Professional Documents

Culture Documents

Wind Energy Tutorial

Uploaded by

Maso0 ratings0% found this document useful (0 votes)

5 views42 pagesWind Energy Tutorial

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentWind Energy Tutorial

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

5 views42 pagesWind Energy Tutorial

Uploaded by

MasoWind Energy Tutorial

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 42

WIND TURBINE POWER

MEASUREMENTS

AND MECHANICAL

CONSTRUCTION

I

OBJECTIVES

After reading and studying this chapter, you will:

« Understand the key factors that affect and control wind power

Be able to apply these factors to calculate available power to a

wind turbine

Be able to estimate annual available power as a function of rotor

swept area and wind speed

Be able to estimate the increases in wind speed as a function of

tower height

© Understand the limitations of wind power available to the turbine

rotor as related to Betz’s Law

a7

* Understand the factors that affect system efficiency

* Be able to estimate annual energy output using the swept

area method

* Be able to estimate annual energy output applying a

power curve

* Understand the mechanical nomenclature of horizontal

axis and vertical axis wind turbines

* Be able to discuss speed control and braking

Early windmill

Modern wind turbine

BERGE

This chapter discus explains the main factors affecting wind energy and

hhow these factors are used to calculate available wind power. Wind speed and the

area inscribed by the rotor blades in motion are key variables used to estimate an~

nual energy available to a turbine.

Examples will illustrate the use of graphs and power curves for calculating wind

speed, power, and energy output. Just as wind speed isa key factor in producing

Power, itcan also havea damaging effect on the mechanics ofa turbine. This chap

ter will discuss methods used to protect against excessive wind speed,

Wind is a source of renewable energy, as is power from the sun, hydropower,

geothermal, and fuel cells. For these sources to achieve a high level of usefulness,

478 Chapter 11. WIND TURBINE POWER MEASUREMENTS AND MECHANICAL CONSTRUCTION

they must be used efficiently and cost-effectively in renewable enerBy Syren. Well

tieeigned, assembled, and maintained wind systems have met these ‘challenges, but

there is always more work to be accomplished.

‘This chapter explains and illustrates some of the key factors involved when

applying wind power to generate electrical power.

Horizontal axis wind turbine

BASIC WIND TURBINE DESIGN

[Notall ofthe energy from wind flowing past a point can be recovered. According ‘0

seta ons aa ideal wind machine can extract no more than 59.3% of the available

wvind power ata points therefore, if a wind turbine is 100% efficient it can extract

only 59.3% of the available wind power.

vo common designs are horizontal axis and vertical axis wind turbines,

Fone eerie wind turbine (HAWT) has the generator mounted a the top of

ie tl axis wind turbine (VAWT) has the generator mounted near”

the bottom of the tower close to the ground.

croatarind turbines are mounted on towers and catch the wind’s energy with

blades attached to a bub and shaft. As the blades catch the wind, they rotate the

haf spinning a rotor in a generator o alternator that produces electrical pove

sane pee a wind turbine converts wind energy to mechanical energy, which is

seer ted to electrical energy. Ifa turbine is placed on a taller tower, wind

‘elocity improves and power output increases. Wind turbines come it different

vizen ranging from output power of less than 1 kilowatt to many megawatts, Com:

panies and laboratories have categorized turbines by three general electrical pine

Patput ratings: small turbines from 1KW to 1OOKW, midsize turbines from 100KW

fo IMW, and utility size turbines greater than IMW. Another general range some,

Moa teed is residential from 400W to SOKW, industrial from 30KW to 250kW, and

vulty greater than 950KW, Note the overlap of ranges and gaps in ranges so KeeP

in mind that these are only guidelines.

Chapter 11. WIND TURBINE POWER MEASUREMENTS AND MECHANICAL CONSTRUCTION 479

Rotor blades range in total length from less than 10 feet to more than 200 feet,

Ifthe length of the blade from the tip to the hub is 20 feet, then the diameter is

2X 20 feet, or 40 feet.

‘The next sections explain the effects that factors such as wind. ‘speed, power den-

_ sity, and energy density have on power output of a wind turbine.

SPEED OF THE WIND

and when in motion, the potential energy i ey

fem is mass (weight) and vis velocity (wind speed). The higher the wind speed,

the higher the wind energy. As explained in Chapter 2, power (P) is energy (1) per

unit of time (Q, or

P = energy/time = E/t = Ymv'/t

A more useful equation for finding available wind power makes a substitution for

‘mass, and the equation becomes ere P (tho) isair density,

A is the inscribed area of the rotating blades, and V* is wind velocity cubed. Ay

density (p) is easly found on air density charts, area (A) is measured of calculated,

and velocity (V) is measured or obtained from wind charts and tables, Obserce

{hat wind power is proportional tothe cube of wind speed. If wind speed doubles

ad density and area remain constant, wind power increases by a factor of eight,

For example, if the speed increases from 0 2

2=8 ion P

Pesatneat $2 level and a temperature at 59°F (15°C), the density of air (p) is

0.07651Ib/f* or 1.225kg/m’. This is referred to as “standard conditions” At cea

dard conditions and where the swept area of the rotor blades is constant, turbine

Power (P) is controlled by wind speed cubed (V). It should be obvious that wind

speed has a significant effect on turbine power.

A Strong constant wind, within the design limits of the turbine, generates

significant power, but keep in mind that air isa fluid, although much less dense

than water. The force of water is understood by all of us. During a tsunami and

4 flood, water knocks over buildings and washes away complete towns. As with

foods, local weather conditions play a central role in affecting wind speed, When

the wind exceeds a certain turbine design maximum, then the turbine ie shat

down before the electric generator or the tower structure is damaged by the force

of the wind.

Physical properties ofthe land have a significant effect on the speed and turbu-

lence of the wind. If you have the choice of placing the turbine at the foot of « bill

‘or atthe ridge ofthe hill, select the ridge or just below the ridgeline away from the

direction of the prevailing wind. Wind speed is usually

a {greater at this location rather than at the base ofthe hill.

f wind passing over a hi

FIGURE 44-4. Contour o

Win direction

issue can usually be resolved having a sufficiently high

© Cengage Lesring 2013,

480 Chapter 11. WIND TURBINE POWER MEASUREMENTS AND MECHANICAL CONSTRUCTION

FIGURE 44-2 Wind

Wind Turbine turbine above area of

Turbulence:

tower Increasing tower height wil move the rotor blades above the turbulence caused

bya building ot hill obstruction (Figure 11-2)

“Turbulence is 2 pid change indirection and speed caused by obstacles inthe»

in “These can be buildings, trees, or rough ground surface and must be

Ed when selecting a site fora wind turbine

WIND POWER DENSITY

“When evaluating the available power at a location bel

bine, measurements are made relative to

of these measurements is called wind power den:

ry

vind speed, and area, A, isa specific surface area thatthe wine is blowing through

vr striking. Power, P.is measured in watts and PIA is (W/m)

EXAMPLE 14-1. anon eee 8 a

Wind is blowing at a constant speed of 10mis (meters per second)

‘hrough a oytinder, as illustrated in Figure 11-3. The density

1 agli (tandar contions) Find wind power density (WPD).

WPD is the ratio of power to area, or WPD = PIA = YapV*

a“

PIA = Ye x 1.225kg/m® x (1OmIs)> = % X 1. 225 x 1000

= SrzeWine | wes

Observe that the-area-of the. front. surface of the eylinder isn't

per square area. (Note: The front surface of the cylinder is a circa, FIGURE 14-4 Example 1-2

‘and the area of a circle is A = nr’, which is also the area inscribed by dev! Sepicnanae

the rotating blades of a wind turbine.) [ i

| Dia=7.0t

EXAMPLE 14-2 |

Wind fe stiking the rotor blades of the wind turbine in Figure 11-4 |

Hin ent opeed of 1Omis. Density 9,8 1225kgim’. Find WPD. |

PIA = Yap = ve x 1.225 x 1000 = 612.5Wim?

Radius = ia.

Beast

Chapter 11 WIND TURBINE POWER MEASUREMENTS AND MECHANICAL CONSTRUCTION 484

epsnr cami ht i hwnd i aying ogre

WEDS of both examples are equal, even though the diameter swept

hve area is larger than the cylinder (b

"\Targer area) Power density (P/A) isan interesting relation, since its based on a

Note: Values of air density (p) at sea level and 15°C (59°F): 1 225kg/m? and 0.076Ib/A®,

Power density (P/A) at sea level and 15°C (59°F): In the formula P/A = Y4pV" the

2, GH term "Ap can be substituted as follows:

Co s PIA = 0.6125 V? where V is m/s, A is m?, and P is watts

\; “PIA = 0.0550 V? where V is mph, A is m?, and P is watts

s © > [5 , PIA= 0.0051 V? where V is mph, A is f2, and Pis watts

roure sss ———SSS«C-EFFECTS OF AREA

air _ | ON POWER

Wind power density is PIA = ¥pV* and can be con.

verted to power: P = YpaV

When dealing

with a wind turbine, that area is the swept area of the

turbine blades, or the area inscribed by the rotation of

the blades. Figure 11-5, the inscribed area

19 Leaning

dius, r, is half the diameter of

EXAMPLE 11-3

If the blade diameter from tip to tip in Figure 11-5 is 7 meters (23 feet), find the

swept area.

