Professional Documents

Culture Documents

SKF Bearings With Solid Oil

Uploaded by

LuisSilvaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SKF Bearings With Solid Oil

Uploaded by

LuisSilvaCopyright:

Available Formats

SKF bearings with solid oil

The third lubrication choice

The Power of Knowledge Engineering

SKF bearings with solid oil

– the third lubrication choice

There are three ways to supply oil to a ball or roller bearing: enabling the bearing components to rotate freely. The oil,

which seeps into the gap, provides good lubrication for the

• oil bath, oil recirculation or nozzles

bearing, right from the start.

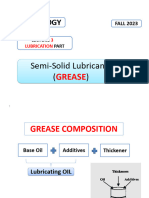

• oil in a thickened form (grease)

• solid oil, where oil is retained in a polymer matrix

When to use solid oil

In most appli

Benefits of solid oil Typical solid oil application areas

cations, standard

Solid oil, which was developed for applications where • dirty or humid

greases and oils

traditional relubrication methods are not practical, can • aggressive chemicals

provide an ad

provide a number of benefits, including: • very cold equate amount of

• supplies more oil to the bearing than grease • centrifugal forces lubricant to a

• vertical shafts bearing. However,

• keeps contaminants out of the bearing cavity

• hard to reach in cases where

• eliminates the need for relubrication

• oscillating movements accessibility to the

• eliminates the need for seals to retain the lubricant bearing for relubri-

• high cleanliness demands

• resistant to chemicals cation purposes is

• can withstand high g-forces impractical or impossible, solid oil is an excellent solution.

• environmentally friendly Solid oil can also be used effectively in applications where

premature bearing failure is the result of high levels of

About solid oil contamination.

Solid oil is an oil-saturated, polymer matrix that completely

Solid oil is really two solutions in one. It provides lubricant

fills the free space in the bearing, encapsulating both the

to the bearing and acts as an extremely effective seal.

rolling elements and cage. The polymer material has a

porous structure, with millions of micro-pores, to hold the

lubricating oil. The pores are so small that the oil is retained

in the material by surface

tension.

As the oil-filled polymer

material is pressed into the

bearing, a very narrow gap

forms around the rolling

elements and raceways,

Solid oil forms a narrow gap around

the rolling elements and raceways.

The oil in the micro pores will seep

into the gap.

Advantages of solid oil

Consistent lubricant supply Eliminates relubrication

When a metal surface, like the raceway of Solid oil contains such a large reservoir of

a bearing, slides against solid oil, it is oil that relubrication is not required.

coated with an even and consistent film Oil

of oil. Then, with only a moderate increase No seals required

in operating temperature, oil is pushed Seals are not needed to retain the lubricant

toward the surface of the polymer matrix. in the bearing, even on vertical shafts.

This “flow” of oil within the polymer matrix However, if the arrangement already

occurs because the oil has a higher incorporates seals, they should be retained

coefficient of thermal expansion than the as extra protection against contamination.

polymer matrix and because the viscosity

of the oil decreases with increasing Resistant to chemicals

temperature. The solid oil polymer matrix is unaffected

by most chemicals. However, organic

When the bearing stops running, excess oil solvents like kerosene, will remove the oil

is reabsorbed into the polymer matrix. from the polymer matrix.

Grease- Solid oil

More lubricant available Withstands high g-forces

lubricated bearing

bearing

A bearing with solid oil contains two to four Solid oil becomes an integral part of the

times more oil than a conventional grease- bearing so that lubricant cannot be A bearing with solid oil contains between two and

lubricated bearing. This is because the expelled, even when subjected to high four times more oil than a corresponding

bearing is completely filled with the solid centrifugal forces. grease-lubricated bearing.

oil, whereas a grease-lubricated bearing

normally operates with approximately one

third of its free space filled with grease.

Keeps contaminants out

Because solid oil fills the bearing cavity

completely, it is difficult for contaminants

to reach the bearing contact surfaces.

In highly contaminated environments, SKF

recommends filling the free space in the

housing with a suitable grease to provide

an additional layer of protection.

