Professional Documents

Culture Documents

LS PEKK CF HT23 Material Datasheet 201705

Uploaded by

Angel LagrañaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

LS PEKK CF HT23 Material Datasheet 201705

Uploaded by

Angel LagrañaCopyright:

Available Formats

PEKK CF HT23

L A S E R S I N T E R I N G M AT E R I A L S P E C I F I C AT I O N S

Highlights Applications

• Superb strength-to-weight ratio • High performance and high temperature applications including

• Low outgassing aerospace, defense, motorsports, petrochemical and downhole

• Operating temperature -300° F to 400° F under load • Satellite parts where strength to weight and operation in

• Carbon fiber compounded into PEKK base material for extremes of heat and cold characteristics are required

isotropic X/Y properties • Cooling ducts

• Superior chemical resistance • Hot/cold air mixing manifolds to maintain temperature to optics

• Fire retardant, low smoke and toxicity and sensitive electronic components

TYPICAL PHYSICAL PROPERTIES

TEST ENGLISH METRIC

MECHANICAL PROPERTIES

METHOD XY A XIS ZX AXIS XY A XIS ZX AXIS

Color/Appearance Visual Grey Grey

Specific Gravity ATSM D792 0.051 lb/in 3 1.4 g/cc

Elongation at Break ASTM D638 1.16% 1.06% 1.16% 1.06%

Flexural Strength ASTM D790 14,300 psi 11,500 psi 102 MPa 81.3 MPa

Flexural Modulus ASTM D790 840 ksi 711 ksi 6030 MPa 5120 MPa

Heat Deflection Temp @ 66 psi ASTM D648 527°F 525°F 275°C 274°C

Heat Deflection Temp @ 264 psi ASTM D648 413°F 395°F 212°C 202°C

Tensile Modulus ASTM D638 966 ksi 875 ksi 6610 MPa 5850 MPa

Tensile Strength ASTM D638 10,250 psi 8,600 psi 72.5 MPa 59.6 MPa

Izod Impact Strength (Notched) ASTM D256 0.286 ft-lb/in 0.284 ft-lb/in 15.27 J/m 15.17 J/m

Coefficient of Thermal Expansion: -94 to 347°F (-70 to 175°C) ASTM E831 17 ppm/°F 19 ppm/°F 30 ppm/°C 34 ppm/°C

Coefficient of Thermal Expansion: 347 to 437°F (175 to 225°C) ASTM E831 43 ppm/°F 63 ppm/°F 77 ppm/°C 113 ppm/°C

Surface Resistivity (Ω/square) ASTM D257-14 (X = 1.46E+14) (Z = 1.68E+15)

(X = 5.04 E13 ohm-in) (Z = 8.19 E14 (X = 1.28E+14 ohm-cm) (Z = 2.08E+15

Volume Resistivity ASTM D257-14

ohm-in) ohm-cm)

The information presented represents typical values intended for reference and comparison purposes only. It should not be used for design specifications or quality control

purposes. End-use material performance can be impacted (+/-) by, but not limited to, part design, end-use conditions, test conditions, color etc. Actual values will vary with

build conditions. Product specifications are subject to change without notice.

The performance characteristics of these materials may vary according to application, operating conditions, or end use. Each user is responsible for determining that the

material is safe, lawful, and technically suitable for the intended application. Stratasys makes no warranties of any kind, express or implied, including, but not limited to, the

warranties of merchantability, fitness for a particular use, or warranty against patent infringement.

XZ = X or “on edge”

XY = Y or “flat”

ZX = or “upright”

INFO@STRATASYSDIRECT.COM / STRATASYSDIRECT.COM

©2017 Stratasys Direct, Inc. All rights reserved. Stratasys, Stratasys Direct Manufactruing, Stratasys signet and Stratasys Direct Manufacturing

Logo are trademarks or registered trademarks of Stratasys Ltd. and/or its subsidiaries or affiliates and may be registered in certain jurisdictions.

