Professional Documents

Culture Documents

Gulf Harmony Aw Plus PDF

Uploaded by

Harsh AiwaleOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Gulf Harmony Aw Plus PDF

Uploaded by

Harsh AiwaleCopyright:

Available Formats

Gulf Harmony AW Plus

Premium quality anti-wear hydraulic oil

Product Description

Gulf Harmony AW Plus series are premium quality anti-wear hydraulic oils specially developed to meet the

requirements of the most demanding modern hydraulic systems in industrial and mobile service. These oils

are formulated with severely hydroprocessed Group II base oils and a carefully selected additive system to

satisfy the performance requirements of a wide range of hydraulic equipment subjected to high operating

pressures & temperatures and to provide extended drain intervals. They possess outstanding thermo-

oxidative stability, anti-wear property, rust & corrosion protection, water separation & air-release properties

and hydrolytic stability to prolong the equipment and oil life. They are available in ISO 10 through ISO 100

viscosity grades and exceed the performance requirements of global industry standards viz. DIN 51524

Part 2-HLP, AFNOR NFE 48-603 (HM) & ISO 11158 HM and majority of the international OEMs viz.

Denison, Fives Cincinnati (MAG IAS, LLC) & Eaton (Vickers).

Features & Benefits

Outstanding thermo-oxidative stability reduces deposit formation, improves pump & valve

performance and allows extension of oil and filter change intervals

Exceptional anti-wear property results in fewer breakdowns, longer pump life and reduced

maintenance costs

Excellent demulsibility helps in faster separation of water from oil and resists formation of emulsions

Special rust & corrosion inhibitors protect multi-metallurgy components against negative effects of

moisture presence in the system

Rapid air release property minimises chances of pump cavitation and thus prevents component

damage, reduces vibration and maintains efficiency especially in modern hydraulic systems where

sump sizes are becoming smaller

Offers long term hydrolytic stability and yellow metal compatibility in presence of water

Compatible with multi-metals and sealing materials commonly used in hydraulic systems

Applications

Most demanding hydraulic systems subjected to high pressures and loads

Applications requiring extended oil change intervals

Hydraulic systems in industrial and mobile service employing gear, vane and piston pumps where

anti-wear hydraulic oils are recommended

Mobile hydraulic fluid power transmission systems and general machine lubrication

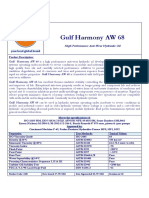

Specifications, Approvals & Typical Properties

ISO Viscosity grades 10 15 22 32 46 68 100

Meet the following Specifications

DIN 51524 Part 2-HLP x x x x x x x

AFNOR NFE 48-603 (HM), ISO 11158 HM x x x x x x x

Denison HF-0, HF-1, HF-2 x x x

Eaton (Vickers) M-2950-S, M-2952-S, I-286-S x x x

Bosch Rexroth 07 075 for vane, piston & gear

X X X

pumps, Sauer Danfoss 520L0463

Has the following Approvals

Fives Cincinnati (MAG IAS, LLC) P-68 P-70 P-69

Typical Properties

Test Parameters ASTM Typical Values

Method

Viscosity @ 40 C, cSt D 445 10.2 15.3 22.2 31.0 46.3 68.1 98.7

Viscosity Index D 2270 109 109 108 105 104 100 99

Flash Point, C D 92 142 168 192 206 218 226 238

Pour Point, C D 97 -33 -27 -27 -24 -24 -24 -15

Density @ 15C, Kg/l D 1298 0.837 0.843 0.848 0.852 0.855 0.858 0.861

Rust Test D 665A/B Pass Pass Pass Pass Pass Pass Pass

Emulsion Test @ 54 oC Pass Pass Pass Pass Pass Pass -

30 minutes max D 1401

@ 82 oC - - - - - - Pass

Foam Test, foam after 10 minutes of

D 892 Nil Nil Nil Nil Nil Nil Nil

settling for all sequences

Turbine Oil Stability Test, hrs D 943 3000+ 4500+ 5000+ 4000+

FZG, fail load stage, minimum DIN 51354 - - - 11 11 11 11

Part II

August 2015

You might also like

- Gulf Harmony Hvi April22 - 20220407195423Document2 pagesGulf Harmony Hvi April22 - 20220407195423AbhishekNo ratings yet

