Professional Documents

Culture Documents

175 014400

Uploaded by

Abu Anas M.Salaheldin0 ratings0% found this document useful (0 votes)

14 views1 pageSeamless tube and ferrule stock of copper and various copper alloys up to 31/8” inch inclusive, in diameter for use in surface condensers, evaporators, and heat exchangers.

Original Title

175-014400

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentSeamless tube and ferrule stock of copper and various copper alloys up to 31/8” inch inclusive, in diameter for use in surface condensers, evaporators, and heat exchangers.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

14 views1 page175 014400

Uploaded by

Abu Anas M.SalaheldinSeamless tube and ferrule stock of copper and various copper alloys up to 31/8” inch inclusive, in diameter for use in surface condensers, evaporators, and heat exchangers.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

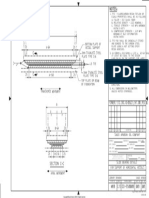

INSPECTION & TESTING REQUIREMENTS REVISION: 06/99 CODE NUMBER: PAGE

REPLACES: 08/93 014400

SAUDI ARAMCO FORM-175

SCOPE: CONDENSER TUBES: Seamless tube and ferrule stock PURCHASE ORDER NUMBER:

of copper and various copper alloys up to 31/8” inch

inclusive, in diameter for use in surface condensers,

evaporators, and heat exchangers.

TEST and INSPECTION PER: ASTM B-111, and Specifications As Noted ITEM NUMBER(s):

Below.

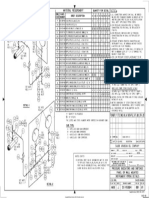

(1) VISUAL INSPECTION / WITNESSING BY BUYER REPRESENTATIVE (Note 1)

(2) CERTIFICATES / RECORDS TO BE CHECKED BY BUYER REPRESENTATIVE

LINE

NO (3) CERTIFICATES / DATA TO BE PROVIDED BY VENDOR / SUPPLIER / MANUFACTURER

Pre-Fabrication / Pre-Production Requirements Specification Details / Notes:

01 X Material Test Reports

When specified in P.O, tubes of Copper Alloy UNS Nos. C23000, C28000,

Tubes Selected for a Stress Corrosion Cracking

02 X C44300, C44400, C44500, C60800, C61300, C61400 and C68700 shall be

Environment

subjected to a stress-relieving thermal treatment subsequent to straightening.

03

In-Process Inspection & Testing Requirements

04

05 Mechanical Properties and Tests:

The flattened elements shall not show cracking or rupture to the unaided eye. See

06 X a) Flattening Tests

ASTM B-111 for exceptions.

Samples of annealed-temper tubes shall be subjected to Microscopic

07 X b) Microscopic Examination

Examination at a magnification of 75 diameters.

The expanded tube shall show no cracking or ruptures visible to the unaided eye.

08 X c) Expansion Tests

See ASTM B-111 for exceptions.

The test specimens shall withstand without cracking, an immersion in a mercurous

nitrate solution per Test Method B-154. This test is restricted to Copper Alloy UNS

09 X d) Mercurous Nitrate Test

Nos. C23000, C28000, C44300, C44400, C44500, C60800, C61300, C61400 and

C68700.

10 X e) Tensile Tests

11

12 X Hydrostatic Test The pressure shall not exceed 1,000 psi unless otherwise stated in the P.O.

Each tube shall be subjected to an internal air pressure of 60 psig minimum, for 5

13 X Pneumatic Test

seconds without showing evidence of leakage.

Tubes may be tested in the final drawn, annealed, or heat-treated temper or in the

14 X Eddy Current Test in Lieu of Hydrotest drawn temper prior to final anneal or heat treatment unless otherwise stated in

P.O.

15

16

17

Final Inspection & Testing Requirements

18

With emphasis on outside diameter, wall thickness, Length, and squareness of cut

19 X Dimensional Requirements

ends.

20

In addition to line items above, the cut ends shall be deburred. Annealed or

stress-relieved tubes shall be clean and smooth but may have a superficial, dull

21 X Final Visual Inspection

iridescent film on both the inside and outside surface. Drawn-temper may also

have a superficial film of drawing lubricant present.

22 X Identification Marking of the Product

The material shall be separated by size, composition, and temper, and prepared

23 X Packaging and Package Marking

for shipment.

24

25

26

Notes:

(1) May only be waived by the responsible Saudi Aramco, ASC, AOC Inspection Offices.

