Professional Documents

Culture Documents

Hardox HiTuf 2016-01-14 264 371857150 en

Uploaded by

RodrigoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hardox HiTuf 2016-01-14 264 371857150 en

Uploaded by

RodrigoCopyright:

Available Formats

HARDOX HITUF

HARDOX HITUF

General Product Description

The extra-high tough steel for structural wear parts

Hardox® HiTuf is an abrasion-resistant plate with guaranteed impact toughness. With a nominal hardness of 350 HBW, it’s a good

choice for structural wear parts like thick cutting edges, demolition tools and rippers.

Dimension Range

Hardox HiTuf is available in thicknesses of 40 – 160 mm. Hardox HiTuf is available in widths up to 3350 mm and lengths up to

14630 mm. For thicknesses over 125 mm preferred width is 1650 mm. More detailed information on dimensions is provided in the

dimension program.

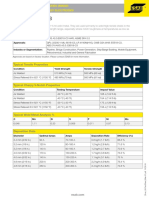

Mechanical Properties

Thickness Hardness (HBW) Typical yield strength, not guaranteed

(mm) Min - Max 1) (MPa)

40.0 - 160.0 310 - 370 850

1)

Brinell hardness, HBW, according to EN ISO 6506-1, on a milled surface 0.5 – 3 mm below surface. At least one test specimen per heat and 40 tons.

The nominal material thickness will not deviate more than + 15 mm from that of the test specimen.

Hardox is through-hardened. Minimum core hardness is 90 % of the guaranteed minimum surface hardness.

Impact Properties

Grade Min. Impact energy (J) for transverse tests Charpy V 10x10 mm

test specimen2)

Hardox HiTuf 40 J / - 40 C

2)

Impact testing according to ISO EN 148 per heat and thickness group. Average of three tests. Single value minimum 70% of specified average.

Data sheet 170 Hardox HiTuf 2016-01-14

HARDOX HITUF

Chemical Composition (heat analysis)

C *) Si *) Mn *) P S Cr *) Ni *) Mo *) B *)

(max %) (max %) (max %) (max %) (max %) (max %) (max %) (max %) (max %)

0.20 0.60 1.60 0.050 0.020 0.70 2.0 0.70 0.005

The steel is grain refined. *) Intentional alloying elements.

Carbon Equivalent CET(CEV)

Thickness 40.00 - 70.00 70.10 - 160.00

(mm)

Max CET(CEV) 0.38 (0.56) 0.41 (0.66)

Tolerances

More details are given in SSAB´s brochure 41-General product information Strenx, Hardox, Armox and Toolox-UK and Hardox®

Guarantees or on www.ssab.com.

Thickness

Tolerances according to Hardox Thickness Guarantees. Hardox® Guarantees meets the requirements of EN 10 029 Class A but offers

more narrow tolerances.

Length and Width

According to SSAB’s dimension program. Tolerances conforms to EN 10 029 or to SSAB’s standard after agreement.

Shape

Tolerances according to EN 10 029

Flatness

Tolerances according to Hardox Flatness Guarantee class C, which are more restrictive than EN 10 029 Class N.

Surface Properties

EN 10 163-2 Class A Subclass 1

Delivery Conditions

The delivery condition is Quenched. The plates are delivered with sheared or thermally cut edges. Untrimmed edges

after agreement. Delivery requirements can be found in SSAB’s brochure 41-General product information Strenx, Hardox, Armox and

Toolox-UK or www.ssab.com.

Data sheet 170 Hardox HiTuf 2016-01-14

HARDOX HITUF

Fabrication and Other Recommendations

Welding, bending and machining

Recommendations can be found in our brochures on www.hardox.com or consult Tech Support, techsupport@ssab.com.

Hardox HiTuf is not intend for further heat treatment. It has obtained its mechanical properties by quenching and when necessary

by means of subsequent tempering. The properties of the delivery condition cannot be retained after exposure to temperatures in

excess of 450ºC .

Appropriate health and safety precautions must be taken when welding, cutting, grinding or otherwise working on this product.

Grinding, especially of primer coated plates, may produce dust with a high particle concentration.

