Professional Documents

Culture Documents

Ows Esd Unit XXX

Uploaded by

harmlesdragonOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ows Esd Unit XXX

Uploaded by

harmlesdragonCopyright:

Available Formats

WELL TESTING OPERATIONS: Surface Well Testing Equipment WELL TESTING OPERATIONS: Surface Well Testing Equipment

Well Testing Equipment Catalogue Surface Well Testing Equipment . Well Testing Equipment Catalogue Surface Well Testing Equipment .

EMERGENCY SHUT DOWN (ESD) CONTROL PANEL Specification – ESD Unit

Oiltest’s E. S. D. Panels offer a portable and fast

response well head shut down system. Dual outlet ESD System VALVES

An E.S.D. control panel is a vital piece of well test Maximum Allowable Hydraulic W.P.: 10000 psig Fluid Inlet: 2” 600# RF flange Balon Ball Valve

safety equipment, designed to pick up an emergency Maximum Allowable Pneumatic W.P.: 150 psig Oil Outlet: 3” 150# RF flange Butterfly Valve

signal from any of the E.S.D. remote stations located on Nominal pneumatic O.P.: 90 psig Bypass line: 2” 600# RF flange Balon Ball Valve

all the well test equipment. Design Temperature: -50°F to 250°F Drain line: 2” 150# RF flange Butterfly Valve

ESD System response time: 3 Secs.

When a remote station is activated, the pneumatic (air) CONNECTIONS

pressure is bled off. The gate valve held in open MATERIALS

position by hydraulic/spring actuator bleeds down Fluid Inlet: 2” # 150 RF flange x 2” fig 602

hydraulic back to the panel reservoir in a closed circuit Housing/tank reservoir: Stainless Steel female

and the valve on spring will force the gate to close. Only Fluid Outlet: 3” # 150 RF flange x 3” fig 206

air is bled to the atmosphere, no spill of hydraulic oil. SYSTEM DESIGN FEATURES Drain line: 3” # 150 RF flange x 3” fig 206 male

ESD is designed to work with ESD control Panel.

Air operated dual pump system MISCELLANEOUS

Typical ESD response time is 3 seconds.

Control valves, gauges on front panel Temperature Indicator points:3/4” NPT female x 2”

150# RF flange

The E.S.D. unit is sized for the surface flowhead ESD CONTROL PANEL

Single reservoir Fluid sampling points: 3/4” NPT female x 2”

pressure rating and hydraulic actuator swept volume.

Pumps complete with lever attachment to 150# RF flange

Specification – ESD Panel facilitate manual operation

Air filter DIMENSIONS

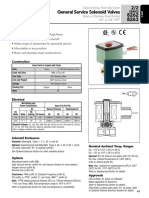

Service & Supply & Pump Type & Valves Reservoir Cabinet Dimensions Weight Inlet mains air pressure regulator and gauge

Output Pilot Ratio Capacity Material hxlxw Pump control pressure regulator and gauge Weight: 3787 kg (Skid & Empty Vessel)

Pressure Pressure Pilot line air pressure regulator

Psi Psi U.S. Galls ins lbs

(bar) (bar) (litres) (mm) (kgs) Pilot line air throttle choke control valve

Pilot line system charge button

Standard & 150 Manual Relay: 8 316 stn stl 18.12 x 22.215 x 18.25 120

Pilot line bulkhead fitting, quick connect fittings 6mm

10,000 (10.3) Hand, lever Low press’ manual (30.28) (460 x 565 x 464) (55)

(690) operated & auto. Panel Emergency stop button

ESD override valve

Auto Hydraulic control: Hydraulic and Pneumatic circuit gauges

1 x Haskel M-110 High press’ 3 - way

Hydraulic relief valve

Ratio Relief H.P: Air and Hand operated high pressure release valves

Air : hydraulic 10,000 psi stn stl High pressure bulkhead connector, 1/4” NPT.

1 : 110 Control panel ESD valve and 5 stainless remote ESD

Relief L.P:

1.0 psi valve units.

