Professional Documents

Culture Documents

316 SS A4-70

Uploaded by

Nicholas VineyCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

316 SS A4-70

Uploaded by

Nicholas VineyCopyright:

Available Formats

DataSheet

Fasteners for maximum performance

FASTENERS FOR MAXIMUM PERFORMANCE

In modern constructions there is a demand for fasteners having ever inc- was specified. We have now further developed our products and in this

reasing properties in order to reduce the weight, decrease the cost and brochure we present two new product lines the BUMAX 88 and BUMAX

at the same time increase the safety of the construction. Here the low 109, having unique properties. For these products we have set the goal

alloyed hardenable steels have had a leading position in industry inclu- to reach the same Tensile and Yield strength as those valid for steel

ding many high strength variants such as 8.8, 10.9 and 12.9. A big screws 8.8 and 10.9. At the same time these products should have bet-

disadvantage for fasteners in these types of steels is their very poor cor- ter corrosion properties and other features than that of normal acid

rosion resistance in aggressive environments, their low strength at eleva- proof A4 products normally sold in the market. In this brochure, we pre-

ted temperatures and that they become very brittle at cryogenic tempe- sent the most important characteristics for our unique products and

Fasteners for maximum performance

ratures. Bulten Stainless have for a long time been at the leading edge where they clearly differ from the normal Trade Standard. In table 1

of development in high strength fasteners of corrosion resistant steels the mechanical properties for A4 Trade Standard are shown compa-

and was one of the main driving factors in pursuit of the international red to those of BUMAX 88 and BUMAX 109.

standard ISO 3506, where among other things, the property class 80

BUMAX 88: 800/640 N/mm2 BUMAX 109: 1000/900 N/mm2

Load Load

in N/mm2 in N/mm2

1000 1000

Rm 800 N/mm2 min Rm 1000 N/mm2 min 900

750 Rp 0,2 640 N/mm2 min Rp 0,2 900 N/mm2 min 750

640 80 % of the tensile strength 90% of the tensile strength

500 500

250 250

0 0

0,2% permanent Linear strain 0,2% permanent Linear strain

strain strain

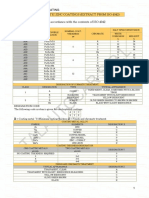

MECHANICAL PROPERTIES FOR FASTENERS IN AUSTENITIC STEELS

GROUP/ STRENGTH- DIAMETER ULTIMATE TENSILE STRESS AT 0,2% PERMA- ELONGATION

TYPE CLASS RANGE STRENGTH Rm N/mm2 NENT STRAIN RP 0,2 N/mm 2

AT FAILURE

A4-70 70 M24 700 450 0,4 x d

A4-80 80 M24 800 600 0,3 x d

BUMAX 88 80 M36 800 640 0,3 x d *

BUMAX 109 100 M12 1000 900 0,2 x d

BUMAX 109 100 M14 - M20 1000 800 0,2 x d

TABLE 1 * For dimensions >M30 the elongation at failure is 0,2 x d min.

PRINCIPAL ANALYSIS FOR SOME ACID PROOF STEELS

BUMAX 88 and BUMAX 109 are produced in a version of the Swedish In Table 2, the chemical composition for (316,316 L) A4 and BUMAX

steel grade SS2343 having the carbon content (C) maximised to 88 and BUMAX 109 are shown.

0,030%, we call this grade 316 L Hi Mo.

STEELGRADE C max Cr Ni Mo

A4 (316) 0,080 16,0-18,0 10,0-14,0 2,0-3,0

A4 (316L) 0,030 16,0-18,0 10,0-14,0 2,0-3,0

BUMAX 88 0,030 16,5-18,5 11,0-14,5 2,5-3,0

BUMAX 109 0,030 16,5-18,5 11,0-14,5 2,5-3,0

TABLE 2

CORROSION PROPERTIES

The three most common and most severe types of corrosion in falling Also the Carbon content (C) have influence, especially at elevated tem-

severeness are Pitting, Crevise and General Corrosion. peratures. The seemingly small differences of these alloying elements

The chemical composition of the steel have an important influence on has a great influence on the properties of the steel.

how well it can combat the different types of corrosion. The most impor- A number of laboratory tests have proved that the 316 L Hi Mo

tant elements for this ability are Chromium (Cr), Molybdeunum (Mo) (SS2343) the grade used in BUMAX 88 and BUMAX 109, is superior

and Nitrogen (N). to normal trade standard A4 for all different media and all types of cor-

rosion.