A=n0 andr =% x diemeter = % x 7 = 3.5m

A= 3.14 x 3.5% = 38,46m?

EXAMPLE 11-4

Find the available wind power (P) in Example 11-3 when air density is at sea level

and 18°C and wind speed is 6.68mis (ismph).

‘A= 38.46m? (from Example 11-3)

Power density is PIA = YipV?, Therefore, powers P= VspVEA,

P= 4 1.25 x 86 x 98.46 = 14% 1.225 x 290 348 = ARE?

EXAMPLE 44-5

Find the available wind power if the swept area of Example 11-4 is doubled and

other conditions remain the same.

182 Chapter 11 WIND TURBINE POWER MEASUREMENTS AND MECHANICAL CONSTRUCTION

‘The new area is A=

x 38.46

yo x 1.226 x 6,68" X 76.92 = Ye X 1.225 X 299 X 76.92

mes —

What is the blade diameter in Example 11-57

BETz’S LAW

risk rec BA io gn

all of the available wind ferman scientist, Albert Betz, developed a rela-

tion that indicates dae seetmen Limit of converting wind energy t0 power i50.599 niga

or 39.3%. IFa turbine was designed to be 100% efficient, Moses theme ST

smum power output would be 59.3% of the available power. This can be written as oe

an equation: P = 4p X A X V" X 0.593. “Therefore, in Example 11-5, P = 14,086 X FA

0,593 = 8353 watts. 2

Ses do not yield 59.3% eficiency. A well-designed resdentit

emul wind turbine with ficient mechanics and clectrca! sytem ‘will seldom yield

me wyaluate a system conservative:

Iyuse an ef Jeh inchides the mechanics and the generator.

DETERMINING WIND POWER

DENSITY USING WIND SPEED

TABLES AND DISTRIBUTIONS

|Wind speed varies from day to day and from month to mon’

year woud require cleatons

Mae pany measurements during the year. IF48 measurements 1°

he per day, then the numberof measurements per Yea s 500 (48 X 365). This

srould require a computer program to calculate WED for each data point and then

| fof data points. As a formula this would be

FIGURE 14-6 Plovofwind’spgedm

Sistaburone= Raz ler Ae

12, and the average PIA is

‘average

pa= Dey Hove + vapv2 + Oe ay

a

factor

plotted as graphs

1 graph is illustrated in Fig-

distributions have been put into tabl

for sites throughout ¢

les and also

hhe world. A typical

Cangnae vearing

Chapter 11 WIND TURBINE POWER MEASUREMENTS AND MECHANICAL CONSTRUCTION 183

‘These graphs (curves) have a parameter called the

‘The EPF varies for curves with different shapes. I the

and the wind speed distributio h

as illustrated in Figure 1

ip (e

the actual

ow does aver. -d ie power density .

Sazression becomes P/A = % X p x V? EPE. Ifa site has a published Rayleigh

distribution, then annual average wind speed is available from the graph. Many

ugas of North America and parts of Europe can be represented by Rayleigh dis-

tribution. Mat

0 cr fe ese data (annual average

speed and p) are then “plugge 1 PIA expression using an EPF of 1.9,

EXAMPLE 11-6

Gasume the Rayleigh distribution in Figure 11-6 applies to a site, and the air

‘ensity is 1225kg/m”. The average wind speed is 5.6m/s and EPF is 1.9, Fing Pan

PIA = Ye X px V9X EPF = Ya x 1.225 x 5.5? 1.9 = 193.6Wim?

When using an EPF of 1.9 be sure the site is represented bya Rayleigh distribution.

Sites that are represented by other distributions can have the EPF greater than or

less than 1.9.

wind

explore

Average wind speed varies by site location. The Rayleigh distribution ean shitt

881he location changes, but the factor 1.9 is still used for determining the WD if

the shifted distribution is stil represented by a Rayleigh distribution, A site hae

© average wind speed of §.5m/s, pis standard density, and the distribution isn’t

Rayleigh. Find WPD (P/A). At site that has an EPF of 2.4

EXAMPLE 11-7

In Example 11-6, PIA is "92.6Wim*. Apply Betz’ Lew to find the maximum

available power density

prepa Department

est Laboratory. Maps and tables are listed for wind

speed a: er density, inthe chert is Bard on a Rayleigh

i sonnei ae ne

apie height fom a speed at another height, Maps and tables list ranges of lessee

of Bower density for small, medium, and large wind turbines as‘ function ot

Wind speed, The measurements are listed at heights of 10m, 30m, and 50m Deters

Selecting a specific site for a wind turbine(s), always make measurements to verify

484 Chapter 11. WIND TURBINE POWER MEASUREMENTS AND MECHANICAL CONSTRUCTION

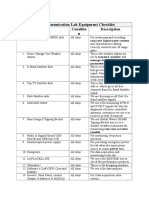

FIGURE 41-7 Classes of wind power density

CLASSES OF WIND POWER

‘Small Wind Turbine

‘Wind Speed and Power Wind Speed and Power

‘at 10m (33 f) ‘at 20mm (100 ft)

clase Power ‘Speed Power Speed

Density laws) (ph) |, Density (ers) (mph)

(wim) (wim) "

v bo eo 8 2 8 a1 92

| —|— 10 ——— 44 99 |— 160——— 51 114

2

|— —|— 160 ——— 51 1s |— 40 ——— 59 115

3

|. —|— 209 ——— 55 123 |— 30——— 65 146

4

| —|— 250 ———— 60 134 | — 400 ———_ 70157

e 2

| —|— 300 ——— 63 143 |— 480———— 74 166 &

6 2

| —|— 400 ——— 70 157 |— 640 ———— 82 184

7

| —|—1000 ——— 95 213 |—1600——— 11.1 248

8 a

| —|— 1200 ——— 10.1 22.6 | — 1920 ———_ 118 264 | | 2

ite-specific variables. These maps and tables are available at

stuptatd or mae indi ml a 117illustrates the

typeof table available from the “Wind Energy Resource Atlas ofthe United States”

Pawer is equal to Power Density times Area or P = P/A X Swept Area.

a y pt

wi ast this question may ae: “What th wi HEHE >

cree in wind sped a fonction of tower

height canbe cal tion

Vy = Hy/Ho)!” X Vo

cw wind speed, Vo = old wind speed, Hy = new height, Ho = old A as

sht, and 1/7 (0.1 mnent. The exponé cored abo zarfe

where Vix

hei

EXAMPLE 11-8

‘A.wind turbine is installed on a 10m (33ft) tower. The turbine is reinstalled on @

‘25m (82ft) tower, Average wind speed at 10m is 4.4mis, What is the estimated

wind speed at the new height? (Use the 1/7 Power Law.)

Vo = 4.4mis, Ho = 10m, and Hy = 25m,

Vy = (Hy/HolP%2* x Vo

Vac = (25/10)"2" x 4.4 = 1.14 x 4.4 = 5.01mis (14% increase)

Power Law).

Chapter 11 WIND TURBINE POWER MEASUREMENTS AND MECHANICAL CONSTRUCTION 485

es begin to produce output

(7.5-Smph), ee

Power (kw)

6 8 1012141618202224267830323436

Wind Speed [mph

2 4 6 8 10 12 14 16 18 20 22 24 26 28

Wind Speed (mph)

€

&

@ Cy

As previously discussed, wind speed varies; therefore, power output varies

throughout the ye

turers usually publis

and

power curve can be used for srpose

‘most medium to large turbines, points on the curve are monitored through a table,

which i stored in a computer and used to adjust rection to improve

wer curve canbe used to find the energy autpt (kWh) by miping ower,

year ifthe number of hours at a certain win

speed is known. For example, from the curve in Figure 11-8a, if t is 12mph

for 240 hours in a month, then for that period the energy output X 240hr =

1320KWh; he gee! averages 10mph for 240 hours, then for that period the

energy output 240hr = 720kWh; and ifthe wind speed averages l4mph for

240 hours, then for that period the energy output 240hr = 1776kWh, The

average output for the month is 1320 + 720 + 1776 = 3816kWh. For improved accu

racy, the period (720 hours/month) is broken into additional samples of wind speed and

time period results are entered into a spreadsheet.

