Professional Documents

Culture Documents

CE6302-Mechanics of Solids

Uploaded by

Maharaja PlacementCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CE6302-Mechanics of Solids

Uploaded by

Maharaja PlacementCopyright:

Available Formats

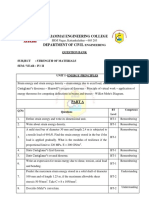

VALLIAMMAI ENGINEERING COLLEGE

SRM Nagar, Kattankulathur 603 203

DEPARTMENT OF CIVIL ENGINEERING

QUESTION BANK

III SEMESTER

CE6302MECHANICS OF SOLIDS

Regulation 2013

Academic Year 2017 18

Prepared by

Mr. SATTAINATHAN SHARMA.A, Assistant Professor/CIVIL

Mr. KARTHICK S, Assistant Professor/CIVIL

Ms. G.VAITHIYANATHAN/ Assistant Professor/CIVIL

VALLIAMMAI ENGINEERING COLLEGE DEPARTMENT OF CIVIL ENGINEEERING

VALLIAMMAI ENGINEERING COLLEGE

SRM Nagar, Kattankulathur 603 203

DEPARTMENT OF CIVIL ENGINEERING

SUBJECT CODE: CE 6302 YEAR: II

SUBJECT NAME: MECHANICS OF SOLIDS SEM : III

QUESTION BANK

(As per Anna University 2013 Regulation)

UNIT 1- STRESS AND STRAIN

Stress and strain at a point Tension, Compression, Shear Stress Hookes Law Relationship among elastic

constants Stress Strain Diagram for Mild Steel, TOR steel, Concrete Ultimate Stress Yield Stress Factor of

Safety Thermal Stresses Thin Cylinders and Shells Strain Energy due to Axial Force Resilience Stresses

due to impact and Suddenly Applied Load Compound Bars

PART A (2 Marks)

Q.No. Questions BT Competence

1. Define the terms young modulus, bulk modulus & shear modulus. BT-1 Remembering

2. State Hookes law. BT-2 Understanding

3 Recall modular ratio & Poissons ratio. BT-1 Remembering

4. Explain longitudinal strain and lateral strain with a neat sketch. BT-4 Analysis

5. Outline what do you mean by principle of super position? BT-4 Analysis

6. Discuss the relationship between Elastic Constants BT-2 Understanding

An alloy bar of 1m length has a square section throughout which tapers

7. from one end of 10mmx10mm to other end of 20x20mm. Find the BT-6 Creating

change in length due to an axial load of 30kN. Take E=120GPa.

Relate the terms with one another

8. Creating

a) resilience b) proof resilience c) modulus of resilience BT-6

Sketch the stress-strain diagram for TOR Steel/HYSD bars and mark the

9. BT-1 Remembering

Salient points.

10. Discuss about thermal stresses. BT-1 Remembering

11. Report what do you mean by strain energy density. BT-3 Applying

12. Relate shear stress and shear strain. BT-3 Applying

Determine the Poissons ratio and modulus is 1.2 x 105N/mm2 and

13. BT-3 Applying

modulus of rigidity is 4.8 x 104 N/mm2.

14. Define the term limit of proportionality elastic limit and yield point. BT-1 Remembering

List the types of stresses developed in thin cylinders subjected to

15. BT-1 Remembering

internal pressure?

A brass rod 2m long 2is fixed at both its ends. If the thermal stress is not

16. to exceed 76.5N/mm . calculate the temperature - through which the rod

BT-2 Understanding

should be heated. Take the values of = 17x10 6/K and E =90Gpa.

Prepared by

A.SATTAINATHAN SHARMA/A.P S.KARTHICK/A.P G.VAITHIYANATHAN/A.P

VALLIAMMAI ENGINEERING COLLEGE DEPARTMENT OF CIVIL ENGINEEERING

Summarize the procedure for finding the thermal stresses in a composite

17. BT-5 Evaluating

bar?

18. Distinguish between cylindrical shell and spherical shell. BT-4 Analysis

19. Differentiate thin cylinder & thick cylinder BT-2 Understanding

20. Justify why wire winding is done in thin cylinder? BT-5 Evaluating

PART B (13 Marks)

A tensile test was conducted on a mild steel bar. The following data was

obtained from the test:

i. Diameter of the steel bar = 4 cm

ii. Gauge length of the bar = 22 cm

iii. Load at elastic limit = 250 kN

iv. Extension at a load of 160 kN = 0.235 mm

1. v. Maximum load = 390 kN BT-1 Remembering

vi. Total extension = 70 mm

vii. Diameter of rod at failure = 2.35 cm

Examine:

a) The Youngs modulus (4 marks)

b) The stress at elastic limit (3 marks)

c) The percentage of elongation (3 marks)

d) The percentage decrease in area. (3 marks)

A member ABCD is subjected to point loads P1,P2,P3and P4 as shown.

Find P2 required for necessary equilibrium, if P1 = 45kN, P3 = 450kN

and P4=130kN. Determine the total elongation of the member.

2. BT-2 Understanding

A reinforced concrete column is 300mm x 300mm in section. The

column is provided with 8 bars each of 20mm diameter. The column

3 BT-2 Understanding

carries a load of 360kN. Calculate the stresses in concrete and the steel

bars. Take Es=210 GN/m2 and Ec=14 GN/m2

Three bars made of copper, zinc and aluminium are of equal length and

have cross section 555, 705, and 1020 sq.mm respectively. They are

4. BT-6 Creating

rigidly connected at their ends. If this compound member is subjected to

a longitudinal pull of 255kN, Write the proportional of the load carried

Prepared by

A.SATTAINATHAN SHARMA/A.P S.KARTHICK/A.P G.VAITHIYANATHAN/A.P

VALLIAMMAI ENGINEERING COLLEGE DEPARTMENT OF CIVIL ENGINEEERING

on each rod and the induced stresses. Take the value of E for copper =

1.310 5 N/mm2, for zinc = 1105 N/mm2and for aluminium = 0.8105

N/mm2

A C.I plate, 300mm long and of 30mm x 50 mm uniform cross section, is

acted upon by the following forces uniformly. 25kN(T), 35kN (T), and

5. BT-2 Understanding

45kN(T) in x,y and z axis respectively. Estimate the change in volume

of the plate. E=140GN/m2 and m=4

a) Obtain a relation for change in length of a bar hanging freely under its

own weight (7 Marks)

6. BT-5 Evaluating

b)Assess the relationship between modulus of elasticity and modulus of

rigidity (6 marks)

A cylindrical vessel, whose ends are closed by means of rigid flange

plates, is made up of steel plate 3 mm thick. The length and internal

diameter of the vessel are 55 cm and 25.5 cm respectively. Determine the

7. BT-3 Applying

longitudinal and hoop stresses in the cylindrical shell due to an internal

fluid pressure of 3.5 N/mm2. Also calculate the increase in length,

diameter and volume of vessel. Take E = 2105 N/mm2 and =0.3

Outline the stressstrain diagram for mild steel, brittle material

8. BT-4 Analysis

and a ductile material and indicate salient points.

st

A tension bar is made of 2 parts. The length of 1 part is 300 cm and area is

2 2

20cm while the second part is of length 210 cm and 30cm . An axial

9. load of 90kN is gradually applied. Identify the total strain energy BT-1 Remembering

produced in the bar and compare its value with that obtained in a uniform

bar of same length and having same volume under same load. Take

5 2

E = 2.1x10 N/mm

A load of 200N falls through a height of 20mm onto a collar rigidly

attached to the lower end of a vertical bar 2m long and 1.5 sq.cm c/s

5 2

area. The upper end of vertical bar is fixed. Take E = 2x10 N/mm .