Disclaimer: While every reasonable effort has been made to ensure that this document is correct at the time of printing, Hobson Engineering, its agencies and employees, disclaim

any and all liability to any person in respect of anything or the consequences of anything done or omitted to be done in reliance upon the whole or any part of this document.

Release: October 8, 2014 www.conxtruct.com.au

DataSheet

Fasteners for maximum performance

MECHANICAL PROPERTIES AT HIGH AND LOW TEMPERATURES

The properties of a steel is effected by the temperature at which it will table, values for class 70 and 80 in A4 together with the BUMAX 88

be working. When the temperature increases, the mechanical strength and BUMAX 109 products, are shown. For Class 50, which is the same

will decrease. In Table 3, the remaining yield strength at elevated tem- as the steel in annealed condition, we refer to the valid steel standard

peratures is shown as a percentage of the value at room temperature. data sheets. In the table, we also show the highest recommendable wor-

The values in the table are only to be regarded as guidelines. In the king temperature in air for fasteners in each grade and property class.

STEEL AND REMAINING YELD STRENGTH IN % OF THAT AT ROOM TEMPERATURE (RT) WORKING

STRENGTH CLASS 100C 200C 300C 400C 500C 600C TEMP. IN AIR

A4-70/80 85 80 75 70 450500

Fasteners for maximum performance

BUMAX 88 90 90 85 80 75 70 600

BUMAX 109 95 95 95 90 90 85 600

TABLE 3

IMPACT TEST AT DIFFERENT TEMPERATURES

At low temperatures the normal low alloyed steels becomes very brittle test of screws in different property classes are shown. The impact streng-

whereas the austenitic steels keep their toughness and can be used at th decreases with increased strenght. In spite of the high strenght of

very low temperatures. The steel ability to function at low temperatures BUMAX 88 and BUMAX 109 the impact strength is relatively good and

is defined by its impact strength. In the table 4 the results from impact considerably better than that of steel screw 8.8 and 10.9.

STRENGTH CLASS IMPACT STRENGTH IN JOULE (J) AT C

20 -50 -100 -140 -196

A4-70 96,9 91,9 84,5 80,5 73,4

BUMAX 88 79,5 74,5 69,0 60,0 47,4

BUMAX 109 36,0 34,0 32,9 31,0 29,5

TABLE 4

RELATIVE PERMEABILITY FOR SOME STEEL GRADES AND PROPERTY CLASSES

Permeability is a measurement on a materials ability to let a magnetic is of greatest importance to use use fasteners having low magnetic per-

field go through and is described as the permeability value km. This is meability (km). In table 5 the km for some stainless and acid proof steels

the value for the permeability of a material in relation to vacuum, where are presented. There is a noticeable difference between BUMAX 88,

the km is 1,0 i.e. totally non-magnetic. In high-tech market segments such BUMAX 109 and the other grades. The values for the BUMAX products

as electronics, computer industry and some parts of the marine industry it are so low that they could be regarded as non magnetic.

STEEL GRADE Rp 0,2 I N/mm2 MAXIMUM RELATIVE PERMEABILITY

AND CLASS km

A2-70 450 1,400

A2-80 600 1,800

A4-80 600 1,012

BUMAX 88 640 1,006

BUMAX 109 900 1,007

TABLE 5

FRICTION IN BOLTED JOINTS

Friction in bolted joints is characterised by and is a value on how in the joint. Bulten Stainless BUMAX 88 and BUMAX 109 are treated

smooth the surfaces are gliding against each other. In order to be able with a special anti friction media and there is normally no demand for

to make use of the high strength fasteners in a proper way, it is essenti- additional lubrication when they are assembled with a nut. When

al that the joint gets the correct preload and is tightened by using a assembling in a threaded hole, additional treatment is often needed. In

dynamometric wrench. The condition to obtain a correct tightening tor- figure 1, a friction test of A4 trade standard (untreated) compared with

que resulting in a correct preload is to have as low friction as possible BUMAX 88 and BUMAX 109 are shown.

0,5

0,4

0,3

0,2

A4-(316)-80

0,1

BUMAX 88

FIGURE 1 BUMAX 109

0,0

Thread Head Total

Disclaimer: While every reasonable effort has been made to ensure that this document is correct at the time of printing, Hobson Engineering, its agencies and employees, disclaim

any and all liability to any person in respect of anything or the consequences of anything done or omitted to be done in reliance upon the whole or any part of this document.

