Professional Documents

Culture Documents

Phoenix 7018 Phoenix 6013

Uploaded by

Pedro SilvaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Phoenix 7018 Phoenix 6013

Uploaded by

Pedro SilvaCopyright:

Available Formats

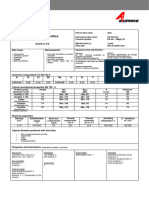

Phoenix 6013 Phoenix 7018

Covered electrode Covered electrode

Classifications EN 499 AWS A 5.1 Classifications EN 499 AWS A 5.1

E 42 0 RC 11 E6013 E 42 5 B 32 H5 E7018-1

Characteristics Basic covered electrode with very good welding characteristics

Characteristics Rutile cellulose covered electrode. and field of use including out of position work; weld metal recovery about

and field of use General purpose; useable in all positions; excellent gap-bridging 120 %; crack-free weld metal when welding high-carbon steels.

and arc-striking ability; for tack-welding and bad fit-ups; excel- Suitable for use in tank construction, boilermaking, apparatus

lent vertical down characteristics. engineering, vehicle manufacture and shipbuilding.

Redry for 2 h at 250-350 °C (482-662 °F).

Materials S235JRG2 - S355J2, GS-38, GS-45; P265 Materials S235JRG2 - S355J2, E295, E355, C 35; boiler steels P235GH,

boiler steels P235GH, P265GH, P295GH; shipbuilding steels P265GH, P295GH, P355GH; fine grained structural steels up to

corresp. to app.-grade 2; fine grained structural steels up to S420N; shipbuilding steels A, B, D, E; offshore steels;

P355N; weldable reinforcing steel bars pipe steels P265, P295; L290NB - L415NB,

L290MB - L415MB; X 42 - X 60; cast steel GS-38, GS-45,

GS-52;

Typical analysis C Si Mn

in % 0.09 0.35 0.50 Typical analysis C Si Mn

in % 0.07 0.35 1.20

Mechanical proper- Heat- Yield strength Tensile Elongation Impact values Mechanical proper- Heat- Yield strength Tensile Elongation Impact values

ties of the weld treatment 0.2 % strength (L0=5d0) in J treatment 0.2 % strength (L0=5d0) in J

ties of the weld

N/mm2 N/mm2 % CVN N/mm2 N/mm2 % CVN –50 °C

metal according metal according

to EN 1597-1 AW 420 510 22 50 to EN 1597-1 AW 420 510 25 120 47

(min. values at RT) (min. values at RT) SR 400 500 26 130 47

N 295 440 30 140

Welding position Polarity = – / ~ Welding position Polarity = + / ~

Approvals ABS (3H10/3Y) Controlas (0484)

Approvals ABS (Grade 2) DNV (3YH10) LR (3/3YH15) GL

LR (Grade 2/2Y)

DNV (Grade 2) Packaging, weights Dimensions (mm) pcs./pack kg/pack Amperage A

and amperages 2.5 x 350 200 4.2 65-100

3.2 x 350 110 4.3 100-145

Packaging, weights Dimensions (mm) pcs./pack kg/pack Amperage A 3.2 x 450 110 5.5 100-145

and amperages 2.5 x 350 279 5.0 70-110 4.0 x 350 80 4.5 135-200

3.2 x 350 173 5.0 110-160 4.0 x 450 80 5.8 135-200

4.0 x 350 113 5.0 140-200 5.0 x 450 55 5.7 180-280

5.0 x 450 80 6.9 170-280 6.0 x 450 40 7.0 240-375

62 Böhler Schweisstechnik Deutschland GmbH – 09_2005 Böhler Schweisstechnik Deutschland GmbH – 09_2005 63

You might also like

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- RISK ElevatorDocument4 pagesRISK ElevatordashNo ratings yet

- Diode, Transistor & Fet Circuits Manual: Newnes Circuits Manual SeriesFrom EverandDiode, Transistor & Fet Circuits Manual: Newnes Circuits Manual SeriesRating: 4.5 out of 5 stars4.5/5 (7)

