Professional Documents

Culture Documents

Wood Member (Beam, Column, Brace, Truss Web & Chord) Design Based On NDS 2015

Uploaded by

Janaka SenanayakaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Wood Member (Beam, Column, Brace, Truss Web & Chord) Design Based On NDS 2015

Uploaded by

Janaka SenanayakaCopyright:

Available Formats

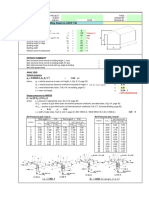

PROJECT : PAGE :

CLIENT : DESIGN BY :

JOB NO. : DATE : REVIEW BY :

Wood Member (Beam, Column, Brace, Truss Web & Chord) Design Based on NDS 2015

INPUT DATA & DESIGN SUMMARY

SPECIES & GRADE Timberstrand LSL 1.55E

LENGTH L= 15 ft

SECTION SIZE LSL 3 1/2 x 8 5/8 THE MEMBER DESIGN IS ADEQUATE.

AXIAL COMPRESSION FORCE P= 10 kips, ASD

STRONG AXIS EFFECTIVE LENGTH keLx = 15 ft, (NDS Table G1/Figure 3F)

WEAK AXIS EFFECTIVE LENGTH keLy = 7.5 ft, (NDS Table G1)

STRONG AXIS BENDING MOMENT Mx = 0.4 ft-kips, ASD

BENDING EFFECTIVE LENGTH Le = 8 ft, (NDS Table 3.3.3)

WEAK AXIS BENDING MOMENT My = 0.1 ft-kips, ASD

CRITICAL/MAXIMUM SECTION SHEAR FORCE V= 2.5 kips, ASD

`

ANALYSIS

DETERMINE DESIGN VALUES (NDS Supplement Tables or ICC ESR)

Fb Fv Fc Ex,min Ey,min b, (in) d, (in) A, (in2) Ix, (in4) Sx, (in3) Iy, (in4) Sy, (in3)

psi ==> 2,325 525 2170 788000 788000 3.5 8.6 30.2 187.1 43.4 30.8 17.6

CHECK COMPRESSION CAPACITY (NDS Table 4.3.1 & Table 5.3.1)

Fc' = Fc CD CM Ct CF Ci Cp = 902 psi

> fc = P / A = 331 psi [Satisfactory]

Where CD CM Ct CF Ci Cp CT

0.90 1.00 1.0 1.00 1.0 0.46 1.0

(Tab. 2.3.2) (4.4.3/5.5.3) (Tab. 2.3.3) (NDS 4.3.6) (NDS 4.3.8) (NDS 4.4.2 for Truss only)

CP = (1+F) / 2c - [((1+F) / 2c)2 - F / c]0.5 ,(NDS 3.7.1)

Fc* = Fc' / Cp = 1953 psi

Le / d = Max( keLx / d , keLy / b) = 26 (NDS Table G1/Figure 3F)

< 50 , (NDS 3.7.1.4) [Satisfactory]

E'min = 788000 psi, (Weak Axis Controls.)

FcE = 0.822 E'min / (Le/d)2 = 980 psi

F = FcE / Fc* = 0.502

c = 0.9

CHECK BENDING CAPACITY (NDS Table 4.3.1 & Table 5.3.1)

Fbx' = Fb CD CM Ct CL (CF Ci Cr ) (CV Cc CI ) = 2074 psi

> fbx = Mx / Sx = 111 psi [Satisfactory]

Where CD CL CF Cr CV Cc CI

0.90 0.99 1.00 1.00 1.00 1.00 1.00

(Tab. 2.3.2) (NDS 4.3.6) (NDS 4.3.9) (NDS 5.3.6) (NDS 5.3.8) (NDS 5.3.9)

CL = (1+F) / 1.9 - [((1+F) / 1.9) 2 - F / 0.95]0.5 ,(NDS 3.3.3)

Fb* = Fbx' / (CV CL) = 2093 psi

RB = ( Le d / b2)0.5 = 8 (NDS Eq. 3.3-5)

< 50 , (NDS 3.3.3.7) [Satisfactory]

E'min = 788000 psi

FbE = 1.20 E'min / RB2 = 13990 psi

F = FbE / Fb* = 7

Fby' = Fb CD CM Ct Cfu (CF Ci Cr ) (CV Cc CI ) = 2171 psi

> fby = My / Sy = 68 psi [Satisfactory]