- Gulf Oil Marine - Product Data SheetDocument10 pagesGulf Oil Marine - Product Data SheetObydur RahmanNo ratings yet

- PDS - GulfSea Hydraulic AW Series-1Document2 pagesPDS - GulfSea Hydraulic AW Series-1Zaini YaakubNo ratings yet

- Gulf Harmony AW: High Performance Anti-Wear Hydraulic OilDocument2 pagesGulf Harmony AW: High Performance Anti-Wear Hydraulic Oilatripathi2009No ratings yet

- PDS - GulfSea Hydraulic HVI Plus 68Document2 pagesPDS - GulfSea Hydraulic HVI Plus 68Obydur Rahman100% (1)

- Mobil DTE 10 Excel SeriesDocument3 pagesMobil DTE 10 Excel SeriesSuprastowo Bin SarinoNo ratings yet

- Gulf EP Lubricant SY - PAODocument1 pageGulf EP Lubricant SY - PAOatripathi2009No ratings yet

- Gulf Harmony: Premium Quality Rust & Oxidation (R&O) Inhibited Multipurpose Lubricating OilsDocument1 pageGulf Harmony: Premium Quality Rust & Oxidation (R&O) Inhibited Multipurpose Lubricating Oilsatripathi2009No ratings yet

- Gulf HarmonyDocument1 pageGulf HarmonyRina Gazel EndracaNo ratings yet

- Gulf Synthetic Gear Oil - PAGDocument1 pageGulf Synthetic Gear Oil - PAGatripathi2009No ratings yet

- Gulf Geartek - Hd-Sept2021 - 20211102102844Document1 pageGulf Geartek - Hd-Sept2021 - 20211102102844magadali7814No ratings yet

- Tds Atlantic Hydraulic OilsDocument1 pageTds Atlantic Hydraulic Oilsmgamal1080No ratings yet

- GulfSea Hydraulic HVI Plus Series PDFDocument2 pagesGulfSea Hydraulic HVI Plus Series PDFObydur RahmanNo ratings yet

- Gulf EP Lubricant HDDocument1 pageGulf EP Lubricant HDatripathi2009No ratings yet

- Gulf FidelityDocument1 pageGulf FidelityBudi SetiawanNo ratings yet

- Gulf Gear WT: High Performance Industrial Gear OilDocument1 pageGulf Gear WT: High Performance Industrial Gear Oilatripathi2009No ratings yet

- Repsol Telex HVLP 32Document2 pagesRepsol Telex HVLP 32ibrahim maulanaNo ratings yet

- Glxxencvlmomobiltrans HDDocument2 pagesGlxxencvlmomobiltrans HDedilfreddyzNo ratings yet

- Hydraulic Oil Iso VG 46Document1 pageHydraulic Oil Iso VG 46KarthikeyanNo ratings yet

- Q8 El Greco 220 - enDocument1 pageQ8 El Greco 220 - enDeepak YadavNo ratings yet

- Q8 Handel 46Document1 pageQ8 Handel 46chandan sahooNo ratings yet

- Renolin CLP - enDocument7 pagesRenolin CLP - enDANE80No ratings yet

- 5010 5020 5030 5040 5070 5100 5090 2110 HYDRAULIC OIL AW PDS Vesion 3Document2 pages5010 5020 5030 5040 5070 5100 5090 2110 HYDRAULIC OIL AW PDS Vesion 3tauhidrockNo ratings yet