All other trademarks belong to their respective owners. Product specifications subject to change without notice. Last update 05/2017

You might also like

- Valtek Mark One Channelstream Three Stage & Fisher Cavitrol V Control Valve CageDocument3 pagesValtek Mark One Channelstream Three Stage & Fisher Cavitrol V Control Valve CageGirishkumar B PrajapatiNo ratings yet

- TRIZ Class1 Aug 26Document89 pagesTRIZ Class1 Aug 26ChrisNo ratings yet

- Proceedings of the Metallurgical Society of the Canadian Institute of Mining and Metallurgy: Proceedings of the International Symposium on Fracture Mechanics, Winnipeg, Canada, August 23-26, 1987From EverandProceedings of the Metallurgical Society of the Canadian Institute of Mining and Metallurgy: Proceedings of the International Symposium on Fracture Mechanics, Winnipeg, Canada, August 23-26, 1987W. R. TysonNo ratings yet

- KSB Cellular Surface Wear Rings en Downobject, Property FileDocument2 pagesKSB Cellular Surface Wear Rings en Downobject, Property FileJasmina TepšaNo ratings yet

- Basic Additive ManufacturingDocument35 pagesBasic Additive ManufacturingVeronica Cenci SebaldNo ratings yet

- Metamxaoex PDFDocument164 pagesMetamxaoex PDFKevin TanNo ratings yet

- Corrosive Behavior of 3D-Printed 316L Stainless SteelDocument14 pagesCorrosive Behavior of 3D-Printed 316L Stainless SteelshameekaNo ratings yet

- A182 PDFDocument16 pagesA182 PDFExport priminoxNo ratings yet

- TRIZ 40 Principles1Document42 pagesTRIZ 40 Principles1mancheung6429No ratings yet

- 04 Ansys DX PDFDocument21 pages04 Ansys DX PDFFilip StojkovskiNo ratings yet

- Value Engineering (4-5)Document19 pagesValue Engineering (4-5)Amr RaghebNo ratings yet

- Severe service, bubble-tight Ball Valves for high performance applicationsDocument12 pagesSevere service, bubble-tight Ball Valves for high performance applicationskuraimundNo ratings yet

- Allencomm Microlearning Powerful Training Tool For OnboardingDocument14 pagesAllencomm Microlearning Powerful Training Tool For OnboardingJStone100% (1)

- PADT Webinar Series: An Example of Moving Mesh Modeling of A ValveDocument20 pagesPADT Webinar Series: An Example of Moving Mesh Modeling of A ValvevahidssNo ratings yet

- SIHI Applications and Products E 092011Document9 pagesSIHI Applications and Products E 092011Menze de JongeNo ratings yet

- NWC15 JMS PresentationDocument16 pagesNWC15 JMS PresentationJonNo ratings yet

- RESUMEDocument2 pagesRESUMEJesse CookNo ratings yet

- CAD Designer or CAD TechnicianDocument1 pageCAD Designer or CAD Technicianapi-79041757No ratings yet

- Roache 1997Document38 pagesRoache 1997hawxflyNo ratings yet

- 12 - PCB Testing Methods Guide - PCB Testing Methods TypesDocument7 pages12 - PCB Testing Methods Guide - PCB Testing Methods TypesShreyas AdkiNo ratings yet

- Trim Number Chart API ValveDocument2 pagesTrim Number Chart API ValveVelu .cNo ratings yet

- Setting Up Rfid For Microsoft Dynamics Ax 2009Document16 pagesSetting Up Rfid For Microsoft Dynamics Ax 2009Ranjani C Narayan100% (1)

- Automated Design Exploration and OptimizationDocument77 pagesAutomated Design Exploration and OptimizationrrathoreNo ratings yet

- The Six Step Guide To: PracticalDocument27 pagesThe Six Step Guide To: PracticalKaly Cristobal AlcantaraNo ratings yet

- DFMA OverviewDocument75 pagesDFMA Overviewanwar anwaryNo ratings yet

- Rotordynamics Analysis Using Abaqus/StandardDocument5 pagesRotordynamics Analysis Using Abaqus/Standardsüleyman tazebayNo ratings yet

- ANSYS DesignXplorerDocument4 pagesANSYS DesignXplorerVasundhara Kumari PeddintiNo ratings yet

- A Plasma Doping Process For 3D FinFET Source - Drain ExtensionsDocument16 pagesA Plasma Doping Process For 3D FinFET Source - Drain ExtensionssamactrangNo ratings yet

- What Is The Stress Strain CurveDocument5 pagesWhat Is The Stress Strain CurveEASHWAR PRODUCTIVENo ratings yet

- Electronics Cooling Summer 2018 DigitalDocument36 pagesElectronics Cooling Summer 2018 DigitalRakesh SandarativjuNo ratings yet

- Anti Surge App BrochureDocument4 pagesAnti Surge App Brochuresamy7354No ratings yet