Where Cfu

1.04

(4.3.7/5.3.7)

CHECK BENDING & COMPRESSION CAPACITY (NDS 3.9.2)

2 f

fc 1 f bx 1 by

' ' 0.25 < 1.0 [Satisfactory]

F 'by

1 f c F cEx F bx 1 f / F 2

Fc f bx / F bE

c cEy

Where E'x,min = 788000 psi

E'y,min = 788000 psi

FcEx = 0.822 E'x,min / (keLx/d)2 = 1487 psi

FcEy = 0.822 E'y,min / (keLy/b)2 = 980 psi

2

f c f <

'bx 0.36 1.0 [Satisfactory]

F 'cEy F bE

CHECK SHEAR CAPACITY (NDS Table 4.3.1 & Table 5.3.1)

Fv' = Fv CD CM Ct (Ci) (Cvr) = 473 psi

> fv = 3 V / (2 A) = 124 psi [Satisfactory]

Where CD Cvr

0.90 1.0

(Tab. 2.3.2) (NDS 5.3.10)

PROJECT : PAGE :

CLIENT : DESIGN BY :

JOB NO. : DATE: REVIEW BY :

Wood Beam Design Based on NDS 2012

INPUT DATA & DESIGN SUMMARY

MEMBER SIZE LSL 3 1/2 x 8 5/8 Timberstrand LSL 1.55E

MEMBER SPAN L = 15 ft

UNIFORMLY DISTRIBUTED DEAD LOAD wD = 112 lbs / ft

UNIFORMLY DISTRIBUTED LIVE LOAD wL = 0lbs / ft

CONCENTRATED DEAD LOADS PD1 = 1500 lbs

(0 for no concentrated load) L1 = 4 ft

PD2 = 3936 lbs

L2 = 5 f

DEFLECTION LIMIT OF LIVE LOAD DL = L / 360 #N/A

DEFLECTION LIMIT OF LONG-TERM DKcr D + L = L / 180

#N/A

Does member have continuous lateral support by top diaphragm ?

(1= yes, 0= no) 0 No

Code Duration Factor, CD Condition

1 0.90 Dead Load

2 1.00 Occupancy Live Load

3 1.15 Snow Load

4 1.25 Construction Load

5 1.60 Wind/Earthquake Load

6 2.00 Impact Load

Choice => 4 Construction Load 8 Southern Pine

ANALYSIS

DETERMINE REACTIONS, MOMENT, SHEAR

wSelf Wt = #N/A lbs / ft RLeft = #N/A kips RRight = #N/A kips

VMax = #N/A #N/A MMax = #N/A #N/A

DETERMINE SECTION PROPERTIES& ALLOWABLE STRESSES

b = #N/A in E'min = #N/A ksi E = Ex = #N/A ksi Fb* = #N/A psi

d = #N/A in FbE = #N/A psi Fb = #N/A psi F = FbE / Fb* = #N/A

A = #N/A in 2

I = #N/A in 4 Fv = #N/A psi Fb' = #N/A psi

Sx = #N/A in3 RB = #N/A #N/A E' = #N/A ksi Fv' = #N/A psi

lE = #N/A (ft, Tab 3.3.3 footnote 1)

CD CM Ct Ci CL CF CV Cc Cr

1.25 1.00 1.00 1.00 #N/A 1.00 #N/A 1.00 1.00

CHECK BENDING AND SHEAR CAPACITIES

fb = MMax / Sx = #N/A psi #N/A Fb = #N/A psi #N/A

fv' = 1.5 VMax / A = #N/A psi #N/A Fv' #N/A

CHECK DEFLECTIONS

D(L, Max) = #N/A in, at 7.500 ft from left end, #N/A DL = L / 360 #N/A

D(Kcr D + L , Max) = #N/A #N/A #N/A DKcr D + L = L / 180 #N/A

Where Kcr = 1.50 , (NDS 3.5.2)

DETERMINE CAMBER AT 1.5 (DEAD + SELF WEIGHT)

D(1.5D, Max) = #N/A #N/A

CHECK THE BEAM CAPACITY WITH AXIAL LOAD

AXIAL LOAD F = 8.1 kips

THE ALLOWABLE COMPRESSIVE STRESS IS

Fc' = Fc CD CP CF = #N/A psi

Where Fc = #N/A psi

CD = 1.60

CF = 1.00 (Lumber only)