- Api Spec 6a Annex M PDFDocument3 pagesApi Spec 6a Annex M PDFtoxicity23100% (2)

- Api Spec 6a Annex M PDFDocument3 pagesApi Spec 6a Annex M PDFtoxicity23100% (2)

- Geometry and Dimensional Tolerances of Engine BearingsDocument8 pagesGeometry and Dimensional Tolerances of Engine BearingsAnonymous K3FaYFlNo ratings yet

- Publication PDFDocument202 pagesPublication PDFYoucefChaabnaNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- (Iso/tr 17671-5) (Iso/tr 17671-6) (Iso/tr 17671-7) (Iso/tr 17671-8)Document1 page(Iso/tr 17671-5) (Iso/tr 17671-6) (Iso/tr 17671-7) (Iso/tr 17671-8)Ivan Briscoe100% (7)

- DevOps Culture Q&ADocument3 pagesDevOps Culture Q&APriti Sharma50% (2)

- Functional Safety and IEC 61508 A Basic Guide PDFDocument9 pagesFunctional Safety and IEC 61508 A Basic Guide PDFfitasmounirNo ratings yet

- Q4 Structural EngineerDocument4 pagesQ4 Structural Engineerpaul machariaNo ratings yet

- Haulotte Compact 8-10-12 Elec Scissor ManualDocument76 pagesHaulotte Compact 8-10-12 Elec Scissor Manualezeizabarrena96% (27)

- Haulotte Compact 8-10-12 Elec Scissor ManualDocument76 pagesHaulotte Compact 8-10-12 Elec Scissor Manualezeizabarrena96% (27)

- En 60974-4 2007 - Arc Welding EquipmentDocument18 pagesEn 60974-4 2007 - Arc Welding EquipmentPedro SilvaNo ratings yet

- En 60974-4 2007 - Arc Welding EquipmentDocument18 pagesEn 60974-4 2007 - Arc Welding EquipmentPedro SilvaNo ratings yet

- En 60974-4 2007 - Arc Welding EquipmentDocument18 pagesEn 60974-4 2007 - Arc Welding EquipmentPedro SilvaNo ratings yet

- Is 4326 2013Document35 pagesIs 4326 2013Harsh Machchhar100% (2)

- Astm A995 A995m 13 2013 PDFDocument4 pagesAstm A995 A995m 13 2013 PDFdelta lab sangli0% (1)

- Astm A479Document8 pagesAstm A479Orlando Rojas100% (3)

- A488Document18 pagesA488Pedro SilvaNo ratings yet

- En 1011 2 Welding RecommendationsDocument2 pagesEn 1011 2 Welding RecommendationsRam TN100% (1)

- Astm A217 A217m 2010 PDFDocument4 pagesAstm A217 A217m 2010 PDFPedro SilvaNo ratings yet

- Bohler-Welding-Germany 26Document1 pageBohler-Welding-Germany 26misthahNo ratings yet

- Barrettetig Catalogo Oerlikon 35035Document44 pagesBarrettetig Catalogo Oerlikon 35035mp303No ratings yet

- Fincord DB: MMA Electrodes C-MN and Low-Alloy SteelsDocument1 pageFincord DB: MMA Electrodes C-MN and Low-Alloy SteelsbrunizzaNo ratings yet

- Union TG 55 M: Classifications EN ISO 17632-A EN ISO 17632-B AWS A5.20Document2 pagesUnion TG 55 M: Classifications EN ISO 17632-A EN ISO 17632-B AWS A5.20brunizzaNo ratings yet

- FLUXOFIL 42 Cored Wires for High-strength SteelsDocument1 pageFLUXOFIL 42 Cored Wires for High-strength SteelskarthiksaadhanaNo ratings yet

- Fluxofil M42: Cored Wires High-Strength SteelsDocument1 pageFluxofil M42: Cored Wires High-Strength SteelsCristian BoselliNo ratings yet

- Fluxofil 41 (T 55 6 1nimo B M, C 3 h5)Document1 pageFluxofil 41 (T 55 6 1nimo B M, C 3 h5)brunizzaNo ratings yet