Technical data

Composition of solid oil Limiting speeds Table 2

Solid oil is normally produced with a very Table 2 lists recommended limit values for

high quality synthetic oil which is suitable the speed factor A. Recommended limit for speed factor A

for most applications. Bearing type limit for A

A = n ¥ dm

Oil viscosity 140 mm2/s at 40 °C Single row deep groove ball bearings 300 000

Where with a steel cage

(105 °F)

A = speed factor [mm/min]

19 mm2/s at 100 °C Ball bearings with a polyamide cage 40 000

n = rotational speed [r/min] (including Y-bearings)

(210°F)

dm = bearing mean diameter Angular contact ball bearings 150 000

Oils having other viscosities can also be = 0.5 (d + D)

used successfully, as can special oils for the d = bearing bore diameter [mm] Cylindrical roller bearings 150 000

food industry. Additives, such as rust D = bearing outside diameter [mm] Tapered roller bearings 45 000

inhibitors, can be added to solid oil to

It is important to remember that the higher Spherical roller bearings

provide extra protection. For additional • E-design 42 500

the speed, the higher the operating • other designs 85 000

information, contact SKF.

temperature. It may therefore be necessary

to limit the bearing speed for high tem If temperature exceeds 20 °C the speed limit will be lower.

Bearing types available

perature operation so that the temperature

Most standard SKF bearings can be

limit for the solid oil is not exceeded. As

supplied with solid oil. Bearings fitted with

with most lubricants, the service life of a

large-volume cages made of polyamide or

bearing with solid oil is extended if the

machined brass are not recommended for

operating temperature is kept low.

solid oil, because the space available for

the solid oil matrix within the bearings is The speed limits listed in table 2 apply to

too limited. open (unsealed) bearings.

Bearings with solid oil are identified by the For bearings with integral seals, 80% of the

designation suffix W64. quoted values should be used.

Temperature limits If bearings with solid oil are to operate

The temperature limits for bearings under extreme conditions, contact the SKF

lubricated with solid oil, measured on the application engineering service for add

bearing outer ring, are listed in table 1. itional information.

Load carrying capacity

The basic dynamic load ratings for solid oil

bearings are the same as for corresponding

standard bearings.

Table 1

Temperature limits

Max. continuous operating 85 °C

temperature (185 °F)

Max. intermittent operating 95 °C

temperature (205 °F)

Min. start-up temperature –40 °C

(standard oil) (–40 °F)

Note: The temperature limits in table 1

apply to both open and sealed versions.

In general, sealed bearings have higher

operating temperatures. Bearings with solid oil can be heated to a maximum of

100 °C (210 °F) for mounting purposes.

Our world faces serious issues

Diminishing energy supplies. Endangered water and air supplies. Overflowing and

potentially hazardous landfills. Global warming.

In addition to other issues driving today’s design engineers, a product’s environmental

impact is a major consideration. You need to be concerned with your product’s energy

efficiency, as well as its total life cycle.

SKF supports your sustainability goals in a number of ways, many of which we are

using in our manufacturing plants worldwide, as part of our BeyondZero initiative.

Solutions for sustainability • Built-in condition monitoring devices

• Low friction, high capacity SKF Explorer that enable end users to optimize

bearings that enable machines to be efficiency and reduce energy use

downsized and more energy-efficient • Sealed-for-life bearing units that require

• Specialized bearings such as CARB no additional lubrication

toroidal roller bearings that accommo- • Environmentally friendly lubricants and

date axial movement within the bearing, lubrication systems

without inducing axial forces, and

decrease power consumption. • Magnetic bearings that run at high

speeds with no surface contact or

• Mechatronic solutions that eliminate the lubrication

need for hydraulics

• Lubrication distribution systems that

• Engineered units that reduce the number optimize lubrication and minimize the

and weight of components use of lubricants and cutting oils

See inserts for more details

about SKF solutions for mining,

mineral processing and cement

industries and auxiliary

equipment.

