Professional Documents

Culture Documents

Fyp Ii

Uploaded by

Siti FatehaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fyp Ii

Uploaded by

Siti FatehaCopyright:

Available Formats

THE PERFORMANCE OF CONCRETE BRICK

CONTAINING PALM OIL FUEL ASH (POFA) AS

REPLACING CEMENT

TARMIDZI BIN MOHD ZAILANI

MOHD SUFYAN BIN ABDULLAH, PROF MADYA DR SURAYA HANI BINTI ADNAN

____________________________________________________________________

DEPARTMENT OF CIVIL ENGINEERING TECHNOLOGY

FACULTY OF ENGINEERING TECHNOLOGY

ABSTRACT

Material waste is one of the major problems in Malaysia. Factors such as large population growth, urbanization and rapid economic growth had contributed to the

increasing of waste generation. In recent years, awareness and concern over the impact of the increase in the amount of waste in landfills has made many members of the

science and technology especially in the field of engineering to adapt the waste into valuable products. Palm oil fuel ash (POFA) is a by-product from biomass thermal

power plants where oil palm residues are burned to generate electricity. The total 84 concrete brick samples will be used for laboratory work in compressive strength test

and water absorption test in order to obtain the concrete block performance at 7 days and 28 days respectively. The replacement material of POFA is used in the concrete

mixing by replacing cement at percentage of 10% and 20%. Therefore, the optimum strength of the percentage POFA replacing cement in concrete brick are identified.

INTRODUCTION METHODOLOGY

➢ Production of concrete leads to a reduction in natural resources.

➢ POFA can be used in concrete as three kinds of elements include coarse

aggregate, fine aggregate, and cement.

➢ Reduce the agricultural waste as decrease the using of cement.

➢ POFA has potential pozzolanic property coupled with aims at reducing the

Brick were Brick were The load imposed on

potential environmental problems associated with disposing of POFA. removed from weight before the brick until the

Brick that has

been tested

curing in water tank compression test brick fail

Figure 3.4: Compression Test

Compression Test

OBJECTIVE

1. To determine the compressive strength of brick. Research Initial dry mass Brick were Wet mass of

Brick are placed

2. To determine the water absorption of brick. Methodology in drying oven

of brick is weight immersed in water brick was weight

and recorded tank for 24 hours and recorded

Water Absorption Test

L I T E R AT U R E R E V I E W

R E S U LT & D I S C U S S I O N

➢ POFA contains large amounts of silica and has recently

been accepted as a pozzolanic material in concrete [1].

➢ POFA has low pozzolanic characteristics, and its use should not

exceed 10% by cement mass when used in partial substitution to cement [2].

➢ POFA had good potential to suppress expansion associated with alkali-silica

reaction in concrete [3].

➢ There has been a school of thought that the strength development concrete

containing pozzolans at early ages is slower than that of concrete with only

Portland cements [4]. Compressive strength for 10% and 20% POFA

➢ A period of about three months is usually needed for fly ash concrete to

achieve the full benefit through pozzolanic reactions [4].

`

Water absorption variation percentage and size of POFA

➢ The optimum percentage of POFA replaced cement is at 10%.

Compressive strength versus age for different level of POFA replacement. ➢ The higher percentage of POFA cause the decreasing in concrete strength.

➢ Compressive strength for 10% and 20% replacing POFA as cement lower

than the compressive normal concrete brick.

CONCLUSION ➢ Water absorption at 10% POFA replaced cement lower than the normal

concrete brick.

➢ Compressive strength and water absorption of palm oil fuel ash shows its

optimum at 10% of POFA replacement. REFERENCES

➢ From the results, it indicates that the POFA has a higher potential to use as an

alternative material in the concrete mix to replace cement at a lower [1] Weerachart Tangchirapat, Chai Jaturapitakkul, Prinya Chindaprasirt. (2009). Use of Palm Oil Fuel Ash As A Supplementary Cementitious Material for

Producing High-Strength Concrete. Construction and Building Materials, 2009, Volume 23, Pg 2641–2646.

percentage. In the future, research can be continued using the optimum [2] Tayfun Çiçek & Yasin Çinçin. (2015). Use of Fly Ash in Production of Light-Weight Building Bricks. Construction and Building Materials, 2015, Volume 94, Pg

521–527.

percentage of POFA to replace cement into the same concrete mix and use [3] A.S.M. Abdul Awal & M. Warid Hussin. (1999). Durability of High Performance Concrete Containing Palm Oil Fuel Ash. (Edited by M.A. Lacasse & D.J.

Vanier). Institute for Research in Construction, Ottawa ON, K1A 0R6, Canada, 1999, Durability of Building Materials and Components 8, Pg 465-474.

different water-cement ratio with an optimum percentage. [4] A.S.M. Abdul Awal & I.A. Shehu. (2015). Performance Evaluation of Concrete Containing High Volume Palm Oil Fuel Ash Exposed To Elevated Temperature.