(2) See form SA175 – 000003 for instructions on using this form.

You might also like

- Special-2 Stainless Steel EnclosureDocument1 pageSpecial-2 Stainless Steel EnclosureAbu Anas M.SalaheldinNo ratings yet

- Plasite 7159 PDSDocument4 pagesPlasite 7159 PDSAbu Anas M.SalaheldinNo ratings yet

- HEAVY WALLED PV MANUFACTURINGDocument28 pagesHEAVY WALLED PV MANUFACTURINGAbu Anas M.SalaheldinNo ratings yet

- Buttweldshrinkagepaper BasavarajuDocument9 pagesButtweldshrinkagepaper BasavarajuAbu Anas M.SalaheldinNo ratings yet

- BGAS QustionDocument47 pagesBGAS QustionAbu Anas M.SalaheldinNo ratings yet

- DD 950008 001Document1 pageDD 950008 001Abu Anas M.SalaheldinNo ratings yet

- Hydraulics - Offshore SuppliesDocument1,214 pagesHydraulics - Offshore SuppliesAbu Anas M.SalaheldinNo ratings yet

- Iso 10423-2022Document12 pagesIso 10423-2022Abu Anas M.SalaheldinNo ratings yet

- Comparative Tracking Index of Electrical Insulating MaterialsDocument6 pagesComparative Tracking Index of Electrical Insulating MaterialsAbu Anas M.SalaheldinNo ratings yet

- Stauffenberg RBW5RUL PDFDocument172 pagesStauffenberg RBW5RUL PDFErikas AbepaNo ratings yet

- 2014 Yang MaterialEffectonShrinkage WJ 2014 11 s421Document11 pages2014 Yang MaterialEffectonShrinkage WJ 2014 11 s421Abu Anas M.SalaheldinNo ratings yet

- Esab Xpert 7018 Low Hydrogen ElectrodeDocument1 pageEsab Xpert 7018 Low Hydrogen ElectrodeAbu Anas M.SalaheldinNo ratings yet

- DD-950005, Rev 00, SHT 001, 05.31.1985 PDFDocument1 pageDD-950005, Rev 00, SHT 001, 05.31.1985 PDFRami ELLOUMINo ratings yet

- Metals 11 00568 v2Document18 pagesMetals 11 00568 v2Abu Anas M.SalaheldinNo ratings yet

- DD 950008 001Document1 pageDD 950008 001Abu Anas M.SalaheldinNo ratings yet

- DC 950041 001Document1 pageDC 950041 001Abu Anas M.SalaheldinNo ratings yet

- DC 950042 001Document1 pageDC 950042 001Abu Anas M.SalaheldinNo ratings yet

- DC 950042 001Document1 pageDC 950042 001Abu Anas M.SalaheldinNo ratings yet

- DD-950005, Rev 00, SHT 001, 05.31.1985 PDFDocument1 pageDD-950005, Rev 00, SHT 001, 05.31.1985 PDFRami ELLOUMINo ratings yet

- DC 950045 001Document1 pageDC 950045 001Abu Anas M.SalaheldinNo ratings yet

- Notes:: List of Material Detail Qty. ForDocument1 pageNotes:: List of Material Detail Qty. ForAbu Anas M.SalaheldinNo ratings yet

- DC 950041 001Document1 pageDC 950041 001Abu Anas M.SalaheldinNo ratings yet

- AC-036413-001 Orifice Flange AssemblyDocument1 pageAC-036413-001 Orifice Flange Assemblynarutothunderjet216No ratings yet

- DD 950008 001Document1 pageDD 950008 001Abu Anas M.SalaheldinNo ratings yet

- Aa 036025 002Document1 pageAa 036025 002Abu Anas M.SalaheldinNo ratings yet

- Notes:: Typical Installation DrawingDocument1 pageNotes:: Typical Installation DrawingAbu Anas M.SalaheldinNo ratings yet

- Notes:: List of Material Detail Qty. ForDocument1 pageNotes:: List of Material Detail Qty. ForAbu Anas M.SalaheldinNo ratings yet

- Aa 036025 001Document1 pageAa 036025 001Abu Anas M.SalaheldinNo ratings yet

- Aa 036007 002Document1 pageAa 036007 002Abu Anas M.SalaheldinNo ratings yet

- Aa 036015 001Document1 pageAa 036015 001narutothunderjet216No ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Vortex Quantum SeriesDocument34 pagesVortex Quantum SeriesmiguelcNo ratings yet