10. Examine BT-1 Remembering

1. Maximum instantaneous stress (4 marks)

2. Maximum instantaneous strain (3 marks)

3. Maximum instantaneous elongation (3 marks)

4. Strain energy (3 marks)

A steel rod of 3.6cm diameter and 5m long is connected to two grips and

o

the rod is maintained at a temperature of 105 C. Examine the stress and

11. o BT-1 Remembering

pull exerted when the temperature falls to 40 C if,

i. The ends do not yield (7 marks)

ii. The ends yield by 0.13cm (6 marks)

12. A tensile load of 55N is acting on a rod of diameter 55mm and length BT-4 Analysis

Prepared by

A.SATTAINATHAN SHARMA/A.P S.KARTHICK/A.P G.VAITHIYANATHAN/A.P

VALLIAMMAI ENGINEERING COLLEGE DEPARTMENT OF CIVIL ENGINEEERING

4.5m. A bore of diameter 25mm is made centrally on the rod. Analyze

To what length the rod should be bored so that the total extension will

increase 35% under the same tensile load. Take E = 2x105 N/mm2

A steel tube of 30mm external diameter and 20mm internal diameter

encloses a copper rod of 15.5mm diameter to which it is rigidly joined at

o

each end. If, at a temperature of 10 C there is no longitudinal stress, Analyze

13. o BT-4 Analysis

the stresses in the rod and the tube when the temperature is raised to 200 C.

5 2 5 2

Take Es = 2.1x10 N/mm , Ec = 1x10 N/mm , Co-efficient of linear

-6 o -6 o

expansion 11x10 per C and 18x10 per C

A cast iron pipe of 220 mm internal diameter and 12mm thick is wound

closely with a single layer of circular steel wire of 5mm diameter, under

2

a tension of 60N/mm . Find the initial compressive stress in the pipe

14. section. Also find the stresses set up in the pipe BT-3 and steel wire, when BT-3 Applying

2

water under a pressure of 3.5N/mm is admitted into the pipe. Take E =

5 2 5 2

2x10 N/mm for steel and E = 2x10 N/mm for cast iron and poissons

ratio as 0.3.

PART-C (15 Marks)

Estimate the values of change in length, breadth and thickness of a steel

bar 4.2m long, 35mm wide and 25mm thick. When subjected to an axial

1. pull of 130kN in the direction of its length. Take E=200Gpa and BT-4 Analysis

poissons ratio = 0.3

A bar of 25mm diameter is subjected to a pull of 40kN. The measured

extension on gauge length of 200mm is 0.085mm and the change in

2. diameter is 0.003mm. Estimate the values of Poissons ratio and the three BT-5 Evaluating

moduli

A steel tube of 25mm external diameter and 18mm internal diameter

encloses a copper rod of 15.5mm diameter to which it is rigidly joined

at each end. If, at a temperature of 12oC there is no longitudinal stress,

3 Examine the stresses in the rod and the tube when the temperature is BT-3 Applying

raised to 190oC. Take Es = 2.1x105 N/mm2 , Ec = 1x105 N/mm2 , Co-

efficient of linear expansion 11x10-6 per oC and 18x10-6 per oC

A compound bar is made of a central steel plate 60mm wide and 10mm

thick to which copper plates 40mm wide and 5mm thick are connected

rigidly on each side. The length of the bar at normal temperature is 1m. If

4. the temperature is raised by 80oc, Indicate the stresses in each metal and BT-2 Understanding

change in length. Take the value of E for steel = 210 5 N/mm2, for

copper = 1105 N/mm2. Coefficient of thermal expansion for steel and

copper are 12 x 10-6 per oc and 17 x 10-6 per o c

Prepared by

A.SATTAINATHAN SHARMA/A.P S.KARTHICK/A.P G.VAITHIYANATHAN/A.P

VALLIAMMAI ENGINEERING COLLEGE DEPARTMENT OF CIVIL ENGINEEERING

UNIT 2- SHEAR AND BENDING IN BEAMS

Beams and Bending- Types of loads, supports Shear Force and Bending Moment Diagrams for statically

determinate beam with concentrated load, UDL, uniformly varying load. Theory of Simple Bending Analysis of

Beams for Stresses Stress Distribution at a cross Section due to bending moment and shear force for Cantilever,

simply supported and overhanging beams with different loading conditions - Flitched Beams.

PART A (2 Marks)

Q.No. Questions BT Competence

1. Classify the types of beams with neat sketch BT-4 Analysis

2. Discuss about shear force and bending moment. BT-2 Understanding

3 Explain what do you meant by point of contra flexure? BT-6 Creating

4. Differentiate between hogging and sagging bending moment. BT-2 Understanding

Design maximum bending moment for a simply supported beam

5. BT-6 Creating

subjected to uniformly distributed load and where it occurs?

Draw the S.F. & B.M. diagrams for cantilever beam of length L

6. BT-3 Applying

carrying a UDL of W/unit length throughout its span.

Draw the SF and BM diagrams for a cantilever beam 2m long carrying a

7. gradually varying load from zero @ free end to 2500N/m at the fixed BT-3 Applying

end

A SSB of span 4m is subjected to audlof2 kN/m over its entire length.

8. BT-3 Applying

Sketch the bending moment diagram for the beam.

9. Derive the relation between bending moment and shear force. BT-5 Evaluating

Summarize and sketch the types of supports used for a beam indicating

10. BT-2 Understanding

the reactions in each case.

11. Describe theory of simple bending equation. BT-1 Remembering

12. Discuss about moment of resistance of a beam? BT-2 Understanding

13. Define section modulus. BT-1 Remembering

14. Write any four assumptions in the theory of simple bending? BT-4 Analysis

What do you understand by neutral axis & neutral plane? How do you

15. BT-1 Remembering

locate Neutral axis?

Tell about Shear stress and also sketch the shear stress variation for

16. BT-1 Remembering

symmetrical I section

17. How would you find the bending stress in unsymmetrical sections? BT-1 Remembering

A beam subjected to a bending stress of 5N/mm2 and the section

18. BT-5 Evaluating

modulus is 3530 cm3. Evaluate the moment of resistance of the beam

19. Define flitched beams. Why it is used? BT-1 Remembering

Write the formula for section modulus for a circular and hollow circular

20. BT-4 Analysis

section.

PART B (13 Marks)

Predict and plot the shear force and bending moment diagram for the

1. BT-2 Understanding

beam shown in figure

Prepared by

A.SATTAINATHAN SHARMA/A.P S.KARTHICK/A.P G.VAITHIYANATHAN/A.P

VALLIAMMAI ENGINEERING COLLEGE DEPARTMENT OF CIVIL ENGINEEERING

A cantilever beam of 2 m long carries a uniformly distributed load of

2. 1.5 kN/m over a length of 1.6 m from the fixed end and 2 kN at free BT-3 Applying

end. Draws shear force and bending moment diagrams for the beam.

