Professional Documents

Culture Documents

Welded C Channel

Uploaded by

Немања КараклајићOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Welded C Channel

Uploaded by

Немања КараклајићCopyright:

Available Formats

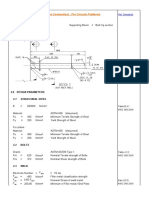

Princess Noura Bint Abdulrahman University for Women Project Joint venture

Riyadh, Kingdom of Saudi Arabia El Seif/CCC

part / package: package 3 - Utillity area references: time: date:

department: ENGINEERING 1:58 PM 1/16/2018

calcs by: Aleksandar Jankovic sr.str.eng

4 .0 THE CHECK OF WELDED CONNECTION AT STUB BOTTOM

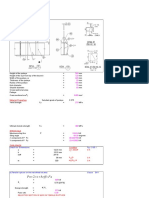

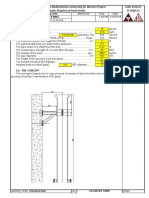

4 .1 Input data Y

Steel grade….. ASTM A36 ,Py= 245 N/mm2

The strength of the weld...Pyw= 147 N/mm2 a2

Safety factor as per AISC ASD 2

Designed strength of the weld 73.5 N/mm2

Adopted C channel…………….. 240x85x33 a1

Flange thickness…………….Tf= 13 mm

Web thickness………..……Tw= 9.5 mm

y2

Yc

y1

The height of the section..…b1= 240 mm

a3 tw a3

The width of the section……a2= 85 mm

Dimension Xc= 17.3 Yc= 67.7 mm

b1

b2

X

Adopted flange weld…………… 10 mm Xc

Adopted web weld size……….. 10 mm

The leg of the flange weld….b3= 7 mm

The leg of the web weld……a3= 7 mm

Dimensions:

b3 tf b3

y1= 51.2 mm

y2= 71.2 mm

b2= 200 mm x1

x2

a1= 68.5 mm

x1= 4.3 mm

x2= 20.8 mm

x3= 33.45 mm

x4= 25.2 mm

ymax= 74.7 mm

xmax= 67.7 mm

4 .2 The loads

Fx= 5.153 kN Mx= 12.195 kNm

Fy= 8.13 kN My= 4.573 kNm

Fz= -4.387 kN Mz= 0 kNm

4 .3 The section property of the designed welded connection

The moment of inertia at the major axis: Ix= 21286036 mm4

The moment of inertia at the minor axis: Iy= 3685491 mm4

The section area……………………………..Aa= 5229 mm2

The area for shear paralell to the web…...Aaw= 3080 mm2

The area for shear paralell to the flange....Aaf= 2149 mm2

Torsional moment of inertia (Ix+Iy)………….It= 24971527 mm4

Section modulus at major axis…..……….Wx= 284953.6 mm3

Section modulus at minor axis……………Wy= 54438.57 mm3

Torsional constant………………………….Wo= 247700 mm3

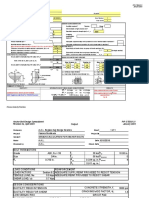

4 .4 The check of the designed welded capacity

Shear capacity, Pscap=Aa*Pyw=……………… 307.4652 > 9.6255031 kN-total shear safe

Tension capacity Ptcap=K*Pscap=……………. 384.3315 > -4.387 kN-tension F safe

Shear parallel to flange, Psfcap=Aaf*Pyf=…… 157.9515 > 5.153 kN-shear at X safe

Shear parallel to the web, Pswcap=Aaw*Pyw= 226.38 > 8.13 kN-shear at Y safe

Bending at major axis, Mxbcap=Wx*Pyw=…… 20.94409 > 12.195 kNm - Mx safe

Bending at minor axis, Mybcap=Wy*Pyw=…… 4.001235 <= 4.573 kNm - My not safe

Torsional capacity Mtcap=Wo*Pyw=………….. 18.20595 > 0 kNm-torsion safe

Stress ratio R1=(((Fz/Ptcap)+(Mx/Mxbcap)+(My/Mybcap))^2+(Fy/Pscap)^2)^0.5= 1.714 not safe