Release: October 8, 2014 www.conxtruct.com.au

DataSheet

Fasteners for maximum performance

TIGHTENING TORQUE AND FORCES

In order to keep a joint tight, it is of greatest importance that the This is due to the fact that the tightening force is used to overcome

correct preload is reached when assembling. TIGHTENING TORQUE

The values in Table 6 are calculated to give a preload of about

AND

friction FORCES

instead of tensioning the joint. BUMAX 88 and BUMAX 109

are treated with a high performance lubricant in order to obtain low

In order

65% to Rp

of the keep0,2a(0,2%

joint tight, it is ofstrain).

permanent greatest importance that the This is due to the fact that the tightening force is used to overcome

friction.

correct preload

Correct preload iscanreached

only bewhen assembling.

reached in a joint having low friction. friction

For instead

these of tensioning

products, the joint.

the variation BUMAX

of the 88 andvalues

preloading BUMAXare109

not

IfThe

novalues in Table

anti friction media6 are calculated

is used to givecan

the preload a preload of about

vary heavily and are treated

more than with a high

+/-15% performance

when assembling lubricant

in nutsin using

order to

a obtain low

calibrated

65%reach

can of theasRplow

0,2levels

(0,2%aspermanent

20% of thestrain).

given value. friction.

dynamometric wrench.

Correct preload can only be reached in a joint having low friction. For these products, the variation of the preloading values are not

If no anti friction media is used the preload can vary heavily and more than +/-15% when assembling in nuts using a calibrated

can reach as low levels as 20% of the given value. dynamometric wrench.

