Working Life:

when used to bond Belzona® Supergrip or Will vary according to temperature. At 77oF Cleavage

Surefoot to the surface. The system (25oC) the usable life of mixed material is When tested to ASTM D1062 typical values

provides a durable non-slip surface with 15 minutes. will be:

excellent adhesion, wear and chemical Mild steel 2,100 psi (148 kgs/cm2)

resistance.

• Coverage Rate:

Applications This depends on the choice of aggregate

• Chemical Resistance:

Tank tops and nature of substrate as a practical guide Once fully cured, the material will demon-

Fire escapes an 800 gm unit will cover 6.6 sq.ft. (0.6 strate excellent resistance to most com-

Walkways sq.m.) at a thickness of 20 mil (500 monly found inorganic acids and alkalis at

Vehicle step-ups microns). concentrations up to 20%. The material is

Loading ramps also resistant to hydrocarbons, mineral oils,

Chequer plate access areas lubricating oils and many other commonly

• Volume Capacity: found chemicals.

Conveyor drive drums The volume capacity of an 800 gm unit of

Brake test rollers mixed Belzona® 1821 is 20.72 cu.ins. (340

Take off and feed rollers • Compressive Strength:

Fork lift grab arms cc).

When tested in accordance with ASTM

D695, typical values obtained will be

4. TECHNICAL DATA • Cure Time: 10,000 psi (703 kgs/cm2).

Allow the system to solidify for the times

Base Component shown in the chart below before subjecting • Corrosion Resistance:

Appearance Paste it to the conditions indicated.

Color Dark gray Will show no visible signs of corrosion after

Gel Strength 5,000 hours exposure in the ASTM B117

at 77oF (25oC) > 150 g/cm HF salt spray cabinet.

Density 2.70 - 2.90 g/cm3

CURE TIMES

o o

TEMPERATURE 41 F (5 C) 50 F (10oC)

o

59oF (15oC) 68oF (20oC) 77oF (25oC) 86oF (30oC)

Movement or use involving

no loading 16 hrs 6 hrs 3 hrs 2 hrs 1¼ hrs 1 hr

Machining and/or light loading 24 hrs 8 hrs 6 hrs 4 hrs 3 hrs 2½ hrs

Full mechanical or thermal

loading 3 days 2 days 1½ days 1 day 12 hrs 8 hrs

Contact with chemicals 8 days 6 days 4 days 3 days 2 days 1 day

• Flexural Strength: 6. SURFACE PREPARATION 9. TECHNICAL SERVICES

When tested to ASTM D790, typical values AND APPLICATION Complete technical assistance is available

obtained will be 6,400 psi PROCEDURES and includes fully trained Technical

(450 kgs/cm2). For proper technique, refer to the Consultants, technical service personnel

Belzona® Instructions For Use leaflet which and fully staffed research, development

• Hardness: is enclosed with each packaged product. and quality control laboratories.

The hardness of the material when tested

to ASTM D2240 is typically 80 Shore D. 7. AVAILABILITY AND COST 10. HEALTH AND SAFETY

Belzona® 1821 is available from a net- Prior to using this material, please consult

• Heat Distortion work of Belzona® Distributors throughout the relevant Material Safety Data Sheets.

Temperature: the world for prompt delivery to the

When tested to ASTM D648 (264 psi fiber application site. For information, consult

stress), typical values obtained will be 100oF the Belzona® Distributor in your area.

(38oC).

8. WARRANTY

• Heat Resistance: Belzona® guarantees this product will

For many typical applications, the product meet the performance claims stated herein

is thermally stable up to 300oF (150oC) dry, when material is stored and used as

and 140oF (60oC) wet, and down instructed in the Belzona® Instructions For

to -40oF (-40oC). Use leaflet. Belzona® further guarantees

that all its products are carefully manufac-

• Impact Strength: tured to ensure the highest quality possible

and tested strictly in accordance with

When tested to ASTM D256 is typically 1.9 universally recognised standards (ASTM,

ft.lb./in. (102 J/m). ANSI, BS, DIN, etc.). Since Belzona® has no

control over the use of the product de-

scribed herein, no warranty for any applica-

tion can be given.

Belzona Polymerics Ltd., Private and Confidential - For Internal Use Only

Claro Road, ISO 9001:2000

Harrogate, HG1 4AY,

England. Q 09335

Tel: +44 (0) 1423 567641

Fax:+44 (0) 1423 505967

E-Mail: belzona@belzona.co.uk

Belzona Inc.,

2000 N.W. 88 Court,

Miami, Florida 33172,

U.S.A.