Total stress ratio R=((R1^2+((Mz/Mtcap)+(Fx/Pscap))^2)^0.5= 1.7140329 => 1 not safe

since the total stress ratio is > 1, full penetration butt weld to be used

Building / area: Generator bldg rev: GENERATOR BLDG Sheet:

issued for: APPROVAL 0 fan steel supports 0 1 7

a1

b3 tf b3

y1

Yc

y2

You might also like

- Welded Connection With I BeamDocument8 pagesWelded Connection With I BeamНемања КараклајићNo ratings yet

- Welded PipeDocument2 pagesWelded PipeНемања КараклајићNo ratings yet

- Vertical Movement Connection-TopDocument2 pagesVertical Movement Connection-TopНемања Караклајић100% (1)

- Base Plate DetailDocument16 pagesBase Plate DetailНемања КараклајићNo ratings yet

- Washer PlateDocument2 pagesWasher PlateНемања Караклајић100% (2)

- Section CapacityDocument8 pagesSection CapacityНемања КараклајићNo ratings yet

- Shutter Beam Check and Plate StresDocument2 pagesShutter Beam Check and Plate StresНемања КараклајићNo ratings yet

- Princess Noura Bint Abdulrahman University For Women Project Joint Venture El Seif/CCCDocument9 pagesPrincess Noura Bint Abdulrahman University For Women Project Joint Venture El Seif/CCCНемања КараклајићNo ratings yet

- Shear Steel ConnectionDocument3 pagesShear Steel ConnectionНемања Караклајић100% (1)

- Section Properties: Design of Padeye As Per Aisc 360-2005Document5 pagesSection Properties: Design of Padeye As Per Aisc 360-2005Fadil WimalaNo ratings yet

- Buckling H BeamDocument2 pagesBuckling H BeamНемања КараклајићNo ratings yet

- Tunnel Added Beam On SupportDocument9 pagesTunnel Added Beam On SupportНемања Караклајић100% (1)

- Vertical Bracket With U BoltDocument2 pagesVertical Bracket With U BoltНемања Караклајић100% (1)

- AISC2005 Anchor Bolt Version22042015 FixDocument8 pagesAISC2005 Anchor Bolt Version22042015 FixThuyTranNo ratings yet

- Mset Engineering Corporation SDN BHD: (Ref:Pressure Vessel Design Manual 3rd Edition by Dennis R. Moss Page 291 295)Document17 pagesMset Engineering Corporation SDN BHD: (Ref:Pressure Vessel Design Manual 3rd Edition by Dennis R. Moss Page 291 295)threedlabsNo ratings yet

- AISC360 05 LRFD Shear Plate Bolted Connection Check 17-09-2013Document8 pagesAISC360 05 LRFD Shear Plate Bolted Connection Check 17-09-2013RUBEN BARTOLOME GARCIANo ratings yet

- Calculation For Lifting Lug DesignDocument6 pagesCalculation For Lifting Lug DesignErin JohnsonNo ratings yet

- Cleat Connection For PlatformsDocument29 pagesCleat Connection For PlatformsRajveer SinghNo ratings yet

- Godrej & Boyce calculations for weld strength and size of RIL equipmentDocument10 pagesGodrej & Boyce calculations for weld strength and size of RIL equipmentSajal KulshresthaNo ratings yet

- Calculation of left and right saddle supports for offshore tankerDocument12 pagesCalculation of left and right saddle supports for offshore tankerrustamriyadiNo ratings yet

- Horizontal Lifting LugDocument1 pageHorizontal Lifting LugTushar MangratiNo ratings yet

- Circular Platform Design AISC - ImperialDocument54 pagesCircular Platform Design AISC - ImperialRajveer SinghNo ratings yet