Check:

10,000 psi stn stl

www.oiltestgroup.com www.oiltestgroup.com

You might also like

- Electric Actuated Butterfly Valves: FeaturesDocument7 pagesElectric Actuated Butterfly Valves: FeaturesRicardo NapitupuluNo ratings yet

- Precision Plumbing Products: "Specify With Confidence - Install With Pride"Document2 pagesPrecision Plumbing Products: "Specify With Confidence - Install With Pride"Janavi RajaganapathyNo ratings yet

- wateer hamer arestoDocument2 pageswateer hamer arestozaidabusamaha95No ratings yet

- HD 247 Alarm Valve Model-HDocument16 pagesHD 247 Alarm Valve Model-HMinhthien NguyenNo ratings yet

- Data Sheet Avdo Automatic By-Pass Valve: ApplicationDocument4 pagesData Sheet Avdo Automatic By-Pass Valve: ApplicationganaaNo ratings yet

- Alarm Valve: Model-H (Ductile Iron)Document16 pagesAlarm Valve: Model-H (Ductile Iron)Karen IsananNo ratings yet

- Alarm Valve Detects Fires QuicklyDocument16 pagesAlarm Valve Detects Fires QuicklyChiranjeev NathNo ratings yet

- 13049-03-MIS-003 - Well Head Control PanelsDocument12 pages13049-03-MIS-003 - Well Head Control PanelsJuan Pablo Sanchez MelgarejoNo ratings yet

- Asco Minature PSOL ValvesDocument1 pageAsco Minature PSOL Valvesinstrumed_globalNo ratings yet

- Direct acting directional control valveDocument8 pagesDirect acting directional control valveVendas HidrautrônicaNo ratings yet

- ALARM VALVE TECHNICAL DATADocument14 pagesALARM VALVE TECHNICAL DATARolandNo ratings yet

- Instalación Krk3011a0600h - 01Document2 pagesInstalación Krk3011a0600h - 01Ranses RomanNo ratings yet

- SMC ATEX en - 50 VFEDocument8 pagesSMC ATEX en - 50 VFEmohammedNo ratings yet

- System Sensor Pressure Switch Model EPS40-2Document2 pagesSystem Sensor Pressure Switch Model EPS40-2Brandon TrocNo ratings yet

- HarmanKardon AVR347 7.1 RecDocument218 pagesHarmanKardon AVR347 7.1 RecBill MathesNo ratings yet

- Deluge Valve - SD-DVA PDFDocument15 pagesDeluge Valve - SD-DVA PDFboxyfunNo ratings yet

- Service Manual: Harman/kardonDocument130 pagesService Manual: Harman/kardoncharlyvega100% (3)

- Seawater Service Pressure Relief Valve: ModelDocument2 pagesSeawater Service Pressure Relief Valve: ModelHemant RasamNo ratings yet

- Deluge Valve Installation ManualDocument7 pagesDeluge Valve Installation Manualrahull.miishraNo ratings yet

- J8328A-E-DS-15069 Rev B1 Datasheet for 60kV Gas Insulated Switchgear (GIS)Document5 pagesJ8328A-E-DS-15069 Rev B1 Datasheet for 60kV Gas Insulated Switchgear (GIS)ABDELKADERNo ratings yet

- Avr 700Document60 pagesAvr 7001ostb0y n3v3rlandNo ratings yet

- 115-25Document2 pages115-25fernando.juarezpetroserviciosNo ratings yet

- European Instruction Manual Series 215 Solenoid Valve Gas Shut Off de de 5288058Document4 pagesEuropean Instruction Manual Series 215 Solenoid Valve Gas Shut Off de de 5288058Sergio RodriguezNo ratings yet

- 14706347-22 Process Control Philosophy - Rev5 - For RFQDocument9 pages14706347-22 Process Control Philosophy - Rev5 - For RFQHawk MrNo ratings yet

- The Harman Kardon Avr335Document127 pagesThe Harman Kardon Avr335samNo ratings yet

- Harman Kardon Avr-2600 SMDocument216 pagesHarman Kardon Avr-2600 SMCarollyne SabioniNo ratings yet

- AVR125 Service Manual: Harman/kardonDocument83 pagesAVR125 Service Manual: Harman/kardonjoeNo ratings yet

- 95C 10831Document4 pages95C 10831sandesh sawateNo ratings yet

- Miniature Solenoid Valve For Analytical Applications: Type 200Document4 pagesMiniature Solenoid Valve For Analytical Applications: Type 200Francisco Mones RuizNo ratings yet