Tel: +1 (305) 594 4994

Fax:+1 (305) 599 1140

E-Mail: belzona@belzona.com www.belzona.com

Copyright © 2003 by Belzona International Limited. All rights reserved. Certain portions of this work

copyright © 1996-2002 by Belzona International Limited. No part of this work covered by the copyrights

hereon may be reproduced or used in any form or by any means - graphic, electronic or mechanical

including photocopying, recording, taping or information storage and retrieval systems - without written

permission of the publisher.

Belzona® is a registered trademark Printed in England 12/03 UK Belzona® 1821 - Product Specification Sheet (2)

You might also like

- Belzona 1121: Product Specification SheetDocument2 pagesBelzona 1121: Product Specification SheetQuy RomNo ratings yet

- Product Specification Sheet Belzona 1111Document2 pagesProduct Specification Sheet Belzona 1111Quy RomNo ratings yet

- Belzona 1321: Product Specification SheetDocument2 pagesBelzona 1321: Product Specification Sheetmehdi kamaliNo ratings yet

- BELZONA 1111 Product Specification SheetDocument2 pagesBELZONA 1111 Product Specification SheetMohamed NouzerNo ratings yet

- 3M Scotchkote Epoxy Primer GP220 - Rev2Document2 pages3M Scotchkote Epoxy Primer GP220 - Rev2satya ranjanNo ratings yet

- Urethane Coating 165 PWDocument3 pagesUrethane Coating 165 PWANIBALLOPEZVEGANo ratings yet

- Fast Clad HB Acrylic: Protective & Marine CoatingsDocument4 pagesFast Clad HB Acrylic: Protective & Marine CoatingsAna CabreraNo ratings yet

- Acrolon 218 HS Acrylic PolyurethaneDocument4 pagesAcrolon 218 HS Acrylic PolyurethaneJohn ReevesNo ratings yet

- METALCLAD CeramAlloy CLAC PDFDocument2 pagesMETALCLAD CeramAlloy CLAC PDFskNo ratings yet

- 3M Scotchkote Epoxy Primer GP 120+Document2 pages3M Scotchkote Epoxy Primer GP 120+satya ranjanNo ratings yet

- F13 - Carboguard 893-Zn PDS 10-09Document2 pagesF13 - Carboguard 893-Zn PDS 10-09naveenbaskaran1989No ratings yet

- CemFIL AntiCrak HP 6736 Product Sheet WW 10-2014 Rev8 en FinalDocument2 pagesCemFIL AntiCrak HP 6736 Product Sheet WW 10-2014 Rev8 en FinalvliegenkristofNo ratings yet

- Reinforcekit Beam Fiche TechniqueDocument24 pagesReinforcekit Beam Fiche TechniqueAmel RADJEFNo ratings yet

- EPOXY FLOOR TOPPINGDocument4 pagesEPOXY FLOOR TOPPINGSean HarshaNo ratings yet

- Belzona 1121 InstrustionsDocument2 pagesBelzona 1121 Instrustionssh4kesNo ratings yet

- Ficha Técnica Hdpe (Sabic)Document2 pagesFicha Técnica Hdpe (Sabic)Luis LiraNo ratings yet

- Carboguard 893 PDSDocument2 pagesCarboguard 893 PDSNguyễn Thị Châu TâyNo ratings yet

- Protective & Marine Coatings: Polysiloxane 1KDocument4 pagesProtective & Marine Coatings: Polysiloxane 1KAna CabreraNo ratings yet

- Urethane Coating 165 PWDocument2 pagesUrethane Coating 165 PWANIBALLOPEZVEGANo ratings yet

- Phenoline 187 Primer and FinishDocument2 pagesPhenoline 187 Primer and Finish이선엽No ratings yet

- Carboguard 1209: Selection & Specification DataDocument4 pagesCarboguard 1209: Selection & Specification DataQuy Dom100% (2)

- Loctite PC 7218 TDSDocument2 pagesLoctite PC 7218 TDSDavid MendozaNo ratings yet

- METALCLAD CeramAlloy CPAC PDFDocument2 pagesMETALCLAD CeramAlloy CPAC PDFskNo ratings yet

- SABIC® LLDPE - 218WM - Global - Technical - Data - Sheet 2Document1 pageSABIC® LLDPE - 218WM - Global - Technical - Data - Sheet 2Kenneth ShiNo ratings yet

- SABIC® LLDPE - 218WM - Global - Technical - Data - SheetDocument1 pageSABIC® LLDPE - 218WM - Global - Technical - Data - SheetKenneth ShiNo ratings yet

