Professional Documents

Culture Documents

AFC200-Petroseal 3% FFFP PDF

Uploaded by

kuraimund0 ratings0% found this document useful (0 votes)

68 views2 pagesOriginal Title

AFC200-Petroseal 3% FFFP.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

68 views2 pagesAFC200-Petroseal 3% FFFP PDF

Uploaded by

kuraimundCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 2

DATA SHEET

#AFC200

Description

Petroseal 3% is a superior quality Film-Forming

FluoroProtein (FFFP) fire fighting foam concentrate for

‘extinguishing and securing flammable hydrocarbon liquid

fires.

Its unique formulation is based on advanced protein foam

technology. The protein base material provides a tough

cohesive foam blanket with high resistance to heat that

provides the same postfire security as a top quality

FluoroProtein (FP). Fluorochemical surface active agents,

‘combined with the protein base produce a vapor-sealing

‘aqueous film that provides the same fast control and extin-

guishment as a top quality synthetic AFFF.

+ Film-forming for fast flame knockdown and extin-

guishment.

+ Stable and long-lasting foam blanket for excellent

bumback resistance and post-fire security

+ Detergent-sree for high resistance to fuel pick-up.

+ Foam blanket re-seals when ruptured by personnel or

equipment.

+ Reduced stocks, low cost storage, long shett-lfe, and

low usage levels combine to provide maximum cost-

effectiveness.

Environment

Petroseal 3% is readily biodegradable and virtually non-

toxic to aquatic organisms. Itis based on a natural protein

foaming agent and contains no harmful synthetic deter-

gent or glycol ether.

Petroseal 3% can be successfully treated in biological

waste water treatment systems.

Applications

Potroseal 3% is the ideal fire fighting foam to use in high

risk situations where hydrocarbon (such as aviation

kerosene, crude oil, gasoline, and diesel fuel) are stored.

processed, or transported. Itis used extensively on Rapid

Intervention Vehicles at major intemational airports and

miltary bases where fast extinguishment and postfire

security with limited quantities of foam concentrate are

‘essential. Other typical applications include hydrocarbon

storage tanks, process areas, roadirail loading racks,

‘marine terminals, and offshore platforms.

ANGUS

FIRE

PETROSEAL 3%

FFFP

Petroseal 3% also provides a vapor-suppressing foam

blanket on unignited hydrocarbon spills. Its detergent-ree

formulation ensures that it does not exhibit the wicking

action associated with some synthetic AFFFs when

applied using non-aspirating foam equipment.

Performance

Petroseal 3% is produced to rigorous quality control stan-

dards which ensure consistent fire performance and

excellent product reliability.

The fire performance of Petroseal 3% is measured pri-

marily against Underwriters Laboratories Standard UL 162

(7th Edition). thas also demonstrated outstanding perfor-

mance in fire tests carried out by independent fire author-

ities worldwige.

Approvals and Listings

+ ULListed

Equipment

Petroseal 3% Is intended for use at 3% (3 parts concen-

trate to 97 parts of water).

Itis readily proportioned using conventional foam propor-

tioning equipment such as portable and fixed (in-line)

foam venturi proportioners, handiine nozzles/oranchpipes

with pick-up tubes, balanced pressure variable flow pro-

Portioners, balanced pressure bladder tank proportioners,

and around-the-pump proportioners.

Petroseal 3% can be used with air aspirating discharge

devices such as low expansion branchpipes, monitors, top

pourer sets, rimseal foam pourers, and foamiwater sprin«

krers

‘As with any foam Petroseal 3% is best applied gently on

to the burning liquid surface. However, the exceptional

resistance to fuel contamination of FFFP enables it to

withstand vigorous mixing with fuel (this is recognized by

NFPA 11(1994), Section 1.4, page 6). This makes it ideal

for forceful application on’ to storage tank fires from

ground-based mobile monitors or through base (sub-sur-

face) injection systems.

@ Kidde Fire Fighting

Potroseal 3% also produces top quality medium expan-

sion foam when applied through medium expansion

branchpipes and bund pourers.

Potroseal 3% can be used with non-aspirating discharge

devices such as sprayifog branchpipes and nozzles, mon-

itors, and spraylfog sprinklers. Non-aspirated application

is not recommended as the primary method of attack for

‘major fires where the security of a stable foam cover is

essential,

Typical Physical Properties

ADPEBIANCE -rasnnsmnsenee

Specific Gravity @ 68°F (20°C)

pH @ 68°F (20°C)

Viscosity @ 68°F (20°C)

Maximum Usable Temperature

Minimum Usable Temperature.