CP = (1+F) / 2c - [((1+F) / 2c)2 - F / c]0.5 = #N/A

Fc* = Fc CD CF = #N/A psi

Le = Ke L = 1.0 L = 180 in

b = #N/A in

SF = slenderness ratio = #N/A #N/A 50 #N/A

FcE = 0.822 E'min / SF2 = #N/A psi

E'min = 830 ksi

F = FcE / Fc* = #N/A

c = 0.9

THE ACTUAL COMPRESSIVE STRESS IS

fc = F / A = #N/A psi #N/A Fc' #N/A

THE ALLOWABLE FLEXURAL STRESS IS

Fb' = #N/A psi, [ for CD = 1.6 ]

THE ACTUAL FLEXURAL STRESS IS

fb = (M + Fe) / S = #N/A psi #N/A Fb' #N/A

CHECK COMBINED STRESS [NDS 2012 Sec. 3.9.2]

(fc / Fc' )2 + fb / [Fb' (1 - fc / FcE)] = #N/A #N/A 1 #N/A

You might also like

- Beam With TorsionDocument11 pagesBeam With TorsionR ASTUSNo ratings yet

- Seismic Design For Special MomentDocument2 pagesSeismic Design For Special MomentreynoldNo ratings yet

- Shear Wall Design, Using Cross-Laminated Timber (CLT), Based On NDS 2018 Design CriteriaDocument1 pageShear Wall Design, Using Cross-Laminated Timber (CLT), Based On NDS 2018 Design Criteriaridho ziskaNo ratings yet

- Cable Structure Design Based On ASCE 19-10 & AASHTO 17th: Project: Client: Design By: Job No.: Date: Review byDocument1 pageCable Structure Design Based On ASCE 19-10 & AASHTO 17th: Project: Client: Design By: Job No.: Date: Review byjklo12No ratings yet

- Plain Concrete Footing Design Based On ACI 318-14: Input Data Design SummaryDocument4 pagesPlain Concrete Footing Design Based On ACI 318-14: Input Data Design SummaryShadin Asari ArabaniNo ratings yet

- Daniel Tian Li: Concrete Column Design Based On ACI 318-05Document3 pagesDaniel Tian Li: Concrete Column Design Based On ACI 318-05Lee Kar FungNo ratings yet

- Tables For Wood Post Design Based On NDS 2005: Post Axial Capacity For Douglas Fir-Larch # 1, (Kips)Document22 pagesTables For Wood Post Design Based On NDS 2005: Post Axial Capacity For Douglas Fir-Larch # 1, (Kips)leroytuscanoNo ratings yet

- Free Standing Masonry Wall Design Based On ACI 530-05 & ACI 318-05Document9 pagesFree Standing Masonry Wall Design Based On ACI 530-05 & ACI 318-05SadatcharaMoorthi NNo ratings yet

- Basement Column Supporting Lateral Resisting Frame Based On ACI 318-11 Input Data & Design SummaryDocument46 pagesBasement Column Supporting Lateral Resisting Frame Based On ACI 318-11 Input Data & Design SummaryHizbar ArsjadNo ratings yet

- Project: Client: Design By: Job No.: Date: Review By:: Input Data & Design SummaryDocument2 pagesProject: Client: Design By: Job No.: Date: Review By:: Input Data & Design Summaryjklo12No ratings yet

- RCC32 Ribbed Slabs (A & D) GFDGDocument26 pagesRCC32 Ribbed Slabs (A & D) GFDGLove SemsemNo ratings yet

- Design For Connection To Wall Based On AISC 360-16 & ACI 318-14Document2 pagesDesign For Connection To Wall Based On AISC 360-16 & ACI 318-14jklo12No ratings yet

- W18X46 W3-7 1/2" NW 30 10 106: The Beam Design Is AdequateDocument7 pagesW18X46 W3-7 1/2" NW 30 10 106: The Beam Design Is Adequateஅம்ரு சாந்திவேலுNo ratings yet

- Software Verification: AISC-360-10 Example 001Document9 pagesSoftware Verification: AISC-360-10 Example 001Davico HernandezNo ratings yet

- Concrete Column Design Based On ACI 318-11: Input Data & Design SummaryDocument3 pagesConcrete Column Design Based On ACI 318-11: Input Data & Design Summaryjaimeleoxxx0% (1)