The Power of Knowledge Engineering

Seals Bearings Lubrication

and units systems

Mechatronics Services

The Power of Knowledge Engineering

Drawing on five areas of competence and application-specific

expertise amassed over more than 100 years, SKF brings innova-

tive solutions to OEMs and production facilities in every major

industry worldwide. These five competence areas include bearings

and units, seals, lubrication systems, mechatronics (combining

mechanics and electronics into intelligent systems), and a wide

range of services, from 3-D computer modelling to advanced

condition monitoring and reliability and asset management

services. A global presence provides SKF customers uniform

quality standards and worldwide product availability.

® SKF and CARB are registered trademarks of the SKF Group.

™ SKF Explorer and BeyondZero are trademarks of the SKF Group.

© SKF Group 2009

The contents of this publication are the copyright of the publisher and may not be reproduced

(even extracts) unless prior written permission is granted. Every care has been taken to ensure

the accuracy of the information contained in this publication but no liability can be accepted for

any loss or damage whether direct, indirect or consequential arising out of the use of the

information contained herein.

Publication 6920 EN · February 2009

Printed in Sweden on environmentally friendly paper.

You might also like

- SKF Bearings With Solid Oil - The Third Lubrication ChoiceDocument8 pagesSKF Bearings With Solid Oil - The Third Lubrication ChoiceLuisSilvaNo ratings yet

- Oil BleedingDocument3 pagesOil BleedingDhananjay B KNo ratings yet

- Machinery Oil Analysis & Condition Monitoring : A Practical Guide to Sampling and Analyzing Oil to Improve Equipment ReliabilityFrom EverandMachinery Oil Analysis & Condition Monitoring : A Practical Guide to Sampling and Analyzing Oil to Improve Equipment ReliabilityRating: 3 out of 5 stars3/5 (4)

- LubricationDocument9 pagesLubricationHaseeb BokhariNo ratings yet

- TribiologyDocument36 pagesTribiologySavindra SilvaNo ratings yet

- Lubrication GuideDocument14 pagesLubrication GuideRadu BurloiuNo ratings yet

- Lubricant & LubricationDocument4 pagesLubricant & LubricationmimNo ratings yet

- TI - LubricationDocument5 pagesTI - LubricationAlex LinsNo ratings yet

- 2018.11.25 Grease Book FuchsDocument18 pages2018.11.25 Grease Book FuchsnghiaNo ratings yet

- Ease FundamentalsDocument32 pagesEase FundamentalsHazem Hasan100% (1)

- SKF Bearings With Solid Oil - The Third Lubrication ChoiceDocument0 pagesSKF Bearings With Solid Oil - The Third Lubrication ChoiceJurun_BidanshiNo ratings yet

- Lubrication Question AnswersDocument2 pagesLubrication Question Answersrejeesh_rajendran50% (4)

- 06 WDD012 Tribology (2020)Document31 pages06 WDD012 Tribology (2020)Varun Mahulikar100% (1)

- Lecture 5Document30 pagesLecture 5saxadi4814No ratings yet

- TT Electric Motor Bearing Lubrication GuideDocument7 pagesTT Electric Motor Bearing Lubrication GuidepatipanpanitanNo ratings yet

- What is Grease ExplainedDocument29 pagesWhat is Grease ExplainedAshishNo ratings yet

- Principles of LubricationDocument109 pagesPrinciples of LubricationFaraj Mohamed100% (2)

- GREASE APPEARANCEDocument2 pagesGREASE APPEARANCEMohamed HassanNo ratings yet

- MCE321 - Lubrication and LubricantsDocument9 pagesMCE321 - Lubrication and LubricantsVanina VaniniNo ratings yet

- 2.5 Lubrication System - NotesDocument6 pages2.5 Lubrication System - NotesAustin ChechecheNo ratings yet

- LB Series Asphalt Plant Maintenance ManualDocument38 pagesLB Series Asphalt Plant Maintenance ManualLai_Wei_Wah_7018No ratings yet

- Lubricating OilsDocument22 pagesLubricating OilsShweta PatilNo ratings yet

- LEC5 Lubrication 2022Document37 pagesLEC5 Lubrication 2022mohamed hodiriNo ratings yet

- Lubrication SMBA01 SAMV10Document30 pagesLubrication SMBA01 SAMV10Sadashiva sahooNo ratings yet

