Professional Documents

Culture Documents

Enercon Materials and Methods

Uploaded by

Jhoanie Marie Cauan0 ratings0% found this document useful (0 votes)

29 views2 pagesJhoanie Marie P. Cauan and group (2017) Fire powered thermoelectric smartphone charger

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentJhoanie Marie P. Cauan and group (2017) Fire powered thermoelectric smartphone charger

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

29 views2 pagesEnercon Materials and Methods

Uploaded by

Jhoanie Marie CauanJhoanie Marie P. Cauan and group (2017) Fire powered thermoelectric smartphone charger

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 2

III.

MATERIALS AND METHODS

A. Materials

The specifications and descriptions of the materials that are used in this design project are thermal paste,

aluminum sheet, aluminum heatsink, screws, wires, shrinkable tube, cotton wick, used cooking oil, glass jar, lead, and

Thermoelectric Generator (SP1848-27145).

The tools that are used in this design project are pliers, soldering iron, cutter, wire stripper, rotary tools,

screwdriver, multimeter, thermal gun and thermal scanner.

B. Methods

Design and Construction of the Device

The device has two lamps on its sides, this was made to provide more heat for the Thermoelectric Generator

(TEG) and brighter light for the surroundings. The fuel used for the lamps are used cooking oil for accessible and

environment friendly fuel supply. The body of the device was made up of glass to effectively illuminate the

environment with the light coming from the lamps and the base was made up of aluminum for light and strong

foundation. On the middle part of the device, a heatsink was submerged in water to absorb the heat coming off the

cold side of the TEG. The heat from the hot side of TEG flows to the cold side until it approaches thermal equilibrium,

the water prolongs the time by absorbing the heat from the heatsink at cold side. The water may be replenished when

it becomes warm to provide greater temperature difference to produce greater power. Thermal paste was applied on

the hot and cold side of the TEG for better thermal conduction with the heatsinks. The summary of the flow of energy

on the device is shown on block diagram below.

Design and Construction of the Circuit

The four TEGs are connected in series together with a 0.9-5V DC to 5V DC converter or booster circuit. The

schematic diagram for the booster circuit is shown below. The input voltage (VCC-IN) needs to be between 0.9 V to

5 V for the booster to work and prevent damaging the components. It is connected in parallel with the 1K resistor

(R1) that is in series with a red LED (D1), and with the 0.1 uF capacitor (C1). The LED serves as an indicator if there

is enough voltage for the circuit to work, the resistor absorbs the excess voltage to prevent damaging the LED. The

capacitor charges up with the input voltage and maintain it, making the voltage stable. These parallel circuits are

connected in series with the 47 uH inductor (L1) that is connected on pin 3 of the CE8301 (U1) IC. CE8301 is a

Complementary Metal Oxide Semiconductor Pulse Frequency Modulator (CMOS PFM) controller that mainly

consists of reference voltage source, an oscillator, and a comparator. The block diagram of the internal circuit of the

IC can be seen below. This IC controls the frequency of shorting the ground and inductor to form a closed circuit that

has the inductor as a load. When current flows through the inductor, it induces magnetic field. The IC will open the

circuit and the current will flow through the SS14 (D2), a Schottky diode that serves as reverse polarity protection,

and to the parallel 100 uF capacitor (C2). The induced magnetic field from the inductor will have an induced voltage

therefore the input voltage will increase by adding the voltage induced to the inductor. This will have 5V that is parallel

with the capacitor (C2) that will charge up and stabilize the voltage. The pin LX will protect the IC when the input

voltage exceeded 5 V. The capacitor (C2) that charged up 5V is parallel to the output (VCC-OUT). The VCC-OUT is

connected in parallel to a USB port to charge a smartphone with the use of a USB type A adapter cable.