- PADT Webinar Post26 2012 - 04 - 12Document54 pagesPADT Webinar Post26 2012 - 04 - 12Jack FusionNo ratings yet

- Durability Analysis 101Document4 pagesDurability Analysis 101fkaram1965No ratings yet

- BitsDocument15 pagesBitsBiswadip BanerjeeNo ratings yet

- The Calculation of OEEDocument7 pagesThe Calculation of OEE0302038No ratings yet

- ANSYS 18.2 Mechanical Products UpdateDocument112 pagesANSYS 18.2 Mechanical Products UpdateAnonymous hprsT3WlP100% (1)

- Application of It Grade Range of ToleranceDocument1 pageApplication of It Grade Range of ToleranceBISWAJIT MENo ratings yet

- Ansys Capabilities Chart 2021 r1Document57 pagesAnsys Capabilities Chart 2021 r1presto prestoNo ratings yet

- 10.1.1.144.9002 SW FatigueDocument13 pages10.1.1.144.9002 SW Fatigueb_wooNo ratings yet

- Common Errors and Warnings in FEA Convergence ProblemsDocument5 pagesCommon Errors and Warnings in FEA Convergence Problemsmithun5v5v5No ratings yet

- Ansys Fluent Migration ManualDocument59 pagesAnsys Fluent Migration ManualOlukayode Niyi Ezekiel100% (1)

- SIHI Liquid Ring Compressors enDocument5 pagesSIHI Liquid Ring Compressors enAlexander RivillasNo ratings yet

- MABE 012412 WebDocument4 pagesMABE 012412 WebAltairKoreaNo ratings yet

- ACT Customization Guide For MechanicalDocument62 pagesACT Customization Guide For Mechanicaljoesph killerNo ratings yet

- Design Exploration - Judd KaiserDocument30 pagesDesign Exploration - Judd KaiserSangbum KimNo ratings yet

- Dyneon PTFE All Grades PDFDocument11 pagesDyneon PTFE All Grades PDFRajanSharmaNo ratings yet

- PDFDocument7 pagesPDFDaniel Pinillos0% (1)

- Learn GD&T with Computer-Based TrainingDocument1 pageLearn GD&T with Computer-Based TrainingYogesh2323No ratings yet

- Finite Element Analysis of Large Diameter Concrete Spherical Shell Domes - Hani Aziz AmeenDocument16 pagesFinite Element Analysis of Large Diameter Concrete Spherical Shell Domes - Hani Aziz AmeenHani Aziz AmeenNo ratings yet

- Carpenterguidetomachining PDFDocument170 pagesCarpenterguidetomachining PDFNitin AggarwalNo ratings yet

- Fasteners For Sandwich Struture CatalogDocument69 pagesFasteners For Sandwich Struture CatalogTDNo ratings yet

- Customer Oriented Process (COP) TrainingDocument62 pagesCustomer Oriented Process (COP) TraininglimkeanjinNo ratings yet

- Test FixtureDocument6 pagesTest FixtureSiti Maryam KazimNo ratings yet

- Solidworks WhitePaper Industry Sim Analysis Machines PDFDocument9 pagesSolidworks WhitePaper Industry Sim Analysis Machines PDFMuhammad Salim Abdul AzisNo ratings yet

- Introduction To Abaqus Scripting (ABAQUS)Document19 pagesIntroduction To Abaqus Scripting (ABAQUS)Mario AmellNo ratings yet

- U of A ANSYS Tutorials - Coupled Structural - Thermal AnalysisDocument7 pagesU of A ANSYS Tutorials - Coupled Structural - Thermal AnalysisSantosh KumarNo ratings yet

- Marketplace Summit 22-05-23Document1 pageMarketplace Summit 22-05-23Angel LagrañaNo ratings yet

- Ebook Calculating Roi For Process AutomationDocument18 pagesEbook Calculating Roi For Process AutomationAngel LagrañaNo ratings yet

- Artificial Intelligence Master Program SlimupDocument25 pagesArtificial Intelligence Master Program SlimupAngel LagrañaNo ratings yet

- TPL - Application Form (Part B) (LIFE)Document20 pagesTPL - Application Form (Part B) (LIFE)Angel LagrañaNo ratings yet

- Gabi Ts Leading Sustainability & Lca SoftwareDocument2 pagesGabi Ts Leading Sustainability & Lca SoftwareAngel LagrañaNo ratings yet