- Gulf FidelityDocument1 pageGulf FidelityBassam AljiffryNo ratings yet

- Hyperion TDS 1034Document1 pageHyperion TDS 1034varunchNo ratings yet

- Matrix EP and TK TDS 2035Document1 pageMatrix EP and TK TDS 2035Don HowardNo ratings yet

- TORK HLPDocument1 pageTORK HLPWassim LounissiNo ratings yet

- Hydraulic Oil HM 46: Product Data SheetDocument1 pageHydraulic Oil HM 46: Product Data SheetDavidNo ratings yet

- Repsol Telex E 46,68Document2 pagesRepsol Telex E 46,68ibrahim maulanaNo ratings yet

- JCB HP HYDRAULIC FLUID 46 - enDocument2 pagesJCB HP HYDRAULIC FLUID 46 - enMiguel MacedoNo ratings yet

- Shell Turbo Oil T32: Performance, Features & BenefitsDocument2 pagesShell Turbo Oil T32: Performance, Features & BenefitsCertified Rabbits LoverNo ratings yet

- PDS Mobil Nuto HDocument2 pagesPDS Mobil Nuto HtribolasNo ratings yet

- Atf DX Vi I: SyntheticDocument2 pagesAtf DX Vi I: SyntheticTaller MarioNo ratings yet

- MDS SHELL Turbo Oil T68Document2 pagesMDS SHELL Turbo Oil T68Antonio CardosoNo ratings yet

- Shell Turbo Oil T 68Document2 pagesShell Turbo Oil T 68Muhammad SaputraNo ratings yet

- Hydroflux Ep tcm14-62558Document1 pageHydroflux Ep tcm14-62558Azis GPBNo ratings yet

- Shell Turbo Oil T32: Performance, Features & BenefitsDocument2 pagesShell Turbo Oil T32: Performance, Features & BenefitsHANIF AKBARNo ratings yet

- Mobil Type 8000 Turbine OilDocument4 pagesMobil Type 8000 Turbine OilJJNo ratings yet

- DTE NamedDocument3 pagesDTE NamedDavid LieNo ratings yet

- Acdelco Specs DexronVIDocument1 pageAcdelco Specs DexronVINamer HajiNo ratings yet

- Gpcdoc Local Tds Iraq Shell Turbo T 68 (Ar-Iq) TdsDocument2 pagesGpcdoc Local Tds Iraq Shell Turbo T 68 (Ar-Iq) TdsBar AvaitNo ratings yet

- Shell Turbo T 32 PDFDocument2 pagesShell Turbo T 32 PDFaqas_khanNo ratings yet

- Shell Turbo Oil T46: Performance, Features & Benefits Main ApplicationsDocument4 pagesShell Turbo Oil T46: Performance, Features & Benefits Main Applicationshaider100% (1)

- Gulf-Syngear-Fe-75w-80 - 20-Dec-16 - 20161222052228Document1 pageGulf-Syngear-Fe-75w-80 - 20-Dec-16 - 20161222052228David PomaNo ratings yet

- FUCHS RENOLIN B SeriesDocument1 pageFUCHS RENOLIN B SeriesAnonymous srwHCpANo ratings yet

- 3508 Gulf Harmony AW 68 DataDocument1 page3508 Gulf Harmony AW 68 DataHitesh MahajanNo ratings yet

- 3508 Gulf Harmony AW 68 DataDocument1 page3508 Gulf Harmony AW 68 Datakatty_89No ratings yet

- Mobiltrans - HD SeriesDocument2 pagesMobiltrans - HD Seriesyurik119281No ratings yet

- GulfSea Turbine Oil Series PDFDocument2 pagesGulfSea Turbine Oil Series PDFObydur RahmanNo ratings yet

- Sinopec Antiwear Hydraulic Oil L-HMDocument3 pagesSinopec Antiwear Hydraulic Oil L-HMSumaya Akter100% (1)

