Professional Documents

Culture Documents

HFO Bulk Storage Tank Steam Coil Sizing

Uploaded by

Saeed RehmanCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

HFO Bulk Storage Tank Steam Coil Sizing

Uploaded by

Saeed RehmanCopyright:

Available Formats

SUPPLYCHAIN SERVICES FAUJI FOODS

Prepared By: MMS

Determination of Steam Requirement & Heating Coil Sizing For Un-Insulated Fuel Oil Tanks based on " KELLOGG" METHOD Checked By: ANA

Date: 11/12/2017

CONSULTANT: Supply Chain Services

EQUIPMENT: HFO Bulk STORAGE Tank

CLIENT: IM & S Engineering ( Pvt.) Ltd.

REVISION: 0

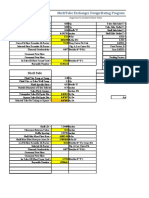

TANK DETAILS

Tank Height = 27.89 ft 8.5 m Input Values

Tank Diameter = 22.97 ft 7 m Calculated Values

Area of Tank Walls = 2012 ft2

Area of Tank Top = 0 ft2 Not Applicable

Area of Tank Bottom = 414 ft²

Total Surface Area of Tank to be heated (Ae) = 2427 ft²

Tank Volume = 11553.8 ft3

Density of Fluid in Tank = 58.9 lb/ft3 945 kg/m3 (from Hysys, FO)

Mass of Fluid in tank = 646,769 lb 95 % Filled of Tank Volume

OPERATING PARAMETERS

Specific Heat of Fluid in Tank = 0.42 Btu/lb/F (from Hysys, FO)

Temperatre of Environment (Te) = 32 F 0.0 C

Temperature of Tank Interior (Ti) = 122 F 50.0 C

Steam Quality = Saturated Steam at 8 barg.

Temperature of Steam at Saturation (Ts) = 347.61 F 175.3 C

Pressure of Steam = 116 psig

Latent Heat of Vapourization of Steam (ΔHv) = 896.40 BTU/Lb

Density of Steam at Saturated Condition (ρs) = 0.2598 Lb/ftᶟ

HEAT TRANSFER RATES

2

Heat Transfer Rates of Coil for Uninsulated Tank (Ue) = 5 BTU/hr/ft /F From "KELLOGG" Vessel Design Manual

Heat Transfer Rates of Coil for Tank Contents [Natural Convection Only, No Agitation] (Us) = 15 BTU/hr/ft²/F From "KELLOGG" Vessel Design Manual

HEAT DUTY & STEAM REQUIREMENT CALCULATIONS

Temprature Differential Across the Tank External Surface (ΔTe) = 90 F

Heat Duty Requirement (Qe) = 1,091,934.91 BTU/hr

Temprature Differential Across the Coil (ΔTs) = 226 F

Steam Flow Rate Requirement (W) = 1,218 Lbs/hr 553 Kg/hr

COIL DETAILS

Coil Surface Area (As) = 323 ft²

Coil Pipe Size NPS = 1.25 in SCH # 40

Inside Diameter of Pipe (d) = 1.38 in

Pipe Surafce Area of Heating Coil/ ft² (Ao) = 0.434 ft²/ft

Total Length of Coil (L) = 743 ft 227 m

Actual Length of Coil Used Based on Bottom Surface Area = 1,020 ft 311 m

Steam Flow Splitter = Yes Tank Diameter > 5m

Steam Flow in each set of Coil (W) = 406 Lbs/hr Number of Steam Coil Set=03 Nos.

STEAM PRESSURE DROP CALCULATION IN COIL

Pressure Drop per ft of Pipe (ΔP/L) = 0.0166 psid/ft

pressure drop/ 100 ft found Ok.