A SS beam of 2 m long carries a uniformly distributed load of 1.5 kN/m

3 over a length of 1.6 m from the right end. Draw shear force and bending BT-1 Remembering

moment diagrams for the beam.

A simply supported beam of length 10m carries the uniformly

distributed load and two point loads as shown in Fig. Label the S.F and

B.M diagram for the beam and also calculate the maximum bending

moment

4. BT-1 Remembering

Label the Shear force and bending moment diagram for the beam shown

in Fig

5. BT-1 Remembering

Locate and Plot the shear force and bending moment diagram for the

beam given in Fig.,

6. BT-1 Remembering

The intensity of loading on a simply supported beam of 7m span

increases gradually from 8.25kN/m run at one end to 2.5kN/m run at the

7. BT-2 Understanding

other end. Intercept the position and the amount of maximum bending

moment. Also Sketch the Shear force and bending moment diagram.

8. BT-3 Applying

9. A simply supported beam of span 4m carries a udl of 6kN/m over the entire BT-2 Understanding

Prepared by

A.SATTAINATHAN SHARMA/A.P S.KARTHICK/A.P G.VAITHIYANATHAN/A.P

VALLIAMMAI ENGINEERING COLLEGE DEPARTMENT OF CIVIL ENGINEEERING

span. If the maximum allowable stress due to bending is restricted to

2

150 N/mm , Estimate the cross sectional dimensions if the section is;

(i) Rectangular with depth twice the breadth (4 marks)

(ii) Solid circular section (5 marks)

(iii) Hollow circular section having a diameter ratio of 0.6

(4 marks)

The cross section of T beam is as follows: Flange thickness = 10mm;

width of the flange = 100mm; thickness of the web = 10mm; depth of

10. the web = 120mm; If a shear force of 2kN is acting at a particular BT-5 Evaluating

section of the beam design and draw the shear stress distribution across

the section

A 100mm X 200mm rolled steel I section has the flanges 12mm thick

and web 10mm thick. Formulate

(i) The safe udl the section can carry over a span of 6m if the

permissible stress is limited to 150 N/mm2 . (7

11. BT-6 Creating

marks)

(ii) The maximum bending stress when the beam carries a

central point load of 20kN.

(6 marks)

A simply supported beam of span 6m is subjected to a UDL of 15kn/m

over its entire length. The cross section of beam is 20 cm wide and

12. BT-4 Analysis

30cm deep. Analyze and Sketch the variation of bending stress and

shear stress in the beam cross section

A steel section shown in figure is subjected to a shear force of 25kN.

Construct the shear stress at the important pointsand sketch the shear

distribution diagram.

13. BT-4 Analysis

A rectangular beam 300 mm deep is simply supported over the span of

4m. Evaluate the uniformly distributed load per metre which the beam

14. BT-4 Analysis

may carry, if the bending stress should not exceed 120N/mm2 . Take

I=8104 mm4

Prepared by

A.SATTAINATHAN SHARMA/A.P S.KARTHICK/A.P G.VAITHIYANATHAN/A.P

VALLIAMMAI ENGINEERING COLLEGE DEPARTMENT OF CIVIL ENGINEEERING

PART-C (15 Marks)

A cantilever beam of 3 m long carries a uniformly distributed load of 10

1. kN/m over a length of 2 m from the free end. Draw shear force and BT-2 Understanding

bending moment diagrams for the beam.

Derive an expression for shear force and bending moment of a simply

2. supported beam carrying a UDL of w/m length throughout its span with BT-4 Analysis

neat sketch of SFD and BMD

Discover an expression for shear force and bending moment of a simply

3 supported beam carrying a UDL of w/metre length throughout its span BT-1 Remembering

with neat sketch.

Find out the section modulus for the follwing

a) Rectangular section (3 marks)

4. b) Hollow rectangular section (4 marks) BT-3 Applying

c) Circular section (3 marks)

d) Hollow circular section (3 marks)

UNIT 3- DEFLECTION

Double integration method - Macaulay's methods - Area moment method - conjugate beam method for

computation of slopes and deflections of determinant beams.

PART A (2 Marks)

Q.No. Questions BT Competence

1. Illustrate what is meant by deflection of beam with neat sketch. BT-2 Understanding

2. Recall the methods for finding out the slope and deflection at a section? BT-1 Remembering

3 Summarize double integration method. BT-5 Evaluating

4. Express the principle of actual beam over conjugate beam. BT-6 Creating

5. State the two theorems in moment area method. BT-1 Remembering

Give the differential relation between bending moment, slope and the

6. BT-1 Remembering

deflection?

Give the maximum slope and maximum deflection of a cantilever beam

7. BT-1 Remembering

subjected to UDL?

8. Illustrate when Macaulays method is preferred? BT-2 Understanding

9. Demonstrate Moment area method with a example. BT-3 Applying

Identify the values of slope and deflection for a cantilever beam of

10. BT-1 Remembering

length L subjected to Moment M at the free end?

11. Distinguish between statically determinate and indeterminate beams. BT-2 Understanding

12. Relate the 2 theorems of conjugate beam method with one another. BT-3 Applying

Formulate the slope at the support for a simply supported beam of

13. BT-5 Evaluating

length L, constant EI and carrying central concentrated load?

Justify why moment method is more useful when compared with double

14. BT-6 Creating

integration?

15. Write down the formula used to find the deflection of beam by Moment- BT-4 Analysis

Prepared by

A.SATTAINATHAN SHARMA/A.P S.KARTHICK/A.P G.VAITHIYANATHAN/A.P

VALLIAMMAI ENGINEERING COLLEGE DEPARTMENT OF CIVIL ENGINEEERING

Area method.

16. Compare and contrast working stress & allowable stress BT-2 Understanding

Write the maximum value of deflection for a cantilever beam of length

17. BT-4 Analysis

L, constant EI and carrying concentrated load W at the end.

Write the relation between deflection of bending moment and flexural

18. BT-4 Analysis

rigidity for a beam.

19. Recall method of Singularity functions. BT-1 Remembering

Among 4 methods of analyzing the beams for deflection and slope,

20. BT-3 Applying

relate the situations when each methods are used.

PART B (13 Marks)

A beam of length 5 m is simply supported at its ends and carries two

point loads of 47 kN and 30 kN at a distance of 1.1 m and 3.2 m

respectively from the left support. Identify

1. (i) Deflection under each load (4 marks) BT-1 Remembering

(ii) Maximum deflection (4 marks)

(iii) The point at which the maximum deflection occurs. (5 marks)

6 4 5 2

Take I=8510 mm E = 210 N/mm

A steel joist, simply supported over a span of 6 m carries a point load of

2. 50 kN at 1.2 m from the left hand support. Find the position and BT-1 Remembering

12 2

magnitude of the maximum deflection. Take EI = 14 X 10 N/mm

For the beam shown in fig Identify the deflection at the B. Use

Macaulays method.

3 BT-1 Remembering

Identify the slope at the supports and deflection of the beam shown in

figure. Take E=2x105N/mm2 and I= 20x106 mm4. Use Macaulays

method

4. BT-1 Remembering

A cantilever of length 2.5m is loaded with an udlof10 kN/m over a

length 1.5m from the fixed end and point load 2kN at 2m from free end.