‘These curves,

should indicate When in doubt with re-

gard to power curve specifications, contact the manufacturer. When comparing

turbines using the power curve, it is important to consider the different variables

‘that can affect power output and ensure that machines are being evaluated against

186 Chapter 17 WIND TURBINE POWER MEASUREMENTS AND MECHANICAL CONSTRUCTION

the same, the environmental

the same conditions: for example, th

‘may be rated at a high watt output, but

"A word of caution: A generator

if hen the generator power

means nothing a 1g when evaluating a system!

explore

rong x¥8000 hes the power curve ilustrated In Figure T-8 Ifthe Aversa

wind speed increases from véeph to ZOMph, what =the approximate Perea

cane Series ee Ho ree Ps tm indus = SS

and ind the total enorgy for 720 hours @ wind speed tomph/240nr, yamph/240hr,

vamphi24onr

ANNUAL ENERGY OUTPUT

Key factors that control turbine power have been examined. They are wind speed

ee. sri pone ens Power density, P/A = 4p XV,

yearend power (watt) when the equation is multiplied by As hen 4p x

‘yi A, and P is measured in wat

[As previously explained, In

Chapter 2, energy is defined as watts times is 3600W and if that

et BY 4g hours, then the energy delivered (or consumed) is 3600 x

360,000Wh, or 360kWh.

"To find the energy delivered

8760 hours (24 X 365 = 8760)

power

104

ply the watts by

pl

se 5760h1/1000 = 31,536KWh/year, or 31.536MWh/ year.

yen AEO = 3600W

EFFICIENCY

(49.6%). The output

to get total efficiency of a system. ficiency is discussed in detail in Chapter 10)

EXAMPLE 11-9

Fora system, PIA = 400Wim’, blade radius is 1.5m, and system efficiency is 38%.

Find AEO,

Calculate swept area:

ani? = 3.14 x 15? = 7.08m

Calculate power:

P= PIA x A= 400Wim? x 7.06m? = 2824W

Chapter 11. WIND TURBINE POWER MEASUREMENTS AND MECHANICAL CONSTRUCTION 487

Calculate AEO:

AEO = (P x helyr)/1000

AEO = (2824 x 87601/1000 = 24,738kWh/yr

At 38% efficiency, AEO is

‘AEO = 24,738kWh x 0.38 =9,400kWh/yr = 9.400MWhiyr

I" the machine output doesn’t meet your yearly requirements, there are some

options: ‘

if the

oF use a hybrid system (wind and solar

Use more grid power;

CAPACITY FACTOR

A measurement hich,

equals actual power output divided by rated power output

Capacity factor = actual output/rated output

AA turbine requires a certain minimum wind velocity before it generates electric-

Ub. Ifless than minimum, the power output is zero. Also, at times during turbine

operation, power will be generated at the maximum output, and at other times, ft

will be below the maximum, but above zero, Capacity factor is onie measure of the

tivity of a wind pe ime. The specification will indicate

She minimum and maximum wind speeds to achieve power input and when power

output is zero; these are usually at cut-in and cut-out

EXAMPLE 11-10

A turbine has a rated (nameplate) energy specification of 10,000kWhiyr, and the

actual energy output is B000kWhiyr. What is the capacity factor?

Capacity factor

sctual output/rated output ~ 8,000kWh/10,000kWh

= 0.8 (80%)

Factors that can affect AEO are

+ Downtime due to maintenance

+ Wind below cutin

+ Wind at cut-out

+ Turbine power not needed; therefore, power is off

onsen INTRODUCTION TO WIND

TURBINE MECHANICAL

CONSTRUCTION

A ‘ind turbine is a machine that converts mechanical energy to

electrical energy. The Figure 11-9 and

ein. shaft, And this is called a

488 Chapter 11 WIND TURBINE POWER MEASUREMENTS AND MECHANICAL CONSTRUCTION

FIGURE 41-9 Horizontal axis wind turbine and

description

blades are connected to the hub, which is connected to

a shaft, and the shaft rotates with the hub. The shaft is

H directly connected to the generator or connected to the

f generator through a gearbox. Housing the gearbox and

generator is the nacelle, which can be accessed from

the support tower. Some large turbines eng |

and windaensorst postion the turbine, and these mé Nacelle

tors the nacelle. For smaller turbines, the i

nacelle and tail are connected by a pipe or tail boom, | ne

Shaft Gearbox

| forming mechanical structural support and wiring ac-

cess, Most sinall and some medium-sized turbines use

a tail to keep them pointing into the wind, as illustrated

there are three basic tower styles: freestanding, fixed

A ower supports the turbine from the ground, and |

ers (Figures 11-10

guyed, and tilt-up. Freestar

and 11-11) are made frot

gue ase and held in place by

steel cables running at an angle from the tower to the

base. These cables are cally" ale ‘Tilt-up towers are usually of

tubular design and hinged at the base. The tilt feature makes it pos-

sible to lower the tower and maintain the tower and generator from

the ground,

' ‘Wind turbines can have the blades oriented either about the hori-

zontal axis, a illustrated in Figure 11-9, or about the vertical axis,

as illustrated in Figure 11-12. When mounted about the vertical axis,

1 they are called vertical axis wind turbines (VAWTS. Figure 11-12 is

called

HAWTs have the blades and generator positioned near the top of

the tower and usually have the blades pointed into the wind, which re-

‘duces the turbulence that would be set up if the wind passed through

the tower and over the generator before striking the blades. Many

sinall turbines have a tail vane that rotates the unit and keeps the

FIGURE 44-40 Freestending tubular

tower

FIGURE 44-14. Freestanding lattice

tower

‘8 Cengage Lanring 2013

Chapter 11 WIND TURBINE POWER MEASUREMENTS AND MECHANICAL CONSTRUCTION 489

FIGURE 14-42 Vertical axis wind

turbine

—Blades

Shaft

Diameter. :

HHolpny

VAWTS have a vertical shaft. The blades are mounted in-line with

the shaft, and the generator is mounted below the blades near the bot-

ofthe shaft and near the

7 surornam | OVERSPEED CONTROL

s Wind turbine designs must consider speed control to prevent me-

L_Senemrcossseramenoon. | na damage so cone el cn operat me

tem is operating above rated speed. When operating above rated

speed, braking is initiated to bring the system to a safe speed. The braking methods

are mechanical and electrical

Mechanical braking often consists of furling, which changes the rotor dynamics

of the blades. The blade pitch can be adjusted, placing the thin edge ofthe blade into

‘the wind rather than the broad side of the blade, changing aerodynamics,

Ifthe blades and generator body are rotated 90 degrees about the vertical axis,

then wind direction is parallel to the blades, and the blades don't rotate. The process

of rotating about the vertical axis is called yaw. The reduction in rotor speed affects

the power output and also prevents mechanical damage to the turbine and tower

under high-wind conditions.

Braking is also initiated by quickly changing electrical load. When a genera-

tor is quickly disconnected from its electrical load and reconnected (switched) to

resistors, causing more current to flow, the generator becomes harder to turn and

decreases turbine speed. This type of speed control is called dynamic braking. Dy-

namic braking and furling can be used together to reduce rotor speed.

In many small turbines, a manual brake (think emergency car brake) is utilized

bya person during maintenance or high winds.

GEARBOXES

Gearboxes are used when the turbine rotor shaft is not connected di-

FIGURE 11-43 Gearbox recliytothe eacraue

Suan to high

Shaft Shaft 4

And, conversely, it

pending on the gear rato, t

Most large turbines use a gearbox. The blades of large power utility

mass and turn at slow speeds.

M, increasing the output

power,

led by

Small turbines often have the rotor shaft connected directly to the

generator because the blades are turning ata faster RPM than in larger

machines with massive blades. i

a ‘The AC can

be rectified to DC and then passed through an inverter to adjust out-

ut. Some ectly c Cc :

190 Chapter 11__ WIND TURBINE POWER MEASUREMENTS AND MECHANICAL CONSTRUCTION

Ns /

What is wind?

2, What is the difference between electrical power and electrical energy?

+3. Avwind turbine converts mechanical energy to what type of energy?

‘4 Explain why power is affected more by wind speed than by swept area

When a wind turbine is installed close to and atthe same height as buildings,

is productivity increased or decreased?

_ When air density increases (gets heavier)-does power increase or decrease?

asa density increases (gets heavier) what could be the mechanical effects

ona turbine?

8, When tower height is increased, what isthe effect on wind speed?

15,

16.

18.

19.

When tower height is increased, what is the effect on swept area?

Explain the Betz limit,

When yaw motion occurs toa HAW, what occurs mechanically? What

occurs electrically?

Find wind power density when p is 1.225kg/m” and V Is 847mls.

Find power for Problem 12 when the rotor diameter is 4.5m.

“Two turbines, Aand B, are located on the same site. Wind speed and air

density are the same for both turbines, Turbine A has a calculated power of

1 e7W, and turbine B has a calculated power of 2494W. What is the most

likely reason why turbine B's power is twice that of turbine A?

In Problem 14, what isthe value of swept area for turbine A and for turbine BE

(p is 1.225kg/m® and V is 4.47m/s)

‘A wind turbine has a nameplate rating of 1000W at 11m/s. What is the

A enum kWh per month (30 days at 24hriday)? What isthe annual KW

{a months? If the actual annual energy produced is 6570KWh, what isthe

capacity factor?

