Professional Documents

Culture Documents

Analisis POT VDA 6.3 2010-2

Uploaded by

Luis SosaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Analisis POT VDA 6.3 2010-2

Uploaded by

Luis SosaCopyright:

Available Formats

Potential Analysis

Potential analysis to VDA 6.3, issue level 2010 VDA-QMC

Organization (Supplier/ Tender):

Supl.-No: ###

(DUNS) Date:

Contract issued Contract

Location: by: number: n/a

Reason for

contract:

Pro. No Project, Product, Process Assessed Findings / requirements:

description:

S550 Injection molding GREEN Injection Molding

A contract cannot be issued for the above Estimation of risk:

RED Barred supplier: project/product.

A contract can be issued conditionally for

YELLOW Controlled supplier: the above project/product.

A contract can be issued for the above

GREEN Fully approved supplier: project/product. Estimation of potential:

NOTE:

Controlled suppliers / tenders commit themselves, after been awarded, to coorperate with

an approved consulting company by accpeting the upgrade qualification agreement. Costs

will be carried by the supplier. Further procedure:

Audit history / Certificates

Audit base Date Conducted Result

ISOTS 16949

Potenzial VDA 6.3

VDA 6.3

VDA 6.3

Distribution: * Participant

1. Date improvement plan: 1/13/1900 Action see "improvement program"

Auditor Leader supplier assessment Signature supplier / tender

Pfad\376375993.xlsx \VDA front sheet Speicherdatum: 01/11/2018

Erstellt: C-P-QM-QEM, Fr. Tauschke Seite 1 / 11

Revision 01 C-SQM_012

Potential Analysis

VDA

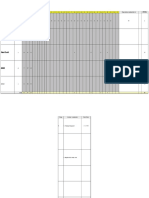

Questionaire potenzial analysis (P1) Assessment Remarks: Entry box

6.3*

Assessment question

Project management

2.1 1.1 Is the project organisation (project

management) establshed and are tasks and

authorities specified for the project

management and team

members?

2.2 1.2 Are the necessary resources planned and

available for the development of the project

and are changes highlighted?

2.3 1.3 Is there a project plan and has this been

agreed with the customer?

2.4 1.4 Is change management within the project

ensured by the project manager?

2.5 1.5 Are the responsible people in the

organisation and in he customer's

organisation involved in the up-dating

system?

Pfad\376375993.xlsx \Assessment page Speicherdatum: 01/11/2018

Erstellt: C-P-QM-QEM, Fr. Tauschke Seite 2 / 11

Revision 01 C-SQM_012

Potential Analysis

2.6 1.6 Is there a quality plan in the project?

Is this implemented and

regularly monitored for compliance?

2.7 1.7 Is an escalation process established and is

this controlled effectively?

Planning the product & process

development

3.1 2.1 Are the product-specific and process-

specific requirements set out?

3.2 2.2 Is manufacturing feasibility assessed on

the basis of the requirements established

for the product and process,

on a cross-functional level?

Pfad\376375993.xlsx \Assessment page Speicherdatum: 01/11/2018

Erstellt: C-P-QM-QEM, Fr. Tauschke Seite 3 / 11

Revision 01 C-SQM_012

Potential Analysis

Carrying out the product & process

development

4.1 3.1 Are the Design FMEA / Process FMEA

drawn up and up-dated in the course of the

project and are corrective actions

specified?

4.5 3.2 Are the necessary demonstrations of

suitability and releases available for the

relevant phases of the project, based on

the requirements?

4.9 3.3 Is the transfer of the project to full

production secure in terms of the product

launch?

Supplier management

5.1 4.1 Are only approved and quality-capable

suppliers appointed?

Pfad\376375993.xlsx \Assessment page Speicherdatum: 01/11/2018

Erstellt: C-P-QM-QEM, Fr. Tauschke Seite 4 / 11

Revision 01 C-SQM_012

Potential Analysis Are only approved and quality-capable

suppliers appointed?

5.2 4.2 Are the customer's requirements taken into

account in the supply chain?

5.4 4.3 Are the necessary approvals available for

out-sourced products and services?

5.5 4.4 Is the agreed quality of out-sourced

products and services guaranteed?

5.6 4.5 Are incoming goods stored in the

appropriate manner?

Process analysis / production

What goes into the process? Process input

6.1.1 5.1.1 Has the transfer of the project from

development to full production been

completed?