- Bridge Design For Prestressed Concrete Box Section Based On AASHTO 17th Edition & ACI 318-14Document3 pagesBridge Design For Prestressed Concrete Box Section Based On AASHTO 17th Edition & ACI 318-14Mukhlish AkhatarNo ratings yet

- Basement Masonry Wall Design Based On TMS 402-16/13: Input Data & Design SummaryDocument2 pagesBasement Masonry Wall Design Based On TMS 402-16/13: Input Data & Design SummaryRidho ZiskaNo ratings yet

- Wind Analysis For Low-Rise Building, Based On ASCE 7-98Document2 pagesWind Analysis For Low-Rise Building, Based On ASCE 7-98reynoldNo ratings yet

- Footing Design of Shear Wall Based On ACI 318-14: Input DataDocument6 pagesFooting Design of Shear Wall Based On ACI 318-14: Input DataAngel CM100% (1)

- LRFD Composite Beam DesignDocument261 pagesLRFD Composite Beam DesignJuan Carlos FloresNo ratings yet

- Bridge Column Design Based On AASHTO 17th & ACI 318-14: Input Data & Design SummaryDocument5 pagesBridge Column Design Based On AASHTO 17th & ACI 318-14: Input Data & Design SummaryGianmarco Garcia DavilaNo ratings yet

- Coupling BeamDocument2 pagesCoupling Beamwilliam6703100% (1)

- Bridge Column Design Based On AASHTO 17th & ACI 318-14: Input Data & Design SummaryDocument5 pagesBridge Column Design Based On AASHTO 17th & ACI 318-14: Input Data & Design SummaryPn EkanayakaNo ratings yet

- Composite Deck DesignDocument16 pagesComposite Deck DesignAhmad FitrahNo ratings yet

- Daniel Tian Li: Input Data & Design SummaryDocument4 pagesDaniel Tian Li: Input Data & Design SummaryARSENo ratings yet

- Slab Punching Design Based On ACI 318-19: Project: Client: Design By: Job No.: Date: Review byDocument2 pagesSlab Punching Design Based On ACI 318-19: Project: Client: Design By: Job No.: Date: Review byAndy BenNo ratings yet

- Steel ColumnDocument8 pagesSteel ColumnLeeCH LeeCHNo ratings yet

- Multi-Tiered Braced Frame Design Based On AISC 341-16: Project: Client: Design By: Job No.: Date: Review byDocument2 pagesMulti-Tiered Braced Frame Design Based On AISC 341-16: Project: Client: Design By: Job No.: Date: Review byRidho ZiskaNo ratings yet

- Section Properties and General Stress AnalysisDocument7 pagesSection Properties and General Stress AnalysiscengizNo ratings yet

- Composite Floor GirderDocument3 pagesComposite Floor GirderlucianduNo ratings yet

- Shearwall Basics Using SDPWS DesignDocument132 pagesShearwall Basics Using SDPWS DesignDixon Antonio MaradiagaNo ratings yet

- Prestressed Concrete Girder Design For Bridge Structure Based On AASHTO 17th Edition & ACI 318-14Document3 pagesPrestressed Concrete Girder Design For Bridge Structure Based On AASHTO 17th Edition & ACI 318-14jklo12No ratings yet

- Wood Column DesignDocument1 pageWood Column DesignsrarancibiaNo ratings yet

- 2 - 4 Gutter and Downspout Sizing and LocationDocument5 pages2 - 4 Gutter and Downspout Sizing and LocationansepachecoNo ratings yet

- Base Plate Anchor Bolt DesignDocument8 pagesBase Plate Anchor Bolt DesignnoneofyourbusineesNo ratings yet

- BMREACT13Document3 pagesBMREACT13NEONo ratings yet

- Wind Analysis For Freestanding Wall & Sign Based On ASCE 7-05 Input DataDocument2 pagesWind Analysis For Freestanding Wall & Sign Based On ASCE 7-05 Input Datavpvipin93No ratings yet

- W14x43 To HSS6x6x1 - 2 Moment ConnDocument21 pagesW14x43 To HSS6x6x1 - 2 Moment ConnrajedmaglinteNo ratings yet

- Aci 318-14 RC-PN-001Document6 pagesAci 318-14 RC-PN-001Bunkun15No ratings yet

- MasonryShearWall CBCDocument2 pagesMasonryShearWall CBCMadhusudan ShewalkarNo ratings yet

