Professional Documents

Culture Documents

QUAD QHD-7 Instruction Leaflet

Uploaded by

Ivan ValentićCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

QUAD QHD-7 Instruction Leaflet

Uploaded by

Ivan ValentićCopyright:

Available Formats

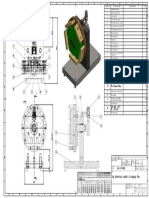

QHD-7 "NANO" HYDRAULIC DISC BRAKE SYSTEM

NO Des. Q'ty NO Des. Q'ty

1 6

QHD-7 “NANO” 11 QHD-7 “NANO”

1. MC assembly 1 7. Caliper assembly 1

2. Reservior cap 1 8. Blanking cap 1

3 3. Torque screw 1 9. O ring 1

2

4. Clamp 1 10. Brake pads 2

9

4 5. Clamp bolts 2 8 7 11. Bleeding grub screw 1

6. Push rod 1 10

Picture 1 Picture 2 Picture 3 5

□ STANDARD FITTINGS

1. QHD-7 "NANO" caliper is compatible with POST MOUNT forks with a distance between mounting of

74.2mm. It can be converted to International Standard by using our front and/or rear adaptor brackets.

2. Mounting bolts: M6 x 18mm (incl. Washer) x 4pcs.

3. Disc rotor:φ160 for the front and φ140 for the rear; using adaptor brackets, it can be φ180 for the front

and φ160 for the rear or φ203 for the front and φ180 for the rear.

4. Rotor screws: 6 pcs.

□ RELATED MOUNTING SPECIFICATIONS

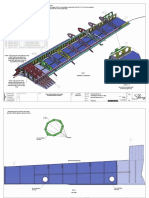

1. Specifications of front fork and rear dropout

QHD-7 "NANO" is compatible to International Standard and POST MOUNT forks,

see drawings below:

5.3°

Picture 4 Picture 5 Picture 6

φ6.2±0.1

51

±0

.1

φ6.2±0.1

5

0.

.1

0±

±0

14

7.3

φ

R8

74 .2±0. 1

.1

R

. 1

78

5 1±0

±0

.1

.7

±0

9

R4

.1

R3

9.9

±0

.1

φ1 6 0

±0 .5

φ1 6 0

±0 .5

5 5 .9

2. Hub

Picture 7 Picture 8 Picture 9

The offset of the hubs for QHD-7 "NANO" disc brake system is the same as SHIMANO

specifications, see drawings below: B

HUB A B

Front hub 10.5 (15.3min)

rear hub 15.25 (15.3min)

A

3. Caliper

Picture 10 Picture 11 Picture 12 QHD-7 "NANO" caliper is completely sealed, and has been tested to take high pressure. DO NOT

loosen any screw/bolt on the caliper (the grub screw can be loosened only when changing brake fluid);

otherwise it could cause leaking and consequently no braking.

*Warning:No brake fluid leaking is allowed. Riding should be stopped at once when there is leaking.

Repairing should be performed by qualified dealers!

4. Rotor

QHD-7 "NANO" rotor specifications are φ160X1.8mm( thickness) for front,φ140X1.8mm for rear.

They can be φ180X1.8mm for front,φ160X1.8mm for rear or φ203X1.8mm for front,φ180X1.8mm for

rear when using adaptor brackets.

*Warning:1. Under normal riding condition, there will be slight wear on the rotor, wear will be greater

after more braking. Therefore it is required to check the wear on rotor regularly. The disc

rotor should be changed when it has been deformed or worn excessively.

2. After a long time and or intensive braking, the temperature of the rotor becomes high. Do

Picture 13 Picture 14 Picture 15 not touch the rotor.

-4- IN-BB-QD7-001 -1-

□ ASSEMBLY .