The UK English version of this document shall prevail in case of discrepancy. Download the latest version of this document at www.ssab.com

Hardox, Strenx, Docol, Dogal, Domex, Toolox, Laser, Armox, Ramor, GreenCoat are trademarks of SSAB Technology AB, Sweden

www.ssab.com

Data sheet 170 Hardox HiTuf 2016-01-14

You might also like

- 2015 KOBELCO Defect PDFDocument25 pages2015 KOBELCO Defect PDFayushNo ratings yet

- Hardox 450 Data SheetDocument2 pagesHardox 450 Data SheetmatthewpincottNo ratings yet

- Data Sheet 2006 Strenx 700 20170420 121 371857150 enDocument2 pagesData Sheet 2006 Strenx 700 20170420 121 371857150 enRodrigoNo ratings yet

- QA vs QC vs INSPECTION: The Key DifferencesDocument138 pagesQA vs QC vs INSPECTION: The Key DifferencesMohd SharainiNo ratings yet

- Fillet Weld DesignDocument2 pagesFillet Weld Designsaj0205037No ratings yet

- Hardox 450 PDFDocument2 pagesHardox 450 PDFAriel Toño Vaquera ZeballosNo ratings yet

- Magnesium and Aluminum Alloys in Automotive Industry PDFDocument11 pagesMagnesium and Aluminum Alloys in Automotive Industry PDFΝΙΚΟΛΑΟΣ ΚΑΡΑΓΚΙΑΟΥΡΗΣNo ratings yet

- ASTM Grades ExplainedDocument4 pagesASTM Grades ExplainedAnonymous 6ZWS6IG2J9No ratings yet

- 107 - WELDOX - 700 - UK - Data Sheet PDFDocument2 pages107 - WELDOX - 700 - UK - Data Sheet PDFDaniel CringusNo ratings yet

- Vertical Pump Repair IssuesDocument53 pagesVertical Pump Repair IssuesAnonymous dq9Cohr100% (1)

- Norme For WeldingDocument3 pagesNorme For Weldingsirambo1No ratings yet

- Datasheet Strenx 700E - en - 2016Document3 pagesDatasheet Strenx 700E - en - 2016peterNo ratings yet

- Chevron Valve SpecificationDocument32 pagesChevron Valve Specificationhtutswe100% (2)

- AWS E8018-B2 welding rodDocument2 pagesAWS E8018-B2 welding rodRodrigoNo ratings yet

- Metallurgical Failure AnalysisDocument2 pagesMetallurgical Failure AnalysisShuaib KunnekkattuNo ratings yet

- Jis G 4052 (SCMXXXH)Document38 pagesJis G 4052 (SCMXXXH)kimthanhleg1010No ratings yet

- Hardox 400 PlateDocument3 pagesHardox 400 PlateAli TalebiNo ratings yet

- 5 - Hituf - Thick Structural WearDocument2 pages5 - Hituf - Thick Structural WearNguyên NguyễnNo ratings yet

- Data Sheet 151uk Hardox 400 Plate 2017-04-19 313 371857150 en PDFDocument2 pagesData Sheet 151uk Hardox 400 Plate 2017-04-19 313 371857150 en PDFLuis GuevaraNo ratings yet

- Hardox 500 PlateDocument3 pagesHardox 500 PlateYousab CreatorNo ratings yet

- Hardox 450 Plate: General Product DescriptionDocument2 pagesHardox 450 Plate: General Product Descriptiongorane11No ratings yet

- Data Sheet 2067uk Hardox 500 Sheet 2016-03-02 50 371857150 enDocument3 pagesData Sheet 2067uk Hardox 500 Sheet 2016-03-02 50 371857150 enPtbbi TubanNo ratings yet

- Hardox® 400: General Product DescriptionDocument2 pagesHardox® 400: General Product Descriptionmini p shendeNo ratings yet

- Hardox® 600: General Product DescriptionDocument2 pagesHardox® 600: General Product DescriptionTimur SonkayaNo ratings yet

- Data Sheet 159 Hardox 600Document3 pagesData Sheet 159 Hardox 600Ehab Attia SelimNo ratings yet

- 1 500tufDocument2 pages1 500tufNguyên NguyễnNo ratings yet

- Hardox Hiace: General Product DescriptionDocument2 pagesHardox Hiace: General Product DescriptionFilipe CordeiroNo ratings yet

- Data Sheet 173 Armox 440T 2016-04-22 34 371857150 enDocument3 pagesData Sheet 173 Armox 440T 2016-04-22 34 371857150 enJose ManuelNo ratings yet

- 500 TuffDocument2 pages500 TuffSubodh ShindeNo ratings yet

- Hardox 500 DatasheetDocument2 pagesHardox 500 DatasheetPetrus Slamet Putra WijayaNo ratings yet

- 6 - HiAce - Acidic WearDocument2 pages6 - HiAce - Acidic WearNguyên NguyễnNo ratings yet

