Professional Documents

Culture Documents

02 396 Zwicki PI E

Uploaded by

Usman HameedOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

02 396 Zwicki PI E

Uploaded by

Usman HameedCopyright:

Available Formats

Product Information

zwickiLine materials testing machines Z0.5 up to Z2.5

zwickiLine range with testControl II electronics zwickiLine with CE-compliant safety device

Range of application Innovative high-quality load-frame design

zwickiLine is a powerful, flexible and cost-effective • The new zwickiLine extruded profile possesses

testing solution for many different materials and compo- 6 continuous, freely accessible standard-profile

nents and is ideal for both research and development slots for individual mounting of specimen materials,

and routine quality assurance. A wide range of equip- fixtures, safety devices, accessories etc.

ment options allows zwickiLine to be used for tests on • The generous test-area depth enables larger fixtures

plastics, elastomers, metals, composites, paper, board, to be used and larger components tested, the wide

textiles, foams, foodstuffs and components. base crosshead enabling optimum securing and

retaining.

Made in Germany • High-quality machine design, including for example

zwickiLine, including all mechanical, electronic and soft- hard-wearing ceramic control buttons for the

ware components, together with the extensive range electronics, ensures a long service life.

of accessories are developed and produced at Zwick

Roell’s production facility in Germany and are therefore High stiffness and precision crosshead guide

ideally matched to each other. This means that The stiff load-frame profile and large connecting sur-

zwickiLine is an extremely high-quality product and also faces reduce the inclination angle of the crosshead

allows Zwick to offer the best possible support. under load, enabling very precise alignment and appli-

cation of force to the specimen. This is advantageous

Powerful drives for flexure tests, compression tests, precision tests on

Extremely low minimum speeds can be set, combined components etc.

with excellent speed-accuracy. The drive also delivers

high crosshead travel resolution; this is important in Safety for you and the entire testing system,

tests on components requiring a high degree of travel- and the modern safety device

precision and in tests on specimens with high levels of Features ensuring safety include the 2-channel (= dou-

stiffness and low travel, for example. ble safeguard) safety circuit, operating-mode selector-

switch and Drive Off switch. The operator is shielded

The high test speed range can be used without restric- from flying specimen fragments or other hazards by the

tion. In addition, test loads up to 110% of the machine CE-compliant safety device featuring a large test area,

nominal load are permissible to compensate for heavy transparent design and excellent accessibility.

combinations of test fixtures, accessories etc.

PI 396 2.0916

Product Information

zwickiLine materials testing machines Z0.5 up to Z2.5

Powerful, innovative testControl II electro- Built-in safety in accordance with EC Machine-

nics ry Directive

The statutory safety requirements of the EC Machinery

zwickiLine is equipped with testControl II digital mea- Directive are implemented in all Zwick machines, which

surement and control electronics, mounted vertically on are accompanied by an EC Declaration of Conformity

the load frame for better protection against ingress of on delivery. Only the latest safety technologies and pro-

liquids or conductive particles. ven industrial components are used. A very high level

of safety is guaranteed for user, test results, specimen

testXpert II – intelligent and reliable material and testing system.

testXpert II testing software and testControl II

electronics are perfectly matched, ensuring safe, Ergonomic remote control with display

efficient, reliable operation of the materials testing The entire test can be performed via the display-

machine. testXpert II offers the optimum solution for any equipped remote control unit, independently of the PC.

testing requirement. In addition, rapid, high-precision positioning is possible

via the rocker switch with integrated thumbwheel.

Eco mode

testControl II automatically switches to eco mode when

not in use, saving energy.

Overview of key advantages of testControl II electronics

Flexibility through modularity Fast, adaptive drive-controller

1- 6 testControl II provides 6 flexible, time-syn- The high drive control frequency of

chronized slots, enabling several sensors 1000 Hz enables fast, precise force and

to be in use at the same time, with monito- strain control. Benefits include enabling

ring and protection, regardless of use. components to be loaded very quickly and

accurately with the specified force.