*Warning:As the disc pads are self-adjusting, DO NOT pull the brake lever before it is fully assembled 1. Tools:

with the rotor in the caliper slot. The more pulls on brake lever without the rotor in the caliper ‧Empty container( for used fluid) ‧DOT#4 fluid kit

slot makes the gap between disc pads becomes too narrow. Use the spacer provided with ‧T 10 Torque key (BMC screw) ‧2.5 mm Allen key (Caliper bleed grub screw)

the bike to insert in between the pads and push them back to attain the ideal gap. ‧QBK-05 twin syringe kit ‧Plastic insert

I、Assemble the BMC bracket onto the handle bar. ‧Clean water and a cloth

II、Use the 6 rotor screws( T25 Torque key, torque 40~50 kgf-cm ) to tighten the disc rotor onto the disc hub.

※Caution: 2. Remove the caliper from front fork or dropout, and keep the torque screw on the BMC in an upper

1. Follow the arrow mark for rotor direction. horizontal position.

2. The 6 rotor screws must be tightened before riding. 3. Remove the bleeding grub screw from the caliper by using a 2.5mm Allen key. See picture ..6

3. The 6 rotor screws should be tightened in a diagonal sequence. 4. Insert a flat blade screwdriver between the disc pads then lever the pads fully back into the piston

4. The 6 rotor screws should be replaced after disassembly for 3-4 times as the Nylok will not function housings. Place the thickest edge of plastic insert in-between the center of disc pads. It is important

correctly. that the pads are fully pushed into the piston housings when bleeding the system. See picture ..7

III、Assemble the wheel onto the front fork or rear dropout and tighten the screws or QR. 5. Connect the plastic tube with the appropriate M5 adaptor screw for the caliper to the syringe.

IV、Assemble the caliper onto the front fork or rear dropout.: 6. Draw up the DOT #4 brake fluid from the bottle and ensuring there are no air pockets.

1. International standard fork: 7. Screw the M5 adaptor into the caliper finger tight. See picture ..8

Tighten the front or rear adaptor bracket onto the front fork or dropout.( Use 2pcs M6×18mm bolts, 8. Remove the torque screw on the upper side of the BMC. See picture ..9

torque 60±5 kgf-cm ). 9. Connect the plastic tube with the appropriate M5 adaptor screw for the BMC to the syringe.

Mount the caliper to the adaptor bracket with 2pcs M6×18 bolts.( DO NOT TIGHTEN THE BOLTS, so 10. Screw the M5 adaptor into the BMC finger tight. See picture ..10

that the caliper can move freely on the bracket ) 11. Start bleeding:

2. MANITOU fork: a) Keeping the caliper at the lowest possible position relative to the BMC, inject approximately all the

Mount the caliper to the MANITOU fork with 2pcs M6 x 18 bolts. ( DO NOT TIGHTEN THE BOLTS, so fluid in the caliper syringe until it fills the BMC syringe.

that the caliper can move freely on bracket ) b) When the fluid runs clear (no bubble or dirt) in the BMC syringe, remove the BMC syringe and

V、 Pull the brake lever to make the disc pads clamp to the disc rotor ( caliper will self adjust alignment ),then adaptor and replace the torque screw. (10 kgf-cm torque). See picture ..11

tighten the 2pcs M6 bolts. c) Remove the caliper syringe and M5 adaptor and replace the bleeding grub screw and tighten to

VI、 Spin the wheel to make sure the disc rotor is clear to disc pads. If it is not clear then slack the bolts and 40-45 kgf-cm torque. See picture ..12

redo step V above. 12. Wash any excess fluid from the BMC and caliper with clean water. See picture ..13

VII、 Adjust the reach of brake lever on the BMC with 2mm Allen key. ( Clockwise, for larger angle; 13. Insert the plastic insert between the pads and pump the BMC lever until the pads close inwards. Keep

Anti-clockwise, for smaller angle ). pumping until the lever feels firm against the plastic insert.

VIII、Test riding: 14. Remove the plastic insert and slide the caliper onto the rotor and screw in the 2pcs M6x 18 bolts but

Braking force on the first 10~30 pulls is not as powerful.( New disc pads need to be bedded in ) not fully tightened, still allowing the caliper to move freely side to side.

