Professional Documents

Culture Documents

Checklists Title: Checklist For Preventive Maintenance of Equipments TG & Bop Maintenace Department Dirty / Leakage / Clean Oil Pump

Uploaded by

jp mishraOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Checklists Title: Checklist For Preventive Maintenance of Equipments TG & Bop Maintenace Department Dirty / Leakage / Clean Oil Pump

Uploaded by

jp mishraCopyright:

Available Formats

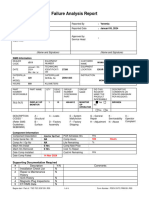

JINDAL POWER LIMITED

CHECKLISTS

Doc. No. TMD/CL/015

TITLE : CHECKLIST FOR PREVENTIVE MAINTENANCE OF EQUIPMENTS Issue No. / Date 01 / 01-09-2008

TG & BOP MAINTENACE DEPARTMENT Rev No. / Date 00 / 01-09-2008

UNIT : EQUIPMENT : DIRTY / LEAKAGE / CLEAN OIL PUMP

WORK ORDER NO. : DATE :

PERMIT NO. : PTW ISSUE DATE : PTW CLOSING DATE :

Take proper PTW and ensure all mechanical, electrical and C&I isolations have been

Sl. done. Design Actual

Work Instructions Frequency Remarks

No. 2. Value Value

3.

Work to4.be done/carried out when the equipment is isolated

5.

1 Quarterly

6.

7.

2 8. Carry out external cleaning of equipment. Quarterly

9.

3 10.Check all joints for leakages if any arrest it. Quarterly

4 Check all holding down bolts for tightness and take corrective action if required Quarterly

Check gland leakages if leakage is to be observed, same to be attended either by replacing

5 Quarterly

the glands or by tightening it.

6 Check coupling spider for damage, if necessary replace it. Quarterly

7 Check the tightness of coupling bolts. Quarterly

Checking of alignment of Pump with Motor, if required and do the necessary correction

8 Quarterly

if required. (QUATERLY)

Spill over oil / water / grease / cotton waste / etc in surrounding area and floor to be

9 Quarterly

cleaned and disposed.

Return the PTW and trial run of the equipment. If any leakage persists same is to be

10 Quarterly

rectified.

Signature of Contractor Signature of JPL Engineer Signature of JPL Engineer in charge

Page No. : 01

Prepared By : Reviewed & Approved By : HOD

You might also like

- JPL Checklist for Preventive Maintenance of Oil Vapor Extraction FansDocument1 pageJPL Checklist for Preventive Maintenance of Oil Vapor Extraction Fansjp mishraNo ratings yet

- Checklists Title: Checklist For Preventive Maintenance of Equipments TG & Bop Maintenace Department Gas DryerDocument1 pageChecklists Title: Checklist For Preventive Maintenance of Equipments TG & Bop Maintenace Department Gas Dryerjp mishraNo ratings yet

- Checklists: Title: Checklist For Preventive Maintenance of EquipmentsDocument1 pageChecklists: Title: Checklist For Preventive Maintenance of Equipmentsjp mishraNo ratings yet

- JINDAL POWER LIMITED CHECKLIST FOR PREVENTIVE MAINTENANCE OF CONDENSATE EXTRACTION PUMPSDocument1 pageJINDAL POWER LIMITED CHECKLIST FOR PREVENTIVE MAINTENANCE OF CONDENSATE EXTRACTION PUMPSjp mishraNo ratings yet

- Checklists Title: Checklist For Preventive Maintenance of Equipments TG & Bop Maintenance Department Condenser On Load Tube Cleaning PumpDocument1 pageChecklists Title: Checklist For Preventive Maintenance of Equipments TG & Bop Maintenance Department Condenser On Load Tube Cleaning Pumpjp mishraNo ratings yet

- PM F 11 HydDoz PumpsDocument1 pagePM F 11 HydDoz Pumpsjp mishraNo ratings yet

- PM F 10 AmmDoz PumpsDocument1 pagePM F 10 AmmDoz Pumpsjp mishraNo ratings yet

- Checklists Title: Checklist For Preventive Maintenance of Equipments TG & Bop Maintenace Department Main Centrifuging UnitDocument1 pageChecklists Title: Checklist For Preventive Maintenance of Equipments TG & Bop Maintenace Department Main Centrifuging Unitjp mishraNo ratings yet