- Hardox 450Document2 pagesHardox 450Brandon Vicuña GalánNo ratings yet

- Hardox 500 Sheet: General Product DescriptionDocument2 pagesHardox 500 Sheet: General Product DescriptionDylkanWingsNo ratings yet

- Hardox® 450: General Product DescriptionDocument2 pagesHardox® 450: General Product DescriptionAmal RajNo ratings yet

- Hardox 450: General Product DescriptionDocument2 pagesHardox 450: General Product DescriptionJaime PérezNo ratings yet

- 152 - HARDOX - 500 - UK - Data Sheet PDFDocument2 pages152 - HARDOX - 500 - UK - Data Sheet PDFneto-portoNo ratings yet

- Hardox 550: General Product DescriptionDocument2 pagesHardox 550: General Product DescriptionNguyên NguyễnNo ratings yet

- Armox 600T: General Product DescriptionDocument2 pagesArmox 600T: General Product Descriptionehudingram6535No ratings yet

- 168 Hardox 450 Uk Data SheetDocument2 pages168 Hardox 450 Uk Data SheetBambang WibisonoNo ratings yet

- 151 Hardox 400 Uk Data SheetDocument2 pages151 Hardox 400 Uk Data SheetArief TirtanaNo ratings yet

- Hardox 450: General Product DescriptionDocument2 pagesHardox 450: General Product DescriptionTeodor EzaruNo ratings yet

- 168 - HARDOX - 450 - UK - Data Sheet PDFDocument2 pages168 - HARDOX - 450 - UK - Data Sheet PDFemad sabriNo ratings yet

- 151 Hardox 400 Uk Data-SheetDocument2 pages151 Hardox 400 Uk Data-Sheetanon_94641581No ratings yet

- Hardox 450 Abrasion Resistant Steel Data SheetDocument2 pagesHardox 450 Abrasion Resistant Steel Data SheetpedroNo ratings yet

- Hardox 600: General Product DescriptionDocument2 pagesHardox 600: General Product DescriptionNguyên NguyễnNo ratings yet

- Data Sheet 159us Hardox® 600 2021-02-22Document2 pagesData Sheet 159us Hardox® 600 2021-02-22Kevin GuoNo ratings yet

- 170 Hardox Hituf Uk Data SheetDocument2 pages170 Hardox Hituf Uk Data SheetTimNo ratings yet

- Data Sheet 197 Armox® 600T 2017-04-19Document2 pagesData Sheet 197 Armox® 600T 2017-04-19idanfriNo ratings yet

- Hardox 400 UkDocument2 pagesHardox 400 Uksingaravelan narayanasamyNo ratings yet

- Abrasion Plate Data SheetDocument2 pagesAbrasion Plate Data SheetMario MereniNo ratings yet

- Hardox 450 Uk Data SheetDocument2 pagesHardox 450 Uk Data SheetNenad BozicNo ratings yet

- 173 Armox 440t Uk Data SheetDocument2 pages173 Armox 440t Uk Data SheetErnestoNo ratings yet

- Data Sheet Raex 450Document3 pagesData Sheet Raex 450Amit GauravNo ratings yet

- Raex 400: General Product DescriptionDocument2 pagesRaex 400: General Product DescriptionFilipe CordeiroNo ratings yet

- Tehnical Sheets For HardoxxDocument2 pagesTehnical Sheets For HardoxxZeu AressNo ratings yet

- Armox 370T Class 1: General Product DescriptionDocument2 pagesArmox 370T Class 1: General Product DescriptionSuneelNo ratings yet

- 171 HARDOX Extreme UK Data SheetDocument2 pages171 HARDOX Extreme UK Data SheetMiguel Matias ReineroNo ratings yet

- Strenx 960: General Product DescriptionDocument2 pagesStrenx 960: General Product DescriptionJean Paulo SalvatiNo ratings yet

- 107 Weldox 700 Uk Data SheetDocument2 pages107 Weldox 700 Uk Data SheetAnurag JainNo ratings yet

- Strenx 700: General Product DescriptionDocument2 pagesStrenx 700: General Product DescriptionpeterNo ratings yet

- Hilti HIT-HY 170 mortar anchor manualDocument15 pagesHilti HIT-HY 170 mortar anchor manualAlexZaNo ratings yet

- 932 Entechsupport 65 V22022Document4 pages932 Entechsupport 65 V22022VALNo ratings yet

- Data Sheet 2007 Strenx 700 CR 2017-04-20 52 371857150 enDocument2 pagesData Sheet 2007 Strenx 700 CR 2017-04-20 52 371857150 enThainã NavarroNo ratings yet

