Professional Documents

Culture Documents

Annex-3 Vetogrout CG518

Uploaded by

MdShahbazAhmedOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Annex-3 Vetogrout CG518

Uploaded by

MdShahbazAhmedCopyright:

Available Formats

Annexure -3

Construction Materials Product Data Sheet

Vetogrout CG518

Universal micro-concrete for large

thickness repair & grouting

Uses

uu Precast panels wall and base segment grouting

uu Repair of broken structural concrete elements

where large segments are of concern.

uu Casting structural members and elements

where conventional grouts can not perform.

uu Base plate grouting where sections are in excess

of 70 mm.

Product Description

Vetogrout CG518 is a single component polymer modified fibered cementitious structural and non-shrink micro-

concrete that is ready to use and only requires the addition of water on site. Once mixed the products becomes a

self compacting micro-concrete that is applied by pouring into prepared form-work for the repair of demanding

structural repair while being compatible with host concrete. Vetogrout CG518 is composed of a blend of hydraulic

cements, carefully selected and graded aggregates, fibers and special additives to give it its unique properties.

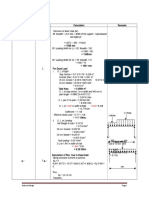

Advantages Technical Data

uu Factory controlled pre-blend ensures consistent

high quality. Vetogrout CG518 Typical Values

Drying Shrinkage <300 Microstrain @ 7 d

Technical Data Sheet -Vetogrout CG518

uu Designed for large thickness grouting & repair.

ASTM C157 <500 Microstrain @ 28 d

uu Requires only addition of water on-site at the Water Penetration

time of usage. <10 mm

DIN 1048

uu Compatible with normal concrete. Fresh Mixed Density Approximately 2.4 kg/ltr

Maximum Aggregate

uu High freeze-thaw resistance. 2.4 mm

Size

uu Low porosity and Non-shrink characteristics. Coefficient of Thermal

11x10-6 m/m per C

uu High bond strength. Expansion

Compressive Strength

uu Bond strength. > 65 N/mm2@ 28 days

BS 4551

uu Cost effective. Flexural strength

> 9 @ 28 days.

BS 4551

Tensile Strength

Standards Compliance > 3 MPa @ 28 days

BS 4551

hh ASTM C1107/1107M-14 (previously CRD621) as Application Thickness 50 - 500 mm

Type B. VOC Content <10 gm / Liter

ASTM D2369 (LEED Compliant)

hh ASTM C938-10

Water Demand 5.5 - 6.5 liter /50 kg bag

hh Sampling as per ASTM C943

hh EN 934: 2012 (testing as per EN480, EN 13395) Usage Instructions

Surface Preparation

The surface should be sound, clean, free from loose

material, grease, laitence, dirt curing compound, etc.

Product Data Sheet Construction Materials

Wet the substrate to achieve a saturated and surface to minimize heat build-up. Typically a 10 mm aggregate

dry condition prior to application of Vetogrout CG518. is suitable. Any bolt pockets must be grouted prior to

grouting between the substrate and the base plate.

Erect hopper system and form-work, make sure that

the shuttering is watertight by use of a polyurethane Continuous grout flow is essential. Sufficient grout

sealant such as Vetoflex PU780 or a rubber gasket seal. must be prepared before starting. The time taken to

This step is important to insure no cement paste and pour a batch must be regulated to the time to prepare

water leak from the shuttering. Contact you Savetos the next one.

local representative for more technical information and

Savetos grouting detailed method statement and CAD Curing

details. On completion of the grouting operation, exposed

It is essential that the base plate is clean and free from areas should be thoroughly cured. This should be

oil, grease or scale. Air pressure relief holes should be done by the use of Vetocure XT425 water based curing

provided to allow venting of any isolated high spots. compound and wrapping with polyethylene sheets.

If leveling shims are used and are to be removed after Cleaning

the grout has hardened, they should be treated with a

thin layer of grease. Vetogrout CG518 should be removed from tools and

equipment with clean water immediately after use.

Unrestrained Surface Area Cured material can be removed mechanically.