Figure 1:Block Diagram of the Device

Figure 2: Schematic Diagram of the TEG Connected to Booster Circuit

Figure 3:Block Diagram of CE8301 Internal Circuit

You might also like

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Electrical Energy Audit of Barangay San Agustin 2 FROM 2014-2015: A SURVEYDocument1 pageElectrical Energy Audit of Barangay San Agustin 2 FROM 2014-2015: A SURVEYJhoanie Marie CauanNo ratings yet

- AppendicesDocument11 pagesAppendicesJhoanie Marie CauanNo ratings yet

- Development of A Portable Electronic Limbs Therapy EquipmentDocument1 pageDevelopment of A Portable Electronic Limbs Therapy EquipmentJhoanie Marie CauanNo ratings yet

- 2 Biographical DataDocument2 pages2 Biographical DataJhoanie Marie CauanNo ratings yet

- 10-List of AppendixDocument1 page10-List of AppendixJhoanie Marie CauanNo ratings yet

- Ijert Ijert: Method of Coffee Bean Defect DetectionDocument3 pagesIjert Ijert: Method of Coffee Bean Defect DetectionJhoanie Marie CauanNo ratings yet

- LogicDesign PDFDocument23 pagesLogicDesign PDFJhoanie Marie Cauan0% (1)

- 1 Template Telkomnika Jun'15Document6 pages1 Template Telkomnika Jun'15goniNo ratings yet

- 1 3 3 Engineering Lettering GuidlinesDocument2 pages1 3 3 Engineering Lettering GuidlinesJJ AcotNo ratings yet

- Implementation of Microelectronics Track in Electronics Engineering in A Philippines State UniversityDocument6 pagesImplementation of Microelectronics Track in Electronics Engineering in A Philippines State UniversityJhoanie Marie CauanNo ratings yet

- 00-1 IJEECS Jun'16 v2 n3 (Print)Document4 pages00-1 IJEECS Jun'16 v2 n3 (Print)nono heryanaNo ratings yet

- A3 1-CauanDocument5 pagesA3 1-CauanJhoanie Marie Cauan100% (1)

- DSP SyllabusDocument2 pagesDSP SyllabusJhoanie Marie CauanNo ratings yet

- Energy Conversion Kenneth C. Weston SECOND EDITION - 2000 PDFDocument601 pagesEnergy Conversion Kenneth C. Weston SECOND EDITION - 2000 PDFeko krisma100% (2)

- 00-1 IJEECS Jun'16 v2 n3 (Print)Document4 pages00-1 IJEECS Jun'16 v2 n3 (Print)nono heryanaNo ratings yet

- Energy Is Needed For Fast Transportation Purposes. None of Vehicles Work Without EnergyDocument2 pagesEnergy Is Needed For Fast Transportation Purposes. None of Vehicles Work Without EnergyJhoanie Marie CauanNo ratings yet

- 278-316 CH08 61939Document39 pages278-316 CH08 61939aravind100% (2)

- According To QuijadaDocument2 pagesAccording To QuijadaJhoanie Marie CauanNo ratings yet

- rw1 2Document5 pagesrw1 2Jhoanie Marie CauanNo ratings yet

- Chinese Literature JhoanieDocument6 pagesChinese Literature JhoanieJhoanie Marie CauanNo ratings yet

- Psychoanalytic TheoryDocument3 pagesPsychoanalytic TheoryJhoanie Marie CauanNo ratings yet

- Floor PlanDocument6 pagesFloor PlanJhoanie Marie CauanNo ratings yet

- ENGL2 Act1Document6 pagesENGL2 Act1Jhoanie Marie CauanNo ratings yet

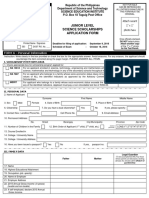

- Junior Level Science Scholarships Application Form: FORM A - Personal InformationDocument4 pagesJunior Level Science Scholarships Application Form: FORM A - Personal InformationAbigail SaballeNo ratings yet

- DocumentDocument11 pagesDocumentJhoanie Marie CauanNo ratings yet

- Front Page IIDocument7 pagesFront Page IIJhoanie Marie CauanNo ratings yet

- 3VGSDocument1 page3VGSJhoanie Marie CauanNo ratings yet

- Front PageDocument1 pageFront PageJhoanie Marie CauanNo ratings yet

- 2VGSDocument1 page2VGSJhoanie Marie CauanNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Katalog NYMDocument2 pagesKatalog NYMlaily izmiaNo ratings yet

- Beginner Introduction Guide To TubesDocument14 pagesBeginner Introduction Guide To TubesShivaji Rao100% (1)

- Universal Laboratory Power SupplyDocument5 pagesUniversal Laboratory Power SupplyIliescu CristianNo ratings yet

- ATS115 - 220440 - USER MANUAL - LOGICA CONTROL PANEL - Rev01 - ENDocument41 pagesATS115 - 220440 - USER MANUAL - LOGICA CONTROL PANEL - Rev01 - ENarasNo ratings yet