DESCRIPTION CLASS DIMENSION

M3 M4 M5 M6 M8 M10 M12 M14 M16 M18 M20 M24 M27 M30 M36

Fasteners for maximum performance

DESCRIPTION CLASS DIMENSION

A4-70 0,9 2,0 4,1 7,0 17 33 57 91 140 195 273 472 682 930 1620

TIGHTENING M3 M4 M5 M6 M8 M10 M12 M14 M16 M18 M20 M24 M27 M30 M36

A4-80 1,2 2,7 5,4 9,3 22 44 76 121 187 261 364 629 909 1240 2160

TORQUE

BUMAX

A4-7088 1,3

0,9 2,9

2,0 5,7

4,1 9,8

7,0 25

17 47

33 82

57 129

91 198

140 275

195 385

273 665

472 961

682 1310

930 2280

1620

Mv I Nm

TIGHTENING

BUMAX

A4-80109 1,7

1,2 4,1

2,7 8,1

5,4 14

9,3 34

22 66

44 115

76 161

121 248

187 344

261 481

364 629 909 1240 2160

TORQUE

BUMAX 88 1,3 2,9 5,7 9,8 25 47 82 129 198 275 385 665 961 1310 2280

Mv I Nm

BUMAX 109 1,7 4,1 8,1 14 34 66 115 161 248 344 481

DESCRIPTION CLASS DIMENSION

M3 M4 M5 M6 M8 M10 M12 M14 M16 M18 M20 M24 M27 M30 M36

DESCRIPTION CLASS DIMENSION

A4-70 1,5 2,6 4,2 5,9 11 17 25 34 47 56 72 103 134 164 239

PRELOAD M3 M4 M5 M6 M8 M10 M12 M14 M16 M18 M20 M24 M27 M30 M36

A4-80 2,0 3,4 5,5 7,8 14 23 33 45 61 75 96 138 179 219 319

APPLIED

BUMAX

A4-7088 2,1

1,5 3,6

2,6 5,9

4,2 8,4

5,9 15

11 24

17 35

25 48

34 65

47 80

56 102

72 181

103 235

134 287

164 418

239

kN

PRELOAD

BUMAX

A4-80109 2,9

2,0 5,2

3,4 8,6

5,5 12

7,8 21

14 34

23 49

33 60

45 81

61 100

75 128

96 138 179 219 319

APPLIED

BUMAX 88 2,1 3,6 5,9 8,4 15 24 35 48 65 80 102 181 235 287 418

kN

BUMAX 109 2,9 5,2 8,6 12 21 34 49 60 81 100 128

DESCRIPTION CLASS DIMENSION

M3 M4 M5 M6 M8 M10 M12 M14 M16 M18 M20 M24 M27 M30 M36

DESCRIPTION CLASS DIMENSION

A4-70 3,5 6,1 9,9 14 26 41 59 81 110 134 172 247 321 393 572

FAILURE LOAD A4-80 M3

4,0 M4

7,0 M5

11 M6

16 M8

29 M10

46 M12

67 M14

92 M16

126 M18

154 M20

196 M24

282 M27

367 M30

449 M36

654

kN BUMAX

A4-7088 4,0

3,5 7,0

6,1 11

9,9 16

14 29

26 46

41 67

59 92

81 126

110 154

134 196

172 282

247 367

321 449

393 654

572

FAILURE LOAD BUMAX

A4-80109 5,0

4,0 8,8

7,0 14

11 20

16 37

29 58

46 84

67 115

92 157

126 192

154 245

196 282 367 449 654

kN BUMAX 88 4,0 7,0 11 16 29 46 67 92 126 154 196 282 367 449 654

BUMAX 109 5,0 8,8 14 20 37 58 84 115 157 192 245

DESCRIPTION CLASS DIMENSION

M3 M4 M5 M6 M8 M10 M12 M14 M16 M18 M20 M24 M27 M30 M36

DESCRIPTION CLASS DIMENSION

A4-70 2,2 3,9 6,4 9,0 16 26 38 52 71 86 110 159 207 253 368

YIELD LOAD A4-80 M3

3,0 M4

5,3 M5

8,5 M6

12 M8

22 M10

35 M12

51 M14

69 M16

94 M18

115 M20

147 M24

282 M27

367 M30

449 M36

654

kN BUMAX

A4-7088 3,2

2,2 5,6

3,9 9,1

6,4 13

9,0 23

16 37

26 54

38 74

52 101

71 123

86 157

110 226

159 294

207 359

253 523

368

YIELD LOAD BUMAX

A4-80109 4,5

3,0 8,0

5,3 13

8,5 18

12 33

22 52

35 76

51 93

69 125

94 154

115 196

147 212

282 275

367 337

449 490

654

kN BUMAX 88 3,2 5,6 9,1 13 23 37 54 74 101 123 157 226 294 359 523

BUMAX 109 4,5 8,0 13 18 33 52 76 93 125 154 196

DESCRIPTION DIMENSION

M3 M4 M5 M6 M8 M10 M12 M14 M16 M18 M20 M24 M27 M30 M36

DESCRIPTION DIMENSION

STRESS AREA mm 2

5,03 8,78 14,2 20,1 36,6 58 84,3 115 157 192 245 353 459 561 817

M3 M4 M5 M6 M8 M10 M12 M14 M16 M18 M20 M24 M27 M30 M36

THREAD PITCH mm 0,5 0,7 0,8 1,0 1,25 1,5 1,75 2,0 2,0 2,5 2,5 3,0 3,0 3,5 4,0

STRESS

TABLE 6 AREA mm2 5,03 8,78 14,2 20,1 36,6 58 84,3 115 157 192 245 353 459 561 817

THREAD PITCH mm 0,5 0,7 0,8 1,0 1,25 1,5 1,75 2,0 2,0 2,5 2,5 3,0 3,0 3,5 4,0

TABLE 6

Disclaimer: While every reasonable effort has been made to ensure that this document is correct at the time of printing, Hobson Engineering, its agencies and employees, disclaim

any and all liability to any person in respect of anything or the consequences of anything done or omitted to be done in reliance upon the whole or any part of this document.

Release: October 8, 2014 www.conxtruct.com.au

DataSheet

Fasteners for maximum performance

STOCK PROGRAMME SERVICE

BUMAX 88 products are stocked in a wide range from M3 to M36 The BUMAX 88 and BUMAX 109 products are manufactured in our

and the most common types of screws, nuts and washers. We also own factories and therefore we can keep a very high service level

stock a range of UNC-threaded products. on these products.

Our stock of BUMAX 109 is unique in the world and we have incre- Thanks to our own manufacturing, we can offer sizes other than

ased this stock range successively. those presented in our stock range enabling us to produce special

Today we stock BUMAX 109 hexagon screws and bolts from products according to each customers needs.

M6 x 20 mm to M12 x 120 mm and in addition nuts and washers We can produce products having even higher strength than the

in corresponding sizes. ones presented in this brochure. In these cases, it is the limitations

on the steel itself deciding how far we can reach in terms of strength

and other properties. We are continuously working on improving

Fasteners for maximum performance

the properties of our products.

QUALITY DURABLE PACKING

ISO 9001-QS 9000 WITH CLEAR MARKING

Within Bulten Stainless AB we are working according to the QA- Our products are packed in high quality sturdy boxes and are mar-

Systems ISO 9001 and QS 9000 and are third party certified by ked according to a colour coded system. This system is described in

TV. our product catalogues. We guarantee full traceability for all our

products in unbroken boxes.

On our labels all data for full traceability is given. The picture below

explains the data given on the label.