5. Use Moment area method. BT-6 Creating

a) Design the beam for slope (6 marks)

b) Design the beam for deflection at the free end. (7 marks)

6. Indicate and solve the slope and deflection at the free end of the BT-2 Understanding

Prepared by

A.SATTAINATHAN SHARMA/A.P S.KARTHICK/A.P G.VAITHIYANATHAN/A.P

VALLIAMMAI ENGINEERING COLLEGE DEPARTMENT OF CIVIL ENGINEEERING

10 2

cantilever shows in fig. Take EI = 1x10 kN/mm

Using conjugate beam method, Indicate the slope and deflections at A,

-2

B, C and D of the beam shown in fig. Take E = 200GPa and I = 2x10

4

m .

7. BT-2 Understanding

For the beam shown in fig Predict the deflection at the B. Use

Macaulays method

8. BT-3 Applying

Point out the deflection under the greater load for the beam shown in fig

using the Moment Area method.

9. BT-4 Analysis

A beam AB of span 6m is simply supported at its ends is subjected to a

point load of 20kN at C at a distance of 2m from left end. Using

10. moment area method, Predict the deflection at the point C, slope at the BT-2 Understanding

8 4

points A, B and C. Take I = 6 x10 mm and E = 200GPa

Indicate and solve the slope and deflection at the free end of the

10 2

cantilever shows in fig. Take EI = 1x10 kN/mm

11. BT-3 Applying

A simply supported beam carrying a triangular distributed load. Label

12. a) the slope at left end (7 marks) BT-1 Remembering

b) deflection at Centre (6 marks)

Prepared by

A.SATTAINATHAN SHARMA/A.P S.KARTHICK/A.P G.VAITHIYANATHAN/A.P

VALLIAMMAI ENGINEERING COLLEGE DEPARTMENT OF CIVIL ENGINEEERING

Derive an expression for deflection of a simply supported beam carrying

13. BT-4 Analysis

an eccentric point load.

A beam of 4m span is carrying a point load of 40kN at a distance of 3m

from the left end. Calculate the slope at the supports and deflection

14. BT-4 Analysis

under the load. Also calculate the maximum deflection. EI= 2.6x107 N-

m2

PART-C (15 Marks)

Derive an expression for slope and deflection of a cantilever beam

1. BT-2 Understanding

carrying point load at free end

Derive an expression for deflection of a simply supported beam carrying

2. BT-4 Analysis

UDL throughout its span

Obtain an expression for Slope and deflection of a simply supported

3 BT-3 Applying

beam carrying point load at mid-span

4. BT-5 Evaluating

UNIT 4- TORSION

Torsion of Circular and Hollow Shafts Elastic Theory of Torsion Stresses and Deflection in Circular

Solid and Hollow Shafts combined bending moment and torsion of shafts - strain energy due to torsion

- Modulus of Rupture Power transmitted to shaft Shaft in series and parallel Closed and Open

Coiled helical springs Leaf Springs Springs in series and parallel Design of buffer springs`

PART A (2 Marks)

Q.No. Questions BT Competence

1. Compare and contrast between torsion, bending and torque BT-1 Remembering

2. List the assumptions made in the theory of torsion? BT-2 Understanding

3 Write about Torsional equation and torsional rigidity BT-1 Remembering

4. Write about modulus of rupture BT-4 Analysis

5. Write the expression for power transmitted by a shaft. BT-4 Analysis

A circular shaft of 80mm diameter is required to transmit torque. Find

6. BT-2 Understanding

the safe torque if the shear stress is not to exceed 80Mpa

Why hollow circular shafts are preferred when compared to solid

7. BT-6 Creating

circular shafts?

8. Define springs. What are the different types of springs? BT-6 Creating

9. What is leaf spring? State the uses of leaf spring. BT-1 Remembering

Write down the expression for torque transmitted by hollow shaft and

10. BT-1 Remembering

solid circular section.

Prepared by

A.SATTAINATHAN SHARMA/A.P S.KARTHICK/A.P G.VAITHIYANATHAN/A.P

VALLIAMMAI ENGINEERING COLLEGE DEPARTMENT OF CIVIL ENGINEEERING

11. Define spring stiffness and Spring index BT-3 Applying

Compare close coiled and open coiled springs under the action of an

12. BT-3 Applying

axial load.

What is the value of maximum shear stress in a close coiled helical

13. BT-3 Applying

spring subjected to an axial force?

A circular shaft is subjected to a torque of 10kNm. The power

14. transmitted by the shaft is 209.33kW. Find the speed of shaft in BT-1 Remembering

revolution per minute.

State the types of stresses when a closed coiled spring is subjected to (i)

15. BT-1 Remembering

axial load and (ii) axial twisting moment.

16. Write the equation for strain energy stored in a shaft due to torsion. BT-2 Understanding

What is meant by stiffness? Write the formula for stiffness of a close

17. BT-5 Evaluating

coiled helical spring subjected to axial load.

18. Give shear stress and deflection relation for close-coiled helical spring BT-4 Analysis

19. How will you apply a moment to produce bending and torque in a shaft? BT-2 Understanding

Design the equivalent bending moment for a shaft subjected to moment

20. BT-5 Evaluating

M and torsion T?

PART B (13 Marks)

A solid steel shaft is subjected to a torque of 45kNm. If the angle of

twist is 0.50 per metre length of the shaft and the shear stress is not to be

allowed to exceed 90MN/m2. & C= 80GN/m2. Evaluate

1. a) Suitable diameter for the shaft (3 marks) BT-1 Remembering

b) Final maximum shear stress (3 marks)

c) Angle of twist (3 marks)

d) Maximum shear strain in the shaft (4 marks)

In a tensile test, a test piece of 25mm diameter, 200mm gauge length

stretched 0.0950mm under a pull of 50kN. In a torsion test, the same rod

is twisted about 0.03radian over a length of 150mm when a torque of

0.5kN.m was applied. Evaluate

2. BT-2 Understanding

a) Poissons ratio (3 marks)

b) Youngs modulus (3 marks)

c) Bulk modulus and (3 marks)

d) Rigidity modulus for a material (4 marks)

A steel shaft ABCD having a total length of 2400mm is contributed by

three different sections as follows. The portion AB is hollow having

outside and inside diameters 80mm and 50mm respectively, BC is solid

3 and 80mm diameter. CD is also solid and 70mm in diameter. If the BT-2 Understanding

angle of twist is same for each section, Solve for the length of each

portion and the total angle of twist. Maximum permissible shear stress is

5

50 MPa and shear modulus 0.82x10 MPa.

A composite shaft consists of copper rod of 25mm diameter enclosed in

a steel tube of external diameter 45mm and 5mm thick. The shaft is

4. BT-6 Creating

required to transmit a torque of 1100N.m and both the shaft have equal

lengths, welded to a plate at each end so that their twists are equal. If the

Prepared by

A.SATTAINATHAN SHARMA/A.P S.KARTHICK/A.P G.VAITHIYANATHAN/A.P

VALLIAMMAI ENGINEERING COLLEGE DEPARTMENT OF CIVIL ENGINEEERING

modulus of rigidity for the steel as twice that of copper, find

a) Shear stress developed in copper (6 marks)

b) Shear stress developed in steel (7 marks)

A solid circular shaft transmits 75kW power at 200rpm. Estimate the

values of shaft diameter, if the twist in the shaft is not to exceed one

2

5. degree in 2m length of shaft and shear stress is not exceed 50 N/mm . BT-2 Understanding