Machine compliance correction In addition, all control parameters required

ST

The high-quality drive technology and on- for fast, accurate approach to target posi-

line machine compliance correction enable tions are automatically set, enabling time

Le L +∆ L

extremely accurate travel measurement and cost savings by eliminating the need

and positioning. for time-consuming pre-tests.

High data transmission rate

High data transmission rate (2000 Hz) Maximum accuracy

allows fast measurement combined with High (24-bit) measured-value resolution

maximum reproducibility. This is highly 24bit for maximum test-result accuracy and

advantageous for rapid tests, short brittle reproducibility. This means for example

fracture events and for tear growth, adhe- that even minimal force changes on the

sion and peel tests, for example. specimen can be recorded and displayed

accurately.

System monitoring Innovative interfaces

Detailed information regarding current E.g. time-synchronised EtherCat® bus sys-

status and usage level of testing equip- tem allows future-proof sensor integration

ment greatly simplifies processes such as to be taken for granted.

planning maintenance and spares/replace-

ment procurement.

Product Information

zwickiLine materials testing machines Z0.5 up to Z2.5

Data Value

Load frame

Finish RAL 7021 black grey and RAL 7037 dusty grey

Ambient temperature +10 ... +35 °C

Air humidity 20 ... 90 %

Conformity to ISO 9000 and CE

Antrieb

Motor DC servo-motor

Input signal, set-value preset digital

Controller / Cycle time adaptive / 1000 Hz

Positioning, repetition accuracy ±2 μm

Measurement and control electronics

Number of slots available for measurement 2 synchronized module bus slots (expandable to 5)(1

and control modules 1 synchronised PCIe slot

Force measurement Grade 0.5 / 1 see load cell, to

DIN EN ISO 75001, ASTM E4, JIS B7721

Measurement range up to 165 % of FN

Calculated resolution (e.g. in tensile / compression direction) 24 bit

Data acquisation rate, internal 400 kHz

Test data transmission rate to the PC 500 Hz (optional 2000 Hz)

Zeropoint correction automatic at start of measurement

Measurement signal runtime correction for all channels yes

Interface Ethernet

Power ratings

Electrical connections 100 ... 240 V (Wide-range input)

Range of tolerance ± 10 %

Power rating 0.5 kVA

Mains frequency 50/60 Hz

(1

A DCSC module is included in delivery (occupies one module bus slot). The drive occupies an optional module bus slot.

Options e.g.:

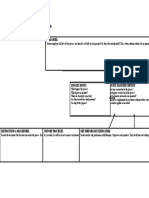

100 200 134

• Large base

• 2000 Hz online test data transmission

• Extension of the throat depth to 205 mm

• Increase of the speed to 3000 mm/min

(only for type Z0.5)

168

• Extension of the Electronics to six slots (measuring s

1289

channels) hmax

105

Accessories e.g.:

751

• Additional upper crosshead

• Extensometer 156 hmin

• Specimen grips 104

• Test tools 411 480

622

We would be glad to give you information to further options and accessories on request.

All data at ambient temperature. All rights reserved.

Type

Item number

058992

058993

058996

058997

058998

058999

059001

059003

059004

Z0.5 TS

Z1.0 TS

Z2.5 TS

Z0.5 TN

Z0.5 TH

Z1.0 TN

Z1.0 TH

Z2.5 TN

Z2.5 TH

Load frame

Test load FN in tensile/compression direction 0.5 0.5 0.5 1 1 1 2.5 2.5 2.5 kN

(1

Height ca. 789 1289 1589 789 1289 1589 789 1289 1589 mm

All data at ambient temperature.