- Epoxy Coating K Sir 88Document2 pagesEpoxy Coating K Sir 88ANIBALLOPEZVEGANo ratings yet

- Carboguard 893: Selection & Specification DataDocument5 pagesCarboguard 893: Selection & Specification DataQuy RomNo ratings yet

- Metalclad Ceramalloy Cp+Ac: Toll Free: 888-4-ENECON (888-436-3266)Document2 pagesMetalclad Ceramalloy Cp+Ac: Toll Free: 888-4-ENECON (888-436-3266)mrchardNo ratings yet

- Acrolon 218 FTDocument4 pagesAcrolon 218 FTEdwin VSNo ratings yet

- SABIC® HDPE - P6006 - Global - Technical - Data - SheetDocument2 pagesSABIC® HDPE - P6006 - Global - Technical - Data - Sheetjemish limbaniNo ratings yet

- Acrolon 218 HsDocument4 pagesAcrolon 218 HsKARENNo ratings yet

- Carbothane 134 HG PDSDocument2 pagesCarbothane 134 HG PDSKhemaraj Path100% (1)

- Protective & Marine Coatings: Acrolon™ 218 HsDocument4 pagesProtective & Marine Coatings: Acrolon™ 218 HsAna CabreraNo ratings yet

- High Build Epoxy Coating for PipelinesDocument3 pagesHigh Build Epoxy Coating for PipelinesAndrea Pamela León AlgarañazNo ratings yet

- Epoxy Sealer SP810Document2 pagesEpoxy Sealer SP810melvinkorahNo ratings yet

- Corrosol VE GP - TDS - Rev 4 - Feb 19Document2 pagesCorrosol VE GP - TDS - Rev 4 - Feb 19mkash028No ratings yet

- High Performance Backing Compound: Technical Data SheetDocument2 pagesHigh Performance Backing Compound: Technical Data SheetNiku SamarthNo ratings yet

- SABIC® FORTIFY™ - C3080 - Global - Technical - Data - Sheet PDFDocument2 pagesSABIC® FORTIFY™ - C3080 - Global - Technical - Data - Sheet PDFvishal mehtaNo ratings yet

- Ozdekan Seismic IsolatorDocument20 pagesOzdekan Seismic Isolatorali babaNo ratings yet

- Crusher Backing: Technical InformationDocument1 pageCrusher Backing: Technical InformationjohnNo ratings yet

- Protective & Marine Coatings: Pro-Cryl Universal PrimerDocument4 pagesProtective & Marine Coatings: Pro-Cryl Universal PrimerAna CabreraNo ratings yet

- TDS Loctite Nordbak Wearing - CompoundDocument3 pagesTDS Loctite Nordbak Wearing - CompoundSadamNo ratings yet

- PC 7337-EnDocument3 pagesPC 7337-EnJuan LondonoNo ratings yet

- PPG Amercoat 370 Data SheetDocument3 pagesPPG Amercoat 370 Data SheetAchraf Boudaya0% (1)

- Technical Data: Plastic Steel Putty (A)Document4 pagesTechnical Data: Plastic Steel Putty (A)francisNo ratings yet

- Plascoat Ppa 571: Performance Polymer Alloy CoatingDocument2 pagesPlascoat Ppa 571: Performance Polymer Alloy CoatingEidrish ShaikhNo ratings yet

- B-Uhb-M: Outstanding Barrier Metallized BOPP FilmDocument2 pagesB-Uhb-M: Outstanding Barrier Metallized BOPP FilmSayed FathyNo ratings yet

- PO Lapox EpogroutDocument4 pagesPO Lapox Epogroutjohn paulNo ratings yet

- Carboguard 893 PDSDocument5 pagesCarboguard 893 PDSTrịnh Minh KhoaNo ratings yet

- WBEpoxyCoating Data SheetDocument2 pagesWBEpoxyCoating Data SheetkaleshNo ratings yet

- 125 Ceramic Wearing Compound: AdvantagesDocument4 pages125 Ceramic Wearing Compound: AdvantagespramanisaNo ratings yet

- Carboguard 893 PDSDocument5 pagesCarboguard 893 PDSUtomoNo ratings yet

- SABIC® HDPE - P6006AD - Global - Technical - Data - SheetDocument1 pageSABIC® HDPE - P6006AD - Global - Technical - Data - SheetNaren RawatNo ratings yet

- Carbothane 134 HG Polyurethane Coating MSDSDocument13 pagesCarbothane 134 HG Polyurethane Coating MSDSjgzlzNo ratings yet

- Rebar Primer/Bond-Ci: Cementitious Corrosion Protection and Bonding AgentDocument2 pagesRebar Primer/Bond-Ci: Cementitious Corrosion Protection and Bonding AgentAbel BerhanemeskelNo ratings yet