‘wind turbine is installed at a site with the following: PIA = 62Wim’, swept

iene is Sin’, EPE = 1.9 (Rayleigh distribution), and p = standard condt

tions, Find power (P) and wind speed (mis).

iA turbine mounted on a 60-ft tower has an average wind speed of 1Smph.

To increase the wind speed by 25%, what tower height is required?

Using Figure 1-8a (power curve) at an average speed of 20mph for 240hr

vad [2h for 480hr, what isthe approximate energy output for 720 hours

(30 days)?

CHAPTER 11 WIND TURBINE POWER MEASUREMENTS AND MECHANICAL CONSTRUCTION 194.

OBJECTIVES

After reading and studying this chapter, you wi

* Understand the advantages of three-phase power

* Understand the basic design of AC generators (alternators)

* Be able to calculate voltage, current, and power for three-phase

wye (Y) and delta (A) connections

* Understand the operating principle of induction motors

* Be able to calculate synchronous speed

* Be able to explain the factors necessary to produce a rotating

magnetic field

« Be able to explain the difference between a synchronous

induction generator and an asynchronous induction

generator

* Be able to explain why a wind turbine drives an induction

machine above synchronous speed

© Be able to explain the operational difference between

a three-phase induction motor and a three-phase

asynchronous induction generator

* Be able to explain the relation between turbine shaft

torque and rotor speed

© Be able to explain why turbine output can increase

significantly with only a small increase in RPM

© Be able to discuss the relationship between torque and

electrical power when a wind turbine is operating above

synchronous speed

* Be able to calculate slip

« Be able to explain advantages of asynchronous induction

generators versus synchronous generators when applied

to wind turbines

* Be able to explain advantages of 2 squirrel cage induction

generator

« Be able to describe a wound rotor induction generator

* Be able to describe a double fed induction generator (DFIG)

* Be able to explain the advantages of a DFIG applied to

wind turbines

the modern world are motors and

wath ofthese are electromechanical machines. A motor, when connected

Senet petvical source, turns a mechanical shaft that does workfor example, the

shaft turns a drill for boring holes. Therefore,

i The current supplies a load and does work—for ‘example, it turns on an

electri light. Therefo

494 Chapter 12 WIND TURBINES & POWER GENERATION

gy by

This chapter explains the

ors used for:

seed, mechanical

FIGURE 12-

Magnetic,

field around eurrent-

a 8 carrying wire

-—a

are made from two basic parts, e stator)

isthe: is usually made from paits of electromagnets§ ————_____

fabricated inside an iron housing. The stator is similar for a number FIGURE 12-2 Turning force exerted

‘of motor types. the id is fabricated differ- on wire

ently, depending on the operating principle applied to the motor. In

this exampl 3 illustrates the operation of a

In Figure 12-3, AC current supplies the electromagnets, produc-

ing a magnetic field. Assume that electromagnet pole 1 begins as a

North Pole and pole 2 begins as a South Pole (Figure 12-33). North

Pole 1 repels the North Pole of the rotor’s permanent magnet, and

South Pole ts the North Pole of the rotor, turning the rotor

clockwise. “The South

Pole of the electromagnet attracts the North Pole of (or, and the

North Pole attracts the South Pole of the rotor (Figure 12-36) until

the rotor is horizontal (rotated 180°).

(Figure 12-4) ind current flow through the coils changes direc-

tion. Blectromagnet poles 1 and 2 change polarity (Figure 12-30). The rotar’s North

sles repelled by the North Pole of the electromagnet (pole 2) and attracted by the

South Pole (pole 1). Figure 12-3d completes the 360-degree rotation of the rotce

and the sine wave again changes polarity, repeating

hang onized tot e-phas and the rotor’s perma-

nent magnet is pulled by the changing field polarity

AC INDUCTION GENERATOR

the same principle as an induction motor, anc 1¢ principle of operation is different

than that of Figure 12-3, in which the rotors permanent magnet i pulled along by

the change infield polarit i ger

current flowing through the stator dev

magnetic field that moves or rotates

from pole to pole. As the rotating stator field cuts the rotor, current are

induced into the rotor, producing a magnetic field.

Chapter 12 WIND TURBINES & POWER GENERATION 195

SCangage Leering

(© Cengage Laing 2073

FIGURE 12-3 Basic AC motor principle FIGURE 42-4 Sine wave excitation for

SS

i electromagnets

Lit |

aot tan} zip" [260° Degrees

a

Co rotor comes up to speed, rotating @ few

than the stator field. Operating in this manner, the

motor can drive a mechanical load.

Pole 2 ye V Pate | "An induction motor becomes an induetion generator

when driven by a prime mover suibaaa od turbine.

| “The prime mover drives the rotor an the stator

we

"| rotating magnetic field; therefore, the roto field now ents

viously mentioned) applied to wind turbines pro}

duce three-phase power. As explained in Chapter 6, three-phase voltage consist of

aa core raves 120 electrical degrees apart. Three-phase powers more efficient than

Trae power because the three phases never goto zeroat the sam time, Whee

le, as indicated in Figure 12-5.

¥ transformers ofa similar frame size, the three-phase rating is about 50%

jgher than the single-phase rating.

FIGURE 12-5 Three-phase A Ve Vb Ve

cee 120°.

SAN

a |

0°

Bs

I LO

fae NS ae

2 ee

496 Chapter 12. WIND TURBINES & POWER GENERATION

Scengege ari

. io the stator coils, inducing a voltage into the stator that

8 produces current to ‘load or to the grid from the stator.

{Oo eisai grtosspy eee AG

i ~~ AV ree |

i Y ~_| THREE-PHASE AC

i 7 Most AC generators (also called alternators, as pre-

‘Three-phase motors run cooler than single-phase motors of the same

horsepower,

‘Three-phase power is more efficient because it does not go to zero,

+ Stator and rotor coils can be smaller because for the same power the current i

"reduced

Jn Figure 125, single-phase power is zero at points 1,2, and 3. Observe that power

never goes to zero on the three-phase waveforms because there is no time when all

three phases are zero at the same time,

THREE-PHASE GENERATORS

I af used in wind turbines are basically of three types:

+ Squirrel cage induction generators

+ Wound rotor induction generators

Synchronous (constant speed) generators

All three have the same type of stator with field windings wound around an iron

frame, ‘hree-phase AC excitation cur-

rent applied to each st of stator cols. The stator excitation sets up a stator mag.

netic field that moves from pole to pole and is called arotatlngraaprate Belt ‘The

rotating field induces current into the rotor, producing a magnetic field around

the rotor. When the generator is connected to the grid, then the stator receives

excitation current from the grid and also supplies power to the grid. Figures 12.6

and 12-7 illustrate a three-phase stator and rotor and {he sator of an induction

machine, respectively. The idea of a r g magnetic field is used to explain the

Qperation of n induction motor and an induction generator, An induction generar

tor is basically an induction motor driven by the wind (or other prime moves) that

produces output power.

FIGURE 12-6 Three-phase stator and rotor FIGURE 12-7 Stator of induction

——— — machine

[— Phase2 Phase 1 Phases |

Phase Leads

10 Stator Fiala

(© Cengage Learning 2013,

lated as

Synchronous speed (RPM) = (120 X frequency of input excitation)/number

of stator poles per phase

or

$= (120 x Aypoles per phase

(Note: Every magnet has two poles, one N and one S. Therefore if there are two

magnets per phase, then there are four poles per phase)

Chapter 12 WIND TURBINES & POWER GENERATION 197

EXAMPLE 12-4

= p0Hiz end poles per phase ~ 6 (3 magnets per Phesey each with 1 Nand 1S}.

What is the synchronous speed?

§ ~ 120 x fipoles per phase = 120 X 60/6 = 1200 RPM

EXAMPLE 42-2

{50 Hz and poles per phase = 6. What isthe synchronous speed?