〔*Warning:Do not ride at high speed when doing test riding, keep safe distance.〕 15. Pump the BMC lever until the pads clamp the rotor. Whilst maintaining the pressure, screw the 2pcs

M6x 18 bolts tightly to the mounting bracket. See picture ..14

□MAINTENANCE 16. Should the lever on the BMC pull back too far, repeat the bleeding process as above. See picture ..15

I. Changing disc pads: III、Shortening the hose:

QHD-7 'NANO' hydraulic caliper is designed with self-adjustment disc pad function, No pad 1. Tools:

adjustment is required before the disc pads are worn out. It is required to stop riding and change ‧8mm open-ended wrench ‧Hose cutter or sharp knife

new disc pads when the brake lever needs to be pulled with a large travel to stop the bike or there is ‧QBK-02 shortening kit ‧Clean water and a cloth

noise between the disc pads and rotor. ※ Hose must be of correct specification.

*Warning:Keep the disc pads free from oil or grease; otherwise it will cause no braking. 2. Cutting hose:

1. Remove the wheel. a) Re-route the hose to approximately the length required from caliper end and then marked with a pen.

2. Insert a flat blade screwdriver between the disc pads then lever the pads fully back into the b) Slide back the rubber hose cone past the cutting mark.

piston housings. See picture ..1 c) Using the 8mm open-ended wrench unscrew the compression nut from the BMC.

3. Remove the used disc pads out through slot. See picture ..2 d) Pull the hose out of the BMC and ensuring the hose remains higher at all times than the caliper.

4. Place new disc pads into the disc pad housings making sure the legs are located in appropriate e) Slide the compression nut past the marked length.

slots. See picture ..3 f) Trim the hose to the position previously marked, slide on the new compression bush from the

5. Insert the plastic insert between the pads and pump the BMC lever until the pads close inwards. shortening kit with the chamfered end to the hose, insert the hose end fitting pushing fully into the

Keep pumping until the lever feels firm against the plastic insert. See picture ..4 hose upto the shoulder, place the rubber O ring on the end of hose end fitting.

6. Remove the plastic insert and put the wheel back on the fork or dropout and tighten. See picture ..5 g) Re-insert the hose into the BMC pushing firmly home, slide the compression nut and screw into the

7. Spin the wheel and make sure it is clear between the rotor and disc pads. If it doesn't clear, BMC. Tighten the compression nut with an 8mm open-ended wrench to between 50 -60 kgf-cm

redo the step VI in Assembly as above. torque.

※Caution : h) Slide the rubber hose cone over the compression nut.

1. Braking force on the first 10~30 pulls is not as powerful.( New disc pads need to be bedded in ) Standard hose length of QHD-7 'NANO': for front →1000mm

Do not ride at high speed when doing test riding, keep a safe distance. for rear →1550mm

2. It is normal that there might be braking noise in the wet. The noise will disappear after the disc

pads become dry.

Compression nut

Brake hose Compression bush

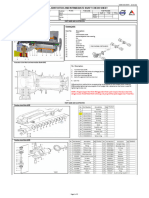

II、Changing brake fluid: Hose cone

QHD-7 'NANO' hydraulic disc brake uses Fuchs DOT#4 brake fluid. Other branded DOT#4 brake Hose insert

fluid is compatible. O ring

*Warning:1. Never add or mix with other mineral oil or other than DOT#4 fluid as it will cause damage to

the seals in the system and cause failure of braking.

2. Brake fluid absorbs moisture after a period of time, which will reduce its boiling

temperature. Brake fluid should be changed in 2 years to avoid poor braking.

3. Brake fluid causes irritation to the skin, avoid direct contact the brake fluid. chamfered end

Run water onto the skin if in contact with brake fluid.

IV. Changing hose:

Please contact a qualified dealer for correct replacement accessories.