- Steel Connections v1.3Document83 pagesSteel Connections v1.3Mateus GehlenNo ratings yet

- Sendai: Eversendai Consulting Engineers (P) LTDDocument6 pagesSendai: Eversendai Consulting Engineers (P) LTDfsijestNo ratings yet

- Padeye DolphinDocument38 pagesPadeye DolphinMuhammad FadelNo ratings yet

- Weld ConnectionDocument70 pagesWeld ConnectionSudhakar KrishnamurthyNo ratings yet

- FILLET WELD STRENGTH CALCULATIONSDocument8 pagesFILLET WELD STRENGTH CALCULATIONSshadab521No ratings yet

- Anchor BoltsDocument10 pagesAnchor BoltsLex LiwNo ratings yet

- Base Plate DesignDocument3 pagesBase Plate DesignrajarshiboseNo ratings yet

- The Clamp BoltsDocument2 pagesThe Clamp BoltsНемања Караклајић100% (1)

- Calculation Chemical Storage (Steel)Document38 pagesCalculation Chemical Storage (Steel)bonnicoNo ratings yet

- Skid LiftDocument2 pagesSkid LiftAmi PutraNo ratings yet

- Beam Šina MonorailDocument11 pagesBeam Šina MonorailNiko NištićNo ratings yet

- Pad Eye Connected To Bottom PieceDocument7 pagesPad Eye Connected To Bottom PieceAsaru Deen0% (1)

- Beam GravityDocument11 pagesBeam GravitylucianduNo ratings yet

- Lifting Analysis Report - Mahadi KurniawanDocument31 pagesLifting Analysis Report - Mahadi KurniawanDian SasNo ratings yet

- Joist and Beam Design SummaryDocument11 pagesJoist and Beam Design Summaryspsingh_jmdNo ratings yet

- Anchor Bolt - StrengthDocument2 pagesAnchor Bolt - StrengthSana UllahNo ratings yet

- Concrete Corbel Design SummaryDocument14 pagesConcrete Corbel Design Summarynavneet3bawaNo ratings yet

- Shutter ConnectionDocument2 pagesShutter ConnectionНемања КараклајићNo ratings yet

- Elbow SupportDocument3 pagesElbow SupportНемања КараклајићNo ratings yet

- Design OF Flush-Extended End Plate ConnectionsDocument3 pagesDesign OF Flush-Extended End Plate Connectionskapilnandwana100% (1)

- Sendai Project Lifting Lug DesignDocument6 pagesSendai Project Lifting Lug DesignkalpanaadhiNo ratings yet

- Fillet Welding ConnectionDocument1 pageFillet Welding ConnectionUmesh ChamaraNo ratings yet

- 吊耳计算Document4 pages吊耳计算huangjlNo ratings yet

- Lifting Lug CalculationDocument4 pagesLifting Lug CalculationLokesh PatelNo ratings yet

- Clip PlatformDocument24 pagesClip Platformwisnu_bayusaktiNo ratings yet

- Beam Simply SupportedDocument16 pagesBeam Simply SupportedVengatesh HariNo ratings yet

- End Plate DesignDocument4 pagesEnd Plate DesignAgnon Fung100% (4)

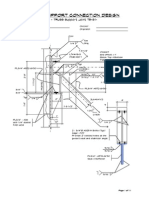

- Truss Support Connection Design T5-S1Document11 pagesTruss Support Connection Design T5-S1rajedmaglinteNo ratings yet

- Sfex Pad Eyes Calculations 35T - 32MMDocument1 pageSfex Pad Eyes Calculations 35T - 32MMJohn Rom CabadonggaNo ratings yet

- Conical Water TankDocument64 pagesConical Water TankRiyaz Siddique100% (1)

- Bolted Moment Connection 2x2Document22 pagesBolted Moment Connection 2x2Немања КараклајићNo ratings yet

- 234Document40 pages234hakimNo ratings yet

- A.2 MC Conexion PIPE A W6x22Document7 pagesA.2 MC Conexion PIPE A W6x22Vivaldi ChangraNo ratings yet