Pressure Drop per 100 ft of Pipe [(ΔP/L)*100] = 1.66 psid/100ft ( Normal range 1.5 to 2 psid)

Total Pressure Drop = 16.94 psid

FILE: HFO Bulk Storage Tank Steam Coil Sizing SHEET 1 OF 1

You might also like

- Design Calculation For Coil in The HFO Tank - TK14 & TK 15Document4 pagesDesign Calculation For Coil in The HFO Tank - TK14 & TK 15chintanNo ratings yet

- Internal Coil CalculationDocument19 pagesInternal Coil CalculationMr Incognito100% (3)

- Ael-2597-Mec-Cl-0305-R0 - Design Calculation of Heating CoilDocument2 pagesAel-2597-Mec-Cl-0305-R0 - Design Calculation of Heating CoilbecpavanNo ratings yet

- Heating Coil Sizing For Fuel Oil TankDocument2 pagesHeating Coil Sizing For Fuel Oil TankPouria Sabbagh100% (1)

- Sizing Heating Coil Insulated Fuel TankDocument2 pagesSizing Heating Coil Insulated Fuel Tankypatels50% (2)

- Calculating heat transfer and temperature change in a crude oil storage tankDocument3 pagesCalculating heat transfer and temperature change in a crude oil storage tankbadelitamariusNo ratings yet

- Sizing of Steam Coil of Insulated Tank Rev 3 PDFDocument2 pagesSizing of Steam Coil of Insulated Tank Rev 3 PDFdhavalesh1No ratings yet

- Vertical Storage Tank Heat Loss Calcs - Rev.1 31.12.2010Document16 pagesVertical Storage Tank Heat Loss Calcs - Rev.1 31.12.2010jnmanivannanNo ratings yet

- API 650 Water Storage TankDocument60 pagesAPI 650 Water Storage TankHgagselim Selim100% (1)

- PVV Cal Sheet LabixDocument45 pagesPVV Cal Sheet LabixPranpath Narupantawart50% (2)

- Air Eliminator Datasheet PDFDocument2 pagesAir Eliminator Datasheet PDFbecpavanNo ratings yet

- TankHeatingCoil&BoilerCapacityRequirement Rev 2Document1 pageTankHeatingCoil&BoilerCapacityRequirement Rev 2sooner123456No ratings yet

- Steam Coil CalculationDocument10 pagesSteam Coil CalculationRefqi Kemal Habib100% (2)

- Heat Loss Through TankDocument56 pagesHeat Loss Through Tankinamdar_sameerNo ratings yet

- Tank Vessel Overflow Line SizingDocument4 pagesTank Vessel Overflow Line SizingSteve Wan100% (1)

- Fresh HDO Storage TankDocument42 pagesFresh HDO Storage TankHgagselim SelimNo ratings yet

- TEMA Sheet Heat Exchanger SpecificationDocument3 pagesTEMA Sheet Heat Exchanger SpecificationSonNguyenNo ratings yet

- Steam Coil SizingDocument21 pagesSteam Coil SizingMildogg100% (1)

- API 650 Storage Tank TCA PreparationDocument86 pagesAPI 650 Storage Tank TCA PreparationBimal DeyNo ratings yet

- AST Heating Coil Design Calculation Rev 0Document3 pagesAST Heating Coil Design Calculation Rev 0Pieter Grendel100% (3)

- 4000 m3 Storage Tank - Data SheetDocument3 pages4000 m3 Storage Tank - Data SheetSakthi Vel100% (1)

- GS 158-1 Internal Floating Decks For Storage Tanks: March 1998Document38 pagesGS 158-1 Internal Floating Decks For Storage Tanks: March 1998Mohd KhairulNo ratings yet

- 1 Design Calculation For Tank Bund Wall T-1700 (Offspec Crude Oil Tank) Bund WallDocument2 pages1 Design Calculation For Tank Bund Wall T-1700 (Offspec Crude Oil Tank) Bund WallShahrin MamatNo ratings yet

- Mechanical Calculation For Crude Oil Storage Tanks (TK-6001 6020)Document38 pagesMechanical Calculation For Crude Oil Storage Tanks (TK-6001 6020)Hamid MansouriNo ratings yet

- Reduce Engine Noise with Exhaust SilencersDocument4 pagesReduce Engine Noise with Exhaust Silencersjessito2No ratings yet

