Professional Documents

Culture Documents

SIL-TRODE (ERCuSi-A) PDF

Uploaded by

borovniskiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SIL-TRODE (ERCuSi-A) PDF

Uploaded by

borovniskiCopyright:

Available Formats

Technical Data Sheet

SIL-TRODE®

Description and Application Welding Procedure

A silicon bronze welding alloy (UNS With gas metal-arc welding, the weld

C65600) for the inert gas welding of metal should be deposited in stringer

copper-silicon, copper zinc, copper to beads, maintaining a small molten pool to

themselves, and also to mild steel. Used avoid overheating the hot short silicon

extensively in the welding of galvanized bronze base metal. Use argon gas for

steel. The silicon content of 2.8 - 4%, shielding and relatively high welding travel

increases tensile strength, hardness, and speeds.

work hardening rates. Silicon bronze also

provides good corrosion resistance and

has good weldability. With the gas-tungsten arc welding

process, welding is accomplished with

Silicon bronze is hot short and extreme DCEN (direct current electrode negative)

care must be exercised to avoid current and argon or helium gas shielding.

overheating the joint which tends to cause ACHF (alternating current high-frequency)

cracking. with argon gas shielding may be used to

take advantage of the arc cleaning action.

Chemistry

% (Filler Metal)

Copper .................................................balance Preheat

Silicon .................................................2.8-4.0 Preheat slightly to remove moisture.

Zinc ...................................................1.0 max. Interpass temperature should not exceed

Tin .......................................................1.0 max. 150°F (66°C).

Manganese .......................................1.5 max.

Iron ..................................................0.50 max.

Aluminum ..........................................0.01 max. Specification

Lead ................................................0.02 max. AWS A5.7 Class ER CuSi-A

Others ..............................................0.50 max.

Mechanical Properties (nominal)

Tensile Strength, ksi ..................50(350 MPa)

Elongation, % in 2" .......................................40

BHN (500kg.)

1/4" deposit ..................................................80

You might also like

- Copper AlloysDocument4 pagesCopper AlloysMuhammed SulfeekNo ratings yet

- Welding Complete PPT With QuestionDocument50 pagesWelding Complete PPT With QuestionKBSMANITNo ratings yet

- Welding Definition: by S K MondalDocument26 pagesWelding Definition: by S K MondalSaajal SharmaNo ratings yet

- TIG Welding of Aluminium: A Concise ReportDocument11 pagesTIG Welding of Aluminium: A Concise ReportMohnishNo ratings yet

- Soft and Hard Soldering +brazingDocument28 pagesSoft and Hard Soldering +brazingJoseph Magbanua Dato-on67% (3)

- Cladding PDFDocument6 pagesCladding PDFlibid_rajNo ratings yet

- Pub139 16 PDFDocument1 pagePub139 16 PDFsatnamNo ratings yet

- 6.0 Brazing: 14 - Copper-Nickel Welding and FabricationDocument1 page6.0 Brazing: 14 - Copper-Nickel Welding and FabricationsatnamNo ratings yet

- Alloy Steels: Table 4.2 Typical Mechanical Properties of Some Commercial Steels at Room TemperatureDocument2 pagesAlloy Steels: Table 4.2 Typical Mechanical Properties of Some Commercial Steels at Room TemperatureBharathi SrinivasanNo ratings yet

- Aluminium Die CastingDocument8 pagesAluminium Die CastingsivamettNo ratings yet

- Welding of Copper and Its AlloysDocument30 pagesWelding of Copper and Its Alloysaj87_goswami100% (2)

- Austenitic stainless steels properties and welding guideDocument4 pagesAustenitic stainless steels properties and welding guideandy1036No ratings yet

- Ch-19 Gas Welding, Gas Cutting & Arc WeldingDocument122 pagesCh-19 Gas Welding, Gas Cutting & Arc WeldingshuklahouseNo ratings yet

- Welding of Austenitic Stainless Steel - Part 2 - TWIDocument6 pagesWelding of Austenitic Stainless Steel - Part 2 - TWISumantaNo ratings yet

- Joining Stainless Steel by Soldering, Brazing and Resistance WeldingDocument4 pagesJoining Stainless Steel by Soldering, Brazing and Resistance WeldingA K SinghNo ratings yet