- (A) Bihar Electricity Supply Code 2007Document113 pages(A) Bihar Electricity Supply Code 2007abhishekNo ratings yet

- Background and Justification 1.1 Renewable Energy Status in EthiopiaDocument9 pagesBackground and Justification 1.1 Renewable Energy Status in EthiopiadebelaNo ratings yet

- K33 Hvac Control Module Document ID# 2877120Document2 pagesK33 Hvac Control Module Document ID# 2877120Data TécnicaNo ratings yet

- World Charger 36 Volt Fully Automatic Dual Mode Battery ChargerDocument6 pagesWorld Charger 36 Volt Fully Automatic Dual Mode Battery ChargerStephen BridgesNo ratings yet

- Power Generation Handbook - Links To EbookDocument4 pagesPower Generation Handbook - Links To EbookperpanersNo ratings yet

- Boston Gear Dcx202erp Ratiotrol PDFDocument31 pagesBoston Gear Dcx202erp Ratiotrol PDFlalo100% (1)

- CenterPointEnergy ServiceStandards2013RevisionOct2013Document97 pagesCenterPointEnergy ServiceStandards2013RevisionOct2013Carol HernandezNo ratings yet

- Three Phase Induction RegulatorDocument5 pagesThree Phase Induction RegulatormohamedmohebNo ratings yet

- Overhead Design Manual: © ENERGEX 2007 BMS 01613 2.0 Last Update: 15/01/2007Document68 pagesOverhead Design Manual: © ENERGEX 2007 BMS 01613 2.0 Last Update: 15/01/2007Mecmed MomodNo ratings yet

- Experiment# 10: Measure The Power and Power Factor by Three Ammeter MethodDocument10 pagesExperiment# 10: Measure The Power and Power Factor by Three Ammeter MethodFarwa MunirNo ratings yet

- Power Systems: Power Systems Undervoltage and Overvoltage Time Lag RelaysDocument4 pagesPower Systems: Power Systems Undervoltage and Overvoltage Time Lag RelaysHarkishen SinghNo ratings yet

- Unit 3 Power Electronics For Renewable Energy SystemsDocument88 pagesUnit 3 Power Electronics For Renewable Energy SystemsTamil SelvanNo ratings yet

- DGEG EsquemaDocument15 pagesDGEG EsquemaAlexander James ThorntonNo ratings yet

- Automatic Synchronisation of AlternatorDocument2 pagesAutomatic Synchronisation of AlternatorInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Chernobyl Disaster: "Historicizing" ManagementDocument12 pagesChernobyl Disaster: "Historicizing" Managementindranil biswasNo ratings yet

- Sliver3000 Panel SpecificationsDocument5 pagesSliver3000 Panel SpecificationsembokoNo ratings yet

- Ee 2022Document9 pagesEe 2022LATIGAR, JEFFERSON 0.No ratings yet

- Rps PlantDocument23 pagesRps PlantHemant ShrivastvaNo ratings yet

- Arduino-Info - Dt9205a-Multimeter-Manual PDFDocument12 pagesArduino-Info - Dt9205a-Multimeter-Manual PDFZoranTrailovićNo ratings yet

- BLDC Motor Driven Solar PV Array Fed Water PumpingDocument26 pagesBLDC Motor Driven Solar PV Array Fed Water PumpingKarthik DmNo ratings yet

- Bro Dhg400 enDocument1 pageBro Dhg400 enAzkha EsaNo ratings yet

- Advanced Tips and Tricks Power Supply STR 6701Document2 pagesAdvanced Tips and Tricks Power Supply STR 6701Kiray VillanuevaNo ratings yet

- CHABUADocument1 pageCHABUAbedanta duttaNo ratings yet

- Panimalar Engineering Collge: Department of Mechanical Engineering Ii Year / Iii SemesterDocument32 pagesPanimalar Engineering Collge: Department of Mechanical Engineering Ii Year / Iii SemestersivaNo ratings yet

- Solar Panel Installation TechnicianDocument298 pagesSolar Panel Installation TechniciansanjoybapiNo ratings yet

- Practical Approach in Designing Conducted EMI Filter To Mitigate Common Mode and Differential Mode Noises in SmpsDocument20 pagesPractical Approach in Designing Conducted EMI Filter To Mitigate Common Mode and Differential Mode Noises in Smpsbacuoc.nguyen356No ratings yet