- Steam Tracing CalculationDocument44 pagesSteam Tracing CalculationsafaldNo ratings yet

- Sizing For Vaporiser/Flash Vessel: InputsDocument3 pagesSizing For Vaporiser/Flash Vessel: InputsSaravana ChandranNo ratings yet

- Storage Tank Venting CalculationDocument1 pageStorage Tank Venting Calculationام يمنى ايمنNo ratings yet

- Design Calculations - Insulation Thickness REV-1Document4 pagesDesign Calculations - Insulation Thickness REV-1delMAK100% (1)

- Heating Coil CalculationDocument1 pageHeating Coil Calculationyatin888100% (1)

- THERMAX BAG FILTER TECHNICAL DATA SHEETDocument18 pagesTHERMAX BAG FILTER TECHNICAL DATA SHEETpavaniNo ratings yet

- Insulation ThicknessDocument2 pagesInsulation ThicknessShashi Kant KumarNo ratings yet

- API 620 DesignDocument27 pagesAPI 620 Designrsubramani100% (2)

- Output Summary: SI UnitsDocument42 pagesOutput Summary: SI UnitsAkhil JoseNo ratings yet

- Double Pipe Heat Exchanger Design: Chemical Engineering SpreadsheetsDocument2 pagesDouble Pipe Heat Exchanger Design: Chemical Engineering Spreadsheetsrudy_423522658No ratings yet

- Tank Venting API 2000Document3 pagesTank Venting API 2000Gusfi CarsurinNo ratings yet

- Storage Tank DesignDocument21 pagesStorage Tank Designravi456compNo ratings yet

- Insulation Thickness Calculation for Steam PipesDocument29 pagesInsulation Thickness Calculation for Steam Pipesrajachem100% (2)

- UHX - Osweiller - WhitePaper PDFDocument20 pagesUHX - Osweiller - WhitePaper PDFMichael BasaNo ratings yet

- Case D9.03 Storage Tank Heating SystemDocument3 pagesCase D9.03 Storage Tank Heating SystemBarmar Sbahi0% (1)

- API 650 Datasheet 1Document16 pagesAPI 650 Datasheet 1alwacsNo ratings yet

- External Floating Roof RequirementsDocument3 pagesExternal Floating Roof RequirementsSajeev NarayananNo ratings yet

- Hydrocyclone Data SheetDocument4 pagesHydrocyclone Data SheetHimmahSekarEagNo ratings yet

- Datasheet For Vent ScrubberDocument5 pagesDatasheet For Vent ScrubbercliffrajjoelNo ratings yet

- Tank coil design thermal calculationsDocument7 pagesTank coil design thermal calculationsElton Situmeang100% (3)

- Storage Tank Design Calculation - Api 650Document21 pagesStorage Tank Design Calculation - Api 650miteshpatel191100% (2)

- Storage Tank Normal Venting Capacity Calculations PDFDocument1 pageStorage Tank Normal Venting Capacity Calculations PDFNathan MoralesNo ratings yet

- Condensate Line SizingDocument2 pagesCondensate Line SizingAnonymous oVRvsdWzfBNo ratings yet

- D-STEAM SIZING FOR VAPORIZING AMMONIADocument2 pagesD-STEAM SIZING FOR VAPORIZING AMMONIAVinh Do ThanhNo ratings yet

- Datasheet TankDocument1 pageDatasheet TankAnonymous lQiANQusxiNo ratings yet

- Sulfuric Acid Tank - APIDocument4 pagesSulfuric Acid Tank - APISakthi VelNo ratings yet

- Ael-2597-Mec-Cl-0305-R1 - Sizing Calculation of Heating CoilDocument3 pagesAel-2597-Mec-Cl-0305-R1 - Sizing Calculation of Heating CoilpavanNo ratings yet

- 50T TANK EXTERNAL HEATING COIL CALCDocument7 pages50T TANK EXTERNAL HEATING COIL CALCArjunNo ratings yet

- CHPT 5 ST Excel Heat Exch - Edit - 2Document5 pagesCHPT 5 ST Excel Heat Exch - Edit - 2Claimir GuinzelliNo ratings yet