- Buckling C ChannelDocument2 pagesBuckling C ChannelНемања КараклајићNo ratings yet

- GergDocument18 pagesGergOuseppachan AmbookenNo ratings yet

- Design of Steel BeamDocument18 pagesDesign of Steel BeamOuseppachan Ambooken100% (4)

- Connections 1 - Ch.5 Basic Principles - Exercise Solutions (196-214)Document5 pagesConnections 1 - Ch.5 Basic Principles - Exercise Solutions (196-214)travis8zimmermannNo ratings yet

- Slab Design Parameters from Excel SheetDocument29 pagesSlab Design Parameters from Excel SheetKhim KhadkaNo ratings yet

- As Tutorial MetricDocument168 pagesAs Tutorial Metrichonestman1No ratings yet

- Tunnel Section 0-250-Rev 01Document51 pagesTunnel Section 0-250-Rev 01Немања Караклајић100% (2)

- Air SeparatorsDocument2 pagesAir SeparatorsНемања КараклајићNo ratings yet

- Vertical Bracket With U BoltDocument2 pagesVertical Bracket With U BoltНемања Караклајић100% (1)

- Typical TemplateDocument4 pagesTypical TemplateНемања КараклајићNo ratings yet

- Tunnel Section 0-250-Rev 01Document51 pagesTunnel Section 0-250-Rev 01Немања Караклајић100% (2)

- Air SeparatorsDocument2 pagesAir SeparatorsНемања КараклајићNo ratings yet

- Tunnel Added Beam On SupportDocument9 pagesTunnel Added Beam On SupportНемања Караклајић100% (1)

- The Clamp BoltsDocument2 pagesThe Clamp BoltsНемања Караклајић100% (1)

- Steel DropersDocument94 pagesSteel DropersНемања КараклајићNo ratings yet

- Air SeparatorsDocument2 pagesAir SeparatorsНемања КараклајићNo ratings yet

- Support RadiatorsDocument5 pagesSupport RadiatorsНемања КараклајићNo ratings yet

- Steel DropersDocument94 pagesSteel DropersНемања КараклајићNo ratings yet

- Steel Dropers-Tunnel 0+200Document95 pagesSteel Dropers-Tunnel 0+200Немања Караклајић100% (1)

- Storm Water Pump StationDocument6 pagesStorm Water Pump StationНемања КараклајићNo ratings yet

- Shutter Beam Check and Plate StresDocument2 pagesShutter Beam Check and Plate StresНемања КараклајићNo ratings yet

- Section CapacityDocument8 pagesSection CapacityНемања КараклајићNo ratings yet

- Shutter ConnectionDocument2 pagesShutter ConnectionНемања КараклајићNo ratings yet

- Irrigation-Hanging BracketDocument5 pagesIrrigation-Hanging BracketНемања КараклајићNo ratings yet

- Elevated Tank 150Document6 pagesElevated Tank 150Немања КараклајићNo ratings yet

- Shear Steel ConnectionDocument3 pagesShear Steel ConnectionНемања Караклајић100% (1)

- ReportDocument5 pagesReportНемања КараклајићNo ratings yet

- Air SeparatorsDocument2 pagesAir SeparatorsНемања КараклајићNo ratings yet

- Pump Station-CoverDocument1 pagePump Station-CoverНемања КараклајићNo ratings yet

- Potable-Cover-Rev 1Document2 pagesPotable-Cover-Rev 1Немања КараклајићNo ratings yet

- Simple Syrup I.PDocument38 pagesSimple Syrup I.PHimanshi SharmaNo ratings yet

- Puskesmas Dua Puluh Tiga Ilir Publishes Vaccination Ticket ListDocument98 pagesPuskesmas Dua Puluh Tiga Ilir Publishes Vaccination Ticket ListLaboratorium PKM 23 IlirNo ratings yet