- System - Rated - Plus - W - Sub - 150 Water Hammer PPPDocument2 pagesSystem - Rated - Plus - W - Sub - 150 Water Hammer PPPJeffry GabilanNo ratings yet

- Paar-B: Potter Automatic Air ReleaseDocument3 pagesPaar-B: Potter Automatic Air ReleaseCesar GonzalesNo ratings yet

- Harman Kardon hs300 SM PDFDocument109 pagesHarman Kardon hs300 SM PDFboroda2410No ratings yet

- 3-Way Flow Control Valves: 1 DescriptionsDocument6 pages3-Way Flow Control Valves: 1 Descriptionsmuhammad taufik rahmanNo ratings yet

- Harman Kardon AVR 645 Service ManualDocument139 pagesHarman Kardon AVR 645 Service ManualAlaa KanjNo ratings yet

- Avr 240Document155 pagesAvr 240botelhodurskiNo ratings yet

- 0hulgldq &rqwuro 6/Vwhpv 'HvfulswlrqDocument2 pages0hulgldq &rqwuro 6/Vwhpv 'Hvfulswlrqrichr49No ratings yet

- Harman Kardon AVR-1700Document97 pagesHarman Kardon AVR-1700jose valderiNo ratings yet

- Mokon: Central Chillers and Pump TanksDocument4 pagesMokon: Central Chillers and Pump Tanksbird99No ratings yet

- Techniical DetailDocument42 pagesTechniical DetailAhmed AbdelgawadNo ratings yet

- IMI Herion Double Valve Series XSZDocument7 pagesIMI Herion Double Valve Series XSZShigueo EnamotoNo ratings yet

- CW-3000 Industrial Chiller User ManualDocument7 pagesCW-3000 Industrial Chiller User ManualMalick SyNo ratings yet

- Instructions 100504-1Document2 pagesInstructions 100504-1Maxwell VargasNo ratings yet

- 2.-Catalogue - Chardon Korea Group (CKGR)Document5 pages2.-Catalogue - Chardon Korea Group (CKGR)Martin RodriguezNo ratings yet

- Harman/Kardon AVR 254 Service Manual)Document189 pagesHarman/Kardon AVR 254 Service Manual)jrubins100% (1)

- Valves Deluge Valve Model h3-bkp-03-04-2018Document16 pagesValves Deluge Valve Model h3-bkp-03-04-2018Benny Kurniawan LimNo ratings yet

- Aviation Fueling Two-Stage Preset Valve Model 115-25Document2 pagesAviation Fueling Two-Stage Preset Valve Model 115-25varadarajck893No ratings yet

- Safgard 500 600 700 Instructions 050919 WebDocument4 pagesSafgard 500 600 700 Instructions 050919 Webzidan080606No ratings yet

- Specification 33KV GIS ZX0.2Document16 pagesSpecification 33KV GIS ZX0.2BADRI VENKATESHNo ratings yet

- Deluge Valve Model-H2: HD Fire Protect Pvt. Ltd. (Cast Steel) Technical DataDocument16 pagesDeluge Valve Model-H2: HD Fire Protect Pvt. Ltd. (Cast Steel) Technical DataNethajiNo ratings yet

- MagmaDocument3 pagesMagmaСергей ПетровскийNo ratings yet

- WFDEN Series Waterfl Ow DetectorDocument4 pagesWFDEN Series Waterfl Ow Detectorioan cristian cotorobaiNo ratings yet

- Direct Acting Solenoid Valves SpecificationsDocument4 pagesDirect Acting Solenoid Valves SpecificationsjiseobNo ratings yet

- DV Fast TrackDocument8 pagesDV Fast Tracker3456dfNo ratings yet

- TFV Series CatalogueDocument4 pagesTFV Series CatalogueNiranjan NagellaNo ratings yet

- Ss 03034Document4 pagesSs 03034Necati Yunus OrbayNo ratings yet

- Subplate Mounting ISO 4401-03 P Max Bar Max L/min: Mounting Interface Operating PrincipleDocument18 pagesSubplate Mounting ISO 4401-03 P Max Bar Max L/min: Mounting Interface Operating PrincipleCarlos AugustoNo ratings yet