- General-Mga Horizon-Euratom enDocument126 pagesGeneral-Mga Horizon-Euratom enAngel LagrañaNo ratings yet

- Integrated Mci Calculation Gabi Circularity ToolkitDocument1 pageIntegrated Mci Calculation Gabi Circularity ToolkitAngel LagrañaNo ratings yet

- 5 Reasons Why Enterprises Are Moving To GoogleDocument4 pages5 Reasons Why Enterprises Are Moving To GoogleAngel LagrañaNo ratings yet

- Gabi Life Cycle Engineering SuiteDocument4 pagesGabi Life Cycle Engineering SuiteAngel LagrañaNo ratings yet

- TPL - Description of Species and Habitats (LIFE)Document2 pagesTPL - Description of Species and Habitats (LIFE)Angel LagrañaNo ratings yet

- TPL - Cofinancing Declaration (LIFE)Document1 pageTPL - Cofinancing Declaration (LIFE)Angel LagrañaNo ratings yet

- h2020 Mga Gga Multi - enDocument167 pagesh2020 Mga Gga Multi - enAngel LagrañaNo ratings yet

- TPL - Participant Info (LIFE)Document1 pageTPL - Participant Info (LIFE)Angel LagrañaNo ratings yet

- Fiber Sizing 101 + Emerging TechnologiesDocument31 pagesFiber Sizing 101 + Emerging TechnologiesAngel LagrañaNo ratings yet

- MHI Ebook - HYDROGEN-POWERING A NET ZERO FUTUREDocument20 pagesMHI Ebook - HYDROGEN-POWERING A NET ZERO FUTURElpczyfans100% (2)

- Energy Intensity and Environmental Analysis of MecDocument6 pagesEnergy Intensity and Environmental Analysis of MecAngel LagrañaNo ratings yet

- Controls and Audits in Horizon 2020Document10 pagesControls and Audits in Horizon 2020Angel LagrañaNo ratings yet

- Optimization of Aircraft Boarding Processes Considering Passengers' Grouping CharacteristicsDocument13 pagesOptimization of Aircraft Boarding Processes Considering Passengers' Grouping CharacteristicsAngel LagrañaNo ratings yet

- Estimation of Quench Air Quantity For A Given Throughput in PET Melt SpinningDocument10 pagesEstimation of Quench Air Quantity For A Given Throughput in PET Melt SpinningAngel LagrañaNo ratings yet

- Participant Register User's GuideDocument67 pagesParticipant Register User's GuideAngel LagrañaNo ratings yet

- SilicatewasteDocument13 pagesSilicatewasteAngel LagrañaNo ratings yet

- Palace Downtown Asado Vat 2018 Tcm113-117846Document5 pagesPalace Downtown Asado Vat 2018 Tcm113-117846Angel LagrañaNo ratings yet

- Strength Characterization of E-Glass Fiber ReinforDocument5 pagesStrength Characterization of E-Glass Fiber ReinforMian Qamar MurtazaNo ratings yet

- Exhibition Catalogue: 3rd International Conference & Exhibition On Thermoplastic CompositesDocument47 pagesExhibition Catalogue: 3rd International Conference & Exhibition On Thermoplastic CompositesAngel LagrañaNo ratings yet

- Commposite Technology at Airbus Germany Present Part and FutureDocument20 pagesCommposite Technology at Airbus Germany Present Part and FutureAngel LagrañaNo ratings yet

- Clean Sky Aviation Event in ValladolidDocument3 pagesClean Sky Aviation Event in ValladolidAngel LagrañaNo ratings yet

- Horizon 2020 Work Programme From 2018 To 2020Document4 pagesHorizon 2020 Work Programme From 2018 To 2020Angel LagrañaNo ratings yet

- Start Your Evening The Italian Way: AperitivoDocument6 pagesStart Your Evening The Italian Way: AperitivoAngel LagrañaNo ratings yet

- Structural Design Optimization of A Morphing Trailing Edge Flap For Wind Turbine BladesDocument1 pageStructural Design Optimization of A Morphing Trailing Edge Flap For Wind Turbine BladesAngel LagrañaNo ratings yet

- Applications: H D P TDocument2 pagesApplications: H D P TEnrique MurgiaNo ratings yet

- Actividad 1 Mecanica FLuidosDocument5 pagesActividad 1 Mecanica FLuidosAngel HCastNo ratings yet