Generally the gap width between the perimeter form- Packaging & Coverage

work and the plate edge should not exceed 150 mm on

the pouring side and 50 mm on the opposite side. It is Product Pack Size Consumption

advisable where practical to have no gap at the flank 25 Kg Bag 11.5 Liters Yield

sides. Vetogrout CG518

50 Kg Bag 23.0 Liters Yield

Mixing Vetobond AB432 4 Liter Can 6-8 m2 / Liter

Vetoprime EP310 1 Liter Can 7.5 m2 / Liter

For best results a mechanically powered grout mixer Vetobond EB430 1 Liter Kit 8 m2 / Liter

should be used. When quantities up to 50 kg are

used, a slow speed drill fitted with a high shear mixer

is suitable. Larger quantities will require a high shear

Shelf Life & Storage

vane mixer. Do not use a colloidal impeller mixer. Original sealed kits of Vetogrout CG518 has a shelf life

of 12 months provided it is stored clear of ground in

Technical Data Sheet -Vetogrout CG518

To enable the grouting operation to be carried out

continuously, it essential that sufficient mixing capacity a dry and shaded temperature controlled place <35C.

and labor are available. The use of a grout holding Vetogrout CG518 repair area should not exceed 2.5 m2

tank with provision to gently agitate the grout may be in single application.

required.

Water to be added is 11-13% by weight of the grout and

Health & Safety

should be accurately measured into the mixer. The total Vetogrout CG518 Contains reins which may cause

contents of the Vetogrout CG518 bag should be slowly sensitization by skin contact. Avoid contact with

added and continuous mixing should take place for 5 skin and eyes and inhalation of vapor. Wear suitable

minutes. This will ensure that the grout has a smooth protective clothing, gloves and eye/face protection.

even consistency. Barrier creams provide additional skin protection.

Should accidental skin contact occur, remove

Placing immediately with a resin removing cream, followed by

At 25C place the grout within 20 minutes of mixing to soap and water. Do not use solvent. In case of contact

gain full benefit of the expansion process. with eyes, rinse immediately with plenty of clean water

and seek medical advice. If swallowed seek medical

Vetogrout CG518 can be placed in thicknesses up to attention immediately. Do not induce vomiting.

100 mm in a single pour when used as an under-plate

grout. For thicker sections it is necessary to fill out Vetogrout CG518 is non-flammable.

Vetogrout CG518 with well-graded silt free aggregate

LEGAL DISCLAIMER

Saveto endeavors to ensure that any advice, recommendations, information it may give, is accurate and correct. It cannot accept any

liability either directly or indirectly arising from the use of its products, because it has no direct or continuous control over where or how

its products are applied, whether or not in accordance with any advice, specification, recommendation or information given by us.

Saveto has the right to change any of the specifications mentioned in the Technical data sheets upon its discretion without prior

notification. Hard copies of TDSs are printed once or twice a year, while our technical data sheets are continuously being updated as per

R&D improvements and new 3rd party testing; kindly refer to our website for the latest updated TDSs.

Ref No.: G2-GA027-03-17 www.saveto.com

You might also like

- PF2Document4 pagesPF2nhulugallaNo ratings yet

- Design of angle and ISMC section splicesDocument2 pagesDesign of angle and ISMC section splicesPartha GangopadhyayNo ratings yet

- Wind LoadDocument5 pagesWind LoadPATEL JIGARNo ratings yet

- Slab Design of Partially Fixed Circular SlabDocument4 pagesSlab Design of Partially Fixed Circular SlabBithika DattaNo ratings yet

- Shear Key DesignDocument2 pagesShear Key DesignmaheshbandhamNo ratings yet

- BW - Calculation Sheet - Rev01Document15 pagesBW - Calculation Sheet - Rev01Ernest NavarroNo ratings yet

- TSS 35 / 205 sheet thickness & load data for aluminium & steel roofingDocument1 pageTSS 35 / 205 sheet thickness & load data for aluminium & steel roofingAkhil VNNo ratings yet

- GratingDocument8 pagesGratingGhanshyam PandeyNo ratings yet

- Appendix - Ii: Principles of Construction, Material and Design of Ferrocement TankDocument5 pagesAppendix - Ii: Principles of Construction, Material and Design of Ferrocement TankbenzzenhdNo ratings yet