Orange lable BUMAX 88

SS2343/1.4436/316L HI MO

Type symbol

Norm./standard Part number

Number of pcs. Charge number

and dimensions Production lot No

in the box Packing date

APPLICATIONS

Bulten Stainless products are already used today in applications Within the off-shore industry, weight saving is of great importance

where there are demands for high strength, good corrosion properti- and here the high strength technology correctly applied, resulted in

es and high finish for safe assemblies, e.g. pumps and flange con- extremely good weight savings at the same time keeping, or even

nections for high vacuum. Another interesting area is the marine sec- increasing, the safety. The VCF Compact Flange System is a good

tor for power transmission joints where our BUMAX 109 have repla- example on this technology. The new products are also of interest

ced 10.9 steel screws which corroded in the actual environment. for the automotive industry where weight saving and increased safe-

ty are now becoming more important than ever before.

VCF-Compact flange from VERAX. Aquadrive-coupling from Svenska Uni-Cardan AB

Disclaimer: While every reasonable effort has been made to ensure that this document is correct at the time of printing, Hobson Engineering, its agencies and employees, disclaim

any and all liability to any person in respect of anything or the consequences of anything done or omitted to be done in reliance upon the whole or any part of this document.

Release: October 8, 2014 www.conxtruct.com.au

You might also like

- ASTM & SAE Grade Markings For Bolts and ScrewsDocument2 pagesASTM & SAE Grade Markings For Bolts and ScrewsDavid D'AgostinoNo ratings yet

- Mil S 13165Document20 pagesMil S 13165Francisco Ribeiro FernandesNo ratings yet

- Training ModuleDocument44 pagesTraining ModulegereNo ratings yet

- Blackodizing CPDocument1 pageBlackodizing CPx yNo ratings yet

- ISO 8752 PinDocument7 pagesISO 8752 PinCarlos SolerNo ratings yet

- Tata Steel - YMPRESS S500MC - Data SheetDocument2 pagesTata Steel - YMPRESS S500MC - Data SheetpnagarajjNo ratings yet

- Root and Face Bend TestsDocument3 pagesRoot and Face Bend TestsErlinawati Bintu SupiyoNo ratings yet

- 2430 & TB2448 ComarisionDocument6 pages2430 & TB2448 ComarisionpiyushNo ratings yet

- Electrolytic Zinc Coating PDFDocument2 pagesElectrolytic Zinc Coating PDFzoran100% (1)

- IS 2062 E 250 GR A BS EN 10025-2 S 235 JR Chamical Thikness 16 16 40 40 C% SI% MN% P% S% Cu% N%Document10 pagesIS 2062 E 250 GR A BS EN 10025-2 S 235 JR Chamical Thikness 16 16 40 40 C% SI% MN% P% S% Cu% N%kartikNo ratings yet

- Ralin Group Brochure 2013Document3 pagesRalin Group Brochure 2013n1ghtfallNo ratings yet

- Gyproc 2Document3 pagesGyproc 2Govind NataniNo ratings yet

- Thành Phần, Cơ Tính JIS G4801 SUP10 Steel PlateDocument2 pagesThành Phần, Cơ Tính JIS G4801 SUP10 Steel PlateĐình Sỹ TTPNo ratings yet

- Geomet 500 PDFDocument2 pagesGeomet 500 PDFKaran Chadha100% (1)

- M6x1.0x23 Long HHS Control PlanDocument2 pagesM6x1.0x23 Long HHS Control PlanDhanluxmi AutomaticsNo ratings yet

- Fabory Fasteners Basic StandardsDocument12 pagesFabory Fasteners Basic Standardsjuan carlos galvez abantoNo ratings yet

- Tolerance CalculatorDocument4 pagesTolerance CalculatorAshok Kumar UppariNo ratings yet

- Din 908Document2 pagesDin 908Dani Quirante Flaaut EtcNo ratings yet

- Surface Finish TerminologyDocument30 pagesSurface Finish TerminologyXin YuNo ratings yet

- Meiser GratingDocument122 pagesMeiser GratingTtx Endless LoveNo ratings yet

- Jis D0203 PDFDocument6 pagesJis D0203 PDFsabaris ksNo ratings yet

- AMADA Painutustooriistade Kataloog 2012Document0 pagesAMADA Painutustooriistade Kataloog 2012sssf-dobojNo ratings yet

- Material SpecificationDocument9 pagesMaterial SpecificationMuthu GaneshNo ratings yet

- Hammer Drive ScrewDocument1 pageHammer Drive ScrewNisa BN QANo ratings yet

- Laser WeldingDocument11 pagesLaser WeldingnkalaiNo ratings yet

- Automatic Portable Spot Welding MachineDocument24 pagesAutomatic Portable Spot Welding MachinekeerthanaNo ratings yet