- Tabla de Conversiones de Unidades PDFDocument3 pagesTabla de Conversiones de Unidades PDFJavier Hernández RequenaNo ratings yet

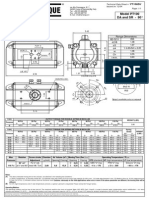

- Pt100du Air TorqueDocument1 pagePt100du Air TorqueAurelio SuarezNo ratings yet

- Controladores 4150 - 4160Document40 pagesControladores 4150 - 4160Juan Carlos DavidNo ratings yet

- ZF - Ergopower 3 WG 116-171: Repair Instructions 1-2Document25 pagesZF - Ergopower 3 WG 116-171: Repair Instructions 1-2Alex RobledoNo ratings yet

- 180144A Flow Unit Conversion ChartDocument1 page180144A Flow Unit Conversion ChartALP69No ratings yet

- Control Valve Sizing PDFDocument5 pagesControl Valve Sizing PDFjainrakeshj4987No ratings yet

- VAM HTF 4vb-Sumitomo 1210Document8 pagesVAM HTF 4vb-Sumitomo 1210mhhashemiNo ratings yet

- ASTM C-1306 - Standard Method For Hydrostatic Pressure Resistance of A Liquid-Applied Waterproofing Membrane PDFDocument3 pagesASTM C-1306 - Standard Method For Hydrostatic Pressure Resistance of A Liquid-Applied Waterproofing Membrane PDFLeonardo Otto CoutinhoNo ratings yet

- F1-F5 Adj PDFDocument21 pagesF1-F5 Adj PDFtpedrosa22No ratings yet

- Experiment No. 9:: Compressive Strength of Cylindrical Concrete SpecimenDocument5 pagesExperiment No. 9:: Compressive Strength of Cylindrical Concrete SpecimencarloNo ratings yet

- Pressure. Pressure Loss in A Steam Pipe. Tyler ExampleDocument70 pagesPressure. Pressure Loss in A Steam Pipe. Tyler ExampleMinh Tran0% (1)

- 2013 Catalog PDFDocument67 pages2013 Catalog PDFprajakt_pieNo ratings yet

- Conversation Tables For SI To American UnitsDocument2 pagesConversation Tables For SI To American UnitsGaurav YadavNo ratings yet

- Instrumentation and ControlDocument121 pagesInstrumentation and ControlabbutalibbNo ratings yet

- W26 358 9004Document29 pagesW26 358 9004MROstop.comNo ratings yet

- Love HM28 ManualDocument16 pagesLove HM28 ManualALEJANDRO IPATZINo ratings yet

- BellowsDocument34 pagesBellowsRicky Ocktavi RizkyNo ratings yet

- Quantity Metric (SI) Units of Measure US Customary (USC) Units of Measure Conversion Factors (SI) To (USC)Document1 pageQuantity Metric (SI) Units of Measure US Customary (USC) Units of Measure Conversion Factors (SI) To (USC)Aadarsh bhandariNo ratings yet

- BFV 19Document1 pageBFV 19arjnittNo ratings yet

- GE Energy Gas Engines Starting Systems Air Volume and Pressure Guidelines For 12V275GL GL+ and 12VAT27GLDocument2 pagesGE Energy Gas Engines Starting Systems Air Volume and Pressure Guidelines For 12V275GL GL+ and 12VAT27GLecavalinNo ratings yet

- Williams Milton Roy V Series PumpsDocument11 pagesWilliams Milton Roy V Series PumpsIsaias Rodriguez Jimenez100% (2)

- Description Assembly Order No. Static DataDocument29 pagesDescription Assembly Order No. Static DataMROstop.comNo ratings yet

- Condition Sensing SwitchesDocument64 pagesCondition Sensing SwitchesksathishgreenNo ratings yet

- NRC exam questions on water manometers and level detectorsDocument14 pagesNRC exam questions on water manometers and level detectorselsayedNo ratings yet

- Swagelok - Check Valve PDFDocument14 pagesSwagelok - Check Valve PDFClemente Rafael Marval Escalona100% (1)

- Eja510e Eja530eDocument11 pagesEja510e Eja530eAndre ChaviNo ratings yet

- Gas Velocity CalculatorDocument4 pagesGas Velocity CalculatorNur Ezreen Fara MustaffaNo ratings yet

- RefrigerationDocument84 pagesRefrigerationGeorge AbrahamNo ratings yet