Assume the modulus of rigidity of the material of the shaft as 100

2

kN/mm

Derive the following torsional equation

6. BT-5 Evaluating

7. Derive an expression for strain energy stored in a body due to torsion BT-3 Applying

A closely coiled helical spring made out of a 10mm diameter steel bar

has 12 complete coils, each of mean diameter of 100mm. Calculate

a) the stress induced in the section of rod, (4 marks)

b) the deflection under the pull and (4 marks)

8. c) Amount of energy stored in the spring during the extension. BT-4 Analysis

(5 marks)

If It is subjected to an axial pull of 200N. Modulus of rigidity is

5 2

0.84x10 N/mm

A close coiled helical spring has a stiffness of 5N/mm. its length when

fully compressed with adjacent coils touching each other is 40 cm. the

4 2

9. modulus of rigidity of the material of the spring is 8x10 N/mm . BT-1 Remembering

Determine the wire diameter and mean coil diameter if their ratio is

1/10. What is the corresponding maximum shear stress in the spring

a) A circular shaft of 1000mm diameter and 2m length is subjected

to a twisting moment. This creates a shear stress of 20N/mm2 at

30mm from the axis of the shaft. Calculate the angle of twist and

4 2

the strain energy stored in the shaft. Take G=8x10 N/mm

(6 marks)

10. b) A leaf spring 750mm long is required to carry a central load of BT-1 Remembering

8kN. If the central deflection is not to exceed 20mm and the

2

bending stress is not to be greater than 200N/mm . Determine

the thickness, width and number of plates. Assume the width of

the plates is 12 times, their thickness and modulus of elasticity

2

of the springs material as 200kN/mm (7 marks)

a) A solid shaft is subjected to a bending moment of 2.3 KN-m and

twisting moment of 3.45KN-m find the diameter of shaft if the

permissible tensile and shear stress for the material of the shaft

are limited to 703 MN/m2 and 421.8 MN/m2. ( 6 marks)

11. BT-1 Remembering

b) A open coil helical spring is made up 5mm diameter wire has 16

coils 100mm diameter with helix angel of 160 calculate the

deflection maximum direct and shear stress induced due to an

axial load of 300N. Take G=90GPa and E=200GPa. (7 marks)

Prepared by

A.SATTAINATHAN SHARMA/A.P S.KARTHICK/A.P G.VAITHIYANATHAN/A.P

VALLIAMMAI ENGINEERING COLLEGE DEPARTMENT OF CIVIL ENGINEEERING

Two solid shafts AB and BC of aluminum and steel respectively are

rigidly fastened together at B and attached to two rigid supports at A

and C. Shaft AB is 7.5cm in diameter and 2m in length. Shaft BC is 5.5

12. cm in diameter and 1m in length. A torque of 20000 N-cm is applied at BT-4 Analysis

the junction B. compute the maximum shearing stresses in each

material. What is the angle of twist at the junction? Take Cal = 0.3x105

N/mm2 and Cst = 0.9 N/mm2.

a) Find the size of a square shaft to transmit 75kW at 120 rpm if

shear stress is not to exceed 50N/mm2 (3 marks)

b) Hollow shaft having inside diameter 60% of its outside diameter

is to replace a solid shaft transmitting a same power at the same

13. speed calculate the % saving in material, if the materials to be BT-4 Analysis

used is also the same. (6 marks)

c) Calculate the maximum torque that a shaft of 125 mm diameter

can transmit, if the maximum angle of twist 10 in a length of 1.5

m. C=7x105 N/mm2 (4 marks)

Two close coiled helical springs wound from the same wire, but with

different core radii having equal no.of coils are compressed between

rigid plates at their ends. Calculate the maximum shear stress induced in

14. BT-3 Applying

each spring, if the wire diameter is 10mm and the load applied between

the rigid plates is 500N. the core radii of the spring 100 mm and 75mm

respectively.

PART-C (15 Marks)

A shaft has to transmit 245 kW power at 240 rpm. The maximum torque

may be 1.5 times the mean torque. The shear stress in the shaft is not to

2

exceed 40 N/mm and the twist must not exceed 10 per metre length,

find a suitable diameter. If

1. BT-2 Understanding

a) Tha shaft is solid (7 marks)

b) The shaft is hollow with external diameter twice the internal

diameter

4

Take C = 8x104 N/mm (8 marks)

A helical spring in which mean diameter of the coil is 8times the wire

diameter is to be designated to observe 0.2 KN of energy with an

extension of 100mm. the maximum shear stress is not to exceed

2. BT-4 Analysis

125N/mm2 . determine the mean diameter of wire and diameter of

springs and number of turns also find the load with an extension of 40

mm could be produced in the spring assume G= 84KN/mm2

What is the speed of circular shaft is subjected to a torque of 15kNm.

3 BT-3 Applying

The power transmitted by the shaft is 209.33kW

A composite concrete shaft is made up of a solid steel shaft of 25mm

radius encased in a hollow steel tube of 40mm inner radius and 60 mm

4. BT-6 Creating

outer radius. If both the shafts is of length 1m, find shear stress induced

in both the shafts and angle of twist. C= 1x105 MPa T= 1kN.m

Prepared by

A.SATTAINATHAN SHARMA/A.P S.KARTHICK/A.P G.VAITHIYANATHAN/A.P

VALLIAMMAI ENGINEERING COLLEGE DEPARTMENT OF CIVIL ENGINEEERING

UNIT 5- COMPLEX STRESSES AND PLANE TRUSSES

2 D State of Stress 2 D Normal and Shear Stresses on any plane Principal Stresses and Principal

Planes Mohr's circle - Plane trusses: Analysis of plane trusses - method of joints - method of sections

PART A (2 Marks)

Q.No. Questions BT Competence

What is mean by Circumferential stress (or hoop stress) and

1. BT-1 Remembering

Longitudinal stress?

2. Give the maximum shear stresses at any point in a cylinder? BT-2 Understanding

3 Define state of stress at a point BT-1 Remembering

4. Define principal plane BT-4 Analysis

5. Define principal stress BT-4 Analysis

Generalize the formula for finding circumferential strain and

6. BT-2 Understanding

longitudinal strain?

7. Define plane stress problem with example BT-6 Creating

8. Define plane strain problem with example BT-6 Creating

9. Distinguish between uniform and non-uniform state of stress BT-1 Remembering

Draw the Mohrs circle for a state of pure shear and indicate the

10. BT-1 Remembering

principal stresses

11. Distinguish between perfect and imperfect frame? BT-3 Applying

12. Compare and contrast deficient and redundant frame. BT-3 Applying

Justify how method of joints applied to Trusses carrying Horizontal and

13. BT-3 Applying

inclined loads

14. Discuss the assumptions made in finding out the forces in a frame? BT-1 Remembering

15. List the methods available for analyzing the frames. BT-1 Remembering

16. Differentiate a frame and truss BT-2 Understanding

17. State the advantages of method of section over method of joints BT-5 Evaluating

18. A perfect frame consists of 7 members. Decide the number of joints. BT-4 Analysis

Show the difference between a cantilever and simply supported frame?

19. BT-2 Understanding

How will you find the reactions in both the cases?