- Thermanit P23Document1 pageThermanit P23Branko FerenčakNo ratings yet

- Ficha Técnica CarborodDocument1 pageFicha Técnica CarborodAndres NuñezNo ratings yet

- PDS - Bohler N ER 70 S-2 NACE PDFDocument1 pagePDS - Bohler N ER 70 S-2 NACE PDFwesley59No ratings yet

- Bohler-Welding-Germany 207Document1 pageBohler-Welding-Germany 207Anghelache RazvanNo ratings yet

- Union MV Mo and RV 71 Flux Cored WiresDocument1 pageUnion MV Mo and RV 71 Flux Cored WiresAnghelache RazvanNo ratings yet

- Supercito (E 42 5 B 32 h5)Document1 pageSupercito (E 42 5 B 32 h5)brunizzaNo ratings yet

- SUPERCITO MMA Electrodes for Structural and Heavy WorkDocument1 pageSUPERCITO MMA Electrodes for Structural and Heavy Workantonio111aNo ratings yet

- EJ Handbook.A5Document261 pagesEJ Handbook.A5ElMacheteDelHuesoNo ratings yet

- Tenacito 70Document1 pageTenacito 70Luis Angel Unocc FernandezNo ratings yet

- Bohler Fox S Ev 50: Stick Electrode, Unalloyed BasicDocument1 pageBohler Fox S Ev 50: Stick Electrode, Unalloyed Basickiki270977No ratings yet

- Böhler Er 70 S-2Document1 pageBöhler Er 70 S-2brayanNo ratings yet

- Tencord KB (E 42 4 Z B 42 h5)Document1 pageTencord KB (E 42 4 Z B 42 h5)brunizzaNo ratings yet

- Böhler Eas 2 PW-FDDocument1 pageBöhler Eas 2 PW-FDHAKANNo ratings yet

- Böhler Cat 409 Cb-Ig: Classifi CationsDocument1 pageBöhler Cat 409 Cb-Ig: Classifi CationsBranko FerenčakNo ratings yet

- Flux Cored Arc Welding for Low Carbon 18%Cr-12%Ni-2%Mo Stainless SteelDocument1 pageFlux Cored Arc Welding for Low Carbon 18%Cr-12%Ni-2%Mo Stainless Steelmohamed AdelNo ratings yet

- Flexal 80Document1 pageFlexal 80joseNo ratings yet

- Boehler CN 23 12 PW-FDDocument1 pageBoehler CN 23 12 PW-FDbrayanNo ratings yet

- 11042016000000T - Thermanit 22 - 09 - Tig RodDocument1 page11042016000000T - Thermanit 22 - 09 - Tig RodKonrad MatuszkiewiczNo ratings yet

- Flux Cored Arc Welding for Stainless SteelDocument1 pageFlux Cored Arc Welding for Stainless SteelMohd Farid OsmanNo ratings yet

- Cored Wires For CMN & Low Alloy Steels: Oerlikon Fluxofil 14 HDDocument3 pagesCored Wires For CMN & Low Alloy Steels: Oerlikon Fluxofil 14 HDBranko FerenčakNo ratings yet

- Böhler Ti 2 Ni T-FD: Seamless Cored WireDocument2 pagesBöhler Ti 2 Ni T-FD: Seamless Cored WireThanh TamNo ratings yet

- DATASHEET WELDING CONSUMABLE - ESAB OK Tubrod 15.15-Rev14Document2 pagesDATASHEET WELDING CONSUMABLE - ESAB OK Tubrod 15.15-Rev14Dries VandezandeNo ratings yet

- B - Boehler NiMo 1-IG - de - en - 5Document1 pageB - Boehler NiMo 1-IG - de - en - 5cristian popescuNo ratings yet

- Citoflux R82 SR Cored Wires for Low-Temperature Welding of C-Mn and Low-Alloy SteelsDocument1 pageCitoflux R82 SR Cored Wires for Low-Temperature Welding of C-Mn and Low-Alloy SteelsbrunizzaNo ratings yet

- High corrosion resistant stick electrode for duplex and lean duplex alloysDocument1 pageHigh corrosion resistant stick electrode for duplex and lean duplex alloyscristian popescuNo ratings yet