- V5329A TWDocument4 pagesV5329A TWS M NaveedNo ratings yet

- Section 3 Surge ArrestorsDocument14 pagesSection 3 Surge Arrestorsthumula.rameshNo ratings yet

- Power Distribution SystemDocument9 pagesPower Distribution SystemDiosdado ReynaNo ratings yet

- Wall Sleeves: Pipe A-44Document4 pagesWall Sleeves: Pipe A-44perezismaelNo ratings yet

- 3329245Document10 pages3329245Giuseppe FerrariNo ratings yet

- Flexible Duct in A Trench: InstallationDocument1 pageFlexible Duct in A Trench: InstallationharmlesdragonNo ratings yet

- FPM1100 Basic Design PrinciplesDocument8 pagesFPM1100 Basic Design PrinciplesharmlesdragonNo ratings yet

- RPPF SizesDocument8 pagesRPPF SizesharmlesdragonNo ratings yet

- FPM1100 Basic Design PrinciplesDocument8 pagesFPM1100 Basic Design PrinciplesharmlesdragonNo ratings yet

- ATS Four Types of AtsDocument2 pagesATS Four Types of AtsSzynrd Yrojo100% (1)

- MEDELEC Automatic Transfer Switch SDocument7 pagesMEDELEC Automatic Transfer Switch SharmlesdragonNo ratings yet

- Hewitt Trade Services Sandgate 4017 DocumentDocument1 pageHewitt Trade Services Sandgate 4017 DocumentharmlesdragonNo ratings yet

- ELECTRICAL POWER SYSTEM OVERCURRENTS Chap2Document6 pagesELECTRICAL POWER SYSTEM OVERCURRENTS Chap2giolgau01No ratings yet

- Lec 25Document19 pagesLec 25deciohNo ratings yet

- Safe Work Method Statement - Service: Date Created: Approved By: Review DateDocument2 pagesSafe Work Method Statement - Service: Date Created: Approved By: Review DateharmlesdragonNo ratings yet

- Duct and Conduit PDFDocument41 pagesDuct and Conduit PDFsorry2qazNo ratings yet

- Eyewash Station: Requirements For Eyewash Stations in Standby Battery RoomsDocument1 pageEyewash Station: Requirements For Eyewash Stations in Standby Battery RoomsmealysrNo ratings yet

- EyeWAsh RequirementsDocument5 pagesEyeWAsh RequirementsharmlesdragonNo ratings yet

- ACpower PDFDocument4 pagesACpower PDFnwnwasdNo ratings yet

- Safe Work Method Statement - Service: Date Created: Approved By: Review DateDocument2 pagesSafe Work Method Statement - Service: Date Created: Approved By: Review DateharmlesdragonNo ratings yet

- Self Excitation Concerns XXXDocument4 pagesSelf Excitation Concerns XXXharmlesdragonNo ratings yet

- Electrical Technical DataDocument1 pageElectrical Technical DataharmlesdragonNo ratings yet

- Motor Start Current DetectionDocument18 pagesMotor Start Current Detectionramjaya165No ratings yet

- Self Excitation Concerns XXXDocument4 pagesSelf Excitation Concerns XXXharmlesdragonNo ratings yet

- Learning Series 1Document4 pagesLearning Series 1estaji50No ratings yet

- 09 - Chapter 2 - XXDocument20 pages09 - Chapter 2 - XXharmlesdragonNo ratings yet

- Short Circuit StudyDocument29 pagesShort Circuit StudyPramod B.Wankhade100% (3)

- RPPF SizesDocument1 pageRPPF SizesharmlesdragonNo ratings yet

- Electrical Technical DataDocument1 pageElectrical Technical DataharmlesdragonNo ratings yet

- Importance of X-R RatiosDocument6 pagesImportance of X-R RatiosNayreth MezonesNo ratings yet

- Motor Starting - NormalDocument14 pagesMotor Starting - NormalTugino GinoNo ratings yet

- VC8036Document5 pagesVC8036harmlesdragonNo ratings yet

- 8KV 500mA Ultra Fast Recovery High Voltage DiodeDocument1 page8KV 500mA Ultra Fast Recovery High Voltage Diodeedilbertos_4No ratings yet

- SpaceLogic TC903 ThermostatDocument3 pagesSpaceLogic TC903 ThermostatIonut Viorel TudorNo ratings yet