20. Differentiate a strut from tie BT-5 Evaluating

PART B (13 Marks)

A rectangular block of material is subjected to a tensile stress of

110N/mm2 on one plane and a tensile of 47 N/mm2 on a plane at right

1. angles to the former. Each of the above stresses is accompanies by a BT-1 Remembering

shear stress of 63N/mm2. Determine the principal stresses, principal

planes and the maximum shear stresses.

2

At a point in a strained material, the principal stresses are100 N/mm

2

2. (T) and 40 N/mm (C). Determine the resultant stress in magnitude and BT-2 Understanding

0

direction in a plane inclined at 60 to the axis of major principal stress.

What is the maximum intensity of shear stress in the material at the

Prepared by

A.SATTAINATHAN SHARMA/A.P S.KARTHICK/A.P G.VAITHIYANATHAN/A.P

VALLIAMMAI ENGINEERING COLLEGE DEPARTMENT OF CIVIL ENGINEEERING

point?

The stresses at a point in a strained material is Px= 200 N/mm2, Py = -

150N/mm2 and Q = 80 N/mm2. Solve for the principal plane and

3 BT-2 Understanding

principal stress using graphical method and verify with the analytical

results.

2

The principal stresses in the wall of a container are 40 MN/m and 80

2

4. MN/m . Determine the normal, shear and resultant stresses in BT-6 Creating

magnitude and direction in a plane, the normal of which makes an angle

o

of 30 with the direction of maximum principal stress

An elemental cube is subjected to tensile stresses of 30 N/mm2 and 10

N/mm2 acting on two mutually perpendicular planes and a shear stress

5. of 10N/mm2 on these planes. Draw the mohrs circle if stresses and BT-2 Understanding

hence determine the magnitudes and direction of principal stresses and

also the greatest shear stress.

Derive relations for normal and shear stresses acting on an inclined

6. plane at a point in a stained material subjected to two mutually BT-5 Evaluating

perpendicular direct stresses method

A cantilever truss is show in fig. conclude the forces and its nature in

the members of the truss by the method of joint

7. BT-3 Applying

Analyze the forces in all members of the truss shown in figure by

method of Joints/sections

8. BT-4 Analysis

A truss loaded shown in fig. Analyze and find the reaction and forces in

9. BT-1 Remembering

the members by using any one analytical methods

Prepared by

A.SATTAINATHAN SHARMA/A.P S.KARTHICK/A.P G.VAITHIYANATHAN/A.P

VALLIAMMAI ENGINEERING COLLEGE DEPARTMENT OF CIVIL ENGINEEERING

Analyze the truss by method of Joints

10. BT-1 Remembering

2

A short metallic column of 500mm cross sectional area carries a axial

o

compressive load of 100kN.For a plane inclined at 60 with the

direction of the load arrive at

11. a) Normal stress (3 marks) BT-1 Remembering

b) Resultant stress (2 marks)

c) Tangential stress (3 marks)

d) Maximum shear stress (2 marks)

e) Obliquity of resultant stress (3 marks)

A truss loaded shown in fig. Analyze and find the reaction and forces in

the members by using anyone analytical methods

12. BT-4 Analysis

Analyze and predict the forces in all members of the truss shown in

13. BT-4 Analysis

figure by method of sections

Prepared by

A.SATTAINATHAN SHARMA/A.P S.KARTHICK/A.P G.VAITHIYANATHAN/A.P

VALLIAMMAI ENGINEERING COLLEGE DEPARTMENT OF CIVIL ENGINEEERING

A truss loaded shown in fig. Analyze and find the reaction and forces in

the members by using method of joints

14. BT-3 Applying

PART-C (15 Marks)

Analyze and predict the forces in all members of the truss shown in

figure by using any one analytical method

1. BT-3 Applying

A truss loaded shown in fig. Analyze and find the reaction and forces in

2. BT-4 Analysis

the members by using method of joints

Prepared by

A.SATTAINATHAN SHARMA/A.P S.KARTHICK/A.P G.VAITHIYANATHAN/A.P

VALLIAMMAI ENGINEERING COLLEGE DEPARTMENT OF CIVIL ENGINEEERING

A truss loaded shown in fig. Analyze and find the reaction and forces in

the members by using method of joints

3 BT-1 Remembering

Analyze and find the reaction and forces in the members of a truss

shown below by using any one analytical method

4. BT-5 Evaluating

Prepared by

A.SATTAINATHAN SHARMA/A.P S.KARTHICK/A.P G.VAITHIYANATHAN/A.P

You might also like

- Strength of Materials and Structures: An Introduction to the Mechanics of Solids and StructuresFrom EverandStrength of Materials and Structures: An Introduction to the Mechanics of Solids and StructuresRating: 4 out of 5 stars4/5 (1)

- ST5009 Prestressed ConcreteDocument22 pagesST5009 Prestressed ConcreteHaripriya Sekar100% (1)

- CE8395-Strength of Materials For Mechanical EngineersDocument19 pagesCE8395-Strength of Materials For Mechanical Engineers26 MaheshkannanNo ratings yet

- CE6402-Strength of MaterialssDocument23 pagesCE6402-Strength of MaterialssSedhu CivilNo ratings yet

- ST5101-Advance Concrete StructuresDocument16 pagesST5101-Advance Concrete Structuresraj25% (4)

- Reinforced Concrete Beam Deflection and Minimum ThicknessDocument7 pagesReinforced Concrete Beam Deflection and Minimum ThicknessLester John PrecillasNo ratings yet

- CE6702-Prestressed Concrete Structures - 2013 - Regulation PDFDocument13 pagesCE6702-Prestressed Concrete Structures - 2013 - Regulation PDFShibin VargheseNo ratings yet

- Engineering MechanicsDocument43 pagesEngineering MechanicssrivallinarayanaNo ratings yet

- R13 Jntua Mechanical Engineer Question PaperDocument2 pagesR13 Jntua Mechanical Engineer Question PaperChandrika ReddyNo ratings yet

- Design prestressed concrete beams and sectionsDocument13 pagesDesign prestressed concrete beams and sectionsSuryakant MangajNo ratings yet

- Mehcanics of Solids May2004 RR 220304Document8 pagesMehcanics of Solids May2004 RR 220304Nizam Institute of Engineering and Technology LibraryNo ratings yet

- Mem-402-Mos Final QB-2015Document9 pagesMem-402-Mos Final QB-2015Rohit DiwakarNo ratings yet

- Mechanics of Solids Jun2003 NR 210302Document8 pagesMechanics of Solids Jun2003 NR 210302Nizam Institute of Engineering and Technology Library100% (1)

- Strength of Materials Question BankDocument16 pagesStrength of Materials Question BankTrishul SampathNo ratings yet

- Som Assignment 1 For Iat 1Document2 pagesSom Assignment 1 For Iat 1Selvaraj GNo ratings yet

- PH8151-Engineering PhysicsDocument10 pagesPH8151-Engineering PhysicsVishnu VaradhanNo ratings yet

- 15A01308 Mechanics of Solids PDFDocument2 pages15A01308 Mechanics of Solids PDFmahendra babu mekalaNo ratings yet

- ST5101-Advance Concrete StructuresDocument16 pagesST5101-Advance Concrete Structurescmurugan100% (1)