- Shear Lug Verification Example 2Document1 pageShear Lug Verification Example 2Nasrul AdliNo ratings yet

- Rectangular Spread Footing DesignDocument42 pagesRectangular Spread Footing DesignJedidiah MelakuNo ratings yet

- Strength and Behavior of Reinforced Concrete Obtuse Corners Under Opening Bending MomentsDocument6 pagesStrength and Behavior of Reinforced Concrete Obtuse Corners Under Opening Bending MomentsValdemir ColaresNo ratings yet

- 1 Input Data: Hilti PROFIS Engineering 3.1.1Document10 pages1 Input Data: Hilti PROFIS Engineering 3.1.1Zaido Al HalabiNo ratings yet

- Beam DesignDocument7 pagesBeam DesignKasi ViswanathanNo ratings yet

- Design of Z Purlins ReportDocument18 pagesDesign of Z Purlins ReportAgarwal MittalNo ratings yet

- GRC Design and LoadsDocument4 pagesGRC Design and Loadsmohamed rafiNo ratings yet

- Reference Output Calculations & FormulasDocument4 pagesReference Output Calculations & FormulasAddrien DanielNo ratings yet

- Geometrical Properties Material Properties: Design of Helicoidal StairDocument5 pagesGeometrical Properties Material Properties: Design of Helicoidal StairPrashant Verma100% (1)

- BS EN 1991-1-1:2002, BS EN 1993-1-1:2005 - Chequered Plate Design 3/14/2020Document88 pagesBS EN 1991-1-1:2002, BS EN 1993-1-1:2005 - Chequered Plate Design 3/14/2020MohMohkNo ratings yet

- ASCE7 Wind For Cladding CN8 Block BDocument4 pagesASCE7 Wind For Cladding CN8 Block BCheng KoNo ratings yet

- Moment Connection Using Mathcad PDFDocument11 pagesMoment Connection Using Mathcad PDFbong2rmNo ratings yet

- Bs5950 Calculation Decking SheetDocument6 pagesBs5950 Calculation Decking SheetKho C Ahl100% (1)

- Keshmen Consult SDN BHD: Design of Slab On Grade To TR34Document2 pagesKeshmen Consult SDN BHD: Design of Slab On Grade To TR34Kevin LowNo ratings yet

- RCFootingDesignWebDocument3 pagesRCFootingDesignWebjudeNo ratings yet

- Corrugated Sheets Design GuideDocument12 pagesCorrugated Sheets Design GuideRama KrishnaNo ratings yet

- A&m BSR-2011Document26 pagesA&m BSR-2011Mukesh Jangid100% (1)

- Vertical Weld Design Bolt Design'!A1 Deflection!A1 Material Data'!a1 Index!a1 TrangDocument7 pagesVertical Weld Design Bolt Design'!A1 Deflection!A1 Material Data'!a1 Index!a1 TrangSơn Nguyễn-LêNo ratings yet

- ACI318-08 Circular Column Design AnalysisDocument6 pagesACI318-08 Circular Column Design Analysisazamislam726537No ratings yet

- Daniel Tian Li: Plain Concrete Footing Design Based On ACI 318-05Document2 pagesDaniel Tian Li: Plain Concrete Footing Design Based On ACI 318-05Wintun73No ratings yet

- Sta 11+320 PDFDocument4 pagesSta 11+320 PDFJaime Francisco SimithNo ratings yet

- Staircase Design: 8.28kN/m 15.57kN/mDocument3 pagesStaircase Design: 8.28kN/m 15.57kN/mBikki CyamaNo ratings yet

- General Catalogue VOL1Document330 pagesGeneral Catalogue VOL1lifib23970No ratings yet

- Reinforced Concrete Footing Design SpreadsheetDocument5 pagesReinforced Concrete Footing Design SpreadsheetJamil AlhamatyNo ratings yet

- Cantilever Retaining Wall ExampleDocument10 pagesCantilever Retaining Wall ExampleReab SimanthNo ratings yet