- BROCHURE Premium Greases Guide TNRDocument7 pagesBROCHURE Premium Greases Guide TNRRezhaNo ratings yet

- AIMOL Cement IndustryDocument57 pagesAIMOL Cement IndustryAdrianNo ratings yet

- Lubrication SystemsDocument26 pagesLubrication Systemsshivsena2157No ratings yet

- LUBRICANTS: CLASSIFICATION AND PROPERTIESDocument25 pagesLUBRICANTS: CLASSIFICATION AND PROPERTIESSiontan GhoshNo ratings yet

- Unit - 2 Notes by Rama PawarDocument18 pagesUnit - 2 Notes by Rama PawarKaran ParajapatiNo ratings yet

- Submarine Main Propulsion Diesels - Chapter 7Document32 pagesSubmarine Main Propulsion Diesels - Chapter 7Michael ChungNo ratings yet

- Lecture 3Document52 pagesLecture 3saxadi4814No ratings yet

- Lube Oil AssignmentDocument9 pagesLube Oil Assignmenthassaan100% (1)

- Production of GreaseDocument7 pagesProduction of GreasevisharlanNo ratings yet

- Lubrication: Md. Al Amin Hossain Lecturer (ME)Document8 pagesLubrication: Md. Al Amin Hossain Lecturer (ME)SaHaria SajibNo ratings yet

- JH Step#4 Training Module Lubrication 2Document16 pagesJH Step#4 Training Module Lubrication 2Anonymous pC7MGONo ratings yet

- Function of A Lubricant: Ref To Page 48 Diesel Engines 3rd Edition, A J WhartonDocument11 pagesFunction of A Lubricant: Ref To Page 48 Diesel Engines 3rd Edition, A J Whartonapi-3701567No ratings yet

- Bearing Lubrication BasicsDocument2 pagesBearing Lubrication BasicsMadan YadavNo ratings yet

- Mod 7.03d Lubrication Tools SlideshowDocument24 pagesMod 7.03d Lubrication Tools Slideshowzaidkadiri9No ratings yet

- 6000 en 00 07 LubricationDocument28 pages6000 en 00 07 LubricationM Ferry AnwarNo ratings yet

- Article 66Document4 pagesArticle 66alhusseinalitarkhanNo ratings yet

- chapter Four Lubrication and Corrosion-convertedDocument32 pageschapter Four Lubrication and Corrosion-convertedTemesgen GetaNo ratings yet

- Lubrication: 11.1 Lubrication of Rolling BearingsDocument9 pagesLubrication: 11.1 Lubrication of Rolling BearingskmsrajuNo ratings yet

- Make Bearings Live Longer.: Plain Bearing Lubrication: Product Selection and TipsDocument24 pagesMake Bearings Live Longer.: Plain Bearing Lubrication: Product Selection and TipsMario MullerNo ratings yet

- LubricantsDocument29 pagesLubricantsmuhammadumeryaqoob16No ratings yet

- LEC7 Lubrication 2022Document29 pagesLEC7 Lubrication 2022mohamed hodiriNo ratings yet

- LubricantDocument23 pagesLubricantGADHANo ratings yet

- Amte 126 ReviewerDocument97 pagesAmte 126 ReviewerJanSalvadorTVNo ratings yet

- Automotive Lubrication SystemDocument66 pagesAutomotive Lubrication SystemSadbin MiaNo ratings yet

- 13 Bright Stock Technical BulletinDocument2 pages13 Bright Stock Technical BulletinmaserefinerNo ratings yet

- Select the Right Industrial Lubricant for MachineryDocument14 pagesSelect the Right Industrial Lubricant for MachineryBijendra PrajapatiNo ratings yet

- Grease BasicsDocument6 pagesGrease BasicsnagbabuiNo ratings yet

- Amity - Lubricants - Why So DumbDocument17 pagesAmity - Lubricants - Why So DumbAbhimanyu Singhal100% (2)

- LubricationDocument49 pagesLubricationAdel KlkNo ratings yet

- Basic Chain Lubrication GuideDocument2 pagesBasic Chain Lubrication GuideRakesh PawarNo ratings yet