- Checklists: Title: Checklist For Preventive Maintenance of EquipmentsDocument1 pageChecklists: Title: Checklist For Preventive Maintenance of Equipmentsjp mishraNo ratings yet

- Checklists: Title: Checklist For Preventive Maintenance of EquipmentsDocument1 pageChecklists: Title: Checklist For Preventive Maintenance of Equipmentsjp mishraNo ratings yet

- Checklists Title: Checklist For Preventive Maintenance of Equipments TG & Bop Maintenance Department Lub Oil SystemDocument2 pagesChecklists Title: Checklist For Preventive Maintenance of Equipments TG & Bop Maintenance Department Lub Oil Systemjp mishraNo ratings yet

- Standard Checklist: Preventive Maintenance - 6 MonthsDocument2 pagesStandard Checklist: Preventive Maintenance - 6 MonthsHappy Prakoso adhiNo ratings yet

- CM-ELEC - (61 and 73) - SEND TO MGPS AT (04-11-2020) ReprintDocument2 pagesCM-ELEC - (61 and 73) - SEND TO MGPS AT (04-11-2020) Reprintali morisyNo ratings yet

- Cm-Elec - (53 To 55) - Send To MGPS at (23-08-2020)Document3 pagesCm-Elec - (53 To 55) - Send To MGPS at (23-08-2020)ali morisyNo ratings yet

- Ims-Om-Cl-001-R00 AcdbDocument1 pageIms-Om-Cl-001-R00 AcdbVeerendra YduvanshiNo ratings yet

- Cm-Mech - (49 To 50) - Send To MGPS at (13-08-2020)Document3 pagesCm-Mech - (49 To 50) - Send To MGPS at (13-08-2020)ali morisyNo ratings yet

- Power Transformer - 1M - CDocument3 pagesPower Transformer - 1M - CahmedelgharibNo ratings yet

- JCB VM115 Single Drum RollerDocument9 pagesJCB VM115 Single Drum Roller江柄宏100% (1)

- (F-PR-10) Contingency PlanDocument3 pages(F-PR-10) Contingency PlanshalinmishraNo ratings yet

- 05 Equipment Maintenance ScheduleDocument2 pages05 Equipment Maintenance ScheduleMagda MargaNo ratings yet

- WI-MR-09Document1 pageWI-MR-09cer.qualityNo ratings yet

- All Work InstructionsDocument7 pagesAll Work InstructionsAmine Chahi100% (1)

- MTPL-OM-PPM-CL-003 - PPM Checklist For AFUDocument2 pagesMTPL-OM-PPM-CL-003 - PPM Checklist For AFUVeerendra YduvanshiNo ratings yet

- MARIB GAS POWER GENERATION STATION CORRECTIVE MAINTENANCEDocument1 pageMARIB GAS POWER GENERATION STATION CORRECTIVE MAINTENANCEali morisyNo ratings yet

- Cm-Mech - (73 To 74) - Send To MGPS at (03-11-2020)Document2 pagesCm-Mech - (73 To 74) - Send To MGPS at (03-11-2020)ali morisyNo ratings yet

- Maintaining Electrical SystemsDocument32 pagesMaintaining Electrical Systemsdinie90100% (2)

- Maintaining Power GenerationDocument1 pageMaintaining Power Generationali morisyNo ratings yet

- Tmu-1105 Job Card Ta-2019Document20 pagesTmu-1105 Job Card Ta-2019Anonymous YRyGcKPNo ratings yet

- Forging Machine Preventive MaintenanceDocument4 pagesForging Machine Preventive Maintenancemr. kNo ratings yet

- SPETCO JPF3 Electrical Maintenance ReportDocument1 pageSPETCO JPF3 Electrical Maintenance ReportrijoNo ratings yet

- Cm-Inst - (23 To 24) - Send To MGPS at ( 27-07-2020)Document2 pagesCm-Inst - (23 To 24) - Send To MGPS at ( 27-07-2020)ali morisyNo ratings yet

- MGAS PLC HEATER REPAIRDocument1 pageMGAS PLC HEATER REPAIRali morisyNo ratings yet

- SERD - Form - Closure InspectionDocument1 pageSERD - Form - Closure InspectionAzhar BudimanNo ratings yet