Construction and Building Materials, 2015, Volume 76, Pg 214–220.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Assgnment InfrraDocument3 pagesAssgnment InfrraSiti FatehaNo ratings yet

- Overview of Green Building Rating Tools: ArticleDocument7 pagesOverview of Green Building Rating Tools: ArticleSiti FatehaNo ratings yet

- Draf 1 StructureDocument13 pagesDraf 1 StructureSiti FatehaNo ratings yet

- Detailing Beam Simply SupportedDocument3 pagesDetailing Beam Simply SupportedSiti FatehaNo ratings yet

- Procedure BodDocument32 pagesProcedure BodSiti FatehaNo ratings yet

- GenderDocument1 pageGenderSiti FatehaNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Fin Accounting IFRS 2e Ch13Document62 pagesFin Accounting IFRS 2e Ch13Nguyễn Vinh QuangNo ratings yet

- EPMS System Guide For Subcontractor - V1 2Document13 pagesEPMS System Guide For Subcontractor - V1 2AdouaneNassim100% (2)

- Parrot Mk6100 Userguide Zone1Document100 pagesParrot Mk6100 Userguide Zone1Maria MartinNo ratings yet

- SCIENCE 11 WEEK 6c - Endogenic ProcessDocument57 pagesSCIENCE 11 WEEK 6c - Endogenic ProcessChristine CayosaNo ratings yet

- Chapter 4: Thermal ComfortDocument16 pagesChapter 4: Thermal ComfortWengelNo ratings yet

- ABHA Coil ProportionsDocument5 pagesABHA Coil ProportionsOctav OctavianNo ratings yet

- OsciloscopioDocument103 pagesOsciloscopioFredy Alberto Gómez AlcázarNo ratings yet

- OBOE GougerDocument2 pagesOBOE GougerCarlos GaldámezNo ratings yet

- Bharti Airtel Strategy FinalDocument39 pagesBharti Airtel Strategy FinalniksforloveuNo ratings yet

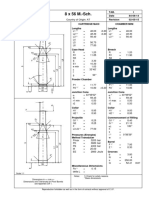

- 8 X 56 M.-SCH.: Country of Origin: ATDocument1 page8 X 56 M.-SCH.: Country of Origin: ATMohammed SirelkhatimNo ratings yet

- Kortz Center GTA Wiki FandomDocument1 pageKortz Center GTA Wiki FandomsamNo ratings yet

- Ubicomp PracticalDocument27 pagesUbicomp Practicalvikrant sharmaNo ratings yet

- E Voting PPT - 1Document11 pagesE Voting PPT - 1madhu100% (2)

- Department of Education: Raiseplus Weekly Plan For Blended LearningDocument3 pagesDepartment of Education: Raiseplus Weekly Plan For Blended LearningMARILYN CONSIGNANo ratings yet

- Ships Near A Rocky Coast With Awaiting Landing PartyDocument2 pagesShips Near A Rocky Coast With Awaiting Landing PartyFouaAj1 FouaAj1No ratings yet

- HR Practices in Public Sector Organisations: (A Study On APDDCF LTD.)Document28 pagesHR Practices in Public Sector Organisations: (A Study On APDDCF LTD.)praffulNo ratings yet

- Ticket: Fare DetailDocument1 pageTicket: Fare DetailSajal NahaNo ratings yet

- Fce Use of English 1 Teacher S Book PDFDocument2 pagesFce Use of English 1 Teacher S Book PDFOrestis GkaloNo ratings yet

- ES Parent Bulletin Vol#19 2012 May 25Document13 pagesES Parent Bulletin Vol#19 2012 May 25International School ManilaNo ratings yet

- This Is A Short Presentation To Explain The Character of Uncle Sam, Made by Ivo BogoevskiDocument7 pagesThis Is A Short Presentation To Explain The Character of Uncle Sam, Made by Ivo BogoevskiIvo BogoevskiNo ratings yet

- SL Generator Ultrasunete RincoDocument2 pagesSL Generator Ultrasunete RincoDariaNo ratings yet

- The One With The ThumbDocument4 pagesThe One With The Thumbnoelia20_09No ratings yet

- Work Sample 2 - Eoc and CrucibleDocument35 pagesWork Sample 2 - Eoc and Crucibleapi-259791703No ratings yet

- Pepsico SDM ProjectDocument6 pagesPepsico SDM ProjectJemini GanatraNo ratings yet

- Emerging Technology SyllabusDocument6 pagesEmerging Technology Syllabussw dr100% (4)

- Celula de CargaDocument2 pagesCelula de CargaDavid PaezNo ratings yet

- LU 5.1 ElectrochemistryDocument32 pagesLU 5.1 ElectrochemistryNurAkila Mohd YasirNo ratings yet

- Zero Tolerance 2010Document16 pagesZero Tolerance 2010Adrian KozelNo ratings yet

- Ppap - 2556 PDFDocument7 pagesPpap - 2556 PDFMohamed ElmakkyNo ratings yet

- Vanguard 44 - Anti Tank Helicopters PDFDocument48 pagesVanguard 44 - Anti Tank Helicopters PDFsoljenitsin250% (2)