- OilmistcatalogDocument16 pagesOilmistcatalogtribologiaNo ratings yet

- Engine Lubrication & Engine Cooling: LubricantsDocument28 pagesEngine Lubrication & Engine Cooling: Lubricantsritvick sharmaNo ratings yet

- Lubrication Solutions For Mineral and Cement ProcessingDocument9 pagesLubrication Solutions For Mineral and Cement ProcessingThanhluan NguyenNo ratings yet

- Lubrication GuideDocument28 pagesLubrication GuideVarun PineamaneniNo ratings yet

- Pump Hand BookDocument37 pagesPump Hand BookAkhlesh Jhallare100% (1)

- Catalogo SKF FX Keyless Bushings PDFDocument32 pagesCatalogo SKF FX Keyless Bushings PDFAndres Edmundo Mercado SolizNo ratings yet

- 2130 - Advanced Fast Balance - 97059 - 1CD PDFDocument432 pages2130 - Advanced Fast Balance - 97059 - 1CD PDFLuisSilva100% (1)

- Catalogo Rotulas SKFDocument136 pagesCatalogo Rotulas SKFedu19__83782850% (2)

- 6101 enDocument112 pages6101 enLuisSilvaNo ratings yet

- 2015-06-07 PDFDocument68 pages2015-06-07 PDFLuisSilvaNo ratings yet

- Bearing in Vibrating ScreensDocument38 pagesBearing in Vibrating ScreensLuisSilva100% (1)

- Rolling Bearings in Paper Machines 2Document28 pagesRolling Bearings in Paper Machines 2LuisSilvaNo ratings yet

- 5230 - E Motores ElectricosDocument118 pages5230 - E Motores Electricoslubricacion100% (1)

- C CR SKF RetenesDocument484 pagesC CR SKF RetenesMixtli Garcia100% (1)

- Balancing PDFDocument17 pagesBalancing PDFLuisSilvaNo ratings yet

- Belt Frequency Meter ManualDocument28 pagesBelt Frequency Meter ManualLuisSilvaNo ratings yet

- Balancing PDFDocument17 pagesBalancing PDFLuisSilvaNo ratings yet

- Acceptance For Phased Array InspectionDocument6 pagesAcceptance For Phased Array InspectionLuisSilva100% (1)

- SRB BlindadosDocument28 pagesSRB BlindadosLuisSilvaNo ratings yet

- YbearingsDocument227 pagesYbearingsmasmuinNo ratings yet

- 6897 enDocument72 pages6897 enLuisSilvaNo ratings yet

- Spherical Roller Bearing SKF CatlougeDocument72 pagesSpherical Roller Bearing SKF Catlougemrkadu_61No ratings yet

- Correas Ing SKFDocument24 pagesCorreas Ing SKFgregorioNo ratings yet

- 6771 enDocument12 pages6771 enLuisSilvaNo ratings yet

- SKF - Plummer Block Bearing-HousingDocument84 pagesSKF - Plummer Block Bearing-HousingneeleshvmNo ratings yet

- 6111 Ii enDocument48 pages6111 Ii enLuisSilvaNo ratings yet

- Belt Tension SystemDocument8 pagesBelt Tension SystemAjay ChughNo ratings yet

- Technical Spec - Final PDFDocument13 pagesTechnical Spec - Final PDFLuisSilvaNo ratings yet

- 04 Vibracon®Document2 pages04 Vibracon®LuisSilvaNo ratings yet

- Selection of Vibracon SM Element For (Marine) Gearboxes: Please Insert Data Into Coloured CellsDocument1 pageSelection of Vibracon SM Element For (Marine) Gearboxes: Please Insert Data Into Coloured CellsLuisSilvaNo ratings yet

- 06 Vibracon®Document13 pages06 Vibracon®LuisSilvaNo ratings yet

- Vib EnginesDocument1 pageVib EnginesLuisSilvaNo ratings yet

- The Filipino FamilyDocument11 pagesThe Filipino FamilyTiger Knee97% (37)