- Isolated Footing Design (ACI-318)Document7 pagesIsolated Footing Design (ACI-318)Abu Yaseen AzizNo ratings yet

- Concrete Box Culvert Design Based On AASHTO 17th & ACI 318-14 Input Data & Design SummaryDocument2 pagesConcrete Box Culvert Design Based On AASHTO 17th & ACI 318-14 Input Data & Design Summaryjklo12No ratings yet

- ACI 318-14 RC Shear Wall Design - Short Walls PDFDocument9 pagesACI 318-14 RC Shear Wall Design - Short Walls PDFHuzil FernandezNo ratings yet

- Daniel Tian Li: Plain Concrete Footing Design Based On ACI 318-05Document2 pagesDaniel Tian Li: Plain Concrete Footing Design Based On ACI 318-05Wintun73No ratings yet

- Design of Masonry Bearing Wall With Opening Based On TMS 402-16/13 Input Data & Design SummaryDocument8 pagesDesign of Masonry Bearing Wall With Opening Based On TMS 402-16/13 Input Data & Design Summaryjklo12No ratings yet

- Truss Analysis Using Finite Element Method: Input Data & Design SummaryDocument1 pageTruss Analysis Using Finite Element Method: Input Data & Design Summaryjklo12No ratings yet

- HEC 18 Contraction ScourDocument5 pagesHEC 18 Contraction Scourjibendra mishraNo ratings yet

- MasonryBearingWall IBCDocument8 pagesMasonryBearingWall IBCAbdul WahabNo ratings yet

- Column, Biaxial Analysis FinalDocument68 pagesColumn, Biaxial Analysis FinalLC LeeNo ratings yet

- Composite Beam Design With Verco Floor Deck Based On AISC Manual 9thDocument6 pagesComposite Beam Design With Verco Floor Deck Based On AISC Manual 9thnugroho87No ratings yet

- Design of Masonry Bearing Wall With Opening Based On TMS 402-11Document1 pageDesign of Masonry Bearing Wall With Opening Based On TMS 402-11Farid TataNo ratings yet

- Aashto I-Beams Section PropertiesDocument45 pagesAashto I-Beams Section PropertiesAnonymous pD2ymRUguNo ratings yet

- Bolted Joint 070506Document146 pagesBolted Joint 070506vijay10484No ratings yet

- Wood Pole or Pile Design Based On NDS 2018: Input Data & Design SummaryDocument1 pageWood Pole or Pile Design Based On NDS 2018: Input Data & Design SummaryafvilavilanoriegaNo ratings yet

- The Design Is Adequate.: Ksi, (345 Mpa) Kips, (120.1 KN) FT, (10.06 M) FT, (2.74 M)Document3 pagesThe Design Is Adequate.: Ksi, (345 Mpa) Kips, (120.1 KN) FT, (10.06 M) FT, (2.74 M)Ridho ZiskaNo ratings yet

- Bolted Moment ConnectionDocument9 pagesBolted Moment ConnectionAmey Gudigar100% (1)

- MomentConnection 1aDocument1 pageMomentConnection 1aKrishnaNo ratings yet

- The Design Is Adequate.: W F F X X X y XDocument3 pagesThe Design Is Adequate.: W F F X X X y Xxuankhoi doanvanNo ratings yet

- SMRF IbcDocument3 pagesSMRF Ibcrahul pathakNo ratings yet

- The Design Is Adequate.: W F F X X X y XDocument3 pagesThe Design Is Adequate.: W F F X X X y Xxuankhoi doanvanNo ratings yet

- Evidence Portfolio Sanjaya1 - MergedDocument46 pagesEvidence Portfolio Sanjaya1 - MergedJanaka SenanayakaNo ratings yet

- Simple and Minimal Printable Daily PlannerDocument1 pageSimple and Minimal Printable Daily PlannerJanaka SenanayakaNo ratings yet

- Guidelines and Rules For Detailing Ofreinforcement in Concrete StructuresDocument403 pagesGuidelines and Rules For Detailing Ofreinforcement in Concrete Structuresamino222No ratings yet

- Purlin DesignDocument16 pagesPurlin DesignxuckozzNo ratings yet

- Pending Approval List 20.11.2017Document1 pagePending Approval List 20.11.2017Janaka SenanayakaNo ratings yet