- Question Paper Mos r15 JntuaDocument2 pagesQuestion Paper Mos r15 JntuaAnonymous ML4hh4MOyBNo ratings yet

- CE6402-Strength of Materials PDFDocument12 pagesCE6402-Strength of Materials PDFSathz FlynnNo ratings yet

- Dss qb1Document7 pagesDss qb1Sushma ThakurNo ratings yet

- 9A01301 Mechanics of SolidsDocument4 pages9A01301 Mechanics of SolidssivabharathamurthyNo ratings yet

- A1101Document6 pagesA1101Khaja BashaNo ratings yet

- Ce 6452 SM Int IDocument2 pagesCe 6452 SM Int Iandrw1987No ratings yet

- STRENGTH OF MATERIALS - I Oct 2016Document7 pagesSTRENGTH OF MATERIALS - I Oct 2016Kashyap ChintuNo ratings yet

- Fracture Mechanics Exercises for Linear-Elastic and Elastic-Plastic BehaviorDocument10 pagesFracture Mechanics Exercises for Linear-Elastic and Elastic-Plastic BehaviorChuoiEmNo ratings yet

- R5210103 Strength of Materials - IDocument1 pageR5210103 Strength of Materials - IsivabharathamurthyNo ratings yet

- Design of Steel Structures Question BankDocument7 pagesDesign of Steel Structures Question BankROOPANo ratings yet

- CE8301-Strength of Materials IDocument4 pagesCE8301-Strength of Materials Isyed1188No ratings yet

- 9A01302 Strength of Materials - IDocument8 pages9A01302 Strength of Materials - IsivabharathamurthyNo ratings yet

- Ce8395 QB PDFDocument10 pagesCe8395 QB PDFMohan Ragava LawrenceNo ratings yet

- Fracture Mechanics ExercisesDocument33 pagesFracture Mechanics Exercises2luckystar100% (1)

- Mechanical ScienceDocument12 pagesMechanical ScienceFernando EyzaguirreNo ratings yet

- Dr. N.G.P. Institute of TechnologyDocument2 pagesDr. N.G.P. Institute of Technologyvasanthmech092664No ratings yet

- R5 210304 Mechanics of SolidsDocument2 pagesR5 210304 Mechanics of SolidssivabharathamurthyNo ratings yet

- SMDocument8 pagesSMShounak KossambeNo ratings yet

- 184 341 1 PBDocument9 pages184 341 1 PBFirdaus LazuardianNo ratings yet

- Candidates Are Required To Give Their Answers in Their Own Words As Far As Practicable. The Figures in The Margin Indicate Full MarksDocument4 pagesCandidates Are Required To Give Their Answers in Their Own Words As Far As Practicable. The Figures in The Margin Indicate Full MarksMadan PanditNo ratings yet

- Mechanics of Solids PDFDocument8 pagesMechanics of Solids PDFprashanthreddy26No ratings yet

- Lec 4Document64 pagesLec 4SSNo ratings yet

- 2022-23Sep-2022IVSupplementaryAR20B Tech MECH20ME404OtherDocument2 pages2022-23Sep-2022IVSupplementaryAR20B Tech MECH20ME404OtherJury.rahulNo ratings yet

- MoM Practice QuestionDocument15 pagesMoM Practice QuestionVallabh MehtreNo ratings yet

- CE6603-Design of Steel StructuresDocument15 pagesCE6603-Design of Steel StructuresVasim Jaman SNo ratings yet

- KONGU ENGINEERING COLLEGE CYCLE TESTDocument10 pagesKONGU ENGINEERING COLLEGE CYCLE TESTsasikskNo ratings yet

- Mechanics of Solids exam questionsDocument14 pagesMechanics of Solids exam questionsmahendra babu mekalaNo ratings yet

- Mechanics of Materials July 2013Document0 pagesMechanics of Materials July 2013Prasad C MNo ratings yet

- CAUSON Assignment 1MDocument5 pagesCAUSON Assignment 1MEmmanuel CausonNo ratings yet

- M.Tech Exam on Prestressed Concrete DesignDocument19 pagesM.Tech Exam on Prestressed Concrete DesignAbdulrhman Abduelgassim OsmanNo ratings yet

- Engi MatarialDocument8 pagesEngi MatarialAnirban BarmonNo ratings yet

- DME-I Model Paper-3 2Document3 pagesDME-I Model Paper-3 2Srinivas KosuriNo ratings yet

- Institute of Aeronautical Engineering: Prestressed Concrete StructuresDocument21 pagesInstitute of Aeronautical Engineering: Prestressed Concrete StructuresAyushi AgarwalNo ratings yet

- Mom - 18me32 AssignmentDocument4 pagesMom - 18me32 AssignmentS KousikNo ratings yet

- Rcd ModulesDocument120 pagesRcd Modulesjeanyencrysta montesaNo ratings yet

- Som I Iat Ques 2019Document3 pagesSom I Iat Ques 2019Siva RamanNo ratings yet

- 1917101-Advanced Concrete and Steel StructuresDocument18 pages1917101-Advanced Concrete and Steel StructuresDeepakNo ratings yet

- Fracture Toughness of Cast Aluminium Alloys: Bulletin of Materials Science March 1982Document8 pagesFracture Toughness of Cast Aluminium Alloys: Bulletin of Materials Science March 1982Aung Khant KyawNo ratings yet

- Question B.Tech (CE) PDFDocument148 pagesQuestion B.Tech (CE) PDFLawrence NgariNo ratings yet

- CE6302Document14 pagesCE6302Daniel MabengoNo ratings yet

- 5 Design Nov 2013 KeyDocument6 pages5 Design Nov 2013 KeyKenneth PadunanNo ratings yet

- Evaluation of Codes of Practice and Modelling of High Strength Circular Concrete-Filled-Steel-Tube ColumnsDocument11 pagesEvaluation of Codes of Practice and Modelling of High Strength Circular Concrete-Filled-Steel-Tube ColumnsBambang PiscesaNo ratings yet

- Information For Authors-BOMS - 7 May PDFDocument8 pagesInformation For Authors-BOMS - 7 May PDFYuvaraj GNo ratings yet

- Module 4,1Document34 pagesModule 4,1Arjun PrasadNo ratings yet

- Guideline For Conduct of Laboratory CoursesDocument1 pageGuideline For Conduct of Laboratory CoursesMaharaja PlacementNo ratings yet

- KTU BTech S6 Exam Time Table July 2021Document7 pagesKTU BTech S6 Exam Time Table July 2021Udith Babu VarrierNo ratings yet

- Stress and Strain Tensors - Stress: Fall, 2006Document25 pagesStress and Strain Tensors - Stress: Fall, 2006Rizqi Ilmal YaqinNo ratings yet

- 1.1 What Is Solid Mechanics?: Section 1.1Document4 pages1.1 What Is Solid Mechanics?: Section 1.1Ingeniero EstructuralNo ratings yet

- Metrology and Measurements: Linear Measuring InstrumentsDocument49 pagesMetrology and Measurements: Linear Measuring InstrumentsGoutham Mareeswaran BNo ratings yet

- APJ Abdul Kalam Technological University AICTE Doctoral Fellowship 2021 - 2022Document2 pagesAPJ Abdul Kalam Technological University AICTE Doctoral Fellowship 2021 - 2022Maharaja PlacementNo ratings yet