- Far LZ400895Document10 pagesFar LZ400895Soubhagya BeheraNo ratings yet

- Form Comm Water Pump NewDocument1 pageForm Comm Water Pump Newekoimamp100% (1)

- Maintenance Transaction Record: Aircraft Identification and StatusDocument1 pageMaintenance Transaction Record: Aircraft Identification and StatusAlejandro BarradasNo ratings yet

- HSE Report Makhazen S/SDocument6 pagesHSE Report Makhazen S/SAnonymous kWfNFbNo ratings yet

- GDI Rig Drillers Cabin Preventive MaintenanceDocument3 pagesGDI Rig Drillers Cabin Preventive MaintenanceMousa PetrolNo ratings yet

- Diesel TankDocument1 pageDiesel TankRejo AbrahamNo ratings yet

- Eo Atr42-72-21001 R00 Ata 72 - Engine - Igniter Plug With Incorrect Terminal - Inspection ofDocument7 pagesEo Atr42-72-21001 R00 Ata 72 - Engine - Igniter Plug With Incorrect Terminal - Inspection ofVince Renier RamosNo ratings yet

- Manual Ultrasonic Testing ProcedureDocument17 pagesManual Ultrasonic Testing Procedurebaskaran ayyapparaj100% (2)

- MTPL-OM-PPM-CL-001 - PPM Checklist For Control Relay Panel (PSS)Document1 pageMTPL-OM-PPM-CL-001 - PPM Checklist For Control Relay Panel (PSS)Veerendra YduvanshiNo ratings yet

- Preventive Maintenance ProcedureDocument4 pagesPreventive Maintenance ProcedureHanin BouzianeNo ratings yet

- Departmental Procedures For CWP: Turbine MaintenanceDocument2 pagesDepartmental Procedures For CWP: Turbine MaintenanceHiltonNo ratings yet

- PRES-E-03 Electrical Equipment - Motor & GeneratorDocument2 pagesPRES-E-03 Electrical Equipment - Motor & GeneratorsalamlinNo ratings yet

- History Card. - Water BathDocument1 pageHistory Card. - Water BathRISHI FOOD TESTING LABNo ratings yet

- Inspection Report: Page 1 of 2 Vendor P.O. NODocument4 pagesInspection Report: Page 1 of 2 Vendor P.O. NOsudipta dasNo ratings yet

- MARIB GAS POWER GENERATION STATION CORRECTIVE MAINTENANCE PERMITDocument1 pageMARIB GAS POWER GENERATION STATION CORRECTIVE MAINTENANCE PERMITali morisyNo ratings yet

- SOP-04 Preventive Maintenance of DG SetsDocument11 pagesSOP-04 Preventive Maintenance of DG SetsPandu BirumakovelaNo ratings yet

- FAR_ZBN41205Document4 pagesFAR_ZBN41205yeremia kristianNo ratings yet

- Cm-Elec - (47 To 47) - Send To MGPS at (03-08-2020)Document1 pageCm-Elec - (47 To 47) - Send To MGPS at (03-08-2020)ali morisyNo ratings yet

- Emergency Air FailureDocument17 pagesEmergency Air Failureabhrrajjit SANo ratings yet

- QCV Key Test CertifiactesDocument1 pageQCV Key Test CertifiactesShashank RajputNo ratings yet

- Aux RelayDocument1 pageAux RelaysupermannonNo ratings yet

- Temporary Revision: Maintenance Manual Extra 300/ScDocument40 pagesTemporary Revision: Maintenance Manual Extra 300/ScmhafizanNo ratings yet

- Pre-Commissioning Format For Reactor: I. General DetailsDocument27 pagesPre-Commissioning Format For Reactor: I. General Detailsmayur dhandeNo ratings yet

- Dasarathi Naik and Engineers Pvt. Ltd. Concrete Pour Card: ClientDocument1 pageDasarathi Naik and Engineers Pvt. Ltd. Concrete Pour Card: ClientTusarranjan BhuyanNo ratings yet

- 05 - Abdul K - VRFDocument34 pages05 - Abdul K - VRFroshan jaiswalNo ratings yet

- Stage II PA System Unit 1 Zone 2 CheckDocument1 pageStage II PA System Unit 1 Zone 2 Checkjp mishraNo ratings yet