- Technical Data Sheet For Hilti HIT HY 200 Injectable Mortar in Concrete Technical Information ASSET DOC 8258686 PDFDocument41 pagesTechnical Data Sheet For Hilti HIT HY 200 Injectable Mortar in Concrete Technical Information ASSET DOC 8258686 PDFiabdillahNo ratings yet

- Clean Copy Metal Building Foundation Rev 2.1Document14 pagesClean Copy Metal Building Foundation Rev 2.1jurieskNo ratings yet

- Repport Steel Structure PDFDocument111 pagesRepport Steel Structure PDFAnonymous fxqnhfKNo ratings yet

- HSFG bolt design capacitiesDocument5 pagesHSFG bolt design capacitiesSanthi KrishnaNo ratings yet

- Base Plate Design (Pin) Asd For CompressionDocument54 pagesBase Plate Design (Pin) Asd For CompressionEmdadul HuqNo ratings yet

- Anchor Design for 219mm Pole SupportDocument1 pageAnchor Design for 219mm Pole SupportS A K ClostreNo ratings yet

- Early Thermal Cracking CalculationsDocument1 pageEarly Thermal Cracking Calculationsmassive85No ratings yet

- Cement BaobabDocument1 pageCement BaobabYogesh GoburdhunNo ratings yet

- As Combined Stress Ratio Is Below 1 So Anchor Bolt Is OKDocument1 pageAs Combined Stress Ratio Is Below 1 So Anchor Bolt Is OKNaresh KumarNo ratings yet

- Consistent determination of flexural and lateral buckling resistanceDocument106 pagesConsistent determination of flexural and lateral buckling resistanceAnonymous hprsT3WlPNo ratings yet

- Davit Trolley - Validation of Davit & Support BracketDocument17 pagesDavit Trolley - Validation of Davit & Support BracketRanjit S KashyapNo ratings yet

- GIRT DESIGN C140x60x20x4 BEAMDocument2 pagesGIRT DESIGN C140x60x20x4 BEAMYaşarUğurNo ratings yet

- Rhomboidal Steel Wire Rope Net Panels SpecificationDocument5 pagesRhomboidal Steel Wire Rope Net Panels SpecificationSOMNATH JANANo ratings yet

- Coupling BeamDocument2 pagesCoupling Beamwilliam6703100% (1)

- Chequered Plate PlatformDocument3 pagesChequered Plate PlatformFilip RisteskiNo ratings yet

- Section A-A: Wall Cheq'D PlateDocument1 pageSection A-A: Wall Cheq'D PlateAL BASTAKI CONTRACTING L.L.C.50% (2)

- 1 Design ដៃរណែងមុំ 35Document1 page1 Design ដៃរណែងមុំ 35Ce Win100% (1)

- 5.0 Connection 4Document3 pages5.0 Connection 4Gaurav BhabadNo ratings yet

- Structural Design Calculations Precast Boundary WallDocument35 pagesStructural Design Calculations Precast Boundary WallrenishkavukattNo ratings yet

- Structural Steel Contractor Alternate Beam Proposal CalculationDocument1 pageStructural Steel Contractor Alternate Beam Proposal CalculationJeff cadavaNo ratings yet

- BoltDocument2 pagesBoltmuhannedNo ratings yet

- AISC-360-16 Composite Column Design ExampleDocument3 pagesAISC-360-16 Composite Column Design Examplealejandro mantillaNo ratings yet

- Hasen Design Summary 20 MetreDocument2 pagesHasen Design Summary 20 MetreAgshin PirimovNo ratings yet

- 14 Vetogrout CG510 - Group 170821Document2 pages14 Vetogrout CG510 - Group 170821faisal dildarNo ratings yet

- Conbextra GPDocument4 pagesConbextra GPm.elsanee.cubicNo ratings yet

- Eurocode 7 Geotechnical Design Worked ExamplesDocument172 pagesEurocode 7 Geotechnical Design Worked ExamplesJevgenijs Kolupajevs100% (1)