Width(2 408 408 408 408 408 408 408 408 408 mm

Width (with electronics console)(2 411 411 411 411 411 411 411 411 411 mm

Depth(2 480 480 480 480 480 480 480 480 480 mm

(2

Depth (with electronics console) 622 622 622 622 622 622 622 622 622 mm

Product Information

Weight approx. (incl. electronics, without any accessories) 68 76 81 68 76 81 68 76 81 kg

Height of the test area hmin ... hmax:(3

angled moving crosshead mounted upwards 235 235 235 235 235 235 235 235 235

...565 ...1065 ...1365 ...565 ...1065 ...1365 ...565 ...1065 ...1365 mm

angled moving crosshead rotated 180° 90 90 90 90 90 90 90 90 90

(without accessories) ...420 ...920 ...1220 ...420 ...920 ...1220 ...420 ...920 ...1220 mm

Maximum travel (s) of the mounting square: if E < h min : s = hmax h min

if E > h min : s = hmax E

E = sum of the mounting dimensions of the complete testing equipment (load cell, specimen grips/testing device, mounting stud)

Width of the test area infinite

Throat depth (Test axis to profile) 105 105 105 105 105 105 105 105 105 mm

Noise level measured at maximum test speed 61 61 61 55 55 55 55 55 55 dB(A)

All rights reserved.

Drive system

Crosshead speed vmin ... vnom 0.0005 0.0005 0.0005 0.0005 0.0005 0.0005 0.0005 0.0005 0.0005

...2000(4 ...2000(4 ...2000(4 ...2000 ...2000 ...2000 ...1000 ...1000 ...1000 mm/min

Drive system’s travel resolution 0.0830 0.0830 0.0830 0.0554 0.0554 0.0554 0.0277 0.0277 0.0277 µm

zwickiLine materials testing machines Z0.5 up to Z2.5

Positioning, repetition accuracy ± 2 ± 2 ± 2 ± 2 ± 2 ± 2 ± 2 ± 2 ± 2 µm

(1

With option „Additional crosshead“ height is increased by 9 mm

(2

Width option „Large base“: Width 586 mm, Depth 565 mm, Depth with electonics console 707 mm

(3

See drawing on page 2

(4

With option the speed can be increased up to 3000 mm/min

You might also like

- SAM Project 1bDocument13 pagesSAM Project 1bNolan Blair0% (2)

- C27 and C32 Generator With EMCP4.2 Electrical SystemDocument2 pagesC27 and C32 Generator With EMCP4.2 Electrical SystemAngel BernacheaNo ratings yet

- Nitric Acid Production & PropertiesDocument50 pagesNitric Acid Production & PropertiesUsman Hameed100% (2)

- SOP - SoftwareTesting v1.1Document19 pagesSOP - SoftwareTesting v1.1Usman Hameed67% (3)

- 7 SurfactantsDocument76 pages7 SurfactantsUsman HameedNo ratings yet

- Manual CMC 356 OMICRONDocument12 pagesManual CMC 356 OMICRONRusber Michel Llama FloresNo ratings yet

- Din en Iso 2039 1 2003 PDFDocument10 pagesDin en Iso 2039 1 2003 PDFUsman HameedNo ratings yet

- Ledger - Problems and SolutionsDocument1 pageLedger - Problems and SolutionsDjamal SalimNo ratings yet

- Metering SystemsDocument3 pagesMetering SystemsmartinNo ratings yet

- Unitized Curtain Wall SystemDocument38 pagesUnitized Curtain Wall Systems.senthil nathan100% (1)

- 2017-Partial Discharge Seminar-Registration BookletDocument8 pages2017-Partial Discharge Seminar-Registration BookletfernandoquecaNo ratings yet

- Three Laws of RoboticsDocument2 pagesThree Laws of RoboticsBav VAansoqnuaetzNo ratings yet

- Cp-117-Project EngineeringDocument67 pagesCp-117-Project Engineeringkattabomman100% (1)

- 2017 Twinscrewextrusion Platsticstechnology 04-2017 enDocument6 pages2017 Twinscrewextrusion Platsticstechnology 04-2017 enUsman HameedNo ratings yet