-2- -3-

You might also like

- Vacon 100 and 100 FLOW Installation Manual DPD0087 PDFDocument118 pagesVacon 100 and 100 FLOW Installation Manual DPD0087 PDFVinicius AlmeidaNo ratings yet

- Instructions For Use: ES350 - ES361Document86 pagesInstructions For Use: ES350 - ES361Rmk HsdNo ratings yet

- Kioti Daedong EX50, EX55, EX5310, EX5810 Tractors Service Manual 04-2019Document19 pagesKioti Daedong EX50, EX55, EX5310, EX5810 Tractors Service Manual 04-2019LisakolyNo ratings yet

- GtFs Builder TemplateDocument97 pagesGtFs Builder TemplateSummer HirschfieldNo ratings yet

- Dyna DM2800 SchematicsDocument4 pagesDyna DM2800 SchematicsRamon Hernandez100% (1)

- Gp1a70r 71RDocument7 pagesGp1a70r 71RVinicius BorbaNo ratings yet

- GP1A70R/GP1A71R: OPIC Photointerrupter With Encoder FunctionsDocument6 pagesGP1A70R/GP1A71R: OPIC Photointerrupter With Encoder FunctionsOleg StrashenkoNo ratings yet

- Project 4Document12 pagesProject 4bijinder06No ratings yet

- DatasheetDocument1 pageDatasheetCesra HMNo ratings yet

- Your Single Source Worldwide: Isolated Phase Bus SystemsDocument15 pagesYour Single Source Worldwide: Isolated Phase Bus Systemssameerray12100% (1)

- Assembly Jig PolygoneDocument1 pageAssembly Jig PolygoneClaudius Barenta BarusNo ratings yet

- Sling Aircraft Construction Manual Web SampleDocument6 pagesSling Aircraft Construction Manual Web SampleFilip DvoracekNo ratings yet

- EagleBurgmann_H75VN_ENDocument3 pagesEagleBurgmann_H75VN_ENlamtony2013No ratings yet

- 10 Spare Parts List: Item Quanti Ty NameDocument2 pages10 Spare Parts List: Item Quanti Ty NamePappa Anton FlorinNo ratings yet

- PC929 - Ic On Line - CNDocument6 pagesPC929 - Ic On Line - CNOrgil-erdene YadamsurenNo ratings yet

- MVP380 Shaft PartsDocument1 pageMVP380 Shaft PartsJuan AcostaNo ratings yet

- LL9DJUU Mechanical SealDocument2 pagesLL9DJUU Mechanical SealMayur PattanshettiNo ratings yet

- B750VN Single Seals: API 682 Seals For Pumps - Standard Cartridge SealsDocument4 pagesB750VN Single Seals: API 682 Seals For Pumps - Standard Cartridge SealsLuis BassoNo ratings yet

- WHEATLEY® Series 500 Swing Check Valve: Installation, Operation, and Maintenance ManualDocument9 pagesWHEATLEY® Series 500 Swing Check Valve: Installation, Operation, and Maintenance ManualWill Freddy MartinezNo ratings yet

- Cylinder Catalogue V21 V32 - Zonder LogoDocument19 pagesCylinder Catalogue V21 V32 - Zonder LogoHernan CortezNo ratings yet

- Bore Gauge Manual PDFDocument2 pagesBore Gauge Manual PDFLU CK YNo ratings yet

- Co., LTD.: WH2002A Character 20x2Document1 pageCo., LTD.: WH2002A Character 20x2Jesus AlfonzoNo ratings yet

- Split Pins Dimensions and Tolerances GuideDocument1 pageSplit Pins Dimensions and Tolerances GuidePedroFarfanMartelNo ratings yet

- PC3Q66QDocument5 pagesPC3Q66QTronix RepaireNo ratings yet

- TM21 Service-ManualDocument48 pagesTM21 Service-ManualRômulo MagalhãesNo ratings yet

- 1 A 05Document4 pages1 A 05ciremanNo ratings yet

- 8x2 LCD DatasheetDocument1 page8x2 LCD DatasheetSENTES CONSTANTIN100% (1)