- Ch-19 Gas Welding, Gas Cutting - Arc WeldingDocument85 pagesCh-19 Gas Welding, Gas Cutting - Arc WeldingdiptyaNo ratings yet

- Welding CopperDocument9 pagesWelding CopperSudhakar KumarNo ratings yet

- Welding of Austenitic Stainless Steel. Part 2: Home Technical Knowledge Job KnowledgeDocument8 pagesWelding of Austenitic Stainless Steel. Part 2: Home Technical Knowledge Job KnowledgeJlkKumarNo ratings yet

- Material Science and Engineering Heat TRDocument18 pagesMaterial Science and Engineering Heat TRSamit NagNo ratings yet

- Welding of Cast IronDocument12 pagesWelding of Cast IronwalitedisonNo ratings yet

- Annealing Stainless Steel 304-316Document4 pagesAnnealing Stainless Steel 304-316nepcom9541No ratings yet

- Ch-19 Gas Welding, Gas Cutting & Arc WeldingDocument30 pagesCh-19 Gas Welding, Gas Cutting & Arc WeldingJAYANT KUMARNo ratings yet

- TIG Welding: Job KnowledgeDocument3 pagesTIG Welding: Job KnowledgeRakesh Kumar Munda100% (1)

- Thermite Welding PDFDocument4 pagesThermite Welding PDFAmiableimpexNo ratings yet

- Welding of Nickel AlloysDocument4 pagesWelding of Nickel AlloysMuhammed SulfeekNo ratings yet

- Welding of Aluminum: Cast Iron Welding Practice: Jobs 9-J45 and J46Document6 pagesWelding of Aluminum: Cast Iron Welding Practice: Jobs 9-J45 and J46Willy UioNo ratings yet

- YintroDocument6 pagesYintroJoshua StrykrNo ratings yet

- Ajp Module-2Document22 pagesAjp Module-2Naveen S BasandiNo ratings yet

- Why Stainless Steel for Rail CoachesDocument83 pagesWhy Stainless Steel for Rail CoachesaravindanNo ratings yet

- ASME Secc II D Appendix 6 Metallurgical PhenomenaDocument6 pagesASME Secc II D Appendix 6 Metallurgical PhenomenaCARLOS MARIONo ratings yet

- Ajp Module-2Document75 pagesAjp Module-2Naveen S BasandiNo ratings yet

- Welding Parameters For Duplex SSDocument2 pagesWelding Parameters For Duplex SSOrhan BAYLANNo ratings yet

- Cast Iron Welding GuideDocument31 pagesCast Iron Welding Guideharoub_nasNo ratings yet

- Carbon Steel Metallurgy DiagramDocument17 pagesCarbon Steel Metallurgy Diagramwessamalex100% (1)

- Welding Consumables-Stainless SteelDocument32 pagesWelding Consumables-Stainless SteelImran Khan100% (1)

- YP-WT 11 - Welding of MetalsDocument71 pagesYP-WT 11 - Welding of MetalsAnnisa UrbaningrumNo ratings yet

- Welding A Cast IronDocument9 pagesWelding A Cast Ironjatin jainNo ratings yet

- AJM & NDT - Module - 2Document23 pagesAJM & NDT - Module - 2Naveen S BasandiNo ratings yet

- Classifying Carbon Steels by Composition & Heat TreatmentDocument19 pagesClassifying Carbon Steels by Composition & Heat TreatmentManoj BallaNo ratings yet

- Welding Austenitic Manganese Steel RailDocument6 pagesWelding Austenitic Manganese Steel RailaladinsaneNo ratings yet

- Welding & Material CS & SS From Go WeldingDocument30 pagesWelding & Material CS & SS From Go WeldingExsan OthmanNo ratings yet

- The Metallurgy of Carbon SteelDocument103 pagesThe Metallurgy of Carbon SteelUmer AhsanNo ratings yet

- Table 7.7 (Continued) : 7.3.12 Stainless SteelsDocument21 pagesTable 7.7 (Continued) : 7.3.12 Stainless SteelsumairNo ratings yet

- Study of Mechanical Properties Microstru PDFDocument6 pagesStudy of Mechanical Properties Microstru PDFAyyappanSubramanianNo ratings yet