- Telecomm SwitchingDocument49 pagesTelecomm SwitchingTalha KhalidNo ratings yet

- Vikash Kumar: 1. Aunico India May 2018Document4 pagesVikash Kumar: 1. Aunico India May 2018Rama Krishna PandaNo ratings yet

- Analysis I - SyllabusDocument3 pagesAnalysis I - SyllabusJUan GAbrielNo ratings yet

- Modul English For Study SkillsDocument9 pagesModul English For Study SkillsRazan Nuhad Dzulfaqor razannuhad.2020No ratings yet

- DX DiagDocument42 pagesDX DiagVinvin PatrimonioNo ratings yet

- Industrial/Organi Zational Psychology: Alday, Angeli Camille M. - 2P2Document51 pagesIndustrial/Organi Zational Psychology: Alday, Angeli Camille M. - 2P2SteffanyNo ratings yet

- Chair Locker Provides Storage and Space SavingsDocument32 pagesChair Locker Provides Storage and Space SavingsElza S. GapuzNo ratings yet

- Theravada BuddhismDocument21 pagesTheravada BuddhismClarence John G. BelzaNo ratings yet

- Learner's Activity Sheet: English (Quarter 4 - Week 5)Document5 pagesLearner's Activity Sheet: English (Quarter 4 - Week 5)Rufaidah AboNo ratings yet

- Image Formation in Plane Mirrors: Ray DiagramsDocument3 pagesImage Formation in Plane Mirrors: Ray DiagramsSouvik BanerjeeNo ratings yet

- Gardiner 1979Document16 pagesGardiner 1979Oswaldo Manuel Ramirez MarinNo ratings yet

- CHECK LIST FOR HIGH RISE BUILDING NOCDocument15 pagesCHECK LIST FOR HIGH RISE BUILDING NOCNedunuri.Madhav Murthy100% (2)

- Austin's Cover Letter Example - Cultivated CultureDocument1 pageAustin's Cover Letter Example - Cultivated CultureYash SNo ratings yet

- Bioav 3Document264 pagesBioav 3Sabiruddin Mirza DipuNo ratings yet

- Slope Stability Analysis MethodsDocument5 pagesSlope Stability Analysis MethodsI am AngelllNo ratings yet

- X TensoqaDocument2 pagesX TensoqaLeo CabelosNo ratings yet

- French Revolution ChoiceDocument3 pagesFrench Revolution Choiceapi-483679267No ratings yet

- M13 - Solution of TrianglesDocument5 pagesM13 - Solution of Triangles9703693564No ratings yet

- ST Veronica Giuliani For OFS PresentationDocument7 pagesST Veronica Giuliani For OFS Presentationleo jNo ratings yet

- Materials Science & Engineering A: Alena Kreitcberg, Vladimir Brailovski, Sylvain TurenneDocument10 pagesMaterials Science & Engineering A: Alena Kreitcberg, Vladimir Brailovski, Sylvain TurenneVikrant Saumitra mm20d401No ratings yet

- Bronchogenic CarcinomaDocument13 pagesBronchogenic Carcinomaloresita_rebongNo ratings yet

- Report Vortex TubeDocument68 pagesReport Vortex TubePravinSharmaNo ratings yet

- Strategicmanagement Finalpaper 2ndtrisem 1819Document25 pagesStrategicmanagement Finalpaper 2ndtrisem 1819Alyanna Parafina Uy100% (1)

- Chich The ChickenDocument23 pagesChich The ChickenSil100% (4)

- Zombie Exodus Safe Haven GuideDocument148 pagesZombie Exodus Safe Haven GuidejigglepopperNo ratings yet

- Analog To Digital Conversion (ADC)Document62 pagesAnalog To Digital Conversion (ADC)Asin PillaiNo ratings yet

- Conditional Sentences in NT Greek Ruben VideiraDocument62 pagesConditional Sentences in NT Greek Ruben Videiraruviso100% (1)

- Description of Classroom Management PlanDocument10 pagesDescription of Classroom Management Planapi-575843180No ratings yet

- 1.9 Bernoulli's Equation: GZ V P GZ V PDocument1 page1.9 Bernoulli's Equation: GZ V P GZ V PTruong NguyenNo ratings yet