- ASTM A615 Grade 70 PDFDocument2 pagesASTM A615 Grade 70 PDFAnonymous vRtCW4hszNo ratings yet

- Aluminum 5052Document2 pagesAluminum 5052Praveen ThomasNo ratings yet

- Hot Rolled Carbon Steel Sheet, Plate and Strip According To IS 1079:2017Document8 pagesHot Rolled Carbon Steel Sheet, Plate and Strip According To IS 1079:2017raghavendragouda patilNo ratings yet

- Controlling Heat Treatment Distortion in Gear Rings - MachineMfgDocument37 pagesControlling Heat Treatment Distortion in Gear Rings - MachineMfgxiao mingNo ratings yet

- Ispat Industries Limited, Kalmeshwar - Nagpur (India) : Specification For Cold Rolled Steel Sheets & CoilsDocument4 pagesIspat Industries Limited, Kalmeshwar - Nagpur (India) : Specification For Cold Rolled Steel Sheets & CoilsAbhi Sheoran100% (2)

- TM-0026M-F (Property Requirements of Externally-Threaded Fasteners, Steel)Document5 pagesTM-0026M-F (Property Requirements of Externally-Threaded Fasteners, Steel)方綵樺100% (1)

- A2 Tool Steel: CompositionDocument1 pageA2 Tool Steel: CompositionSama Umate100% (1)

- Iso 228 1 2000Document9 pagesIso 228 1 2000Ulvi NebiyevNo ratings yet

- Chemical Composition: LM6 LM4Document2 pagesChemical Composition: LM6 LM4SiDdu KalashettiNo ratings yet

- 521+technical Data Sheet V-6Document2 pages521+technical Data Sheet V-6TeenTeen GaMingNo ratings yet

- Blind Rivet Quality Certification ReportDocument1 pageBlind Rivet Quality Certification ReportZain Abedeen0% (1)

- Wire RoadDocument16 pagesWire Road02081987No ratings yet

- The World's Choice For Corrosion Protection The World's Choice For Corrosion ProtectionDocument2 pagesThe World's Choice For Corrosion Protection The World's Choice For Corrosion ProtectionSquidwardNo ratings yet

- Fastener PDFDocument12 pagesFastener PDFdiegomilitojNo ratings yet

- Q Railing KatalogDocument416 pagesQ Railing KatalogТомић ЕминаNo ratings yet

- Gauging Practice For Plain SurfacesDocument20 pagesGauging Practice For Plain SurfacesAVINASHNo ratings yet

- CPK & PPK Calculator V4.1aDocument9 pagesCPK & PPK Calculator V4.1aE-Games E-GamesNo ratings yet

- Timco TDS Drywall ScrewDocument2 pagesTimco TDS Drywall ScrewNajeeb AhmedNo ratings yet

- Carbon Steel Billets, Blooms, Slabs and Bars For Forgings - Specification (Fifth Revision)Document12 pagesCarbon Steel Billets, Blooms, Slabs and Bars For Forgings - Specification (Fifth Revision)SreenathaNo ratings yet

- Pipe SpecificationDocument14 pagesPipe SpecificationAdam NumalNo ratings yet

- HC-49 Engineering SpecificationDocument6 pagesHC-49 Engineering SpecificationarunrathikaNo ratings yet

- ASTM - A572 Grade 50 Chemical & Mechanical PropertiesDocument1 pageASTM - A572 Grade 50 Chemical & Mechanical PropertiesMinhas ArshadNo ratings yet

- BoilerTubes - TechnitubeDocument24 pagesBoilerTubes - TechnitubeMMPAPNo ratings yet

- Gravity and Low Pressure Die Casting of AluminiumDocument11 pagesGravity and Low Pressure Die Casting of AluminiumKrishna Mohan T.RNo ratings yet

- 7 Inch Vamtop SpecDocument2 pages7 Inch Vamtop Specrageshmv100% (1)

- Domex 700 MC Hot Rolled, Extra High Strength, Cold Forming SteelDocument2 pagesDomex 700 MC Hot Rolled, Extra High Strength, Cold Forming Steelflorin_iacob2001No ratings yet

- 2024-T3 ASM Material Data Sheet PDFDocument2 pages2024-T3 ASM Material Data Sheet PDFAnonymous mq0U43UsPNo ratings yet

- Durasin & Shockfast Comparsion EnglishDocument1 pageDurasin & Shockfast Comparsion Englishhassan hamdyNo ratings yet