Pfad\376375993.xlsx \Assessment page Speicherdatum: 01/11/2018

Erstellt: C-P-QM-QEM, Fr. Tauschke Seite 5 / 11

Revision 01 C-SQM_012

Potential Analysis

6.1.3 5.1.2 Are upstream materials stored in the

appropriate manner and do the transport

methods / packing systems take account of

the special

characteristics of upstream materials?

Work content / process sequence (are all

production processes controlled?)

6.2.1 5.2.1 Based on the production control plan, are

all the relevant data fully listed in the

production and test/inspection

documentation?

6.2.3 5.2.2 Can the customer's product-specific quality

requirements be achieved with the

production facilities?

6.2.4 5.2.3 Are significant characteristics controlled in

production?

6.2.5 5.2.4 Are scrap, rework and setting parts, as well

as residual in-house quantities properly

separated and identified?

6.2.6 5.2.5 Is the flow of materials and components

secured against mix-ups / incorrect

identification?

Process support / personnel resources

6.3.2 5.3.1 Are the operators able to carry out their

allotted tasks and are their qualifications

kept up-to-date?

Material resources

6.4.1 5.4.1 Are the maintenance and overhaul of

machines / facilities controlled on a

preventive basis?

6.4.2 5.4.2 Can the quality requirements be monitored

effectively with the measurement, checking

and inspection equipment used?

Pfad\376375993.xlsx \Assessment page Speicherdatum: 01/11/2018

Erstellt: C-P-QM-QEM, Fr. Tauschke Seite 6 / 11

Revision 01 C-SQM_012

Potential Analysis

6.4.3 5.4.3 Are the work-areas and test / inspection

stations suitable for requirements?

6.4.4 5.4.4 Are tools, equipment and test / inspection

devices stored appropriately?

Process effectiveness level

6.5.1 5.5.1 Are targets set for product and process?

6.5.3 5.5.2 If deviations from product and process

requirements occur, are the causes

analysed and corrective actions checked

for effectiveness?

6.5.4 5.5.3 Are processes and products audited

regularly?

What should the process produce? (output)

6.6.1 5.6.1 Are the customer's requirements satisfied

in terms of product and process?

Customer support / customer satisfaction /

service

7.1 6.1 Are the customer's requirements satisfied

in terms of QM system, product (on

delivery) and process?

7.3 6.2 Is the supply of components secure?

0 0 0

Classification criterias

Fully approved supplier

Pfad\376375993.xlsx \Assessment page Speicherdatum: 01/11/2018

Erstellt: C-P-QM-QEM, Fr. Tauschke Seite 7 / 11

Revision 01 C-SQM_012

Potential Analysis

Conditionally approved

controlled by Organisation

Barred supplier

contract can not be issued

GREEN Assessments missing, to less crossess

[GREEN] requirement achieved

[YELLOW] requirement partly achieved

[RED] requirement not achieved

Pfad\376375993.xlsx \Assessment page Speicherdatum: 01/11/2018

Erstellt: C-P-QM-QEM, Fr. Tauschke Seite 8 / 11

Revision 01 C-SQM_012

Potential Analysis

Assessment overview potential analysis Contract: n/a Supplier/Tender: 0

P2 Project management

1.1 0 1.2 0 1.3 0 1.4 0 1.5 0 1.6 0 1.7 0

Project mgmt. 0 Project 0 Project plan 0 Change 0 Changes 0 QM-plan 0 Escalation 0

Project team 0 Resources 0 0 management 0 Cust. / Supplier 0 0 process 0

P3 Planning the product & process development P4 Carrying out the product & process development

2.1 0 2.2 0 3.1 0 3.2 0 3.3 0

Customer 0 Feasibilty 0 FMEA Product 0 Suitability 0 Project transfer 0

Requirements 0 review 0 FMEA Process 0 Approvals 0 Start of serial 0

P5 Supplier management

4.1 0 4.2 0 4.3 0 4.4 0 4.5 0

Approved 0 Cust. Requirement 0 Purchasing 0 Purchasing 0 Storaging 0

Suppliers 0 Supply chain 0 Approved product 0 Product quality 0 Incomming 0

P6 Process analysis / production

Process input Work content / process sequence

5.1.1 0 5.1.2 0 5.2.1 0 5.2.2 0 5.2.3 0 5.2.4 0 5.2.5 0

0

Project transfer Storaging 0 Control 0 Production 0 Significant 0 Labelling 0 Material 0