- MethanolDocument27 pagesMethanolUsman HameedNo ratings yet

- How to Form Good Habits and Break Bad OnesDocument9 pagesHow to Form Good Habits and Break Bad OnesJason DavidNo ratings yet

- Instrument All SiemensDocument16 pagesInstrument All SiemensAmrina RosyadaNo ratings yet

- Revit Mep Vs Autocad MepDocument4 pagesRevit Mep Vs Autocad MepAbdelhameed Tarig AlemairyNo ratings yet

- YavorskyDocument544 pagesYavorskyFilipe PadilhaNo ratings yet

- ZwickiLine Z0 5 Up To Z5 0 Materials Testing Machine PI ENDocument10 pagesZwickiLine Z0 5 Up To Z5 0 Materials Testing Machine PI ENÁngel Rodríguez IsassiNo ratings yet

- 02 375 ProLine 2saeulig PI EDocument4 pages02 375 ProLine 2saeulig PI Ematias arnauNo ratings yet

- Pro LineDocument7 pagesPro LineRAB HFRNo ratings yet

- 02 396 Zwickiline Z0 5 Up To Z5 0 Materials Testing Machine PI ENDocument8 pages02 396 Zwickiline Z0 5 Up To Z5 0 Materials Testing Machine PI ENinfoNo ratings yet

- Zwick Roell Z600EDocument3 pagesZwick Roell Z600EDanijel HarastiNo ratings yet

- Duroline V Series: Hardness TestingDocument12 pagesDuroline V Series: Hardness TestingMinh TBB GlobalNo ratings yet

- Industrial Testing Brochure-041123Document20 pagesIndustrial Testing Brochure-041123elias MoulayNo ratings yet

- Powering Greater Productivity.: Waygate Technologies ISOVOLT Titan - Neo X-Ray GeneratorDocument8 pagesPowering Greater Productivity.: Waygate Technologies ISOVOLT Titan - Neo X-Ray GeneratorMarioNo ratings yet

- Industrial Series BrochureDocument16 pagesIndustrial Series BrochureLitarmjNo ratings yet

- 9 PRO Alpha550 ENDocument12 pages9 PRO Alpha550 ENZayene KhmaisNo ratings yet

- Duroline M Series: Hardness TestingDocument12 pagesDuroline M Series: Hardness TestingMinh TBB GlobalNo ratings yet

- Rexroth PS 6000 - The Integrated System for the Highest Quality in Resistance WeldingDocument12 pagesRexroth PS 6000 - The Integrated System for the Highest Quality in Resistance Weldinguriac86No ratings yet

- HA032952 - 4 - EPC3000 - Data SheetDocument12 pagesHA032952 - 4 - EPC3000 - Data SheetRavi Kant GuptaNo ratings yet

- Komax Alpha 550 1 30 T Fully Automatic Wire Processing MachineDocument12 pagesKomax Alpha 550 1 30 T Fully Automatic Wire Processing MachineZayene KhmaisNo ratings yet

- 1ST Series 2018 PDFDocument8 pages1ST Series 2018 PDFErnesto CorredorNo ratings yet

- Signal Conditioner: Clip. Measure. ControlDocument12 pagesSignal Conditioner: Clip. Measure. ControlMichael GuckesNo ratings yet

- WLR BrochureDocument12 pagesWLR Brochuresrinath rajaramNo ratings yet

- Em0 Table-Top Microtest EnglishDocument6 pagesEm0 Table-Top Microtest EnglishMIGUEL LOPEZNo ratings yet

- CMC 430 Brochure ENUDocument12 pagesCMC 430 Brochure ENUsteve_osullivanNo ratings yet

- TD25ST Model 25ST Electromechanical Materials Testing MachineDocument2 pagesTD25ST Model 25ST Electromechanical Materials Testing MachineMarcelo SánchezNo ratings yet

- IP HDV6 Spec Sheet Ray Ran USDocument3 pagesIP HDV6 Spec Sheet Ray Ran USمحمد مقلدNo ratings yet