- NiCrFe alloy welding electrodeDocument1 pageNiCrFe alloy welding electrodeRoberto_PrrNo ratings yet

- Supercito E: MMA Electrodes C-MN and Low-Alloy SteelsDocument1 pageSupercito E: MMA Electrodes C-MN and Low-Alloy Steelsantonio111aNo ratings yet

- Section 2 - Nikko Welding ConsumablesDocument9 pagesSection 2 - Nikko Welding Consumablesangga franugrahaNo ratings yet

- Pr01, Pr02, Pr03: Vishay BccomponentsDocument19 pagesPr01, Pr02, Pr03: Vishay BccomponentsGabriel pedrosaNo ratings yet

- Cw008a Cu-Of Version1Document1 pageCw008a Cu-Of Version1Gaka RtaNo ratings yet

- 29102015000000B - Boehler DCMS-IG - SWDocument1 page29102015000000B - Boehler DCMS-IG - SWErdinc BayatNo ratings yet

- 29102015000000B - Boehler DCMS-IG - SWDocument1 page29102015000000B - Boehler DCMS-IG - SWErdinc BayatNo ratings yet

- SMAW Bohler Fox S EV 50 1 E7018 1H4RDocument1 pageSMAW Bohler Fox S EV 50 1 E7018 1H4RYoga ArdiansyahNo ratings yet

- UNION ER90S-B3 TIG rodDocument1 pageUNION ER90S-B3 TIG rodbrayanNo ratings yet

- 29102015000000B - Boehler CN 22 9 N-IG - TRDocument1 page29102015000000B - Boehler CN 22 9 N-IG - TRAnibal QuezadaNo ratings yet

- Cored Wires for High Toughness Welding of C-Mn and Low-Alloy SteelsDocument1 pageCored Wires for High Toughness Welding of C-Mn and Low-Alloy SteelsCristian BoselliNo ratings yet

- UTP 6222 MoDocument1 pageUTP 6222 ModantegimenezNo ratings yet

- 6063 ProfilesDocument1 page6063 ProfilesBPP-Tech PythonNo ratings yet

- Standards Approvals & Certificates: Rmrs Ce DNV-GL LR Classnk Tuv BV Abs Rina TL DBDocument2 pagesStandards Approvals & Certificates: Rmrs Ce DNV-GL LR Classnk Tuv BV Abs Rina TL DBKhaled GamalNo ratings yet

- Boehler EAS 4 M-IG - Tig RodDocument1 pageBoehler EAS 4 M-IG - Tig RodbrayanNo ratings yet

- Shield - Bright 2209 FCAW (!)Document2 pagesShield - Bright 2209 FCAW (!)rajNo ratings yet

- Conarc 49C: Basic ElectrodeDocument2 pagesConarc 49C: Basic ElectrodeMark Williams100% (1)

- Electroced LB52Document1 pageElectroced LB52ramadh diyyazNo ratings yet

- Ga-24 Aws E7024Document1 pageGa-24 Aws E7024Bang OchimNo ratings yet

- Ok 67.67 Esab 309Document1 pageOk 67.67 Esab 309Sadashiva sahooNo ratings yet

- Böhler Ti 60 T-FD: Seamless Cored WireDocument2 pagesBöhler Ti 60 T-FD: Seamless Cored WireMilos StoisavljevicNo ratings yet

- Stainless SteelDocument1 pageStainless SteelSadashiva sahoo100% (1)

- Böhler CM 2-Ig: Solid Wire, Low-Alloyed, Creep ResistanceDocument1 pageBöhler CM 2-Ig: Solid Wire, Low-Alloyed, Creep ResistancecocoNo ratings yet

- ZXDocument6 pagesZXPedro SilvaNo ratings yet

- 1Document1 page1Pedro SilvaNo ratings yet

- ZXDocument6 pagesZXPedro SilvaNo ratings yet

- 1 AsdDocument1 page1 AsdPedro SilvaNo ratings yet

- 13 PDFDocument14 pages13 PDFPedro SilvaNo ratings yet

- Poldi Impact Hardness Tester PoldihammerDocument2 pagesPoldi Impact Hardness Tester PoldihammerPedro SilvaNo ratings yet