- Screw CharacteristicsDocument18 pagesScrew CharacteristicsJaokNo ratings yet

- AluminiumHE15 PropertiesDocument3 pagesAluminiumHE15 PropertiesPrashanthNo ratings yet

- Domex 650 MC Hot Rolled, Extra High Strength, Cold Forming SteelDocument2 pagesDomex 650 MC Hot Rolled, Extra High Strength, Cold Forming SteelHugo RodriguezNo ratings yet

- Polycarbonate Data SheetDocument1 pagePolycarbonate Data SheetJoseph Cloyd Lamberte100% (1)

- Product17 - File1 - 0 - Product Pages - Hex Bolt ZP and HDGDocument2 pagesProduct17 - File1 - 0 - Product Pages - Hex Bolt ZP and HDGLavanyanNo ratings yet

- Side Entry Pit (2.0m Inlet) A140.03Document2 pagesSide Entry Pit (2.0m Inlet) A140.03Nicholas VineyNo ratings yet

- Water in SoilsDocument25 pagesWater in SoilsNicholas VineyNo ratings yet

- A140.12 Drain Bedding and Backfill RequirementsDocument2 pagesA140.12 Drain Bedding and Backfill RequirementsNicholas VineyNo ratings yet

- RETAINING WALL How To WaterproofDocument6 pagesRETAINING WALL How To WaterproofJesusBlasVitangcolNo ratings yet

- Temporary Vehicle Crossing in Asphalt For Building Sites A170.13Document2 pagesTemporary Vehicle Crossing in Asphalt For Building Sites A170.13Nicholas VineyNo ratings yet

- A140.09 - Spoon Drain PitDocument2 pagesA140.09 - Spoon Drain PitNicholas VineyNo ratings yet

- Liquefaction Susceptibility Mapping Using Geotechnical Laboratory TestsDocument10 pagesLiquefaction Susceptibility Mapping Using Geotechnical Laboratory TestsNicholas VineyNo ratings yet

- Asphalt Pavement For Secondary Arterial Road A100.01: Applicable LocationDocument2 pagesAsphalt Pavement For Secondary Arterial Road A100.01: Applicable LocationNicholas VineyNo ratings yet

- Reinstatement of Trenches Along Local Asphalt Roads A101.01Document2 pagesReinstatement of Trenches Along Local Asphalt Roads A101.01Nicholas VineyNo ratings yet

- As 4055-2006Document57 pagesAs 4055-2006vilaschodankarNo ratings yet

- Concrete Footpath A110.01: Applicable LocationDocument2 pagesConcrete Footpath A110.01: Applicable LocationNicholas VineyNo ratings yet

- Ajax Fastener HandbookDocument132 pagesAjax Fastener Handbookandrew_ferrier9390No ratings yet

- 1 - Concept of StressDocument40 pages1 - Concept of StressNicholas VineyNo ratings yet

- As 1530.4-2005 PDFDocument165 pagesAs 1530.4-2005 PDFNicholas Viney100% (2)

- Purlin and Girts Design TablesDocument32 pagesPurlin and Girts Design TablesTimothy BarnesNo ratings yet

- Space FrameDocument16 pagesSpace FrameO'dio SabjulapNo ratings yet

- 1 - Concept of StressDocument40 pages1 - Concept of StressNicholas VineyNo ratings yet

- Laterally Loaded Piles - FinalDocument360 pagesLaterally Loaded Piles - Finalcjcute91100% (1)

- HB31 PDFDocument77 pagesHB31 PDFNicholas VineyNo ratings yet

- Hilti Anchor Fastening Technology Manual Chemical Anchor SectionDocument202 pagesHilti Anchor Fastening Technology Manual Chemical Anchor SectionIvy SeahNo ratings yet

- Hyjoist Design Guide 12pp Feb15 (Australia)Document12 pagesHyjoist Design Guide 12pp Feb15 (Australia)Danusha EgodawatteNo ratings yet

- Hex Bolts - Minimum Tensile StressDocument4 pagesHex Bolts - Minimum Tensile StressskkongNo ratings yet

- Hyjoist Design Guide 12pp Feb15 (Australia)Document12 pagesHyjoist Design Guide 12pp Feb15 (Australia)Danusha EgodawatteNo ratings yet

- Powers Blue Tip Screw Bolts PDFDocument16 pagesPowers Blue Tip Screw Bolts PDFNicholas VineyNo ratings yet

- EN 1090 White Paper17 119019 PDFDocument24 pagesEN 1090 White Paper17 119019 PDFZaza PokumbaNo ratings yet