- Reason RPV311: Grid SolutionsDocument8 pagesReason RPV311: Grid SolutionsAldo MolinariNo ratings yet

- YXLON MU2000 D With CTDocument8 pagesYXLON MU2000 D With CTXuân Đài 5.0 (xuandai.,ltd)No ratings yet

- EM1 Series Dual Column Tabletop & Floor Models With Central ActuatorDocument6 pagesEM1 Series Dual Column Tabletop & Floor Models With Central ActuatorMIGUEL LOPEZNo ratings yet

- Sensor Technology: With Modern Protection and Control IedsDocument2 pagesSensor Technology: With Modern Protection and Control IedsngocanhvyNo ratings yet

- Viscopro 2100 Brochure A4 LRDocument4 pagesViscopro 2100 Brochure A4 LRLuz Stella Calixto GomezNo ratings yet

- Omicron 2Document4 pagesOmicron 2kegiw15659No ratings yet

- Digital Direct-Residual Shear Apparatus Complete With Lever Loading Assembly. 220-240V 50-60Hz 1Ph.Document2 pagesDigital Direct-Residual Shear Apparatus Complete With Lever Loading Assembly. 220-240V 50-60Hz 1Ph.Supriyo PNo ratings yet

- Quasar 10 KNDocument1 pageQuasar 10 KNJuan Diego PeñaNo ratings yet

- Utm 4000Document4 pagesUtm 4000jean-pierre dalyNo ratings yet

- Omnicron Substation High Voltage CommissioningDocument16 pagesOmnicron Substation High Voltage CommissioningZahidul zahidNo ratings yet

- Mentor UT: A New Generation of Ultrasonic InspectionDocument8 pagesMentor UT: A New Generation of Ultrasonic InspectionMarioNo ratings yet

- WDW-50 Floor UTM-NS - With Screw Action Grip Rubber Grip and Long Travel ExtensometerDocument17 pagesWDW-50 Floor UTM-NS - With Screw Action Grip Rubber Grip and Long Travel Extensometerhuilemoteur2020No ratings yet

- Siemens Safety Relays PDFDocument18 pagesSiemens Safety Relays PDFkavan hNo ratings yet

- FLK 210604 en 190 III Ds WDocument12 pagesFLK 210604 en 190 III Ds WAmine Hadj HamidaNo ratings yet

- Catalaog Ipc-Utm 2019Document22 pagesCatalaog Ipc-Utm 2019fadil nasutionNo ratings yet

- Bolting Solutions: Manual Torque MultipliersDocument16 pagesBolting Solutions: Manual Torque MultipliersPhi LongNo ratings yet

- Digital Macro Hardness Tester with Precise SensorDocument4 pagesDigital Macro Hardness Tester with Precise Sensordinhhai1613No ratings yet

- SIRIUS Modular System - Brochure1Document6 pagesSIRIUS Modular System - Brochure1Tuhin SarkarNo ratings yet

- CCI 5000 Series In-Line Handler: TechnologyDocument8 pagesCCI 5000 Series In-Line Handler: TechnologymohamedNo ratings yet

- Br043008en Power Xpert CXHDocument20 pagesBr043008en Power Xpert CXHsabeerNo ratings yet

- p40 Agile Brochure en 33136 202005 LTR r0011 LRDocument8 pagesp40 Agile Brochure en 33136 202005 LTR r0011 LRAndrawina NarasuraNo ratings yet

- Quasar 2.5 kN Single Column Universal Testing MachineDocument1 pageQuasar 2.5 kN Single Column Universal Testing MachineJuan Diego PeñaNo ratings yet

- Filtronic Manufacturing Excellence Brochure CMD 003 Rev 2.1Document8 pagesFiltronic Manufacturing Excellence Brochure CMD 003 Rev 2.1maximusala83No ratings yet

- Duroline M Series: Hardness TestingDocument12 pagesDuroline M Series: Hardness Testingİlhan Burak ÖzhanNo ratings yet