- Corrosion Guide - Stainless Internation NickelDocument20 pagesCorrosion Guide - Stainless Internation NickelJohn BurkeNo ratings yet

- Copper and Copper AlloysDocument3 pagesCopper and Copper Alloyskevin herryNo ratings yet

- Welding Galvanized SteelDocument6 pagesWelding Galvanized SteelmperelmuterNo ratings yet

- The Working of Steel: Annealing, Heat Treating and Hardening of Carbon and Alloy SteelFrom EverandThe Working of Steel: Annealing, Heat Treating and Hardening of Carbon and Alloy SteelNo ratings yet

- Oxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonFrom EverandOxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonNo ratings yet

- Sheet Metalwork on the Farm - Containing Information on Materials, Soldering, Tools and Methods of Sheet MetalworkFrom EverandSheet Metalwork on the Farm - Containing Information on Materials, Soldering, Tools and Methods of Sheet MetalworkNo ratings yet

- A Complete Guide to Watch Repair - Barrels, Fuses, Mainsprings, Balance Springs, Pivots, Depths, Train Wheels and Common Stoppages of WatchesFrom EverandA Complete Guide to Watch Repair - Barrels, Fuses, Mainsprings, Balance Springs, Pivots, Depths, Train Wheels and Common Stoppages of WatchesRating: 4 out of 5 stars4/5 (1)

- The Working of Steel Annealing, Heat Treating and Hardening of Carbon and Alloy SteelFrom EverandThe Working of Steel Annealing, Heat Treating and Hardening of Carbon and Alloy SteelRating: 5 out of 5 stars5/5 (4)

- Why Do Metals Rust? An Easy Read Chemistry Book for Kids | Children's Chemistry BooksFrom EverandWhy Do Metals Rust? An Easy Read Chemistry Book for Kids | Children's Chemistry BooksNo ratings yet

- Oxy-Acetylene Welding and Cutting Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonFrom EverandOxy-Acetylene Welding and Cutting Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonNo ratings yet

- Special tool steel for auto diesDocument1 pageSpecial tool steel for auto diesborovniskiNo ratings yet

- SK D 51-G (MF 1-GF-250-T) PDFDocument1 pageSK D 51-G (MF 1-GF-250-T) PDFborovniskiNo ratings yet

- SK 830-MF (NiBSi) Thermal Spraying PDFDocument2 pagesSK 830-MF (NiBSi) Thermal Spraying PDFborovniskiNo ratings yet

- Low Alloy Steel ElectrodesDocument1 pageLow Alloy Steel ElectrodesborovniskiNo ratings yet

- OK Autrod 5556 for welding aluminium alloysDocument1 pageOK Autrod 5556 for welding aluminium alloysborovniskiNo ratings yet

- SK D 15-G (MF 3-GF-60-T) PDFDocument1 pageSK D 15-G (MF 3-GF-60-T) PDFborovniskiNo ratings yet

- C-Steel Composited (E70C-3M, E70C-6M) PDFDocument2 pagesC-Steel Composited (E70C-3M, E70C-6M) PDFborovniskiNo ratings yet

- OK Autrod 13.89 (MN-CR 2-1, MSG-2-GZ-C-350)Document1 pageOK Autrod 13.89 (MN-CR 2-1, MSG-2-GZ-C-350)borovniski100% (1)

- OK Flux 281 (F7AO-EM13K) PDFDocument2 pagesOK Flux 281 (F7AO-EM13K) PDFborovniskiNo ratings yet

- Weld carbon steel plate with OK FLUX 231 fluxDocument2 pagesWeld carbon steel plate with OK FLUX 231 fluxborovniskiNo ratings yet

- OK Femax 39.50 Fematic (E 42 2 RA 53)Document1 pageOK Femax 39.50 Fematic (E 42 2 RA 53)borovniskiNo ratings yet

- Bonding Brackets PDFDocument40 pagesBonding Brackets PDFMaria Yael75% (4)

- ASTM C139 Concrete Masonry Units For Construction of Catch Basins and ManholesDocument2 pagesASTM C139 Concrete Masonry Units For Construction of Catch Basins and ManholesAmanda Ariesta ApriliaNo ratings yet