- WaDocument17 pagesWaJanaka SenanayakaNo ratings yet

- M1 January 2006 Mark SchemeDocument5 pagesM1 January 2006 Mark Schemesahiltourani5992No ratings yet

- Post-Buckling Behaviour of A Steel Column: 4.0 Methods Adopted and ResultsDocument1 pagePost-Buckling Behaviour of A Steel Column: 4.0 Methods Adopted and ResultsBeny AbdouNo ratings yet

- Mode ShapeDocument2 pagesMode ShapezcvzxNo ratings yet

- Read WorksDocument5 pagesRead WorksClarissa HowardNo ratings yet

- Heat and Mass Chapter 3Document56 pagesHeat and Mass Chapter 3Mvelo PhungulaNo ratings yet

- Force and Motion-1Document30 pagesForce and Motion-1drfefvdsfNo ratings yet

- Grid BeamDocument3 pagesGrid Beamfarzi accoNo ratings yet

- JIS F 2023 Chain Stopper For Dia.34-36mm Anchor ChainDocument7 pagesJIS F 2023 Chain Stopper For Dia.34-36mm Anchor ChainusnadiNo ratings yet

- Piles in Sand: A Method Including Residual Stresses: by Jean-Louis Briaud, M. ASCE and Larry Tucker, A. M. AsceDocument15 pagesPiles in Sand: A Method Including Residual Stresses: by Jean-Louis Briaud, M. ASCE and Larry Tucker, A. M. Asce'Vanessa VogtNo ratings yet

- Astm E587-15 R-20Document10 pagesAstm E587-15 R-20hashem Al-NasserNo ratings yet

- Problem Set 4 PSADDocument1 pageProblem Set 4 PSADJerona AyongNo ratings yet

- Design LocomotionDocument36 pagesDesign LocomotionsherlockmsNo ratings yet

- 1 (A) State Why The Velocity and The Acceleration Are Both Described As Vector QuantitiesDocument10 pages1 (A) State Why The Velocity and The Acceleration Are Both Described As Vector QuantitiesJerryNo ratings yet

- CFD Analysis of Missile Shroud Separation PDFDocument108 pagesCFD Analysis of Missile Shroud Separation PDFPhạm Công ÁnhNo ratings yet

- Introduction To FractureDocument10 pagesIntroduction To FractureajmalNo ratings yet

- 07 GravitationDocument32 pages07 GravitationHaltz t00nNo ratings yet

- 103 F 05 Exam 1Document7 pages103 F 05 Exam 1Raufzha AnandaNo ratings yet

- This Study Resource Was: Submitted By: Engr. Ritchie ArdaniDocument3 pagesThis Study Resource Was: Submitted By: Engr. Ritchie ArdaniClint Baring ArranchadoNo ratings yet

- Euler Angles - WikipediaDocument22 pagesEuler Angles - WikipediaHaroon Mohamed MorshedNo ratings yet

- Flow Meter Orifice CalculationDocument27 pagesFlow Meter Orifice CalculationLaksono BudiNo ratings yet

- Pressure DistributionDocument3 pagesPressure DistributionMahadevanNo ratings yet

- Newton PairsDocument8 pagesNewton PairssasikumaranNo ratings yet

- M.Tech MECH HPEDocument48 pagesM.Tech MECH HPEy97146543No ratings yet

- (An Autonomous Institution) Coimbatore-35 Department of Mechanical EngineeringDocument8 pages(An Autonomous Institution) Coimbatore-35 Department of Mechanical EngineeringPost BoxNo ratings yet

- Work Power Energy QuizDocument2 pagesWork Power Energy QuizMarilyn GarciaNo ratings yet

- Chap 2Document48 pagesChap 2Mike BelayNo ratings yet

- 2019 USPAS Lecture 6Document37 pages2019 USPAS Lecture 6MohsenNo ratings yet

- Design Analysis and Optimization of A Baja Sae FrameDocument11 pagesDesign Analysis and Optimization of A Baja Sae Frameyogesh100% (1)

- NEET REPT 2022-23 Centre of Mass A-1 Dt.07.01.2023 - 1139857 - 2023 - 03 - 21 - 00 - 22Document4 pagesNEET REPT 2022-23 Centre of Mass A-1 Dt.07.01.2023 - 1139857 - 2023 - 03 - 21 - 00 - 22AniketNo ratings yet