Freeze Point

Effect of Freeze/Thaw

Storage

Compatibility

Petraseal 3% Is suitable for use in combination with:

+ Soft or hard, fresh, brackish or sea water,

+ Dry powder extinguishing agents either separately or

as twin agent systems

+ Expanded protein-based or synthetic foams for appli-

cation to a fire in sequence or simultaneously.

Dark Brown Liquid

4.160

72

27.0 csks (27.0 mmiisec)

120°F (49°C)

20°F (7°C)

+°F (ATC)

No Performance Loss

Petroseal 3% foam concentrate is exceptionally stable in long-term storage. A shelf-life of at least ten years can be

‘expected if itis stored properly.

Ordering Information

CONTAINER SHIPPING WEIGHT PART NUMBER

'5-Gallon Pails

(19 liters) 51 Ib, (23.1 kg) 3133-4340-6

58-Gallon Drums.

(208 liters) 857 Ib (252.7 kg) 3193-4481-6

275-Gallon IBC Reusable Tote Tank

(1041 liters) 2816 Ib. (1277.3 ka) 3193-4725-6

Bulk 9.7 Ib./gal (1.16 kai!) 3133-4001-6

Palletizing of palls and drums is available upon request.

‘Shipping Cube

5-Gallon Pall

'56-Gallon Drum

275.Gallon IBC Tote Tank

1,13 cu. ft, (0.032 cu. m.)

11.51 cu. ft. (0.326 cu. m.)

51.11 cu.ft (1.061 cu. m)

‘This informations only a general qudelne. The company reserves the right to change any porton ofthis information without notce. Terms and cond

‘lone of sale apply and are avatable on request.

"ODT Rev. 8. Painted in USAAFCZ00.0X0

ANGUS FIRE

180 Sheree Boulevard, Suite 3900

P.O. Box 695 + Exton, PA 19341 USA

Tel: (610) 363-1400 « Fax:(610) 524-9073,

www kidde-fire.com

130 Esna Park Drive

Markham, Ont, Canada L3R 163

Tel: 905-470°0430 + Fax: 905-470-0740

www.kiddecanada.com

You might also like

- VSR Series: Vane-Type Waterflow SwitchDocument1 pageVSR Series: Vane-Type Waterflow SwitchkuraimundNo ratings yet

- RAKTherm Reinforced Piping SystemsDocument13 pagesRAKTherm Reinforced Piping SystemskuraimundNo ratings yet

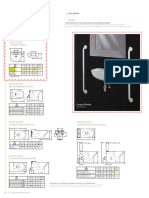

- RAK Compact Disable Wash BasinDocument1 pageRAK Compact Disable Wash BasinkuraimundNo ratings yet

- Fire Safety and Evacuation Plan TemplateDocument19 pagesFire Safety and Evacuation Plan Templatekuraimund100% (1)

- Crane FS Balancing Valve IOMDocument2 pagesCrane FS Balancing Valve IOMkuraimundNo ratings yet

- Standard Sewer DetailsDocument59 pagesStandard Sewer DetailsPhanhai KakaNo ratings yet

- Inst Symbols P ID FunctionDocument37 pagesInst Symbols P ID FunctionkuraimundNo ratings yet

- Review of The WaterMark Certification SchemeDocument107 pagesReview of The WaterMark Certification SchemekuraimundNo ratings yet

- GROHE Specification Sheet 38745001Document1 pageGROHE Specification Sheet 38745001kuraimundNo ratings yet

- Avk Support Bush Series 05/08: Mounting Instruction / Montagevejledning Einbauanleitung / Instruction de MontageDocument2 pagesAvk Support Bush Series 05/08: Mounting Instruction / Montagevejledning Einbauanleitung / Instruction de MontagekuraimundNo ratings yet

- RMC Thermal Balancing ValvesDocument2 pagesRMC Thermal Balancing ValveskuraimundNo ratings yet

- Red Jacket Family BrochureDocument8 pagesRed Jacket Family BrochurekuraimundNo ratings yet

- GH Motor - Roller Shutter DoorDocument2 pagesGH Motor - Roller Shutter DoorkuraimundNo ratings yet

- Omron LY2 Data SheetDocument16 pagesOmron LY2 Data SheetkuraimundNo ratings yet

- F4001ED Safe-Air Tester ManualDocument28 pagesF4001ED Safe-Air Tester ManualkuraimundNo ratings yet

- Argus Introduction FlowserveDocument12 pagesArgus Introduction FlowservekuraimundNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)