Developement/Serial 0 Basic material 0 plan 0 equipment 0 Characteristics 0 Parts; Scrab 0 Flow of material 0

Personnel resources Material resources

5.3.1 0 5.4.1 0 5.4.2 0 5.4.3 0 5.4.4 0

Employee 0 Maintenance 0 Measuring 0 Work place 0 Storaging 0

qualification 0 Maintenance 0 Testing 0 Inspection place 0 Tools/Mesurings 0

Process effectiveness level Process output

5.5.1 0 5.5.2 0 5.5.3 0 5.6.1 0

Objective product 0 Analysis;Root cause 0 Process/Product 0 Achievement Cust.- 0

Objective process 0 Effectiveness 0 Audits 0 requirements 0

P7 Customer support / customer satisfaction / service

6.1 0 6.2 0

QM-System 0 Parts 0

Dispatch 0 supply 0

Amount assessed RED 0 Barred supplier/tender: (1 X red or min. 15 X yellow)

Questions: YELLOW 0 Controlled supplier/tender: (max. 14 X yellow and no X red) Classification: GREEN

0 GREEN 0 Fully approved supplier/tender: (max 7 X yellow and no X red)

Pfad\376375993.xlsx \Assessement overview Speicherdatum: 01/11/2018

Erstellt: C-P-QM-QEM, Fr. Tauschke Seite 9 / 11

Revision 01 C-SQM_012

Potential Analysis

Qualification timing plan VDA-QMC

0 Contract: n/a

Timing Supplier/Tender

Activities Timing

Improvement program received 12/30/1899

I. Concretion and timing of the improvement program (14 days ) 1/13/1900

II. Realization of improvement program ( 12 weeks after award ) offen

III. Selfassessment according to VDA 6.3 ( only by "GREEN" and "YELLOW" if award is made ) 12 CW before SOP

Explanation

The activities must be realized immedeatelly. For large imprvement programs the realization can be subdivided in several

realization phases.

Selfassessment: to assess seriously the selfassessment, we ask for information about the audit timing (man days) and the

qualitfication of the auditors used. In our opinion the audit timing equates a timing of a certification audit. After receiving and

verifying the audit documents we will, if the result is classified as "A", agree our next audit timing. If trhe result is classified

as "B" we ask for realistic timing you will achieve an "A" classification. We expect then the ontime sending of the audit report

of the internals follow up audit, without any specific request from us.

Agreement of upgrade qualification:

Controlled suppliers / tenders commit themselves, after been awarded, to coorperate with an approved consulting company

by accpeting the upgrade qualification agreement. Costs will be carried by the supplier.

Auditor Auditor: Signature Supplier/ Tender

Pfad\376375993.xlsx \Upgrade qualification Speicherdatum: 01/11/2018

Erstellt: C-P-QM-QEM, Fr. Tauschke Seite 10 / 11

Revision 01 C-SQM_012

Potential Analysis

Improvement program potential analysis VDA-QMC

Supplier: 0 Date: 12/30/1899

Contract No: n/a

To be completed by auditor To be completed by audited organization

Ques. Weaknesses / recommanded actions, Actions and root cause analysis Respon- Effective-

Pos.

Timing

No. finding der Organisation sibility ness

Project management

1.1 0

1.2 0

1.3 0

1.4 0

1.5 0

1.6 0

1.7 0

Planning the product & process

development

2.1 0

2.2 0

Carrying out the product & process

development

3.1 0

3.2 0

3.3 0

Supplier management

4.1 0

4.2 0

4.3 0

4.4 0

4.5 0

Process analysis / production

5.1.1 0

5.1.2 0

5.2.1 0

5.2.2 0

5.2.3 0

5.2.4 0

5.2.5 0

5.3.1 0

5.4.1 0

5.4.2 0

5.4.3 0

5.4.4 0

5.5.1 0

5.5.2 0

5.5.3 0

5.6.1 0

Customer support / customer satisfaction /

service

6.1 0

6.2 0

Pfad\376375993.xlsx \Improvement plan Speicherdatum: 01/11/2018

Erstellt: C-P-QM-QEM, Fr. Tauschke Seite 11 / 11

Revision 01 C-SQM_012

You might also like

- Customer Complaint RegisterDocument3 pagesCustomer Complaint RegistermuthuselvanNo ratings yet

- PSW Signature TemplateDocument1 pagePSW Signature TemplateKM MuiNo ratings yet

- Supplier Apqp Basic TrgudhayDocument39 pagesSupplier Apqp Basic TrgudhayVasudev DevNo ratings yet