- Mod 3 - Lec 3Document44 pagesMod 3 - Lec 3Maharaja PlacementNo ratings yet

- Sensors 15 15311 v2Document15 pagesSensors 15 15311 v2Maharaja PlacementNo ratings yet

- Anti Roll BackDocument4 pagesAnti Roll BackMaharaja Placement100% (1)

- ME201 Mechanics of Solids Course SyllabusDocument3 pagesME201 Mechanics of Solids Course SyllabusSudeesh SudevanNo ratings yet

- Metrology and Measurements: Linear Measuring InstrumentsDocument49 pagesMetrology and Measurements: Linear Measuring InstrumentsGoutham Mareeswaran BNo ratings yet

- 514design and Fabrication of Anti Roll Back System in Vehicles Using Ratchet and Pawl Mechanism PDFDocument4 pages514design and Fabrication of Anti Roll Back System in Vehicles Using Ratchet and Pawl Mechanism PDFJeevan Landge PatilNo ratings yet

- 170164Document3 pages170164santosh4103No ratings yet

- TOP MECHANICAL Engineering Interview Questions and AnswersDocument24 pagesTOP MECHANICAL Engineering Interview Questions and Answersrajesh1924No ratings yet

- BEDocument410 pagesBEHariharan SelvarajuNo ratings yet

- National Disposable IncomeDocument3 pagesNational Disposable IncomeMaharaja PlacementNo ratings yet

- Cobb DouglasDocument59 pagesCobb DouglasPrashant Joshi100% (1)

- Business Economics VIDocument20 pagesBusiness Economics VIMaharaja PlacementNo ratings yet

- 1 Stress Strain SMDocument45 pages1 Stress Strain SMMaharaja PlacementNo ratings yet

- Breakeven AnalysisDocument15 pagesBreakeven AnalysisdrajingoNo ratings yet

- Balance SheetDocument71 pagesBalance SheetMaharaja PlacementNo ratings yet

- Ba7206 QBDocument44 pagesBa7206 QBMaharaja PlacementNo ratings yet

- Heat and Mass Transfer - 2 Marks - All 5 UnitsDocument16 pagesHeat and Mass Transfer - 2 Marks - All 5 UnitsMohan Prasad.M100% (2)

- BBA Introduction To Business Economics and Fundamental ConceptsDocument30 pagesBBA Introduction To Business Economics and Fundamental ConceptsMaharaja PlacementNo ratings yet

- Mechanical 5&6Document41 pagesMechanical 5&6Damodar S PrabhuNo ratings yet

- Managerial EconomicsDocument271 pagesManagerial EconomicsRaghu Sabbithi50% (2)

- s3 To s8 Ktu SyllabusDocument119 pagess3 To s8 Ktu SyllabusAnonymous t9L0QI50% (2)

- HS22000 Stanley ManualDocument18 pagesHS22000 Stanley ManualGleynder IraricaNo ratings yet

- 285 Scale Paper Buildings 3Document7 pages285 Scale Paper Buildings 3Richard K100% (3)

- Experimental Behaviour of Steel Fiber Reinforced Concrete With Partial Replacement of Fly Ash and MetakaolinDocument4 pagesExperimental Behaviour of Steel Fiber Reinforced Concrete With Partial Replacement of Fly Ash and MetakaolinEditor IJTSRDNo ratings yet

- Portfolio 2013Document29 pagesPortfolio 2013mucupNo ratings yet

- What Is Design Interpretation?Document17 pagesWhat Is Design Interpretation?Qaisir MehmoodNo ratings yet

- ES0153-75440100-DBR-0003 Dust ExtractionDocument19 pagesES0153-75440100-DBR-0003 Dust Extractionraaj bharathNo ratings yet

- Steel Fibers For Fiber-Reinforced ConcreteDocument4 pagesSteel Fibers For Fiber-Reinforced ConcreteIvan TapiaNo ratings yet

- Module 1 - National Building Code of The Philippines - Part 1Document37 pagesModule 1 - National Building Code of The Philippines - Part 1Rovic VincentNo ratings yet

- Ps-x01 Nls InputdataDocument100 pagesPs-x01 Nls InputdatapckolNo ratings yet

- Standard Method of Measurement for Building Works in QatarDocument158 pagesStandard Method of Measurement for Building Works in Qatarizac007No ratings yet

- Perancangan Struktur Baja 1Document53 pagesPerancangan Struktur Baja 1Saya BimaNo ratings yet

- Preinstallation VerificationDocument5 pagesPreinstallation VerificationbalamuruganNo ratings yet

- Concrete Shell ElementDocument25 pagesConcrete Shell ElementRudranath BhattacharyaNo ratings yet

- Introduction To Prestressing CE 572: Purdue University School of Civil EngineeringDocument21 pagesIntroduction To Prestressing CE 572: Purdue University School of Civil EngineeringNatarajan SaravananNo ratings yet

- Form EE-CH Checklist For COCR Stage 2 / FOC Submission: Name of Building EMSD Ref. No. Name of The READocument6 pagesForm EE-CH Checklist For COCR Stage 2 / FOC Submission: Name of Building EMSD Ref. No. Name of The REAewothjogNo ratings yet

- Sachpazis Raft Foundation Design Analysis Design For Multistorey Building. Calculation According To Bs 8110-1-1997Document14 pagesSachpazis Raft Foundation Design Analysis Design For Multistorey Building. Calculation According To Bs 8110-1-1997sitheeqNo ratings yet

- B-1050 EL Resilient 2012-08Document24 pagesB-1050 EL Resilient 2012-08Karthick VenkateshNo ratings yet

- Preliminary Design of BeamDocument4 pagesPreliminary Design of BeamSaroj DwaNo ratings yet

- Laurie Baker Works and IdeasDocument14 pagesLaurie Baker Works and IdeasCebo DharuNo ratings yet

- Geosynthetics ApplicationsDocument51 pagesGeosynthetics ApplicationsCharlotte TilburyNo ratings yet

- Protection Board PDFDocument2 pagesProtection Board PDFmilanbrasinaNo ratings yet

- 1pf2gf - Pgf-Int-Gp-Re10213Document20 pages1pf2gf - Pgf-Int-Gp-Re10213Johnny JessingNo ratings yet

- Seismic Rules Masonry Walls Eurocode 6Document8 pagesSeismic Rules Masonry Walls Eurocode 6Nikolai BogdanovNo ratings yet

- Imphal EasaaDocument1 pageImphal EasaaKosygin LeishangthemNo ratings yet

- Doubler or Stiffener Plate PDFDocument2 pagesDoubler or Stiffener Plate PDFaams_sNo ratings yet

- 2-Stage D - Part 2 - Structural Design Report - FX Rev1Document168 pages2-Stage D - Part 2 - Structural Design Report - FX Rev1Prima AdhiyasaNo ratings yet

- Alma Phase 2 Community Facilities: 16-084 FFE SpecificationDocument21 pagesAlma Phase 2 Community Facilities: 16-084 FFE Specificationjoe whiteNo ratings yet

- Load Schedule ApartmentDocument3 pagesLoad Schedule Apartmentshaito100% (1)

- POWERPACKDocument31 pagesPOWERPACKcristianNo ratings yet

- Lecture Notes Contract Unit 1Document126 pagesLecture Notes Contract Unit 1Iyyer CookNo ratings yet