- PheDocument32 pagesPhesalamrefighNo ratings yet

- Material Case Study: Building Services Iv-Game Centre DesignDocument45 pagesMaterial Case Study: Building Services Iv-Game Centre DesignSharvani MedaNo ratings yet

- Sandstone Copper Assessment of The Chu-Sarysu Basin, Central KazakhstanDocument74 pagesSandstone Copper Assessment of The Chu-Sarysu Basin, Central KazakhstanJHOEL_GEONo ratings yet

- K2o & P2o5Document8 pagesK2o & P2o5Elwathig BakhietNo ratings yet

- Formula Writing and NamingDocument5 pagesFormula Writing and NamingKwien AustriaNo ratings yet

- Leyden & Stockholm PapyriDocument117 pagesLeyden & Stockholm PapyriSubliminalNo ratings yet

- QQ P 416FDocument18 pagesQQ P 416FBryan MartinezNo ratings yet

- Astm A576 (2017)Document6 pagesAstm A576 (2017)SK ANo ratings yet

- 10th-C Chapter 12 Re-TestDocument2 pages10th-C Chapter 12 Re-TestWasim NawazNo ratings yet

- Qualitative Analysis of Simple Inorganic SaltsDocument6 pagesQualitative Analysis of Simple Inorganic SaltsBinish Cj100% (1)

- A304 - 20 Standard Specification For Carbon and Alloy Steel Bars Subject To End-Quench Hardenability RequirementsDocument48 pagesA304 - 20 Standard Specification For Carbon and Alloy Steel Bars Subject To End-Quench Hardenability RequirementsAlejandro Valdes100% (1)

- Pages From DGS-6300-001 Red Marked PDFDocument1 pagePages From DGS-6300-001 Red Marked PDFvijayachiduNo ratings yet

- GroundingDocument24 pagesGroundingrajeshreni1No ratings yet

- Stainless Steels: Alloy 904L (UNS N08904)Document1 pageStainless Steels: Alloy 904L (UNS N08904)MV ABNo ratings yet

- CH 06 - Corrosion & ErosionDocument22 pagesCH 06 - Corrosion & ErosionvegaronNo ratings yet

- Arsenic PapeDocument25 pagesArsenic PapeМладен БугарчићNo ratings yet

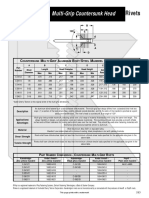

- Rivets Multi Grip CountersunkDocument1 pageRivets Multi Grip CountersunkIsrael OluwagbemiNo ratings yet

- 03 Articol Babut S FinalDocument6 pages03 Articol Babut S FinalduncaemiliaNo ratings yet

- Introduction 2 Study Mineralogy I ToDocument154 pagesIntroduction 2 Study Mineralogy I ToCaracude John100% (1)

- Benguet Corporation Releases 2013 Annual ReportDocument160 pagesBenguet Corporation Releases 2013 Annual Reportruben diwasNo ratings yet

- 0620 s14 QP 63Document12 pages0620 s14 QP 63BrianChanNo ratings yet

- Fire Stopping GuideDocument6 pagesFire Stopping GuidestephlyonNo ratings yet

- Hanger CatalogueDocument4 pagesHanger CatalogueDnyaneshwar100% (1)

- Aluminum 5083Document2 pagesAluminum 5083razormebackNo ratings yet

- DivyaDocument34 pagesDivyaAnonymous 0O7Xpz90% (1)

- Element Symbols Part 1 and 2Document3 pagesElement Symbols Part 1 and 2Lina Na'ilah100% (1)

- Basic Concepts in Engineering Metallurgy - Gate Mechanical Concepts - Mechanical Engineering World - Project Ideas - Seminar Topics - E-Books (PDF) - New TrendsDocument4 pagesBasic Concepts in Engineering Metallurgy - Gate Mechanical Concepts - Mechanical Engineering World - Project Ideas - Seminar Topics - E-Books (PDF) - New TrendsSandeep PrajapatiNo ratings yet

- Slide Gate System DevelopmentDocument14 pagesSlide Gate System DevelopmentA.S.M. Mosayeb RafiNo ratings yet