- Initial Product Quality Control ProcessDocument3 pagesInitial Product Quality Control ProcessSameer SaxenaNo ratings yet

- 8D Report for High Resistance Issue in Coil AssemblyDocument13 pages8D Report for High Resistance Issue in Coil AssemblyAnandha VasanNo ratings yet

- Delivered Voided Application (Surrender Instrument) Returned To at - Sik - Hata Nation of Yamasee MoorsDocument20 pagesDelivered Voided Application (Surrender Instrument) Returned To at - Sik - Hata Nation of Yamasee MoorsMARK MENO©™No ratings yet

- Documents - Pub Cqi 15 Welding Worksheets Process Tables 2Document55 pagesDocuments - Pub Cqi 15 Welding Worksheets Process Tables 2amirkhakzad498No ratings yet

- 8D-CAR CAP reportDocument4 pages8D-CAR CAP reportnugroho yuliantoNo ratings yet

- Process & Product AuditDocument17 pagesProcess & Product AuditPrakash kumarTripathiNo ratings yet

- First Article Inspection Report: Purchase Order Number Supplier NameDocument8 pagesFirst Article Inspection Report: Purchase Order Number Supplier NameTuff qualityNo ratings yet

- Blank Turtle DiagramDocument1 pageBlank Turtle DiagramnormalNo ratings yet

- Histogram X-Bar Chart: Company NameDocument1 pageHistogram X-Bar Chart: Company NameSachin RamdurgNo ratings yet

- Lean Training New PDFDocument93 pagesLean Training New PDFRagu RamsinghNo ratings yet

- Fiacbras (Bkq52) - 87271096 - Auditoria de Pcpa - RMDocument25 pagesFiacbras (Bkq52) - 87271096 - Auditoria de Pcpa - RMAtilio MendonçaNo ratings yet

- Paynter Chart With CCARDocument11 pagesPaynter Chart With CCARKhushboo RajNo ratings yet

- VDA FMEA TemplateDocument53 pagesVDA FMEA Templatewatna0% (2)

- Gap Analysis Vda Vs TsDocument4 pagesGap Analysis Vda Vs TsSeval GünaltayNo ratings yet

- 01 - Layered Process Audit Example B 2011Document7 pages01 - Layered Process Audit Example B 2011RN XaverNo ratings yet

- 8D Report: Vasanth - Production Engineer Vijaykumar - Quality Head Prabhakaran - Final in Charge Premkumar-CNC OperatorDocument4 pages8D Report: Vasanth - Production Engineer Vijaykumar - Quality Head Prabhakaran - Final in Charge Premkumar-CNC OperatorVasanth KumarNo ratings yet

- Iatf ActivitiesDocument6 pagesIatf ActivitiesWizard tube and Engineered componentNo ratings yet

- RMC Case StudyDocument2 pagesRMC Case StudyAmer RahmahNo ratings yet

- Production Part Approval ProcessDocument5 pagesProduction Part Approval Processapi-3701058No ratings yet

- Toolbox Meeting Or, TBT (Toolbox TalkDocument10 pagesToolbox Meeting Or, TBT (Toolbox TalkHarold PonceNo ratings yet

- APQP (27) ElementsDocument31 pagesAPQP (27) Elementssam1hi5No ratings yet

- 8D Report - FormatsDocument1 page8D Report - FormatsAbhinav SinghNo ratings yet

- IATF 16949 Nonconformity ManagementDocument8 pagesIATF 16949 Nonconformity ManagementAbhishek DahiyaNo ratings yet

- Development Time LineDocument1 pageDevelopment Time LineMohitrajranikashyapNo ratings yet

- PPAP Training OverviewDocument17 pagesPPAP Training OverviewRicky MarkNo ratings yet

- Escalation Procedure Updated 020915Document30 pagesEscalation Procedure Updated 020915Joezel Juaman Maglajos100% (1)

- GMs Drill Deep Read Across MatrixDocument10 pagesGMs Drill Deep Read Across MatrixJohn Oo100% (1)

- PDF Process Audit Vda 63Document9 pagesPDF Process Audit Vda 63Shahrazed ZineNo ratings yet

- Siegel Robert Automotive Layered Process Audit ChecklistDocument12 pagesSiegel Robert Automotive Layered Process Audit Checklistmahesh KhatalNo ratings yet