- LH 11 180 190 220 230 270 280 390 400 Breaker Safety & Operating InstructionsDocument304 pagesLH 11 180 190 220 230 270 280 390 400 Breaker Safety & Operating InstructionshadensandorNo ratings yet

- General Specifications: Detail ADocument1 pageGeneral Specifications: Detail AJeniel PascualNo ratings yet

- Natural Resources in PakistanDocument5 pagesNatural Resources in PakistanSohaib ENo ratings yet

- Ensure Even Preload with Proper Tightening Tools and SequenceDocument2 pagesEnsure Even Preload with Proper Tightening Tools and SequenceMachineryengNo ratings yet

- LPBP HPSU Document PDFDocument131 pagesLPBP HPSU Document PDFGanga PrasadNo ratings yet

- Q4 Module 8Document14 pagesQ4 Module 8DerickNo ratings yet

- XDocument266 pagesXTrần Thanh PhongNo ratings yet

- TSS-TS-TATA 2.95 D: For Field Service OnlyDocument2 pagesTSS-TS-TATA 2.95 D: For Field Service OnlyBest Auto TechNo ratings yet

- GTT Module 5Document156 pagesGTT Module 5ABDULRAHIMAN RAJEKHANNo ratings yet

- Indonesia Organic Farming 2011 - IndonesiaDOCDocument18 pagesIndonesia Organic Farming 2011 - IndonesiaDOCJamal BakarNo ratings yet

- Switzerland: Food and CultureDocument18 pagesSwitzerland: Food and CultureAaron CoutinhoNo ratings yet

- The National Building Code of The PhilippinesDocument390 pagesThe National Building Code of The PhilippinesJohn Joseph EstebanNo ratings yet

- Activity No 1 - Hydrocyanic AcidDocument4 pagesActivity No 1 - Hydrocyanic Acidpharmaebooks100% (2)

- Válvulas Flomatic USADocument40 pagesVálvulas Flomatic USAEfrain DuarteNo ratings yet

- RHS NCRPO COVID FormDocument1 pageRHS NCRPO COVID Formspd pgsNo ratings yet

- Workplace Hazard Analysis ProcedureDocument12 pagesWorkplace Hazard Analysis ProcedureKent Nabz60% (5)

- Rapid Cycling in Bipolar DisorderDocument1 pageRapid Cycling in Bipolar Disorderdo leeNo ratings yet

- Frank Wood S Business Accounting 1Document13 pagesFrank Wood S Business Accounting 1Kofi AsaaseNo ratings yet

- To The OneDocument8 pagesTo The OnePizzaCowNo ratings yet

- Sigma monitor relayDocument32 pagesSigma monitor relayEdwin Oria EspinozaNo ratings yet

- Intake Sheet SampleDocument1 pageIntake Sheet SampleRochelleNo ratings yet

- Clinical Case Report No 2Document11 pagesClinical Case Report No 2ملک محمد صابرشہزاد50% (2)

- Stress and FilipinosDocument28 pagesStress and FilipinosDaniel John Arboleda100% (2)

- Thee Correlational Study of Possittive Emotionons and Coping Strategies For Academic Stress Among CASS Studentts - updaTEDDocument23 pagesThee Correlational Study of Possittive Emotionons and Coping Strategies For Academic Stress Among CASS Studentts - updaTEDJuliet AcelNo ratings yet

- Practice of Epidemiology Performance of Floating Absolute RisksDocument4 pagesPractice of Epidemiology Performance of Floating Absolute RisksShreyaswi M KarthikNo ratings yet

- WSAWLD002Document29 pagesWSAWLD002Nc BeanNo ratings yet

- Philippines implements external quality assessment for clinical labsDocument2 pagesPhilippines implements external quality assessment for clinical labsKimberly PeranteNo ratings yet

- How To Practice Self Care - WikiHowDocument7 pagesHow To Practice Self Care - WikiHowВасе АнѓелескиNo ratings yet