- Ficha 3 PDFDocument1 pageFicha 3 PDFMatías BrizzioNo ratings yet

- Daphne Super Hydro A Series: Lubricant Product InformationDocument2 pagesDaphne Super Hydro A Series: Lubricant Product InformationGayuh Wahyu Eska NegaraNo ratings yet

- Synthetic Tractor Hydraulic/Transmission Oil SAE 5W-30 (ATH)Document2 pagesSynthetic Tractor Hydraulic/Transmission Oil SAE 5W-30 (ATH)Bruce Wappman100% (5)

- زيت موبيل PDFDocument3 pagesزيت موبيل PDFSami KahtaniNo ratings yet

- Shell Turbo Oil T32: Performance, Features & BenefitsDocument2 pagesShell Turbo Oil T32: Performance, Features & BenefitsElias GabrielNo ratings yet

- Shell Turbo Oil T 32Document2 pagesShell Turbo Oil T 32Muhammad SaputraNo ratings yet

- Dynatrans Acx 10WDocument1 pageDynatrans Acx 10WsatNo ratings yet

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsFrom EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsRating: 5 out of 5 stars5/5 (1)

- Drilling Fluids Processing HandbookFrom EverandDrilling Fluids Processing HandbookRating: 4.5 out of 5 stars4.5/5 (4)

- Vol 5 0 72 76f PDFDocument5 pagesVol 5 0 72 76f PDFRosario GarnicaNo ratings yet

- (14.0.1) Taxation of Companies Engaged in Manufacturing Trades, Certain Trading Operations Carried On in Shannon Airport and Certain Trading Operations Carried On in The Custom House Docks AreaDocument12 pages(14.0.1) Taxation of Companies Engaged in Manufacturing Trades, Certain Trading Operations Carried On in Shannon Airport and Certain Trading Operations Carried On in The Custom House Docks AreaHarsh AiwaleNo ratings yet

- Indian Fertilizer ScenarioDocument159 pagesIndian Fertilizer ScenarioMani BmvNo ratings yet

- Gulf Harmony AW Plus: Premium Quality Anti-Wear Hydraulic OilDocument2 pagesGulf Harmony AW Plus: Premium Quality Anti-Wear Hydraulic OilHarsh AiwaleNo ratings yet

- Y CurveDocument4 pagesY CurveHarsh AiwaleNo ratings yet

- Accounting ErrorsDocument11 pagesAccounting ErrorsHarsh AiwaleNo ratings yet

- Transparent ValueDocument11 pagesTransparent ValueHarsh AiwaleNo ratings yet

- MBA Interview Prep QuestionsDocument13 pagesMBA Interview Prep QuestionsHarsh AiwaleNo ratings yet

- Q On JournalDocument1 pageQ On JournalHarsh AiwaleNo ratings yet

- Securities Analysis and Portfolio ManagementDocument50 pagesSecurities Analysis and Portfolio ManagementrimonasharmaNo ratings yet

- Transparent ValueDocument11 pagesTransparent ValueHarsh AiwaleNo ratings yet

- IMRB International Report - FINAL - LatestDocument50 pagesIMRB International Report - FINAL - LatestSiddhant1741991No ratings yet

- What Is Investment BankingDocument89 pagesWhat Is Investment BankingNarendra Chhetri100% (1)

- Shipbuilding PDFDocument44 pagesShipbuilding PDFSaid Alauddeen FaiszNo ratings yet

- SpecsDocument5 pagesSpecsGo farNo ratings yet

- Partial Acid Number in Unsaturated Polyester Resin According To EN ISO 2114Document2 pagesPartial Acid Number in Unsaturated Polyester Resin According To EN ISO 2114Mamoon ShahidNo ratings yet

- Chemical Compatibility Chart Metallic Materials Used in Bal Seal ProductsDocument28 pagesChemical Compatibility Chart Metallic Materials Used in Bal Seal Productscgjp120391No ratings yet