- Slab DefinitionDocument5 pagesSlab DefinitionMdShahbazAhmedNo ratings yet

- Pile CapDocument8 pagesPile CapMdShahbazAhmedNo ratings yet

- Cut Slab 120mm Fix Last StepDocument1 pageCut Slab 120mm Fix Last StepMdShahbazAhmedNo ratings yet

- Nominal Dimensions Section Properties, Static DataDocument9 pagesNominal Dimensions Section Properties, Static DataMdShahbazAhmedNo ratings yet

- Step by Step Procedure For Concrete RepairDocument4 pagesStep by Step Procedure For Concrete RepairMdShahbazAhmedNo ratings yet

- Column Design Examples EBCSDocument7 pagesColumn Design Examples EBCSMesfin Derbew89% (28)

- Return - Ksa009 L09 SD A 31009 - BDocument1 pageReturn - Ksa009 L09 SD A 31009 - BMdShahbazAhmedNo ratings yet

- Structure Design Basis: Page - 1Document7 pagesStructure Design Basis: Page - 1MdShahbazAhmedNo ratings yet

- Annex 1 TDS Nitoprime Zincrich Saudi ArabiaDocument3 pagesAnnex 1 TDS Nitoprime Zincrich Saudi ArabiaMdShahbazAhmedNo ratings yet

- Appliacation MethodDocument5 pagesAppliacation MethodMdShahbazAhmedNo ratings yet

- Basement DesignDocument4 pagesBasement DesignMdShahbazAhmedNo ratings yet

- Catwalk Walk Base Plate Grouting 1Document30 pagesCatwalk Walk Base Plate Grouting 1MdShahbazAhmedNo ratings yet

- Method Statement FOR Rectification & Grouting at Catwalk Bracket Location (Façade Envelope)Document4 pagesMethod Statement FOR Rectification & Grouting at Catwalk Bracket Location (Façade Envelope)MdShahbazAhmedNo ratings yet

- C FIX Report3Document10 pagesC FIX Report3MdShahbazAhmedNo ratings yet

- Anchor Calculation - Case 2Document10 pagesAnchor Calculation - Case 2MdShahbazAhmedNo ratings yet

- Design of Beam-Aci-11-01-05Document23 pagesDesign of Beam-Aci-11-01-05aomareltayeb100% (1)

- 4th Floor FinalDocument1 page4th Floor FinalMdShahbazAhmedNo ratings yet

- Design Basis Report For Car Parking Shed r1Document37 pagesDesign Basis Report For Car Parking Shed r1MdShahbazAhmed60% (10)

- Choose and Use - StrengthDocument4 pagesChoose and Use - StrengthMdShahbazAhmedNo ratings yet

- Angle PropertiesDocument9 pagesAngle PropertiesMdShahbazAhmedNo ratings yet

- Beam Design Formulas With Shear and MomentDocument20 pagesBeam Design Formulas With Shear and MomentMuhammad Saqib Abrar100% (8)

- 18-Sep-14 13-Oct-2014 16:05 G+1 (4.8m) R1.std: Job No Sheet No RevDocument1 page18-Sep-14 13-Oct-2014 16:05 G+1 (4.8m) R1.std: Job No Sheet No RevMdShahbazAhmedNo ratings yet

- BS5950 Structural Steel Design RDocument174 pagesBS5950 Structural Steel Design RMdShahbazAhmed100% (6)

- Car Park Shed Structural Design Basis ReportDocument23 pagesCar Park Shed Structural Design Basis ReportMdShahbazAhmed0% (1)

- QuestnDocument3 pagesQuestnMdShahbazAhmedNo ratings yet

- Shear Wall IS13920Document19 pagesShear Wall IS13920Parag KulkarniNo ratings yet

- Screen Cast 012Document7 pagesScreen Cast 012MdShahbazAhmedNo ratings yet

- Column SpliceDocument2 pagesColumn SpliceMdShahbazAhmedNo ratings yet

- 00 Pre-Laboratory NotesDocument13 pages00 Pre-Laboratory NotesAlberto Antonio Jr.No ratings yet

- Eat 356/4 - Wastewater Engineering: Sludge Removal ManagementDocument33 pagesEat 356/4 - Wastewater Engineering: Sludge Removal Managementabas ibrahimNo ratings yet