- Using Cycle Time To Measure PerformanceDocument18 pagesUsing Cycle Time To Measure PerformanceNicholas VineyNo ratings yet

- Whitepaper Structural Bolting and Use of Fasteners 1Document32 pagesWhitepaper Structural Bolting and Use of Fasteners 1sklNo ratings yet

- ART Threaded Fastener Design and AnalysisDocument40 pagesART Threaded Fastener Design and AnalysisAarón Escorza MistránNo ratings yet

- 07 Power Screws and Threaded Fasteners (Handout)Document16 pages07 Power Screws and Threaded Fasteners (Handout)tnvsaikiran3100% (3)

- SCI Design Guide P324Document87 pagesSCI Design Guide P324mdavies20No ratings yet

- tieu chuẩn dri 2045Document4 pagestieu chuẩn dri 2045anhthoNo ratings yet

- Behaviour of Bolted Flange Joints in Tubular Structures Under Monotonic, Repeated and Fatigue Loadings I Experimental TestsDocument11 pagesBehaviour of Bolted Flange Joints in Tubular Structures Under Monotonic, Repeated and Fatigue Loadings I Experimental TestsRino NelsonNo ratings yet

- Senr3130-13 TorqueDocument20 pagesSenr3130-13 TorqueJose luis ConsuegraNo ratings yet

- Mod 1-2Document4 pagesMod 1-2Gopal UttupurathNo ratings yet

- Guia de Mantenimiento 2535Document54 pagesGuia de Mantenimiento 2535Sebastian GarciaNo ratings yet

- Proposed Townhouses & Alteration Works 4 Hyton Cres, Kew: Important NotesDocument17 pagesProposed Townhouses & Alteration Works 4 Hyton Cres, Kew: Important NotesWaelElMeligiNo ratings yet

- ME301chapter08 PDFDocument31 pagesME301chapter08 PDFvtalexNo ratings yet

- CTC12Document2 pagesCTC12Joffre Lautaro Benavides SeminarioNo ratings yet

- Structural Analysis of Lattice Steel Transmission TowersDocument11 pagesStructural Analysis of Lattice Steel Transmission Towersdare93No ratings yet

- IM BSCE 4 - Steel Design Part 1Document86 pagesIM BSCE 4 - Steel Design Part 1acurvz2005No ratings yet

- Astm D4435 13Document3 pagesAstm D4435 13shakeelalam2070No ratings yet

- National Transmission & Despatch Company Limited: P-DraftDocument40 pagesNational Transmission & Despatch Company Limited: P-DraftRamzanNo ratings yet

- Superslim-Technical-Datasheets 17 MARCH 2020Document117 pagesSuperslim-Technical-Datasheets 17 MARCH 2020Miguel PAvonNo ratings yet

- JPL Bolt TorqueDocument24 pagesJPL Bolt TorquegotstogoNo ratings yet

- IMT Electric Hydraulic Maintenance ManualDocument37 pagesIMT Electric Hydraulic Maintenance ManualDimitar LevskiNo ratings yet

- Skoda Octavia III 2013 Octavia III 2014 Manual Gearbox 0ah Workshop Manual Edition 102013Document121 pagesSkoda Octavia III 2013 Octavia III 2014 Manual Gearbox 0ah Workshop Manual Edition 102013miguelokpvNo ratings yet

- 20 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuideDocument1 page20 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuidetvwrightNo ratings yet

- Bolted Connections StudentsDocument56 pagesBolted Connections StudentsKshitizNo ratings yet

- Sorbothane SPG Bushings WashersDocument2 pagesSorbothane SPG Bushings WasherschvbabuNo ratings yet

- Aftercooler Housing PDFDocument3 pagesAftercooler Housing PDFRichard ChuaNo ratings yet

- Bolt Torque ValuesDocument1 pageBolt Torque ValuesAliNo ratings yet

- W SER 0502 AD Manual Flange Torque TighteningDocument8 pagesW SER 0502 AD Manual Flange Torque TighteningAnonymous IJBjI0No ratings yet

- KW1466 PDFDocument279 pagesKW1466 PDFJavierRivasNeira100% (2)

- Connection DesignDocument33 pagesConnection DesignihpeterNo ratings yet

- Sygef Standard Sygef Plus PVDF Flanges: Installation InstructionsDocument7 pagesSygef Standard Sygef Plus PVDF Flanges: Installation InstructionsLUCASNo ratings yet

- Anabond 111 Thread LockerDocument2 pagesAnabond 111 Thread LockerRohit MahaleNo ratings yet