- ZXDocument6 pagesZXPedro SilvaNo ratings yet

- Poldi Impact Hardness Tester PoldihammerDocument2 pagesPoldi Impact Hardness Tester PoldihammerPedro SilvaNo ratings yet

- Catalago Balanca and GR200Document19 pagesCatalago Balanca and GR200Pedro SilvaNo ratings yet

- Catalago Balanca AND GR200 PDFDocument74 pagesCatalago Balanca AND GR200 PDFPedro SilvaNo ratings yet

- Catalago Balanca AND GR200 PDFDocument74 pagesCatalago Balanca AND GR200 PDFPedro SilvaNo ratings yet

- GSR 300eDocument25 pagesGSR 300ePedro SilvaNo ratings yet

- EurotrodDocument76 pagesEurotrodPedro SilvaNo ratings yet

- User Manual Redpoint - PirometroDocument13 pagesUser Manual Redpoint - PirometroPedro SilvaNo ratings yet

- User Manual Redpoint - PirometroDocument13 pagesUser Manual Redpoint - PirometroPedro SilvaNo ratings yet

- BooksDocument1 pageBooksraghavendrarh6464No ratings yet

- Resume of JmarinkovichDocument3 pagesResume of Jmarinkovichapi-24545587No ratings yet

- Who Is An EngineerDocument64 pagesWho Is An EngineerFinney WilsonNo ratings yet

- Vineet Soam resume oil gas internshipDocument2 pagesVineet Soam resume oil gas internshipMANISH SARASWATNo ratings yet

- 2019 2020 Degree Checklist BEng SpaceDocument2 pages2019 2020 Degree Checklist BEng Spacetysonlit27No ratings yet

- PT Astra Honda MotorDocument12 pagesPT Astra Honda MotorharmokoNo ratings yet

- How To Build A RailwayDocument4 pagesHow To Build A RailwayRavidu LakshanNo ratings yet

- Sure-Stop PVC Waterstop BrochureDocument4 pagesSure-Stop PVC Waterstop Brochuremyke_0101No ratings yet

- Comparing CMGC and ECI Project Delivery MethodsDocument15 pagesComparing CMGC and ECI Project Delivery MethodsReyLeonNo ratings yet

- ABB AquaprobeDocument7 pagesABB AquaprobelrpatraNo ratings yet

- 175-026600 10312016Document2 pages175-026600 10312016Prasanna UmapathyNo ratings yet

- 2018 SeismicwindforcesDocument622 pages2018 SeismicwindforcesTerry TriestNo ratings yet

- CCE Certification FlowchartDocument1 pageCCE Certification FlowchartonixexenNo ratings yet

- Specialized Architectural ServicesDocument48 pagesSpecialized Architectural ServicesMyla BarbsNo ratings yet

- ASi-Collapse Analysis of RC AssembliesDocument14 pagesASi-Collapse Analysis of RC AssembliesMuhannad AbdulRaoufNo ratings yet

- BEng EEDocument12 pagesBEng EEJimmy NeoNo ratings yet

- Iffat Abdullah Mahmood Al-HamdaniDocument2 pagesIffat Abdullah Mahmood Al-Hamdanisteev24No ratings yet

- Resume Electrical Engineer HR-Ref#EE-SSM-1602 GLPT April 28 2016Document2 pagesResume Electrical Engineer HR-Ref#EE-SSM-1602 GLPT April 28 2016Bishwa Pokharel0% (1)

- Package II Part I.4.1 BOQ SumpDocument4 pagesPackage II Part I.4.1 BOQ Sumpdox4useNo ratings yet

- Software Engineering Course MaterialDocument29 pagesSoftware Engineering Course Materialvikas desaleNo ratings yet

- Additions, AlterationsDocument4 pagesAdditions, AlterationsTan ChingNo ratings yet

- Appendix oDocument22 pagesAppendix oAlex Joshua MaglasangNo ratings yet