- Keystone Manual Operator Twin Grip F415Document2 pagesKeystone Manual Operator Twin Grip F415Robi KeiNo ratings yet

- Mesin Pencacah Rumput (DWG)Document1 pageMesin Pencacah Rumput (DWG)Muhamad HudaNo ratings yet

- RC1602D DatasheetDocument1 pageRC1602D DatasheetAmr Ayuob SalemNo ratings yet

- Operation Bulletin Style: BCG 7 STYLE Name Foam Padded Des: Molded Parameters IED 600 100% 79% 17 Est Time SAMDocument10 pagesOperation Bulletin Style: BCG 7 STYLE Name Foam Padded Des: Molded Parameters IED 600 100% 79% 17 Est Time SAMgouthamShetty DNo ratings yet

- Schott Brochure Schott Vials English Us 20092017Document28 pagesSchott Brochure Schott Vials English Us 20092017Tomena ÁkosNo ratings yet

- Installation Instruction: 7/16 DIN Female 7/16 DIN Male N Type Male N Type FemaleDocument2 pagesInstallation Instruction: 7/16 DIN Female 7/16 DIN Male N Type Male N Type FemalenguyentraihdNo ratings yet

- An7511 PDFDocument10 pagesAn7511 PDFVenancio GutierrezNo ratings yet

- TSB201801001Document2 pagesTSB201801001Víctor FaríasNo ratings yet

- PFI Housing Filter Cartridge High FlowDocument3 pagesPFI Housing Filter Cartridge High Flowbennypartono407No ratings yet

- Neoasia Training Center: Hydraulic Bottle JackDocument1 pageNeoasia Training Center: Hydraulic Bottle JackdimasNo ratings yet

- WEG w22 Brake Motors European Market 50051533 Brochure English Web PDFDocument28 pagesWEG w22 Brake Motors European Market 50051533 Brochure English Web PDFSudin SyamsudinNo ratings yet

- Klinger: Instructions For Installation and Operation ofDocument8 pagesKlinger: Instructions For Installation and Operation ofluiz vagner pereiraNo ratings yet

- Pro - Super H Maintenance ManualDocument20 pagesPro - Super H Maintenance ManualSivaNo ratings yet

- Saw parts listDocument9 pagesSaw parts listMuhammad Nur FauziNo ratings yet

- Hitch A35EDocument5 pagesHitch A35EImam MuhhudaNo ratings yet

- 'NEC 2581 OptoCoupler PDFDocument12 pages'NEC 2581 OptoCoupler PDFRichard KrillNo ratings yet

- EAO Series 71 Full Data PDFDocument32 pagesEAO Series 71 Full Data PDFAidolan UlrichNo ratings yet

- Robot base bottom view and dimensionsDocument2 pagesRobot base bottom view and dimensionsVickocorp SlpNo ratings yet

- MODEL 1900D Airliner: Maintenance ManualDocument3 pagesMODEL 1900D Airliner: Maintenance ManualAdel KhelifiNo ratings yet

- Angle Straight MFV - LQDocument2 pagesAngle Straight MFV - LQelias garibayNo ratings yet

- Grundfosliterature 4055021Document32 pagesGrundfosliterature 4055021parthivNo ratings yet

- Raystar Optronics, Inc.: RC2002A Character 20x2Document1 pageRaystar Optronics, Inc.: RC2002A Character 20x2Zeyad AymanNo ratings yet

- 186-Car Alcohol Tester PDFDocument1 page186-Car Alcohol Tester PDFzulNo ratings yet

- Floefd Validation Examples: Your Initials, Presentation Title, Month YearDocument21 pagesFloefd Validation Examples: Your Initials, Presentation Title, Month YearVictor HuertaNo ratings yet