- Biochem Proteins ReviewerDocument4 pagesBiochem Proteins ReviewerStefany JoyNo ratings yet

- Marine PurifierDocument30 pagesMarine PurifierJayDelosSantos100% (1)

- محاضرات تغذية عامة د جواد الوبر 1Document53 pagesمحاضرات تغذية عامة د جواد الوبر 1معتصم اليمانيNo ratings yet

- N52 Grade Neodymium Magnets DataDocument1 pageN52 Grade Neodymium Magnets DataSteve HsuNo ratings yet

- The Four Types of Refrigeration Systems You Need To KnowDocument2 pagesThe Four Types of Refrigeration Systems You Need To KnowtakayNo ratings yet

- Powder Metallurgy Process and ApplicationsDocument32 pagesPowder Metallurgy Process and ApplicationsChandan KumarNo ratings yet

- Factors Affecting Rate of EvaporationDocument22 pagesFactors Affecting Rate of EvaporationShimnu MoneNo ratings yet

- VAPOR AND COMBINED POWER CYCLESDocument9 pagesVAPOR AND COMBINED POWER CYCLESzabidullahNo ratings yet

- 85 TPH CFBC Boiler Operation and Maintenance ManualDocument152 pages85 TPH CFBC Boiler Operation and Maintenance ManualAamirMalik100% (1)

- Organic Reactions 28 (1982) eDocument266 pagesOrganic Reactions 28 (1982) eRobNo ratings yet

- Expansion Process of A Perfect Gas PDFDocument11 pagesExpansion Process of A Perfect Gas PDFRaza MutahirNo ratings yet

- Steel Industry PackageDocument9 pagesSteel Industry Packagebatung144100% (1)

- A Simplified Method For The Cultivation of Extreme Anaerobic Archaea Based SULFIDE 2000 !!!!Document6 pagesA Simplified Method For The Cultivation of Extreme Anaerobic Archaea Based SULFIDE 2000 !!!!Vera Brok-VolchanskayaNo ratings yet

- Fiitjee Rit 2Document11 pagesFiitjee Rit 2Baljeet SinghNo ratings yet

- Characteristics - Requirements of Fibre Forming Polymers - Online Textile AcademyDocument1 pageCharacteristics - Requirements of Fibre Forming Polymers - Online Textile AcademyRAFIAHAMMEDNo ratings yet

- Us03cicv21 Unit3Document28 pagesUs03cicv21 Unit3ashokNo ratings yet

- Research Cold StorageDocument6 pagesResearch Cold StorageApivit MalichaiNo ratings yet

- Powder Metallurgy: Crushing and Milling Method To Form PowderDocument12 pagesPowder Metallurgy: Crushing and Milling Method To Form Powder050678No ratings yet

- Nano EmulsionDocument52 pagesNano EmulsionAbdul NadeemNo ratings yet

- Sloss Industries 1062235 M2234300 EX351 V 2Document1 pageSloss Industries 1062235 M2234300 EX351 V 2DanielDeFrancescoNo ratings yet

- Sample Paper For ChemistryDocument23 pagesSample Paper For ChemistryAmit joshiNo ratings yet

- Wall Colmonoy Surfacing Alloys Selector ChartDocument3 pagesWall Colmonoy Surfacing Alloys Selector ChartAjimKe'enNo ratings yet

- Optical Emission From SemiconductorsDocument36 pagesOptical Emission From SemiconductorsvardhanNo ratings yet

- Astm B479 19Document3 pagesAstm B479 19mohamedsamireldeep70No ratings yet

- 06 Chapter 1Document16 pages06 Chapter 1Maharaja PlacementNo ratings yet

- ACRYREX® CM-211: Chi Mei CorporationDocument3 pagesACRYREX® CM-211: Chi Mei CorporationPhuoc Thinh TruongNo ratings yet

- Nanotechnology Applications and Its Importance in Various FieldsDocument24 pagesNanotechnology Applications and Its Importance in Various FieldsSuresh ShahNo ratings yet

- Bioplastic ProjectDocument15 pagesBioplastic ProjectSarthak Verma100% (1)

- Rongalit ST LiqDocument11 pagesRongalit ST LiqMayank DhawanNo ratings yet