- Technical Data: Protective Grease For Overhead Line ConductorsDocument3 pagesTechnical Data: Protective Grease For Overhead Line ConductorssreedharNo ratings yet

- Clickductor EngDocument20 pagesClickductor EngmahmoudglobaltechNo ratings yet

- Introduction To Polyurethane!: Chemistry and Structure-Property RelationshipsDocument31 pagesIntroduction To Polyurethane!: Chemistry and Structure-Property RelationshipsMohammed ShaabanNo ratings yet

- Mark Scheme (Final) January 2009: GCE Chemistry (6244/01)Document20 pagesMark Scheme (Final) January 2009: GCE Chemistry (6244/01)Aaisha AfaNo ratings yet

- Welders Qualification Test Record For Approval: Marjan Development ProgramDocument8 pagesWelders Qualification Test Record For Approval: Marjan Development ProgramJoni Carino SuniNo ratings yet

- List For Biochemistry LabDocument3 pagesList For Biochemistry LabMalik Rizwan Elahi83% (6)

- Activity 14 CO2-InventoryDocument4 pagesActivity 14 CO2-InventoryHao Phan AnhNo ratings yet

- Determination of Crystal Structure and Crystallite SizeDocument17 pagesDetermination of Crystal Structure and Crystallite SizeRohit SatheshNo ratings yet

- Waste ManagementDocument43 pagesWaste Managementالدنيا ساعة فاجعلها طاعةNo ratings yet

- ABS Submersible Mixer RW 200, 50HzDocument2 pagesABS Submersible Mixer RW 200, 50Hzalisya.blwsNo ratings yet

- General - Chemistry 1 Module 2 AY 2022 2023Document17 pagesGeneral - Chemistry 1 Module 2 AY 2022 2023Yzac Barroga PascualNo ratings yet

- SDS Linear Alkylbenzene Sulfonate (NEOPELEX F65)Document6 pagesSDS Linear Alkylbenzene Sulfonate (NEOPELEX F65)yusufkurniawan.smNo ratings yet

- Nanotechnology in Fertilizers: CorrespondenceDocument1 pageNanotechnology in Fertilizers: CorrespondencevskNo ratings yet

- Colored Gemstone GradingDocument1 pageColored Gemstone GradingangelNo ratings yet

- Final Report FB-2018-1 PDFDocument75 pagesFinal Report FB-2018-1 PDFRatik GaonkarNo ratings yet

- Petrochemicals SbuDocument4 pagesPetrochemicals SbuAbhishek MishraNo ratings yet

- MS21919 MS21919: Clamp, Loop Type, Cushioned SupportDocument1 pageMS21919 MS21919: Clamp, Loop Type, Cushioned SupportblackhawkNo ratings yet

- Goncz 2015Document11 pagesGoncz 2015Anonymous LaMda8EXNo ratings yet

- BE. Heat Exchangers.Document97 pagesBE. Heat Exchangers.Gannavarapu KrishnaNo ratings yet

- Chelating AgentDocument13 pagesChelating AgentHiba MusthafaNo ratings yet

- Reference - PIM-SU-3541-D - HydrotestDocument14 pagesReference - PIM-SU-3541-D - Hydrotestaslam.ambNo ratings yet

- Industrial Strainers Filters Y StrainerDocument1 pageIndustrial Strainers Filters Y StrainerEi Ei PhyoNo ratings yet

- Hydraulic Ram Pump ReportDocument42 pagesHydraulic Ram Pump ReportliviciuklNo ratings yet

- Test For CARBOHYDRATESDocument7 pagesTest For CARBOHYDRATESSoham N100% (2)

- BS 1449-1-4 - 1991Document10 pagesBS 1449-1-4 - 1991عمر عمرNo ratings yet

- ARKI ALE Structural NotesDocument5 pagesARKI ALE Structural Notesiloilocity100% (1)