- TG Lube Oil FlushingDocument38 pagesTG Lube Oil Flushingjp mishraNo ratings yet

- Unethical Business Practices and Their Effects Term PaperDocument13 pagesUnethical Business Practices and Their Effects Term Paperjp mishraNo ratings yet

- Operation Best PracticesDocument30 pagesOperation Best Practicesjp mishraNo ratings yet

- Commissioning Procedure for Turbine Barring GearDocument9 pagesCommissioning Procedure for Turbine Barring Gearjp mishraNo ratings yet

- DM Water from DM Plant Nb 150mmDocument4 pagesDM Water from DM Plant Nb 150mmjp mishraNo ratings yet

- Referral Archive-Boiler & Aux. (4X600Mw) : Materials Engineering Drawing Erection DrawingDocument8 pagesReferral Archive-Boiler & Aux. (4X600Mw) : Materials Engineering Drawing Erection Drawingjp mishraNo ratings yet

- Aux Power OptimisationDocument18 pagesAux Power Optimisationjp mishraNo ratings yet

- TG Referal DatapediaDocument20 pagesTG Referal Datapediajp mishraNo ratings yet

- Steam Blowing Scheme For 600mwDocument2 pagesSteam Blowing Scheme For 600mwjp mishraNo ratings yet

- Servo PrimeDocument1 pageServo PrimeRakeshKumarNo ratings yet

- Commissioning of TDBFPDocument22 pagesCommissioning of TDBFPjp mishraNo ratings yet

- TG Deck DrawingDocument3 pagesTG Deck Drawingjp mishraNo ratings yet

- 500 MW GovDocument1 page500 MW Govjp mishraNo ratings yet

- LP BY PASS VALVE202787-88-89-90 - Raigarh - Operation and Maintenance Manual - Par PDFDocument204 pagesLP BY PASS VALVE202787-88-89-90 - Raigarh - Operation and Maintenance Manual - Par PDFjp mishra100% (2)

- FIELD QUALITY PLAN FOR TURBO GENERATOR ERECTION AND COMMISSIONINGDocument85 pagesFIELD QUALITY PLAN FOR TURBO GENERATOR ERECTION AND COMMISSIONINGjp mishraNo ratings yet

- Jindal Power Limited O.P.J.S.T.P.P, Tamnar, Raigarh: Commissioning DepartmentDocument12 pagesJindal Power Limited O.P.J.S.T.P.P, Tamnar, Raigarh: Commissioning Departmentjp mishraNo ratings yet

- Jindal Power Limited O.P.J.S.T.P.P, Tamnar, Raigarh: Commissioning DepartmentDocument12 pagesJindal Power Limited O.P.J.S.T.P.P, Tamnar, Raigarh: Commissioning Departmentjp mishraNo ratings yet

- Schematic Diagram of Sealing & Cooling Water For CepDocument12 pagesSchematic Diagram of Sealing & Cooling Water For Cepjp mishraNo ratings yet

- CP - EDTA Cleaning Mod PDFDocument24 pagesCP - EDTA Cleaning Mod PDFjp mishraNo ratings yet

- LP HeaterDocument12 pagesLP Heaterjp mishraNo ratings yet

- Commissioning of TDBFPDocument22 pagesCommissioning of TDBFPjp mishraNo ratings yet

- Generator Air Tightness TestDocument10 pagesGenerator Air Tightness Testjp mishraNo ratings yet

- PPChem 2014 16 06 344-351Document8 pagesPPChem 2014 16 06 344-351jp mishraNo ratings yet

- Schematic Diagram of Sealing & Cooling Water For CepDocument12 pagesSchematic Diagram of Sealing & Cooling Water For Cepjp mishraNo ratings yet

- Turbine Performance EECDocument19 pagesTurbine Performance EECumamahesh259No ratings yet

- 023 CepDocument12 pages023 Cepjp mishraNo ratings yet

- Boiler Flow DiagramDocument1 pageBoiler Flow Diagramjp mishraNo ratings yet

- Jindal Power Limited O.P.J.S.T.P.P, Tamnar, Raigarh: Commissioning DepartmentDocument9 pagesJindal Power Limited O.P.J.S.T.P.P, Tamnar, Raigarh: Commissioning Departmentjp mishraNo ratings yet