5 = 120 x 60/6 = 1000 RPM

EXAMPLE 12-3

tow many poles per phase are required for @ synchronous speed of 900 RPM

at 60H2?

oles per phase = 120 x 1S = 120 x 60/000 — 8 poles OF 4 magnets per phase

orice tht synehronous RPM is determined by excitation [SST and the

pane tion por phase. Under no [oad the motor SPeed be close to

atau apecd, Butwhen loaded anaoperatnd me aT the rotor speeds

acrcges than synchronous peed by en amount oiled slip. When an induction

na ating ot synchronous speed, the torgueiezere, WT operating os 8

moon rotor iseriven above synchronous sPo8 Py the slip amount,

difference be ¢ ‘1 ve gpeed. When an induction

the atfreres ering above eynchronous epeed, iis cae) 0 ‘asynchronous

machine Pn seyneonous ganerator fs operating 61 Fel synchronous

aera, there 1s no output power. tors oP | synchronous

THREE-PHASE ROTATING

FGURE IES Fovaing meoretie els MAGNETIC FIELD

phase 7

UN Thee-phase induction motors and three-phase induction generators

jaa | each work on the principle of a rotting nagnetic field produced by

| thestator three-phase and ingle phase induction motors are used By

20 aa, | commercial establishments etustry, and residential homes. Induc-

| | tiongeneators ate a speci application of an induction moter.

vA rotating magnetic feld is pro he stator because of

lise

« Three-phase voltage changes poarity wit respect f° cach phase at

regular intervals,

« "Three-phase voltage i 120 degrees out of phast and

| + Stator il windings aqre wound around the pole pieces in a spe-

|" iiesequence to ainsin the 120-degree phase relation.

| Figures 12-8, 12-8, and 12-0 ilustrateass-pol (one N and one S pole

=)

pet phase) stator and the rotating magnetic field sequence. Phase 1 is

Per Eitopoles 1A and 1B, phase2iswired topoles 24 ‘and 2B,and phase 3

© congaae

198 Chaptor 12 WIND TURBINES & POWER GENERATION

FIGURE 12-9 Rotating magnetic field FIGURE 12-10 Rotating magnetic field

hase 2 phase 2

[ Lia |

2A 38 |

é | 3A za |e

2 &

Ss Tie iS

H Hi

is wired to poles 3A and 3B. Three-phase waveforms with phases LI, | ==>

12, and L3 and 120 degrees out of phase are illustrated in Figure 12-11, FIGURE 42.

A rotating magnetic field sequence is explained as follows: To il. - 2

Iustrate movement of the magnetic field as it rotates around the sta.

tor, the figures show the field strength, F, concentrating between field

Poles. Vertical lines are drawn at points A, B, and C on the three sine

‘waves to indicate the magnitude of voltage at an instant in time. As

cone phase increases in magnitude, F increases between the poles asso-

lated with that phase and decreases in strength between other poles.

At point A on the waveform, phase Ll is at maximum positive,

and a strong magnetic field, Fl, is set up between poles Al and Bl,

‘with weaker fields between poles 2 and 3. At point B on the waveform,

phase L2 is at maximum negative, and a strong field, F2,

has rotated to between poles A2 and B2, with weaker

fields between poles 1 and 3, At point C on the acta eee

form, phase L3 is at maximum positive, and a stron,

field, F3, has rotated to between poles A3 and B3, with

weaker fields between poles | and 2 = 4

This should give the idea of how a rotating field is

‘generated, Asthe three phases rotate from A to BtoC, the

strength of the magnetic field also rotates. When cach

phase ofthe AC waveform has completed 360- degree

rotation, the magnetic field will have also rotated ;

su

360 degrees, and a strong magnetic field, F1, will again | u

be produced between poles Al and A2. Figure 12-12 isa

fhtee-phase stator with three-phase excitation current. [|_____

ASYNCHRONOUS

INDUCTION GENERATOR «

‘When the fotor of an induction generator begii turn, maximam current is in-

duced into the rotor by the wroducing a strong rot

“netic field cutting

Jag behind the

tc

r in the application

Chapter 12 WIND TURBINES & POWER GENERATION 199

‘© Cengage Lewring 2079

as.a generator the rotor shafts driven by the mechanical action of he turbine blades.

“The mechanical torque increases with only a small increase in the driven rotor RPM

(see Figure 12-13, in relation to the torque-speed curve), and ‘the generator rotor

texceeds the speed of the stator rotating field and induces current into the sta |

t : stator. The |

. pri 4 The mechanical energy, torque, |

|

applied to the generator rotor is converted to electrical energy and fed from the

stator to the load.

ae enchromous generator is driven about 2%~3% above synchronous spec! tO

deliver maximum power output. (Note: In some applications, the induction geners-

dey started as an induction motor and then connected to the drive source)

SLIP

Rotor speed below or above synchronous speed is called lp, Slip is the difference

_ in speed between the rotor speed and the synchronous speed ‘produced by the stator

- rotating field, or

Slip = synchronous speed ~ rotor speed

Ifthe synchronous speed is 1800 RPM and the rotor speed is 1746 RPM, then

$= 1800 — 1746 = 54RPM

and % slip is slip/synchronous speed 100, or

4 slip = 54/1800 X 100 = 39%

If an asynchronous generator is turning at a negative slip of 396 and the synchro-

nous speed is 1800 RPM, then the rotor is turning at 1800 + 54 = 1854 RPM. Slip

Bove synchronous speed is called negative slip.

EXAMPLE 12-4

'A GOHz, B-poles-perphase induction motor is applied as an asynchronous

Generator at 3% slip. At what speed isthe rotor turning a8 @ generator?

Synchronous speed: S = 120 fipoles per phase

= 120 x 60/8 = 900 RPM

2. Slip: Slip = 900 x 0.03 = 27 RPM

b. Asynchronous speed: Asynchronous speed = 900 + 27= 927 RPM

La eve the Dre oe a eee

machine i fing as an induction moter, tt 1

"stronger than the magnetic field induced into the rot

by the interaction of stator field and the roter field causes the rotor shaft to "0

oy ne drives a mechanical load. The rotor ofan induction motor operates below

synchronous speed and this difference is called slip, When an induction motor is

operating ar anion oer ro one see

“speed by t ve of the wind. As the rotor is driven above synchronous speed,

it becomes harder to turn, increasing =r ncrncoatovaue nrese08™

“Stator current which supplies the electrical load.

A

“When speed eo synchronous speed, the machine operates as a motor

200 Chapter 12 WIND TURBINES & POWER GENERATION

nous speed (to the right of N), the machine operatesasan FIGURE

asynchronous generator. Observe that as speed increases

(blades turning faster), torque increases, and as speed

decreases (blades turning slower), torque decreases. An

important characteristic of an induction generator is that

_ forque is Converted to electrical energy. This conversion

sequence is as follows:

— Range of possible

Speed vation

speed curve shows that torq.

increase in speed,

increases significantly with

is can aso be interpreted to

Tange of speed variation is.

As wind speed increases, ro

lysbut the increase in rotor speed is limited.

as

‘And, atthe same time, the increasing torque increases

power output. Observe that speed can also decrease while

torque remains high, limiting decreased rotor speed as

‘wind speed decreases. This characteristic of an induction

generator isimportant because a wind turbine cannot just. L—

turn the wind off and on, ‘There isa point on the torque-

‘© Cangage Learing 2073

speed curve called pull-out or breakdown torque above —___

which torque decreases as speed increases. Speed mustbe FIGURE 42.44 Grid connection

controlled under these conditions by slowing blade rota-_[-

tion. Under these conditions, if power output cannot be

2

2 ee

controlled, the turbine is taken off-line. Stator

‘When rotor speed drops below synchronous speed, e

the asynchronous generator then becomes a motor and dD u ona |

‘must be removed from the grid, (There are exceptions mm MT a

to this, as explained later in the discussion of double fed Bo :

Rotor

—*M3 M3 3

Lt, 12,13 tine) 5

n the syr ‘M1, M2, M3 (Magnetization) 3

th ynchron é

peed freg 1 grid controls generator power output

frequency and phase when connected, Figure 12-14 illustrates a grid con-

nection. But ifthe grid becomes unavailable, the turbine must then be

/ taken off-line. An asynchronous generator can be operated stand-alone

j if provided with magnetization current, usually supplied by capacitors

FIGURE 12-15 Split phase field

winding

Many small induction motors operate on single-phase input power. coat

ic field, the sta 7

q sw

Run Start

‘To develop a rot

‘ tar cting like

‘two-phase. These are called split phase induction motors, and capaci

tors illustrated in Figure 12-15, are often used to make the start current

lead the run current. These motors are typically used for residential

‘or small commercial applications and seldom used as wind generators, |

SQUIRREL CAGE

INDUCTION ROTOR

As previously mentioned, the stator isthe same for all induction generators, but the

rotors differ with application. The squirrel cage rotor (Figures 12-16 and 12-17) got

its name from the similarity to the exercise machine for pet squirrels, The rotor is

TAC

(© Gongage Leaving 2073,

Chapter 12 WIND TURBINES & POWER GENERATION 204

FIGURE 12-46 Basie squirrel cage rotor FIGURE 12-47 Squirrel cage rotor

— apo

Insulation

Copper Bar __

Laminations

of simple construction and consists of metal bars separated Py insulation and con

orted to end rings. The metal bars are made from aluminum 0; coPPS® and there

aes coils in the rotor. Squtzel cage rotors are used in most Light ‘medium duty

XC motors, primarily because of simple construction and high reliability. Squirrel

age rotor machines ae also used in asynchronous generator

vine stator rotating magnetic field cuts the squirrel cage rotor Bars,

inducing voltage and current in the bars and producing 2 roteivs

magnetic Held, as previously explained (Figure 12-18) The ov fields

FIGURE 42.48 Voltage induced into Be io each other and torques produced. The turbine blades

tor by rotating magnetic field ar at ne sotor ata speed greater than the synchronous speed of the

#___ stato, and the rotor field now cuts the scr Under these conditions,

sat a duces voltage into the stator, increasing stator current ad

supplying grid current. Stator magnetizing current is Nigh ‘when the

ae builds up its magnetic fel, but current is reduced as the

7010 nes operational speed. Istator excitation current is sourced

from the grid, then the generated voltage and frequency are in phase

teith the grid. When a squirrel cage induction motor is operating

“hove syehronous speed, itis called an asynchronous generator ig

dhe rotor was free to turn, it would actually operate as a motor,

‘When this system is grid tied, the voltage and frequency are in

syne with the grid, and additional power management equipment

syne Mequired, Ina hybrid system application (in your home), the

we me turbine feeds the grid when it is generating excess powes

wet ihe grid feeds the Toad when demand is greater than the turbine

can supply.