- Trends in Hardness TestingDocument3 pagesTrends in Hardness TestingipraoNo ratings yet

- Servo-Pneumatic Drive Solution For Welding Guns: Sturdy and Precise!Document6 pagesServo-Pneumatic Drive Solution For Welding Guns: Sturdy and Precise!Irappa HosamaniNo ratings yet

- Duroline M enDocument12 pagesDuroline M enAl GCNo ratings yet

- Unimag Cyble MID Brochure EnglishDocument4 pagesUnimag Cyble MID Brochure EnglishdaskirNo ratings yet

- Recen RC A11 Pro Catalog - OptDocument7 pagesRecen RC A11 Pro Catalog - OptINFO TOP SKYNo ratings yet

- IPC UTM-Systems EN WEB 0516Document12 pagesIPC UTM-Systems EN WEB 0516Kiplagat ChelelgoNo ratings yet

- Electrospinning From The Laboratory: Rotary-Sliding Power Controlled Collector For Tubular DepositionsDocument5 pagesElectrospinning From The Laboratory: Rotary-Sliding Power Controlled Collector For Tubular Depositionsstefano.linari4029No ratings yet

- Mikrotron RUMULDocument8 pagesMikrotron RUMULBenito AllendesNo ratings yet

- Oil & Gas Floating Production SolutionsDocument24 pagesOil & Gas Floating Production SolutionsMikel IglesiasNo ratings yet

- 0 Pro C1370 enDocument6 pages0 Pro C1370 enDaniel GonzalezNo ratings yet

- ISO 9001 Certification and VDA 6.3 Audit Success for Kingfa EuropeDocument3 pagesISO 9001 Certification and VDA 6.3 Audit Success for Kingfa EuropeUsman HameedNo ratings yet

- PS - Country of Origin DeclarationDocument1 pagePS - Country of Origin DeclarationUsman HameedNo ratings yet

- How To Determine The Company Size CategoryDocument4 pagesHow To Determine The Company Size CategoryUsman HameedNo ratings yet

- EMS Objectives and Targets ReductionDocument1 pageEMS Objectives and Targets ReductionUsman HameedNo ratings yet

- Ps Nafta InstructionsDocument2 pagesPs Nafta InstructionsUsman HameedNo ratings yet

- PS - Country of Origin DeclarationDocument1 pagePS - Country of Origin DeclarationUsman HameedNo ratings yet

- Cavitation in Reciprocating Positive Displacement Pumps PDFDocument7 pagesCavitation in Reciprocating Positive Displacement Pumps PDFNagi NayakNo ratings yet

- Process Audit Turtle Diagram TemplateDocument1 pageProcess Audit Turtle Diagram TemplateUsman HameedNo ratings yet

- Torque and Speed How Much EnoughDocument5 pagesTorque and Speed How Much EnoughUsman HameedNo ratings yet

- REACH SummaryDocument5 pagesREACH SummaryUsman HameedNo ratings yet

- 2.008 03im 05S PDFDocument13 pages2.008 03im 05S PDFsilversky09No ratings yet

- MFR Testing Reveals Polymer MW RelationshipDocument26 pagesMFR Testing Reveals Polymer MW RelationshipUsman HameedNo ratings yet

- TroubleshooterDocument5 pagesTroubleshooterUsman HameedNo ratings yet

- Delrin Mold Guide 11 06Document48 pagesDelrin Mold Guide 11 06ibmufnman100% (2)

- A Guide To Polyolefin Injection MoldingDocument49 pagesA Guide To Polyolefin Injection Moldingsilversky09No ratings yet

- A Guide To Polyolefin Injection MoldingDocument49 pagesA Guide To Polyolefin Injection Moldingsilversky09No ratings yet

- Prevention FmeaDocument7 pagesPrevention FmeackopoletoNo ratings yet

- Role of Rheology in ExtrusionDocument25 pagesRole of Rheology in Extrusionmshussein2009No ratings yet

- RheologyDocument38 pagesRheologyKhairul Azman100% (1)