- Chapter17 Corrosion&DegradationofMaterials PDFDocument84 pagesChapter17 Corrosion&DegradationofMaterials PDFAngelaNo ratings yet

- 9210-224 - Sample - Question - Paper - v1-0, 2014Document6 pages9210-224 - Sample - Question - Paper - v1-0, 2014Anonymous emooAdrNo ratings yet

- 18-Channel Smart Lowside Switch TLE6244X: Application NoteDocument26 pages18-Channel Smart Lowside Switch TLE6244X: Application Notemebarki aberraoufNo ratings yet

- Hot Rod III Deluxe and DeVille - Gamp - ManualDocument28 pagesHot Rod III Deluxe and DeVille - Gamp - Manuala personNo ratings yet

- MagnaBend UserManualDocument32 pagesMagnaBend UserManualLuo AmyNo ratings yet

- 2 ILS ApproachDocument6 pages2 ILS ApproachRich GarrNo ratings yet

- Programmable Logic Devices: Mohammed Anvar P.K Ap/Ece Al-Ameen Engineering CollegeDocument52 pagesProgrammable Logic Devices: Mohammed Anvar P.K Ap/Ece Al-Ameen Engineering CollegeThahsin ThahirNo ratings yet

- Frameless09072012C PampDocument8 pagesFrameless09072012C PampLeandro Francisco da SilvaNo ratings yet

- Manual MI 2893, MI 2892, MI 2885 - PowerMaster XT, Power Master, Master Q4 ANG Ver 1.2.2 20753179Document242 pagesManual MI 2893, MI 2892, MI 2885 - PowerMaster XT, Power Master, Master Q4 ANG Ver 1.2.2 20753179Nhật Tân Nguyễn VănNo ratings yet

- RA - 10913 Anti-Distracred DrivingDocument5 pagesRA - 10913 Anti-Distracred DrivingmorningmindsetNo ratings yet

- Aloha For ClassDocument23 pagesAloha For ClassetasureshNo ratings yet

- X-RAY Type Approved Database PDFDocument1 pageX-RAY Type Approved Database PDFsaikumar0% (1)

- Error CodesDocument92 pagesError CodesNando SobaNo ratings yet

- Lec01 Verilog Combinational Circuits Design 2022 SpringDocument64 pagesLec01 Verilog Combinational Circuits Design 2022 Springyanjia8161100No ratings yet

- Burkert Solenoid Valve Type 5420Document4 pagesBurkert Solenoid Valve Type 5420Faulhaber AdrianNo ratings yet

- class-AB Voltage Follower2006Document2 pagesclass-AB Voltage Follower2006tuanka1No ratings yet

- Vacuum Tube - WikipediaDocument33 pagesVacuum Tube - WikipediaHenslsdkgaANo ratings yet

- Sony MZ-B50 Service ManualDocument72 pagesSony MZ-B50 Service ManualDavid PiçarraNo ratings yet

- Unix Interview Questions and AnswersDocument9 pagesUnix Interview Questions and AnswersKarthikReNo ratings yet

- Unipole MultipoleDocument186 pagesUnipole MultipoleNicolas AguilarNo ratings yet

- CT Unidrive SP Lift Drive Basic Setup GuideDocument5 pagesCT Unidrive SP Lift Drive Basic Setup Guidejayb1984No ratings yet

- Maxon EC20 Flat 3wattDocument1 pageMaxon EC20 Flat 3wattElectromateNo ratings yet

- Denon AVR 787Document74 pagesDenon AVR 787noneNo ratings yet

- DTL Training Report Avnish KatiyarDocument71 pagesDTL Training Report Avnish KatiyarKuldip Singh75% (4)

- Indoor & Outdoor Lighting: Better Light ... Better LifeDocument44 pagesIndoor & Outdoor Lighting: Better Light ... Better Lifemorad omr100% (2)

- RoboBASIC English Command Instruction Manual (Version 2.10 20051118)Document149 pagesRoboBASIC English Command Instruction Manual (Version 2.10 20051118)Pham Hoang Minh100% (2)

- Xfetto H2O Technische SpecsDocument44 pagesXfetto H2O Technische SpecskaelcorbettNo ratings yet

- Rotary Blower Discharge Silencer GuideDocument4 pagesRotary Blower Discharge Silencer Guidehk168No ratings yet