- Creusabro 4800 Steel Offers Improved Wear ResistanceDocument3 pagesCreusabro 4800 Steel Offers Improved Wear ResistanceAnonymous 48jYxR1CNo ratings yet

- Hardox 550 Uk Data SheetDocument2 pagesHardox 550 Uk Data SheetCardoso MalacaoNo ratings yet

- EN24 and EN24T SteelDocument3 pagesEN24 and EN24T Steelpatrik710No ratings yet

- Hilti Hit-Hy 200 With Hit-V RodDocument20 pagesHilti Hit-Hy 200 With Hit-V RodFodor ZoltanNo ratings yet

- Lincoln, TECHALLOY® 606 (c14107)Document2 pagesLincoln, TECHALLOY® 606 (c14107)RodrigoNo ratings yet

- Lincoln, Superarc LA-90Document2 pagesLincoln, Superarc LA-90RodrigoNo ratings yet

- Lincoln, Tech-Rod ® 99 (c141022)Document2 pagesLincoln, Tech-Rod ® 99 (c141022)RodrigoNo ratings yet

- World Weather Report Memory TestDocument11 pagesWorld Weather Report Memory TestAlex Rödriguez R50% (2)

- Zeron 100 Brochure Rolled AlloysDocument8 pagesZeron 100 Brochure Rolled AlloysRodrigoNo ratings yet

- Lincoln GMAW Welding GuideDocument96 pagesLincoln GMAW Welding GuideМич БјукенонNo ratings yet

- Verticalshrouds Proteccion VerticalDocument4 pagesVerticalshrouds Proteccion VerticalRodrigoNo ratings yet

- materiales-acero-composicion-quimica-mecanicaDocument2 pagesmateriales-acero-composicion-quimica-mecanicaDanyAlex GarciaNo ratings yet

- ABC 5edDocument93 pagesABC 5edJuan Diego Garcia EsquenNo ratings yet

- Unibraze Er80s-B2 (Tig)Document1 pageUnibraze Er80s-B2 (Tig)RodrigoNo ratings yet

- Essential Factors in Gas Shielded Metal Arc Welding GMAW - 5edDocument33 pagesEssential Factors in Gas Shielded Metal Arc Welding GMAW - 5edCarlo MonsalveNo ratings yet

- Steel Castings, Carbon, For General ApplicationDocument4 pagesSteel Castings, Carbon, For General ApplicationJuan Carlos Chura QuispeNo ratings yet

- Esab, OK Autrod 12.22 (1222252800)Document1 pageEsab, OK Autrod 12.22 (1222252800)RodrigoNo ratings yet

- Esab, OK Autrod 12.10 (A345311)Document1 pageEsab, OK Autrod 12.10 (A345311)RodrigoNo ratings yet

- Esab, OK Flux 10.71 (30.06.16), 420014-En - US-FactSheet - Main-01Document2 pagesEsab, OK Flux 10.71 (30.06.16), 420014-En - US-FactSheet - Main-01RodrigoNo ratings yet

- Esab, Atom Arc 8018 (26-En - US-FactSheet - Main-01, 2016.10.26)Document1 pageEsab, Atom Arc 8018 (26-En - US-FactSheet - Main-01, 2016.10.26)RodrigoNo ratings yet

- Esab, OK Flux 10.71 (30.06.16), 420014-En - US-FactSheet - Main-01Document2 pagesEsab, OK Flux 10.71 (30.06.16), 420014-En - US-FactSheet - Main-01RodrigoNo ratings yet

- Dual Shield 7100 Ultra: Typical Tensile PropertiesDocument3 pagesDual Shield 7100 Ultra: Typical Tensile PropertiesDino Paul Castro HidalgoNo ratings yet

- Esab, Dual Shield T-115 (24!02!17, 266-En - US-FactSheet - Main-01)Document2 pagesEsab, Dual Shield T-115 (24!02!17, 266-En - US-FactSheet - Main-01)RodrigoNo ratings yet

- Esab, OK Autrod 12.10 (A345311)Document1 pageEsab, OK Autrod 12.10 (A345311)RodrigoNo ratings yet

- Esab, Atom Arc 9018 (29-En - US-FactSheet - Main-01, 2016.10.26)Document1 pageEsab, Atom Arc 9018 (29-En - US-FactSheet - Main-01, 2016.10.26)RodrigoNo ratings yet

- Dual Shield II 110 Flux-Cored WireDocument2 pagesDual Shield II 110 Flux-Cored WireRodrigoNo ratings yet