- Reducing Boiler Cooling Time Saves Rs. 13.5 Crore AnnuallyDocument16 pagesReducing Boiler Cooling Time Saves Rs. 13.5 Crore Annuallyjp mishraNo ratings yet

- L Series 1770Document76 pagesL Series 1770JuprayNo ratings yet

- Physics EEDocument4 pagesPhysics EEEjaz AhmadNo ratings yet

- Combustion ChemistryDocument17 pagesCombustion Chemistryrajeev50588No ratings yet

- Map of Indian Refineries CapacityDocument2 pagesMap of Indian Refineries Capacityingbarragan87No ratings yet

- f2 (2) (1) Reviewer Chief Officer Materials.Document20 pagesf2 (2) (1) Reviewer Chief Officer Materials.Alden Almaquer Delizo100% (1)

- Aviation FuelDocument123 pagesAviation FuelFahd_Bugti_7607100% (2)

- Omega Fluid PDFDocument2 pagesOmega Fluid PDFapatzinfedNo ratings yet

- 1703 C014Document10 pages1703 C014Swapnajit KonwarNo ratings yet

- F3 3Document16 pagesF3 3Santoso Wahyudi100% (2)

- Henares Vs LTFRBDocument4 pagesHenares Vs LTFRBCarlos JamesNo ratings yet

- ATP 4-43 Petroleum Supply Operations GuideDocument242 pagesATP 4-43 Petroleum Supply Operations GuideGerry SantosNo ratings yet

- Heat Treatment Process ComparisonDocument2 pagesHeat Treatment Process ComparisonleshickensNo ratings yet

- Energy Master Plan 2010Document192 pagesEnergy Master Plan 2010Retal MohamedNo ratings yet

- 3 03 Small Bore Latest New DevelopmentDocument36 pages3 03 Small Bore Latest New DevelopmentCelesNo ratings yet

- Engine Fuel System Troubleshooting GuideDocument19 pagesEngine Fuel System Troubleshooting GuidePablo Rojas Valenzuela100% (1)

- Front Burner: UpdateDocument3 pagesFront Burner: UpdateHassan ManzarNo ratings yet

- Summer Training Report - Vidit Kumar SinghDocument65 pagesSummer Training Report - Vidit Kumar Singhvidit Singh100% (2)

- Training Courses Registration Information: Registration Type Package Includes Price, Rur, Incl. VAT (18%)Document1 pageTraining Courses Registration Information: Registration Type Package Includes Price, Rur, Incl. VAT (18%)UdhamNo ratings yet

- NR 320801 Mass Transfer Operations IIDocument6 pagesNR 320801 Mass Transfer Operations IISrinivasa Rao G100% (6)

- Analysis of CombustionDocument14 pagesAnalysis of CombustionNARESHNo ratings yet

- S OkeDocument1 pageS OkePaul Rojas CarbajalNo ratings yet

- Investments in Refinery Capaticies in Serbia: September 2016 Belgrade, Energy Community Vladimir Gagic, NIS, RefineryDocument19 pagesInvestments in Refinery Capaticies in Serbia: September 2016 Belgrade, Energy Community Vladimir Gagic, NIS, Refineryingbarragan87No ratings yet

- Enhanced Single Mixed Refrigerant Process For Stranded Gas LiquefactionDocument10 pagesEnhanced Single Mixed Refrigerant Process For Stranded Gas Liquefactionyulian naufalNo ratings yet

- Blasting Terms 2Document10 pagesBlasting Terms 2Lara CharisseNo ratings yet

- Characteristics of Aromatic Compounds: Chemistry Molecule ConjugatedDocument4 pagesCharacteristics of Aromatic Compounds: Chemistry Molecule ConjugatedBobby RedianNo ratings yet

- D187 PDFDocument4 pagesD187 PDFJuan Diego ArizabalNo ratings yet

- Repeatability & Reproducibility of HFODocument5 pagesRepeatability & Reproducibility of HFOshishir4870No ratings yet

- Introduction To Gas EngineeringDocument34 pagesIntroduction To Gas EngineeringArslanQureshiNo ratings yet

- Engineering Manual Viscous and High Density: General Industry SegmentDocument52 pagesEngineering Manual Viscous and High Density: General Industry SegmentingrbarrosNo ratings yet

- 6..resistivity LogDocument29 pages6..resistivity LogSagar DadhichNo ratings yet