- C7 EngineDocument2 pagesC7 EngineOli MijanaNo ratings yet

- 320653NECDocument15 pages320653NECTeyfik koyuncuNo ratings yet

- Turbo Levo SL Alloy Schematics 1Document11 pagesTurbo Levo SL Alloy Schematics 1Simon ChoeNo ratings yet

- Datasheet Butterfly Valve Type 567 - 578 (EN)Document40 pagesDatasheet Butterfly Valve Type 567 - 578 (EN)Omar GuillenNo ratings yet

- Service and Operating Instruction: Mi-512 ENDocument16 pagesService and Operating Instruction: Mi-512 ENanastasios filiosNo ratings yet

- Ee Ferrite Core Coil Formers: Core Type Partnumber Product DescriptionDocument26 pagesEe Ferrite Core Coil Formers: Core Type Partnumber Product DescriptionRudi AnotheerNo ratings yet

- Doodle Bot Instruction ManualDocument12 pagesDoodle Bot Instruction ManualPepe DoserNo ratings yet

- Extec Pitbull Parts Manual - EnglishDocument77 pagesExtec Pitbull Parts Manual - EnglishadasrafalskiNo ratings yet

- Api 623 Cast Steel Globe Valve: Installation, Operation and Maintenance ManualDocument20 pagesApi 623 Cast Steel Globe Valve: Installation, Operation and Maintenance ManualFahmi HaidiNo ratings yet

- Cum Sa Tai Template MicrosimDocument0 pagesCum Sa Tai Template MicrosimrusuclaudiuionutNo ratings yet

- Rotary Polisher Guide for Paint Correction and High Gloss FinishingDocument70 pagesRotary Polisher Guide for Paint Correction and High Gloss FinishingIvan ValentićNo ratings yet

- Welding ProcessDocument6 pagesWelding ProcessIvan ValentićNo ratings yet

- AC DC Power SuppliesDocument20 pagesAC DC Power SuppliesIvan ValentićNo ratings yet

- Hexlogic Guide 2Document1 pageHexlogic Guide 2Ivan ValentićNo ratings yet

- Quick Setup for P-660HW-D ADSL RouterDocument13 pagesQuick Setup for P-660HW-D ADSL RouterIvan ValentićNo ratings yet

- Welding ProcessDocument6 pagesWelding ProcessIvan ValentićNo ratings yet

- Siemens SX763 ManualDocument192 pagesSiemens SX763 ManualIvan ValentićNo ratings yet

- Kaminester, David D. - ADHD and Methylphenidate. When Society Misunderstands MedicineDocument10 pagesKaminester, David D. - ADHD and Methylphenidate. When Society Misunderstands MedicineStefan IonNo ratings yet

- Hydraulic Disc Pads BrochuresDocument7 pagesHydraulic Disc Pads BrochuresIvan ValentićNo ratings yet

- Meritor ManualDocument192 pagesMeritor ManualJanisse B. Padilla100% (1)

- Electronics and Wiring Diagram EPA13 Part 1 PDFDocument32 pagesElectronics and Wiring Diagram EPA13 Part 1 PDFIvan Valentić0% (1)

- On Being Liked On The Web and in The "Real World": Consistency in First Impressions Across Personal Webpages and Spontaneous BehaviorDocument4 pagesOn Being Liked On The Web and in The "Real World": Consistency in First Impressions Across Personal Webpages and Spontaneous BehaviorIvan ValentićNo ratings yet

- Giant Conduct SL User's ManualDocument10 pagesGiant Conduct SL User's ManualRicardo RegoNo ratings yet

- Disc Brake Components and OperationDocument8 pagesDisc Brake Components and OperationJhomz BaldrezNo ratings yet

- Why Brake Fluid It Is ImportantDocument5 pagesWhy Brake Fluid It Is ImportantengrsurifNo ratings yet

- كتاب صيانة النظام الهيدروليكي للفراملDocument47 pagesكتاب صيانة النظام الهيدروليكي للفراملEcu RepairNo ratings yet