- Lapox B-47 - AH-713: Technical Data Sheet - Polymers BusinessDocument4 pagesLapox B-47 - AH-713: Technical Data Sheet - Polymers Businesssriatul2006No ratings yet

- Wearing CompoundDocument2 pagesWearing CompoundJuan GuillermoNo ratings yet

- Sealbond 218-P: Structural Pressure Injection EpoxyDocument2 pagesSealbond 218-P: Structural Pressure Injection EpoxyMarvin BaquialNo ratings yet

- Product Specification Sheet BELZONA 5891: General InformationDocument4 pagesProduct Specification Sheet BELZONA 5891: General InformationMohamed NouzerNo ratings yet

- Plastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965From EverandPlastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965No ratings yet

- Diagnostic Manual EMS Scorpio VLX Sle LX PDFDocument219 pagesDiagnostic Manual EMS Scorpio VLX Sle LX PDFDaniel Canales86% (7)

- AEHQ5338 Caterpillar ® Brief SpecificationsDocument11 pagesAEHQ5338 Caterpillar ® Brief SpecificationsAlex BravoNo ratings yet

- MHAWK LHD Manual Electrico PDFDocument52 pagesMHAWK LHD Manual Electrico PDFAlex BravoNo ratings yet

- Bluetooth OBDII For Android PDFDocument5 pagesBluetooth OBDII For Android PDFsid_nelsonNo ratings yet

- D65 Vs D6TDocument4 pagesD65 Vs D6TAlex BravoNo ratings yet

- Tabla Awg A mm2Document1 pageTabla Awg A mm2Francisco HernandezNo ratings yet

- Usa DDEC IV PDFDocument16 pagesUsa DDEC IV PDFAlex BravoNo ratings yet

- Electrical Schematic Grove RT 9130E PDFDocument5 pagesElectrical Schematic Grove RT 9130E PDFAlex Bravo100% (1)

- PLD Manual MERCEDES INJECTORS FUEL SYSTEMDocument150 pagesPLD Manual MERCEDES INJECTORS FUEL SYSTEMheehawdafty95% (182)

- DS350GM Troubleshooting PDFDocument56 pagesDS350GM Troubleshooting PDFAlex BravoNo ratings yet

- D65EXPXWX-15 KA Sales BrochureDocument12 pagesD65EXPXWX-15 KA Sales BrochureAlex BravoNo ratings yet

- Braden Winch PD15B PDFDocument40 pagesBraden Winch PD15B PDFAlex BravoNo ratings yet

- PDM ColumbiaDocument20 pagesPDM ColumbiaAlex Bravo100% (5)

- ARK DS350 User ManualDocument58 pagesARK DS350 User ManualAlex BravoNo ratings yet

- Spicer d46 170 Parts List PDFDocument34 pagesSpicer d46 170 Parts List PDFAntony Moreno100% (1)

- S60-ch3 Ddeciv PDFDocument184 pagesS60-ch3 Ddeciv PDFAlex BravoNo ratings yet

- Codigos de ZF TransmisionDocument9 pagesCodigos de ZF TransmisionAlex BravoNo ratings yet

- MM 5eDocument137 pagesMM 5eAlex Bravo100% (1)

- Spicer d46 170 Parts List PDFDocument34 pagesSpicer d46 170 Parts List PDFAntony Moreno100% (1)

- Horton Peterbilt Application GuideDocument2 pagesHorton Peterbilt Application GuideAlex BravoNo ratings yet

- Parts Order Form Effective: 1/1/2016: Includes S&HDocument1 pageParts Order Form Effective: 1/1/2016: Includes S&HAlex BravoNo ratings yet

- Approved Fluid ListDocument1 pageApproved Fluid ListAlex BravoNo ratings yet

- Tapa Caja BasicaDocument2 pagesTapa Caja BasicaAlex BravoNo ratings yet

- Valvulas y ManguerasDocument3 pagesValvulas y ManguerasAlex BravoNo ratings yet

- 040201Document10 pages040201Alex BravoNo ratings yet

- Reten Eje de EntradaDocument2 pagesReten Eje de EntradaAlex BravoNo ratings yet

- Grupo RangeDocument4 pagesGrupo RangeAlex BravoNo ratings yet

- Reten Eje de Entrada PDFDocument2 pagesReten Eje de Entrada PDFAlex BravoNo ratings yet