- A Study of Process Variability - Final DraftDocument9 pagesA Study of Process Variability - Final DraftUsman HameedNo ratings yet

- Delrin Mold Guide 11 06Document48 pagesDelrin Mold Guide 11 06ibmufnman100% (2)

- Maximizing ProductivityDocument78 pagesMaximizing ProductivityUsman HameedNo ratings yet

- Extrusion and Compounding ResearchDocument1 pageExtrusion and Compounding ResearchUsman HameedNo ratings yet

- Equilibrium of Supply and DemandDocument4 pagesEquilibrium of Supply and DemandJuina Mhay Baldillo ChunacoNo ratings yet

- Red Lion MP Sensor Product Manual PDFDocument2 pagesRed Lion MP Sensor Product Manual PDFJigneshNo ratings yet

- Big Bang TheoryDocument9 pagesBig Bang TheoryLoo DrBradNo ratings yet

- Introduction To Computing Week 2Document23 pagesIntroduction To Computing Week 2Jerick FernandezNo ratings yet

- Consumer Behavior, Market Segmentation and Marketing PlanDocument57 pagesConsumer Behavior, Market Segmentation and Marketing PlanShubhamNo ratings yet

- ZetaPlus EXT SP Series CDocument5 pagesZetaPlus EXT SP Series Cgeorgadam1983No ratings yet

- Best Practice Guidelines For Cardiac Rehabilitation and Secondary Prevention: A SynopsisDocument16 pagesBest Practice Guidelines For Cardiac Rehabilitation and Secondary Prevention: A SynopsisErdy VincentNo ratings yet

- The Syntactic Alignments Across Three-Ar PDFDocument441 pagesThe Syntactic Alignments Across Three-Ar PDFabiskarNo ratings yet

- ADTHEORENT SOTI Programmatic 102722Document20 pagesADTHEORENT SOTI Programmatic 102722chinmayNo ratings yet

- Adjectives For A Businessman 2023Document2 pagesAdjectives For A Businessman 2023elyvuujavierNo ratings yet

- UI Symphony Orchestra and Choirs Concert Features Mahler's ResurrectionDocument17 pagesUI Symphony Orchestra and Choirs Concert Features Mahler's ResurrectionJilly CookeNo ratings yet

- Technical Data Sheet 01DT-1L..: Type OverviewDocument4 pagesTechnical Data Sheet 01DT-1L..: Type OverviewJNo ratings yet

- Land, Soil, Water, Natural Vegetation& Wildlife ResourcesDocument26 pagesLand, Soil, Water, Natural Vegetation& Wildlife ResourcesKritika VermaNo ratings yet

- Shrub - Wikipedia, The Free EncyclopediaDocument5 pagesShrub - Wikipedia, The Free EncyclopediabmxengineeringNo ratings yet

- SAP Untangled: An Introductory Guide To SAP For New HomesDocument28 pagesSAP Untangled: An Introductory Guide To SAP For New HomestempuserNo ratings yet

- Nodal Officer Wise Student ListDocument48 pagesNodal Officer Wise Student ListguerellaNo ratings yet

- Impact of Aadhaar On Different Sectors of SocietyDocument5 pagesImpact of Aadhaar On Different Sectors of SocietyPunyak SatishNo ratings yet

- Pagewriter TC Cardiograph Service Manual Addendum Battery MaintenanceDocument9 pagesPagewriter TC Cardiograph Service Manual Addendum Battery MaintenanceCarlos ArturoNo ratings yet

- Grade 9 SyllabusDocument23 pagesGrade 9 SyllabusClopzNo ratings yet

- Anuj Singh ResumeDocument4 pagesAnuj Singh ResumeAnuj BaghelNo ratings yet

- Bangladesh Red Crescent Society First Aid Kit SpecificationDocument1 pageBangladesh Red Crescent Society First Aid Kit SpecificationWORLDWIDE TRANSLATIONNo ratings yet