- Part Submission ChecklistDocument8 pagesPart Submission ChecklistGeovanny HernándezNo ratings yet

- Supplier Assesment MaxionDocument23 pagesSupplier Assesment Maxionesivaks2000No ratings yet

- Potential Analysis for VDA 6.3 Issue Level 2010Document11 pagesPotential Analysis for VDA 6.3 Issue Level 2010Luis Sosa100% (1)

- Aspen Plus Tutorial 5 Preparing and Configuring A Distillation Column Using RADFRACDocument13 pagesAspen Plus Tutorial 5 Preparing and Configuring A Distillation Column Using RADFRACRavi Kant TripathiNo ratings yet

- Repair and Modification of Printed Boards and Electronic AssembliesDocument6 pagesRepair and Modification of Printed Boards and Electronic AssembliesArvind NangareNo ratings yet

- DUPLICATE BILL TITLEDocument8 pagesDUPLICATE BILL TITLEMohammed AhmedNo ratings yet

- In House PPM MonitoringDocument2 pagesIn House PPM MonitoringSrinath NavadaNo ratings yet

- Tuv Rheinland Training Schedule 2017Document19 pagesTuv Rheinland Training Schedule 2017ramnathNo ratings yet

- Difference Between Rework Repair PDFDocument19 pagesDifference Between Rework Repair PDFRavichandranNo ratings yet

- Deviation Request: Deviation Request Is For Temporary Changes Only. Submission Is Only Valid With An 8D ReportDocument3 pagesDeviation Request: Deviation Request Is For Temporary Changes Only. Submission Is Only Valid With An 8D ReporttrungNo ratings yet

- Process Mix-ups and Documentation Errors IdentifiedDocument11 pagesProcess Mix-ups and Documentation Errors Identifiedr arumugamNo ratings yet

- 43.8D - 20456 - Cyl Bottom - Thread Perpendicular IssueDocument4 pages43.8D - 20456 - Cyl Bottom - Thread Perpendicular IssueVasanth KumarNo ratings yet

- APQP and PPAP ExplainedDocument3 pagesAPQP and PPAP ExplainedignaunaqNo ratings yet

- APQP TrackerDocument10 pagesAPQP TrackerBharathNo ratings yet

- Phased PPAP WarrantDocument2 pagesPhased PPAP WarrantVaspeoNo ratings yet

- Layered Process Audit Checklist (LPA)Document5 pagesLayered Process Audit Checklist (LPA)ALBERTO ALVARADO CARRILLONo ratings yet

- 5 Why WeldingRobot ToyotaDocument1 page5 Why WeldingRobot ToyotaMickloSoberanNo ratings yet

- Lessons learned from existing tie rod suppliesDocument1 pageLessons learned from existing tie rod suppliesR KumarNo ratings yet

- Standard STD 105-0007: Special CharacteristicsDocument11 pagesStandard STD 105-0007: Special CharacteristicsKrunal PandyaNo ratings yet

- Special Audit of Key Characteritics in Control Plan FAU-F-PSG-0800-En-4Document1 pageSpecial Audit of Key Characteritics in Control Plan FAU-F-PSG-0800-En-4KarlNo ratings yet

- ISO IATF 16949 Gap Tool b70944Document216 pagesISO IATF 16949 Gap Tool b70944SudhagarNo ratings yet

- pure cotton pvt ltd final inspection reportDocument4 pagespure cotton pvt ltd final inspection reportTarun PariharNo ratings yet

- 4m Change Before After FormatDocument3 pages4m Change Before After FormatpsathishthevanNo ratings yet

- 5j GM1927 84 Drill Deep Worksheet 12 Oct 04Document2 pages5j GM1927 84 Drill Deep Worksheet 12 Oct 04jesusmemNo ratings yet

- MAstering IATFDocument20 pagesMAstering IATFGyanesh_DBNo ratings yet

- Procedure For Set Up Approval, in Process & Final InspectionDocument7 pagesProcedure For Set Up Approval, in Process & Final InspectionRavi javaliNo ratings yet

- Fmea 39 PDF FreeDocument5 pagesFmea 39 PDF Freeahya azizahNo ratings yet

- Chintamani Metal 4M Change SheetDocument6 pagesChintamani Metal 4M Change Sheetcmu qmsNo ratings yet

- Statistical Process Control For Attribute Data (SPC)Document45 pagesStatistical Process Control For Attribute Data (SPC)RajanishshettyNo ratings yet