- Power of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesFrom EverandPower of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesRating: 4.5 out of 5 stars4.5/5 (21)

- ISO 50001: A strategic guide to establishing an energy management systemFrom EverandISO 50001: A strategic guide to establishing an energy management systemNo ratings yet

- Introduction to Power System ProtectionFrom EverandIntroduction to Power System ProtectionRating: 5 out of 5 stars5/5 (1)

- Operational Amplifier Circuits: Analysis and DesignFrom EverandOperational Amplifier Circuits: Analysis and DesignRating: 4.5 out of 5 stars4.5/5 (2)

- The Way Home: Tales from a life without technologyFrom EverandThe Way Home: Tales from a life without technologyRating: 4 out of 5 stars4/5 (45)

- Formulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsFrom EverandFormulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsNo ratings yet

- The Grid: The Fraying Wires Between Americans and Our Energy FutureFrom EverandThe Grid: The Fraying Wires Between Americans and Our Energy FutureRating: 3.5 out of 5 stars3.5/5 (48)

- Idaho Falls: The Untold Story of America's First Nuclear AccidentFrom EverandIdaho Falls: The Untold Story of America's First Nuclear AccidentRating: 4.5 out of 5 stars4.5/5 (21)

- Renewable Energy: A Very Short IntroductionFrom EverandRenewable Energy: A Very Short IntroductionRating: 4.5 out of 5 stars4.5/5 (12)

- Asset Integrity Management for Offshore and Onshore StructuresFrom EverandAsset Integrity Management for Offshore and Onshore StructuresNo ratings yet

- The Rare Metals War: the dark side of clean energy and digital technologiesFrom EverandThe Rare Metals War: the dark side of clean energy and digital technologiesRating: 5 out of 5 stars5/5 (2)

- Build Your Own Electric Vehicle, Third EditionFrom EverandBuild Your Own Electric Vehicle, Third EditionRating: 4.5 out of 5 stars4.5/5 (3)

- Shorting the Grid: The Hidden Fragility of Our Electric GridFrom EverandShorting the Grid: The Hidden Fragility of Our Electric GridRating: 4.5 out of 5 stars4.5/5 (2)

- OFF-GRID PROJECTS: A Comprehensive Beginner's Guide to Learn All about OffGrid Living from A-Z and Live a Life of Self-SufficiencyFrom EverandOFF-GRID PROJECTS: A Comprehensive Beginner's Guide to Learn All about OffGrid Living from A-Z and Live a Life of Self-SufficiencyNo ratings yet

- Nuclear Energy in the 21st Century: World Nuclear University PressFrom EverandNuclear Energy in the 21st Century: World Nuclear University PressRating: 4.5 out of 5 stars4.5/5 (3)

- Industrial Piping and Equipment Estimating ManualFrom EverandIndustrial Piping and Equipment Estimating ManualRating: 5 out of 5 stars5/5 (7)

- Handbook on Battery Energy Storage SystemFrom EverandHandbook on Battery Energy Storage SystemRating: 4.5 out of 5 stars4.5/5 (2)

- VSC-FACTS-HVDC: Analysis, Modelling and Simulation in Power GridsFrom EverandVSC-FACTS-HVDC: Analysis, Modelling and Simulation in Power GridsNo ratings yet

- Energy, Light and Electricity - Introduction to Physics - Physics Book for 12 Year Old | Children's Physics BooksFrom EverandEnergy, Light and Electricity - Introduction to Physics - Physics Book for 12 Year Old | Children's Physics BooksNo ratings yet

- Well Control for Completions and InterventionsFrom EverandWell Control for Completions and InterventionsRating: 4 out of 5 stars4/5 (10)

- Air-Cooled Condenser Fundamentals: Design, Operations, Troubleshooting, Maintenance, and Q&AFrom EverandAir-Cooled Condenser Fundamentals: Design, Operations, Troubleshooting, Maintenance, and Q&ARating: 5 out of 5 stars5/5 (1)

- Implementing an Integrated Management System (IMS): The strategic approachFrom EverandImplementing an Integrated Management System (IMS): The strategic approachRating: 5 out of 5 stars5/5 (2)