- Transmission Case 3Document3 pagesTransmission Case 3Alex BravoNo ratings yet

- 0620 s04 QP 1Document20 pages0620 s04 QP 1G M Ali KawsarNo ratings yet

- 1.1 Enzymology (Bravo)Document11 pages1.1 Enzymology (Bravo)Arman Carl DulayNo ratings yet

- IndicatorsDocument11 pagesIndicatorsPremendra YadawNo ratings yet

- The Application of UV Technology To Pharmaceutical Water TreatmentDocument2 pagesThe Application of UV Technology To Pharmaceutical Water Treatmentdepardieu1973No ratings yet

- Science JeopardyDocument26 pagesScience Jeopardyapi-259274653No ratings yet

- Experiment L3 - Isolating hydroxyphenylacetophenonesDocument7 pagesExperiment L3 - Isolating hydroxyphenylacetophenonesstevefox086100% (2)

- Yearly Lesson Plan Chemistry Form 4Document30 pagesYearly Lesson Plan Chemistry Form 4fakiah binti abdul khalid100% (2)

- Setia Budi, Yusmaniar, Febri Rahmadi, Maryanti, Sukro MuhabDocument6 pagesSetia Budi, Yusmaniar, Febri Rahmadi, Maryanti, Sukro MuhabAmir MahmudNo ratings yet

- S Bio Disinfectants PDFDocument9 pagesS Bio Disinfectants PDFWahyu Radityo UtomoNo ratings yet

- Kollidon-90-F Technical Information PDFDocument9 pagesKollidon-90-F Technical Information PDFPalak AgarwalNo ratings yet

- Fertilizer ProjectDocument24 pagesFertilizer ProjectKamal Thakur75% (4)

- Iron Staining Materials in Lightweight Concrete Aggregates: Standard Test Method ForDocument4 pagesIron Staining Materials in Lightweight Concrete Aggregates: Standard Test Method ForJesús Luis Arce GuillermoNo ratings yet

- Metals-11-00474-V2 OKDocument22 pagesMetals-11-00474-V2 OKRebeca Francis Moran CamposNo ratings yet

- Proílenglicol ChinoDocument1 pageProílenglicol Chinojuan aguileraNo ratings yet

- Azu TD Box176 E9791 1976 363Document143 pagesAzu TD Box176 E9791 1976 363mudassir_hasan_1No ratings yet

- Review of Techniques The Sodium-Fusion: in LassaigneDocument2 pagesReview of Techniques The Sodium-Fusion: in LassaigneKthryn93No ratings yet

- Selection Chart For Welding and Brazing Rods - Weldclass - 2021.08Document2 pagesSelection Chart For Welding and Brazing Rods - Weldclass - 2021.08velan73No ratings yet

- Quantitative and QualitativeDocument15 pagesQuantitative and QualitativesquadralsupremeNo ratings yet

- Review of Low Salinity Water Flooding for Oil RecoveryDocument41 pagesReview of Low Salinity Water Flooding for Oil RecoveryPondok Huda100% (2)

- A Review On Manufacturing and Application of Open-Cell Metal FoamDocument5 pagesA Review On Manufacturing and Application of Open-Cell Metal FoamLAKSHMIKANTH.B MEC-AP/MCNo ratings yet

- LSM3243 Assignment 2Document1 pageLSM3243 Assignment 2Ivan John ClementNo ratings yet

- Chemistry Investigatory Project Final 1Document21 pagesChemistry Investigatory Project Final 1lakshya rautelaNo ratings yet

- Znaidi 10 ZnO ReviewDocument14 pagesZnaidi 10 ZnO ReviewTozammel Hossain TusharNo ratings yet

- Acid-Base Behaviour of The Period 3 OxidesDocument13 pagesAcid-Base Behaviour of The Period 3 OxidesAdam KhairulNo ratings yet

- Unit 1 Weekly TestDocument4 pagesUnit 1 Weekly TestManalNo ratings yet

- Flocculants - Polymers For Coagulation of Solids and Sludge - TRAMFLOC, InCDocument7 pagesFlocculants - Polymers For Coagulation of Solids and Sludge - TRAMFLOC, InCRaghavendra Pratap SinghNo ratings yet

- Decomposition Reactions WorksheetDocument2 pagesDecomposition Reactions WorksheetNarci ssusNo ratings yet

- Organic and Biological Chemistry TopicsDocument24 pagesOrganic and Biological Chemistry TopicsGothic_VampiressNo ratings yet

- 15 Organic SynthesisDocument30 pages15 Organic SynthesisJulia MaramatNo ratings yet

- 2015 - Kem Pecutan Kimia SBP - T5Document24 pages2015 - Kem Pecutan Kimia SBP - T5Mohd HaidilNo ratings yet