- Pfmea ExampleDocument5 pagesPfmea Exampleesivaks2000No ratings yet

- Project Management GuideDocument25 pagesProject Management GuideFad RizNo ratings yet

- VDAqmc2014 Engl DownloadDocument172 pagesVDAqmc2014 Engl DownloadLuis SosaNo ratings yet

- RARBGDocument1 pageRARBGLuis SosaNo ratings yet

- PDFDocument21 pagesPDFsekhargmNo ratings yet

- Cropprotectionequipment-Rocker Sprayer - Specification (: Indian StandardDocument9 pagesCropprotectionequipment-Rocker Sprayer - Specification (: Indian Standardgini associatesNo ratings yet

- Atpl Formula MergedDocument74 pagesAtpl Formula Mergeddsw78jm2mxNo ratings yet

- Finimpianti Power EngDocument2 pagesFinimpianti Power EngJosip GrlicaNo ratings yet

- Druckabschaltventil enDocument4 pagesDruckabschaltventil enSakthi Sekar CbiNo ratings yet

- Galvanized and Black Malleable Iron Pipe Fittings SpecificationsDocument24 pagesGalvanized and Black Malleable Iron Pipe Fittings SpecificationsdeniNo ratings yet

- DVOR Principle 코이카 양식Document71 pagesDVOR Principle 코이카 양식Undral Batbayar100% (1)

- CanReg5 InstructionsDocument150 pagesCanReg5 InstructionsdiyafersanNo ratings yet

- Vaje 3 - Macionis in PlummerDocument2 pagesVaje 3 - Macionis in PlummerLazar DjondricNo ratings yet

- Kerala University 2013 Admission ProspectusDocument50 pagesKerala University 2013 Admission ProspectusMuneer SainulabdeenNo ratings yet

- Chapter 1 Optical Fiber Transmission Media PDFDocument46 pagesChapter 1 Optical Fiber Transmission Media PDFGilang AnandaNo ratings yet

- Fish HatcheryDocument14 pagesFish HatcheryYared Mesfin FikaduNo ratings yet

- Trends in Structural Systems and Innovations for High-Rise Buildings over the Last DecadeDocument53 pagesTrends in Structural Systems and Innovations for High-Rise Buildings over the Last DecadeNarasimhaReddy PangaNo ratings yet

- Physical Layer:: SwitchingDocument27 pagesPhysical Layer:: SwitchingPKSachanNo ratings yet

- Veiga Et Al. 2015 - Composition, Structure and Floristic Diversity in Dense Rain Forest inDocument8 pagesVeiga Et Al. 2015 - Composition, Structure and Floristic Diversity in Dense Rain Forest inYakov Mario QuinterosNo ratings yet

- 5e Lesson Plan s16 - MagnetsDocument6 pages5e Lesson Plan s16 - Magnetsapi-317126609No ratings yet

- INJSO Answer Key & SolutionDocument5 pagesINJSO Answer Key & SolutionYatish Goyal100% (1)

- Me8072 Renewable Sources of EnergyDocument13 pagesMe8072 Renewable Sources of EnergyNallappan Rajj ANo ratings yet

- Active-Passive VoiceDocument18 pagesActive-Passive VoiceDivya JainNo ratings yet

- ZXJ 10 SPCDocument7 pagesZXJ 10 SPCMuhammad Yaseen100% (1)

- Basic Facts For Homebooks Stage 7Document3 pagesBasic Facts For Homebooks Stage 7api-311857762No ratings yet

- Development Drop - Number - Peformance - For - EstimateDocument11 pagesDevelopment Drop - Number - Peformance - For - Estimateanon_459056029No ratings yet

- Delhi University SEC Exam Date Sheet March 2023Document2 pagesDelhi University SEC Exam Date Sheet March 2023aamir9ali-42No ratings yet

- EN6VC IIIa 6.2 - 2023 2024Document2 pagesEN6VC IIIa 6.2 - 2023 2024Ma. Feliza SaliganNo ratings yet

- Efficacy of Platelet-Rich Fibrin On Socket Healing After Mandibular Third Molar ExtractionsDocument10 pagesEfficacy of Platelet-Rich Fibrin On Socket Healing After Mandibular Third Molar Extractionsxiaoxin zhangNo ratings yet

- Marketing Assignment (Cool Air India)Document10 pagesMarketing Assignment (Cool Air India)Mandira PantNo ratings yet