Saquirrel cage machines operate eficiently at rated «peed and full

toad bat undet lacked rotor conditions, when the rotor i stalled, cor-

weirs ited only by the circuit resistance, and ifthe condition per-

“Mats, heat builds up, destroying the insulation and the machine,

TRUE POWER

AND REACTIVE POWER

‘As explained in Chapter 7, true power is resistive power and 0) the power is =

A cab then the power factor is equal to one. Reactive power i thet power used by

aie aand capacitive loads when current and voltage ae out of phase, Nese

yrower causes the power factor tobe less than one, and power compan must sup-

ply reactive power although the watt-hour meter measures ‘only true power. Under

ao re naitions, the users of reactive power pay a premium, or they must correct

the power factor by adjusting the reactive power.

202 Chapter 12. WIND TURBINES & POWER GENERATION

FIGURE 12.49 Wouna

Rotor A |

Induction generators supply both true and reactive

power, and, if required, the reactive power is controlled

by using a three-phase capacitor bank on the output.

During starting, a squirrel cage machine draws high

‘magnetizing current. The rotor bars are highly induc-

tive, and the generator’s power factor is ow. As the rotor

comes up to speed, rotor current is limited by resistance

rather than inductive reactance; therefore, current and

voltage are more in phase, and the power factor is im-

proved to a range of 8594-90%.

WOUND ROTOR |

INDUCTION MOTORS

‘The stator winding of the wound rotor induction motor isthe same as

that of the squirrel cage motor. The rotor is different and is illustrated FIGURE 12-20 Rotor of wound rotor

by the schematic in Figure 12-19. The squirrel cage rotor does not have duction

coils, whereas a wound rotor (Figure 12-20) is constructed of field coils

connected to slip rings and brushes; the external connection to the

brushes can be resistors or an external source (Figure 12-21). The ex-

ternal connection allows a certain amount of speed control. The stator

rotating magnetic field induces voltage and current in the rotor coils,

producing a rotating magnetic field. Ifthe rotor circuit is open or if the

resistors have a high resistance, the rotor current decreases, the rotor

field strength reduces, and the rotor will not turn, Torque is developed

‘when sufficient current produces a strong field that interacts with the

stator field, causing rotor rotation,

THREE-PHASE WOUND

‘The wound rotor is assembled with three coils wound 120 degrees

apart, and the coils are connected to slip rings. Brushes ride on the slip

rings and are connected to external resistors that are used to reduce

excitation current when the rotating field first induces voltage into the _ |

rotor when starting, As the rotor field strengthens, the stator field and

rotor field interact, and torque is produced. As the rotor comes up to

speed, magnetizing current in the rotor is reduced, and if used as a

‘motor, the rotor will rotate at less than synchronous speed. But ifused

as a generator, the prime mover's torque and speed increase, and the rotor is driven

to above synchronous speed (see the previous description of asynchronous induc-

tion generators). The increased rotor torque is converted to electrical energy and fed

from the stator to the load, Voltage and frequency are locked in phase with the grid.

The wound rotor generator has some advantages over squirrel cage rotors

Starting excitation current is lower because the resistors can vary the current and

also allows for some rotor speed control, but these advantages should be weighed

against the simple design of the squirrel cage rotor, which is highly reliable and

requires little maintenance, When the external resistance is shorted out, a wound

rotor motor has the same characteristics as a squirrel cage motor. This machine is

an asynchronous generator because it generates power when operated above syn-

chronous speed,

INDUCTION GENERATOR [ “

FIGURE 42-24 Rotor connected to

ROTOR ASYNCHRONOUS send sian

rotor schematic

ey

ee

\ er

a

jotor

Chapter 12 WIND TURBINES & POWER GENERATION 203

aage Lean

Sano

Fane TH oan einai DOUBLE FED

Voltage Controller | IN D U CTI oO N

Le | GENERATOR

Figure 12-22 illustrates the operating

ble fed induction generator (DFIG).

i

po principle of a dou-

Variable ACis converted to DCand

ompatible power, With this configuration,

the electronic controllers are designed to

grid ot feeding the grid.

then back to AC supplying the grid with

the rotor is independently controlled, an‘

operate in either direction, being fed by th

Remember, ifrotorsp

he DEIG hi age a ‘current is

fed into the rotor at the same frequency as the rotor frequency, but 180 degrees out of

‘hase, and if that currentis greater than the rotor curtent then the rotor slows down

Rhos ar tion ofthis induced frequency. For example ifthe current has a frequency

of 2Hiz and the number of rote {i six, then the RPM is

Note: The ‘and is different than

the grid fre: rest, the stator magnetic field is cutting

the sotor at close to synchronous speed, and the induced

a frequency as a function of that speed

‘yoltage and current have

(poles per phase X slip)/120

Frequency is Hz and slip is RPM.

‘This effectively reduces the synchronous speed by 40 RPM: therefore, even

though the mechanical speed ofthe turbine has slowed, the slp requirements have

aaa reduced, allowing the machine to still produce power tothe grid even 2

(Remember sli .

Hexviore

‘A shepote-per-phase induction generator is operating ot 6OHz, and the rotor is

turning at 1224 RPM.

‘sillustrated in Figure 12-22, the voltage controller modules can receive Powe?

the rotor to th

204 Chapter 12. WIND TURBINES & POWER GENERATION

‘The DFIG through its controllers can capture some of this energy by chat

ing the sip requirements, and this power is sext tothe fr Athigh wind spats,

the generator voltage and frequency increase, and this higher voltage is converted

to DC by the controller and then converted back to grid-compatible AC voltage and

frequency, supplying 10%- iditional power above the stator power.

‘There is ‘microprocessor pro-

gram initiates or inerease in rotor current, which in turn controls slip,

Totor frequency, and magnetic field strength. A squirrel cage induction generator

operates at a maximum speed of about +3% above synchronous speed, whereas, a

DEIG can operate at a maximum speed of about +8% above synchronous speed.

It can also operate as a generator at speed below synchronous speed, By control.

ling these parameters, t controlled. Keep in

mind that resistance is fixed, but inductive reactance and impedance change with

frequency, which can be controlled,

DFIG WITH BLADE SPEED

AND PITCH CONTROL

As explained in Chapter 11,

This formula was developed from

as indicated in Figure 12-26. Ina HAWT

blade, pitel zed by rotating the blade in its vertical plane which, changes the

power coefficient

EXAMPLE 12-5

Referring to Figure 12-23, find the tip speed and tip speed ratio where the shaft. FIGURE 42.23

speed is 60 RPM, wind speed is 14mph, and blade radius is 25ft. Example 12-5

Tip speed = 0.071 x distance from hub x shaft RPM

= 0.701 x 25 x 60 = 106.5mph

Tip speed ratio = tip speediwind speed = 106.5/14 = 7.6

Thotpspeed76umos sethantes,

Figure 12-24 adds

(© Cengoge Lawrna 2019

Figure 12-25 is -

{ain type of turbine. Observe that the maximum power coefficient in Figure 12-25,

(approx. 0.5, occurs when the tip speed ratio is (approx. 75, or when the blade tip

Chapter 12 WIND TURBINES & POWER GENERATION 205

FIGURE 12-25 Power coefficient,

versus tip speed ratio

‘Speed and

Pitch Controller | Power coofficient

Maximum

speed is75 times the wind sp

refer

Stator | inmlsormph). As

© cengage Losing

Figure 12-26 io

rd blade

FIGURE 12-26 Power coefficient

id ratio at various blade

5. tanda

ae eith the wind blowing directly inte 1 blades, an

js when the blades have been panel ch that the wind is striking the

A nee page ofthe Blades and very tle wind energy is captured. The

g ther curves are pitch angles between curves 1 and 6. Tv

Power coefficient

sitions; for example, an offshore desi

Speeds 1000 feet above sealevel Forms

or TOO eficent (which it isnt, the outPY

ran $99 ofthe ideal available wind

o congage Los

“therefore, if the generat

power ofthe turbine iso greater

energy. (Remember that the a

bbe co

tional output power.