- Ingredients and Formulation of Laundry DetergentDocument34 pagesIngredients and Formulation of Laundry DetergentMuhammad Usman Hameed80% (5)

- Initial Results On Electron Beam Generation Using Pyroelectric CrystalsDocument3 pagesInitial Results On Electron Beam Generation Using Pyroelectric CrystalsParticle Beam Physics LabNo ratings yet

- Dokumen - Tips Raphex 2001 Cloud Object Storage Store Retrieve Data s3 2012-04-30raphexDocument40 pagesDokumen - Tips Raphex 2001 Cloud Object Storage Store Retrieve Data s3 2012-04-30raphexRuan MouraNo ratings yet

- Excellent Extended Essay (Chemistry)Document38 pagesExcellent Extended Essay (Chemistry)Aqeel JariwallaNo ratings yet

- MSE Admission and Degree RequirementsDocument6 pagesMSE Admission and Degree Requirementsdeathbuddy_87No ratings yet

- Sequential Extraction ProcedureDocument1 pageSequential Extraction ProcedureGangi Reddy UbbaraNo ratings yet

- MethanizerDocument1 pageMethanizerDaniv NguyenNo ratings yet

- Principles of Boiler OperationsDocument35 pagesPrinciples of Boiler Operationseblees100No ratings yet

- BIOC 315 - Biochemistry of Food Processing Lecture NotesDocument55 pagesBIOC 315 - Biochemistry of Food Processing Lecture NotesPerry MasonNo ratings yet

- 9701 s10 QP 21Document12 pages9701 s10 QP 21Hubbak KhanNo ratings yet

- Lab Equipment Worksheet: FlameDocument6 pagesLab Equipment Worksheet: FlameSabu LazerNo ratings yet

- Design and Fabrication of Condenser For A Room Air Conditioning System (Rep1.)Document40 pagesDesign and Fabrication of Condenser For A Room Air Conditioning System (Rep1.)Satish Alan100% (1)

- Prosernat Skid Presentation PDFDocument13 pagesProsernat Skid Presentation PDFAnonymous cVnKDdhNo ratings yet

- Gas Laws 2Document6 pagesGas Laws 2Daniel AuthurNo ratings yet

- G7 Learning Activities 1ST Quarter Sy 2020-2021Document13 pagesG7 Learning Activities 1ST Quarter Sy 2020-2021Zet Gutierrez0% (1)

- Asphalt - WikipediaDocument135 pagesAsphalt - WikipediaEndhy Wisnu Novindra100% (1)

- Chemical Analysis of FoodDocument12 pagesChemical Analysis of Foodprince1900100% (1)

- Griha 12638Document25 pagesGriha 12638AmanDhimanNo ratings yet

- Protein Synthesis EssayDocument5 pagesProtein Synthesis Essaymarybrownarlington100% (2)

- Waste Management: Ala Khodier, Karl Williams, Neil DallisonDocument8 pagesWaste Management: Ala Khodier, Karl Williams, Neil DallisonGillyn CalaguiNo ratings yet

- Final Final PDFDocument117 pagesFinal Final PDFMalik Abdul GhaffarNo ratings yet

- Effect of The Use of Ceramic Filters in Steel CastingDocument6 pagesEffect of The Use of Ceramic Filters in Steel CastingJavier Escalante VillanuevaNo ratings yet

- T1 1 E Automotive 072Document15 pagesT1 1 E Automotive 072Marian OstrowskiNo ratings yet

- Price List Travo LasDocument21 pagesPrice List Travo Laspei sajaNo ratings yet

- Practical List BOP 353PDocument2 pagesPractical List BOP 353Pved.g007No ratings yet

- VW 50133 en 2021-06Document15 pagesVW 50133 en 2021-06xu zhangNo ratings yet

- Lecture BIOCHEMISTRY of CYTOSOL AlfiDocument56 pagesLecture BIOCHEMISTRY of CYTOSOL Alfisennaavia12No ratings yet

- Offset Inks - BasicsDocument5 pagesOffset Inks - BasicsforeverhaleemNo ratings yet