- 2.1 Definisi Rem ABS (Anti Lock Brake System) : Bab Ii Dasar TeoriDocument5 pages2.1 Definisi Rem ABS (Anti Lock Brake System) : Bab Ii Dasar TeoriMuhammad Arif Nur HudaNo ratings yet

- Brakepads 2005Document84 pagesBrakepads 2005Marco AraújoNo ratings yet

- Honda CR-V 2007 Front Bearing Replacement PartsDocument2 pagesHonda CR-V 2007 Front Bearing Replacement PartsBrumeNo ratings yet

- Front Disc Runout Check (70.12.15.01)Document4 pagesFront Disc Runout Check (70.12.15.01)Richard Andrianjaka LuckyNo ratings yet

- Blockdiagram Absd Lf45lf55 4s4m 0519Document1 pageBlockdiagram Absd Lf45lf55 4s4m 0519VladimirNo ratings yet

- Brake Part SectionDocument47 pagesBrake Part SectionKevin WellsNo ratings yet

- Braking Systems - Past Present & FutureDocument6 pagesBraking Systems - Past Present & FutureAkshat SharmaNo ratings yet

- Trotinete Electrice 2019Document9 pagesTrotinete Electrice 2019Popescu RaduNo ratings yet

- BR-M315 SM-RT10 SM-BH59 SM-RT26: Disc BrakeDocument1 pageBR-M315 SM-RT10 SM-BH59 SM-RT26: Disc BrakenNo ratings yet

- Honda Civic EXDocument34 pagesHonda Civic EXJacinto BlancoNo ratings yet

- Pathfinder 2005 - Parking BrakeDocument10 pagesPathfinder 2005 - Parking BrakePaper-FaceNo ratings yet

- Konpar 2018 KatalogDocument92 pagesKonpar 2018 KatalogEndeveurs AlienNo ratings yet

- Parking Brake Overhaul GuideDocument19 pagesParking Brake Overhaul GuideMusat Catalin-Marian100% (2)

- Hawassa University Designs Automatic Emergency Braking SystemDocument25 pagesHawassa University Designs Automatic Emergency Braking SystemYosef TesfayeNo ratings yet

- Parking Brake System: SectionDocument8 pagesParking Brake System: Sectiontipo3331No ratings yet

- Online Test Series and Study Material for Mining ExamsDocument54 pagesOnline Test Series and Study Material for Mining Examsanirudh subbuNo ratings yet

- Brake System Definition Function Types and Applications With PDFDocument13 pagesBrake System Definition Function Types and Applications With PDFAbdulaziz AbdullahiNo ratings yet

- 206-03 Front Disc Brake - Removal and Installation - Brake PadsDocument4 pages206-03 Front Disc Brake - Removal and Installation - Brake PadsCARLOS LIMADANo ratings yet

- BMW ETK InfoDocument3 pagesBMW ETK InfoKifah ZaidanNo ratings yet

- Drum Brakes PDFDocument20 pagesDrum Brakes PDFLuis Oswaldo R PNo ratings yet

- Materi Safety Riding Honda TangerangDocument26 pagesMateri Safety Riding Honda TangerangKusuma Cheep Liiss100% (2)

- Sri Kandi 050717Document14 pagesSri Kandi 050717Fajar Ardy NugrohoNo ratings yet

- Sensotronic Brake Control (SBC) : Purpose and FunctionDocument2 pagesSensotronic Brake Control (SBC) : Purpose and FunctionChandan C RNo ratings yet

- Floating Caliper Vs Fixed Caliper OperationDocument3 pagesFloating Caliper Vs Fixed Caliper OperationRoyal ENo ratings yet

- Braking SystemDocument25 pagesBraking SystemKarani AbrahamNo ratings yet

- Hydraulic Braking System: Prepared by Roshan Kumar Bisoyi Branch-Mechanical 4 SemDocument10 pagesHydraulic Braking System: Prepared by Roshan Kumar Bisoyi Branch-Mechanical 4 SemRoshan kumar BisoyiNo ratings yet