- Steam Consumption and Line SizingDocument3 pagesSteam Consumption and Line SizingpavanNo ratings yet

- Steam Coil SizingDocument2 pagesSteam Coil Sizingpavan100% (1)

- Bottom & Annular Plate Design: We Will Use Bottom Witout AnularDocument25 pagesBottom & Annular Plate Design: We Will Use Bottom Witout AnularhgagNo ratings yet

- Ex Planlha Op2Document5 pagesEx Planlha Op2adilsonrodriguesNo ratings yet

- Steam Coil AnalysisDocument6 pagesSteam Coil AnalysisMyung Ho SynNo ratings yet

- Jacketed Vessel Heat Transfer (Half Pipe Coil) : MM Inch MM RPM MM M /HDocument30 pagesJacketed Vessel Heat Transfer (Half Pipe Coil) : MM Inch MM RPM MM M /Hmanoj67% (3)

- Thermal Expansion Loop Sizing for Pipes and TubingDocument2 pagesThermal Expansion Loop Sizing for Pipes and Tubingzshehadeh0% (1)

- AVMM Ch08Document13 pagesAVMM Ch08Saeed RehmanNo ratings yet

- Thermal Expansion Loop Sizing for Pipes and TubingDocument2 pagesThermal Expansion Loop Sizing for Pipes and Tubingzshehadeh0% (1)

- Mohammad Nadeem Afridi: ObjectiveDocument4 pagesMohammad Nadeem Afridi: ObjectiveSaeed RehmanNo ratings yet

- ASME Section VIII, Division 2Document23 pagesASME Section VIII, Division 2Saeed Rehman100% (1)

- Calculating MAPP PerANSI B31.3Document9 pagesCalculating MAPP PerANSI B31.3Saeed RehmanNo ratings yet

- System Design: Compensating For Expansion and ContractionDocument3 pagesSystem Design: Compensating For Expansion and ContractionSaeed RehmanNo ratings yet

- AVMM Ch08Document13 pagesAVMM Ch08Saeed RehmanNo ratings yet

- WRC 107Document2 pagesWRC 107sudhirm16No ratings yet

- This Certificate Is Dedicated To: Mr./Ms. - in Recognition ofDocument2 pagesThis Certificate Is Dedicated To: Mr./Ms. - in Recognition ofSaeed RehmanNo ratings yet

- Types of VSEPR TheoryDocument4 pagesTypes of VSEPR TheorySaeed RehmanNo ratings yet

- Mohammad Nadeem Afridi: ObjectiveDocument4 pagesMohammad Nadeem Afridi: ObjectiveSaeed RehmanNo ratings yet

- Release Notes IsogenDocument13 pagesRelease Notes IsogenSaeed RehmanNo ratings yet

- Install SPLM & Generate License Key in under 40 stepsDocument1 pageInstall SPLM & Generate License Key in under 40 stepsSaeed Rehman100% (1)

- Saeed CVDocument1 pageSaeed CVSaeed RehmanNo ratings yet

- Saeed CVDocument1 pageSaeed CVSaeed RehmanNo ratings yet

- Saeed CVDocument1 pageSaeed CVSaeed RehmanNo ratings yet

- AutoPLANT ER Diagram v8.5Document1 pageAutoPLANT ER Diagram v8.5Saeed RehmanNo ratings yet

- CV TemplateDocument1 pageCV TemplateSaeed RehmanNo ratings yet

- HellooDocument1 pageHellooSaeed RehmanNo ratings yet

- CV TemplateDocument1 pageCV TemplateSaeed RehmanNo ratings yet

- Certificate of AwardDocument1 pageCertificate of AwardSaeed RehmanNo ratings yet

- CV TemplateDocument1 pageCV TemplateSaeed RehmanNo ratings yet

- Autoplant Font - FIF File.Document727 pagesAutoplant Font - FIF File.Saeed RehmanNo ratings yet

- Young Women's Sexuality in Perrault and CarterDocument4 pagesYoung Women's Sexuality in Perrault and CarterOuki MilestoneNo ratings yet