THREE-PHASE SYNCHRONOUS !

GENERATOR

eee ‘Both squirrel cage and wound rotor induction generators operate above

FIGURE 12-27 Throe-phose synchronous peed. A synchronous generator (Figwe 12-27) is run at

synchronous generstor synchronous speed, which means i rust bbe driven by a prime mover

Fy constant RPM. Stator excitation is not required, but rotor excita-

smn produced by electromagnet (oF Permanet ‘magnets). The stator

tions and output power is taken from the Sa DC rotor excita-

‘| tion can come from an external sOUrCE ‘using slip ringsand ‘brushes, but

‘| tin ommonly there is a DC generator Bult ne he rotor that does

4 rat requite sip rings and brushes, therefore reducing maintenance. DC

ge connected to electromagnets produces a constant magnetic field, andas

3 eroiving | the rote tarns sorptor magnetic ld cuts the stator coils, inducing

— Noltage and current into the stator. When the rotor reaches synichro~

wus apeed, the DC excitation locks the rotor synchronous speed:

206 Chapter 12 WIND TURBINES & POWER GENERATION

Synchronous generators are commonly used at large Zos> 356

utility generating plants that have prime movers pow. TIGURE 12-28 Voltaglandrequency vary

ith, speed

ered by steam or water. These prime movers run at a Misihepe

constant RPM. ‘Therein lies the problem with wind as the y

prime mover it blows at a variable speed. When the ro-

tor is turned by the prime mover, a sine wave voltage is Rectier Inverter

induced into the stator, but as rotor speed varies, both ‘ a

voltage and frequency vary sillustrated in Figure 12-28 cal ee

Synchronous generators are used in certain applications |) ‘teen

where variable voltage and frequency are not a primary | 284 AC rom Generator @ ac

concern, but are not used in grid-tied applications unless rer

rectifiers and power conditioning inverters are also used,

In recent years, powerful permanent magnets have been developed, and in

some applications, permanent magnet rotors have replaced electromagnets. Man-

uufacturers have developed some smaller wind turbines (usually less than 20kW)

using permanent magnets, and the generator is directly coupled to the wind turbine

shaft. The generator output varies in both frequency and magnitude, as illustrated

in Figure 12-28. The AC output is rectified and then fed to an inverter, changing the

DC toa high-quality sine wave, and supplied to the grid.

MORE ON INDUCTION MOTORS

AND GENERATORS

‘The three-phase induction generators that have been explained are basically three-

Phase motors, and understanding motorsleads toa better understanding of motors that

ms isa ieee eld. Mag-

etizing current is supplied to the stator from an external source, usually the grid.

(his is different for a synchronous motor/generator, as was explained previously)

‘The-ratorsare of twougenGtal| typessisquirrel:cage and:wound’rotas. When an

induction motor is energized, current flowing to the stator produces a rotating

‘magnetic field that induces voltage and current into the rotor, producing a rotating

magnetic field; torque is produced between the two fields, and the rotor starts to

turn. The rotor always runs slower than the speed of the rotating stator field, which

is the synchronous speed; this difference is called slip. Motors have positive slip

(less than synchronous speed), and asynchronous generators have negative slip (the

rime mover drives the rotor above synchronous speed),

Slip has an effect on the operating characteristics of induction motors/generators.

When the machine is stalled (rotor not turning), then slip is 100%. When the motor

comes up to speed, but at no load, slip is usually less than 2%; at full load, the slip

increases, but is typically less than 5% (these values are for squirrel cage machines).

Rotor characteristics of a wound rotor machine are similar to those of a squirrel

cage rotor when the external resistors are shorted.

in the rotor and is summarized as follows:

a. Rotor voltage is directly proportional to slips when slip goes up, the induced

voltage goes up.

b. Frequency of induced voltage is directly proportional to slip; when slip goes

up, the frequency of the induced voltage goes up.

¢: Inductive reactance of the rotor is directly proportional to slip; when slip goes

up, XL goes up (XL = 2nfL),

4. Rotor current is maximum at 100% slip, and as slip decreases, rotor current

‘goes down. At no Toad, slip is low and rotor current is low. As load is in-

‘creased, slip increases and rotor current increases.

Chapter 12 WIND TURBINES & POWER GENERATION 207

«e-‘The rotor power factor increases as slip decreases. The power factor can ¥a°y

eeween 0 and 1. When the power factor is 1, the load is purely resistive, and

eerie, the load is a purely reactive. At 100% sip (rotor RPM = 0), the

votor power factor is O.1-0.2 (rotor is very inductive) As slip goes down (rotor

TRIM pncreasing), the power factor increases (0.8). Between no load and full

food: slip is typically less than 5%, and the rotor power factor typically varies

from 09 to 095, The highest power factor occurs at full-load operation.

Keep in mind that these are estimates and are used to show

en non DENS ‘As explained previously in

this chapter, a double fed induction generator trols the rotor power factor,

by injecting current into the rotor, Which affects slip controls the power factor

‘The stator power factor is basically a functiomof stator reste eigaDeS.

—sadimerieguenseand isons ‘when operating at full load. At full load, the

Dower factor is typically in the range of 08-085.

GENERATOR FREQUENCY

Generator output frequency is determined by.twofactorss the speed. of the rolOp

., as shown by the equation £ = > poles per"

Mtthe member of poles is fixed when the machine is assembled; therefore,

EXAMPLE 12-6

Find the output frequency of an AC induction generator that contains four poles

per phase and is turning at 1800 RPM (see Figure 12-29).

{= RPM x poles per phase/120

1200 x 4/120 = 6OHz

FIGURE 12-29 Chart of rotating speed for 60Hz

and S0H2

cor, com, ‘|

Poles per Poles per |

| RPM | Phase Phase

| 3000 2 3000 2

ae Le

ote

GENERATOR OUTPUT

VOLTAGE AND CURRENT

“Output voltage is determined by three factors: (Q);number of turns in the stator or

rotor coils, 2) speed of the rotor rotation; and (3) strength of the magnetic field. The

‘Rimber of turns in the stator or rotor can be changed at the time of construction,

but is fixed after the machine is built, Ifthe rotor speed is changed, then frequency

riiso changed. A common way to change voltage without changing frequency 's

208 Chapter 12. WIND TURBINES & POWER GENERATION

FIGURE 12-30 increasingivottagebyichangingthe FIGURE 42-34 anoreasing current by changing the.

field turns number of branches

1, ey

‘orconteolvexcitatiom current, which changes the miigneticvieldstrengthiand the

spoltage: Figures 12-30 and 12-31 illustrate how to change voltage and current by

changing field windings

MECHANICAL POWER

In Chapter 11, the id iturbinewas calculated ag B=YSBAVALAt

sea level and a temy Power in watts is

Pwatts = 0.6125AV?

where V is m/sand A ism. This expression can be written as Pwatts = 0.6125AV? x

0.59, which is the maximum power when the Betz limit is applied,

To further explain power transfer to watts, shafi torque and speed can be con-

verted to watts. This transformation is Pwatts = 0.142 x RPM X torque where

torque is fe-lb. In the metric system, Pwatts = 0.105 X RPM X torque where torque

is N-m (Newton-meter) (Nofe: Radians are a typical measurement for speed when

torque is N-m, and 0.105 radians per second is 1 RPM, In practice, RPM is an easier

shaft measurement.)

EXAMPLE 12-7

A shaft is driving a generator, and the shaft is rotating at 900 RPM at a constant

torque of 1Sft-Ib. How much power (watts) is the shaft producing? (Speed and

torque are measured at the generator shaft.)

Pwatts = 0.142 x RPM x torque = 0.412 x 900 x 15 = 1917 watts = 1.917kW

Ifthe generator is 100% efficient, then it should produce 1.917kW of power.

EFFICIENCY

Efficiency ofa system is the ‘aio Of eNO divided by powetsingor eficiency =

Paa/P.x Each part ofa system has efficiency, andthe total eficiency isthe product of

cach Part, expressed as total efficiency = efficiency 1 X efficiency 2 X efficiency 3

(also see Chapter 11)...

EXAMPLE 12-8

‘Awind turbine has been tested, and the efficiency of power transfer is illustrated

in Figure 12-32, Find the system efficiency.

ev

TH —t—

bk} wv @ 1a

Chapter 12 WIND TURBINES & POWER GENERATION 208

FIGURE 12-32 Example 12:8

=|

ee Fremromer = tom, 12

feloos {scene freome Powe F

| z

| oon Maa oe oe a

Note: Efficiency as indicated in Figure 12-3218 the electro >

No: a pete copretioony |

=z sits

“The eystom efficiency is (0.95 X 0.95 x 0,96 x 0.98) « 100 5 0 £88 x 100 = 88%.

eee ne om te wind 6AM, et sft owtut DONT

TkW 20.88 = 12.260.