- Dual Shield 7100 Ultra: Typical Tensile PropertiesDocument3 pagesDual Shield 7100 Ultra: Typical Tensile PropertiesDino Paul Castro HidalgoNo ratings yet

- Esab, Coreshield 40 (275-En - US-FactSheet - Main-01) (26.10.16)Document1 pageEsab, Coreshield 40 (275-En - US-FactSheet - Main-01) (26.10.16)RodrigoNo ratings yet

- Esab, Dual Shield 810X Ni1 (248 en - US FactSheet - Main 01)Document2 pagesEsab, Dual Shield 810X Ni1 (248 en - US FactSheet - Main 01)RodrigoNo ratings yet

- Esab, OK Tigrod NiCr-3 (21.06.16) (411170-En - US-FactSheet - Main-01)Document1 pageEsab, OK Tigrod NiCr-3 (21.06.16) (411170-En - US-FactSheet - Main-01)RodrigoNo ratings yet

- Portafolio SoldDocument1 pagePortafolio SoldRodrigoNo ratings yet

- Exploded assembly drawing caster parts listDocument1 pageExploded assembly drawing caster parts listlianaNo ratings yet

- Certificados Sara 2 in Fig 1502Document1 pageCertificados Sara 2 in Fig 1502akaalj qhseNo ratings yet

- Chemistry Micro ProjectDocument29 pagesChemistry Micro Projectnikhil9923707734No ratings yet

- Al-Cu-Si Heat-Treatable Sand Casting AlloyDocument3 pagesAl-Cu-Si Heat-Treatable Sand Casting Alloymanjunath k sNo ratings yet

- Dokumen - Tips Elektrode Jesenice KatalogDocument380 pagesDokumen - Tips Elektrode Jesenice KatalogWelder llcNo ratings yet

- Blacksmithing Primer Covers Tools, TechniquesDocument2 pagesBlacksmithing Primer Covers Tools, Techniquesstubby49No ratings yet

- Notice No.1 Rules For The Manufacture, Testing and Certification of Materials, July 2021Document19 pagesNotice No.1 Rules For The Manufacture, Testing and Certification of Materials, July 2021mathias alfred jeschke lopezNo ratings yet

- Preheating and Post Weld Heat TreatmentsDocument3 pagesPreheating and Post Weld Heat TreatmentssubrataNo ratings yet

- Casting Bronze PDFDocument13 pagesCasting Bronze PDFFIREREALM66No ratings yet

- A668Document8 pagesA668Vladimir JaraNo ratings yet

- A 447Document4 pagesA 447william_m08No ratings yet

- As 3777-2008 Shank Hooks and Large Eye Hooks - Maximum 60 TDocument7 pagesAs 3777-2008 Shank Hooks and Large Eye Hooks - Maximum 60 TSAI Global - APACNo ratings yet

- ZERON 100 For Downstream Processing in Acid Leach MiningDocument11 pagesZERON 100 For Downstream Processing in Acid Leach MiningShankar AcharNo ratings yet

- Metallurgy Question Bank - Questions OnlyDocument6 pagesMetallurgy Question Bank - Questions OnlyMANYAM. HARI KRISHNA MECHANICAL ENGINEERINGNo ratings yet

- 12x6x7aircraft Rated ManholeDocument1 page12x6x7aircraft Rated ManholegemotorresNo ratings yet

- Juntas EnchaquetadasDocument1 pageJuntas EnchaquetadasPablo PasqualiniNo ratings yet

- The Al-Si Phase Diagram: Microsc Microanal 15 (Suppl 2), 2009 60 Doi: 10.1017/S1431927609092642Document2 pagesThe Al-Si Phase Diagram: Microsc Microanal 15 (Suppl 2), 2009 60 Doi: 10.1017/S1431927609092642divyanshNo ratings yet

- Ship and Boat Building and Repair-2Document5 pagesShip and Boat Building and Repair-2navalmamunNo ratings yet

- Faculty of Engineering, UNIMASDocument4 pagesFaculty of Engineering, UNIMASjohnNo ratings yet

- Aisi E50100, E52100: 154/amoyDocument6 pagesAisi E50100, E52100: 154/amoyahmad hafizNo ratings yet

- Gunnebo Catalogue of Container Securing FittingsDocument49 pagesGunnebo Catalogue of Container Securing FittingsAnonymous ugCWo0Acz3No ratings yet

- 8th International Congress On Science and Technology of Ironmaking - ICSTI 2018 - Book of AbstractsDocument101 pages8th International Congress On Science and Technology of Ironmaking - ICSTI 2018 - Book of AbstractsEly Wagner FerreiraNo ratings yet