- Tds G. Beslux Komplex Alfa II (25.10.19)Document3 pagesTds G. Beslux Komplex Alfa II (25.10.19)Iulian BarbuNo ratings yet

- SRS Design Guidelines PDFDocument46 pagesSRS Design Guidelines PDFLia FernandaNo ratings yet

- Idioms & Phrases Till CGL T1 2016Document25 pagesIdioms & Phrases Till CGL T1 2016mannar.mani.2000100% (1)

- Quaternary Protoberberine Alkaloids (Must Read)Document26 pagesQuaternary Protoberberine Alkaloids (Must Read)Akshay AgnihotriNo ratings yet

- Ricoh 4055 PDFDocument1,280 pagesRicoh 4055 PDFPham Nguyen Hoang Minh100% (1)

- Pharmacokinetics and Drug EffectsDocument11 pagesPharmacokinetics and Drug Effectsmanilyn dacoNo ratings yet

- O2 Orthodontic Lab Catalog PDFDocument20 pagesO2 Orthodontic Lab Catalog PDFplayer osamaNo ratings yet

- PC3 The Sea PeopleDocument100 pagesPC3 The Sea PeoplePJ100% (4)

- Chap 2 Debussy - LifejacketsDocument7 pagesChap 2 Debussy - LifejacketsMc LiviuNo ratings yet

- BCP-8000 User's ManualDocument36 pagesBCP-8000 User's ManualAsad PatelNo ratings yet

- Convocation ProgramDocument125 pagesConvocation ProgramZirak TayebNo ratings yet

- 12 Week Heavy Slow Resistance Progression For Patellar TendinopathyDocument4 pages12 Week Heavy Slow Resistance Progression For Patellar TendinopathyHenrique Luís de CarvalhoNo ratings yet

- Laser Surface Treatment ProcessesDocument63 pagesLaser Surface Treatment ProcessesDIPAK VINAYAK SHIRBHATENo ratings yet

- Answer Key p2 p1Document95 pagesAnswer Key p2 p1Nafisa AliNo ratings yet

- FP-XH PGRG eDocument936 pagesFP-XH PGRG ebvladimirov85No ratings yet

- An Online ECG QRS Detection TechniqueDocument6 pagesAn Online ECG QRS Detection TechniqueIDESNo ratings yet

- Project Binder 2Document23 pagesProject Binder 2Singh DhirendraNo ratings yet

- Entrepreneurship Project On Jam, Jelly & PicklesDocument24 pagesEntrepreneurship Project On Jam, Jelly & Picklesashish karshinkarNo ratings yet

- Product ListDocument4 pagesProduct ListyuvashreeNo ratings yet

- Sayre Materia Medica-3Document87 pagesSayre Materia Medica-3ven_bams5840No ratings yet

- Troubleshooting Hydraulic Circuits: Fluid PowerDocument32 pagesTroubleshooting Hydraulic Circuits: Fluid PowerMi LuanaNo ratings yet

- Madeleine Ker - TakeoverDocument91 pagesMadeleine Ker - Takeover66677785100% (1)

- Sibuyan Island ResiliencyDocument12 pagesSibuyan Island ResiliencyEndangeredSpeciesNo ratings yet

- Usjr Temfacil Balance of Work Schedule Aug 25, 2022Document5 pagesUsjr Temfacil Balance of Work Schedule Aug 25, 2022Maribeth PalumarNo ratings yet

- 7890 Parts-Guide APDocument4 pages7890 Parts-Guide APZia HaqNo ratings yet

- Detection and Attribution Methodologies Overview: Appendix CDocument9 pagesDetection and Attribution Methodologies Overview: Appendix CDinesh GaikwadNo ratings yet

- Pioneer XC-L11Document52 pagesPioneer XC-L11adriangtamas1983No ratings yet

- Smart Grid Standards GuideDocument11 pagesSmart Grid Standards GuideKeyboardMan19600% (1)

- Embankment PDFDocument5 pagesEmbankment PDFTin Win HtutNo ratings yet