PARALLELING GENERATORS

Generators are connected in parallel (Figure 12-33) to supply moe

peaertent, When connected in parallel, electrical condinons mt

at toad cor sined between the AC generators and the ged and loads. Fol-

FIGURE 42-33 Parallel generctors

=

| ea

a

lowing are

1. Output voltages of both machines must be the same

2, Phases of both machines must be in sequence.

re phaseL1 ofeach machine must be maximum positive and

- ‘negative at the same time.

InPhase Waveforms b, Phase 12 of each machine must be maximum positive and

negative at the same time.

oe «Phase 13 ofeach machine must be maximurn positive and

\ I negative at the same time. “

7 ty ee 3, Frequencies of both machines must be ‘the same.

| i These requirements

al baal _| WIND SYSTEM

CONFIGURATIONS

‘wind turbine AC generators are considered to operate either 0 YaP

ae’ e Speed or near fixed speed. Variable speed machines 4% the r0-

ree wind speeds when the wind speed increases, the rotor turns

+ re eynd when the wind speed decreases, the rotor turns lowes

_ MaxirumTorqus ‘Fixed speed (not constant speed) machines pse controllers to keep

the ctor barning at or near fixed speed. Squirrel cage machines have

' tnecdency to control their own speed. One of the important char-

| | ere of asynchronous induction generators that they operate

re acre fixed RPM as wind speed increases (reference the tordue:

ipeeeen speed curve in Figure 12-34.

4: . — “The asynchronous generator controls its speed over a wide range

¢Srator Rotor Speed (RPM) of dhaft torque with only a small change in rotor RPM. ‘This reals

ol__— PM) | that wind speed variations have only a small effect on rotor speed

FiGuRE 12-34/ioral

speed curve

Torque fH)

240 Chapter 12. WIND TURBINES & POWER GENERATION

FIGURE 12-35 Fixed speed

‘until wind cut

ilustrtesthisnarrow range a rtorapeed overs rather =

forque Is a Key parameter for

eM porcine ae

maximum torque is exceeded, the rotor breaks away Gearbox -—]_ {nduction

from the magnetic field, and torque quickly reduces as senerator

rotor speed is no longer controllable and output power

is not reliable,

Figures 12-35 through 12-37 illustrate three system |9=———_—

configuration gure 1.35 wih ogi cage tee FIGURE 2236 Varetiapood

‘operates over a narrow fixed speed range (not constant [—

speed). Production is basically over the cut-in and cut-

out range determined by measuring wind speed. It can

be connected to the grid withou

. some aplication’ ean edo

igtt@82-36 isa DFIG and operates using a control

loop that can control rotor current and slip; it operates

over a wide variable wind speed range. The DFIG op-

timizes power output by capturing high and low wind

speeds and utilizes rotor power to increase stator output _

power. Itcan be connected without power conditioning FIGURE 42.37 Variable speed

but requires back-to-back voltage converters. Produc. -——

tion is over a rather wide range within cut-in and cut- oe

ut requirements,

In Figur 12:@70K8 generator is directly coupled and

‘operates over a variable wind speed range, but the out-

put requires voltage rectification and DC-to-AC invert.

ers to supply the required AC sine wave. Production is

over the cut-in and cut-out range.

the

in or cut-out speed occurs. Figure 12-34

Grid

|

L

[variable | Ac [Recier

SS ca

spec

. \

EXAMPLE 12-9 a if

A three-phase induction motor is applied as an | 0 °

asynchronous induction generator in Figure 12-38 and |

will supply reactive (capacitive) excitation current from -

2 capacitor bank at 0.85 power factor. The capacitor | Bed ac Gooa Ac

bank is connected delta. The generator will operate

stand-alone and supply a three-phase load,

engage Leaning 2078

FIGURE 12-38 Example 12.9

Chapter 12 WIND TURBINES & POWER GENERATION 244

——

The motor’ specification is three-phase 440V 3f 60H.

Fullload current is 6.34 (motor excitation current)

Full-toad slip is 3%.

rhe motor's synchronous speed fs 1800 APM

Thad the capacitor values forthe 0.95 power ecto" (PF) and the prime mover

speed.

Power apparent = Py, = = 1.73 x 6.3 x 440 = 4796VA

Power true = Prac

“a Figl = ATO — ATF = 2528008

b.

. Power reactive = Pus =

4, Power reactive per phase = 2626/3 = B42VAR

t

|, = proactiverphase V ~ 842/440 = 1 914 per phase

Ei = agort.gt ~ 230.30 per phase (dette phase voltage = line voltage

= 4a0V)

gC = UlaMX,) = ME2 x 8.24 % 60% 250 3) = 11.51F (per phase)

h. Slip = 1800 x 0.03 = 54RPM

* equired prime mover speed = 1800 * SUP ~ 1900 + 54= 1854 RPM

‘This moter, when driven by @ prime move! and connected to the load, will

generate its own excitation current.

THREE-PHASE AC VOLTAGE,

CURRENT, AND POWER

CALCULATIONS

0 far in this chapter, three-phase induction generators and ens

toon explained. This next section explasne Bd presents examples of calculating

Thee: phase connections are configured 25 W° (WY) or delta (A). Figure 12-39 is

awye connection. The voltage on ge across a winding is called phase voto

and the voltage measured between two lines is

called Line voltage (E,,,J- Current measured through

cars called phase current (l,.) and Curent net

2 col through the line is called line curren’ .

igure 12-40 is a delta connection, and as in the

vwye connection, the voltage measured 26°01 phase

We fed phase voltage (Ep) and the voltae Cor

i fed between two lines is Tine voltage @,,). Cu

set oeryred through a coi s phase current ( ad

rent Tuerent measured through the Tine ising cubrent

(7). Observe, in each configuration, that three line

(Viages and three phase voltages are measured and

wotagrsee tine currents and three phase currents A

measured

aa et. aye configuration in Figure 12-39, (he line

voltage is calculated as

By, = 1732 Ee

and

E,

732

212 Chapter 12 WIND TURBINES & POWER GENERATION

For the wye\configaratioy, equal current flows through the line and FIGURE 12-40 Theo,

the pr: connection .

Te = sie [tines al

For thedeliaconfiguration in Figure 12-40, the line ‘voltage and phase |

voltage are equal, or

Fine = Ease

Avoltiieter eonnected between two input lines in the deltas the same

as being connected across a phase. For the delta:configuration, line ,

current splits between two phases and ,

“= 1732 I,

phase delta

and

= Hy /1.732

Tan

THREE-PHASE POWER

Ina three. hase system, if line Voltage and line current are known, then apparent

VA = 1.732 X By. ny

And ifiphiaSe Wollage and phase current are known, then apparent power is

VA=3x EXT.

tie owerrats)is calculated as

Watts = 1.732 X By, X Tyg, X PF

or

Watts =3 XB x1, % PE

Reactive power (VAR) is calculated as

VAR = 1.732 X Basse X Innenaane

‘Reactive power isthe result of inductors or eapacitorsin the circuit

EXAMPLE 12-10

As an example, Figure 12-41 is a three-phase wye generator connected to a

three-phase delta load. The generator is supplying E, 240VAC, and

{he delta load is resistive 120 por phase. Find Ein wae Exser sur Ince ney

‘heiot ncegraralinegeerter @PPAFENt Power, true power, and reactive

power. FIGURE 12-44 Example 12-10

Ennion Ey = 240V (the generator line voltage is across Generator Losd

tnatons ™ Ein goer me

the load phase) aes.

Eosmette = Einetng = 240V

Pas Da

©: nue tons ~ Enausond A, = 240/12 = 20A (204 is through each delta

phase)

9. Nnwias * 1.732 % Vocenons

(each line is 34,644)

lnetess = 94.644

lone genmter = 34.644 (each phase is 34.644)

9: Py, = 1.782 X Ey, X lagg 1.732 X 240 X 34.64 = 14,399VA

= 1.782 X Ippgge = 1.732 X 20 = 34.648

Chapter 12 WIND TURBINES & POWER GENERATION 243

1. Pagye~ Pun * PFF the PF = 1 bocause the load is resistive:

4,999 x 1 = 14,399

O because the load power is all true power

Prenat

iP,

Comments

1 Ifthe load isa wye connection, then wye calculations af¢ used for phase and

line voltage and carrent.

2. A generator is typically feeding multiple parallel loads, and the generator

A Beata current to al the loads. The generator line current = then the sum

Uf the Load currents (eae = Fat t+ ba? *

4 Loads can also be reactive inductive and capacitive) Reactive current is then

aided as explained in previous chapters.

4. The value 1.732 is used in three-phase calculations Pecan voltages and cur-

rae et 130 degrees out of phase and are combined using Veco"

Qerriore ——_—

‘Awye-connocted generator supplies two loads connected in parallel. Load 1 1s

“ig 4B0VAC. Load 1 is resistive end R= 100

delta and load 2 18 WE. Erg gen

per phase. Load 2 is resistive and R = 120 PSF phase. Draw the diagram for this