Professional Documents

Culture Documents

GD&T Symbols and Guidelines Cheat Sheet: Provided by

Uploaded by

Luis Angel Martinez SotoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

GD&T Symbols and Guidelines Cheat Sheet: Provided by

Uploaded by

Luis Angel Martinez SotoCopyright:

Available Formats

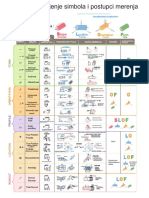

GD&T Symbols and Guidelines Cheat Sheet

Provided by GD&T Basics - www.gdandtbasics.com

For the Premium version of this chart, sign up for our GD&T Basics Fundamentals course at www.gdandtbasics.com/gdt-training

Y

V

Y

The 4 Fundamental X

Elements of GD&T: X

W U

Z X

Z X

SJ[F Location Orientation Form

All drawings made in

first angle projection

SYMBOL NAME ON DRAWING TOLERANCE ZONE GAUGING SURFACES FEATURES OF SIZE

Two parallel lines

0.03 apart

0.03

Straightness

(Surface)

100.050 Cylindrical Tolerance Zone

0.03 when Part = 10.05 Cylinder Gauge ID = M +

Straightness

0.03 M

0.13 when Part = 9.95

M Gauge ID = 10.08

(Derived Median Line w/ M )

Flatness 0.03

Two parallel planes

0.03 apart

F (Derived Median

F

(Surface)

FORM

Line and Plane)

Planar Tolerance Zone Gauge spacing

Flatness 100.05

0.03 M

Two parallel planes

0.03 apart

at Virtual Condition

M + = 10.08

M (Derived Median

Plane w/ M )

Two concentric circles

0.03 0.03 apart

Circularity

Two concentric cylinders

0.03 0.03 apart

Cylindricity

Two parallel planes

0.03 apart

0.03 A parallel to datum

Parallelism A

Datum A

Flat datum block

(Datum A)

Gauge kept parallel to datum

Perpendicularity

0.03 A Two parallel planes

0.03 apart Flat datum block

(Datum A) OF O

ORIENTATION

A

(Feature) 90

Datum A Gauge kept perpendicular to datum

100.05 Gauge pin Pin Gauge OD = M Y

V

Y

V

Axis inserted

0.03 M A

Perpendicularity Tolerance Zone perpendicular Pin Gauge = 9.92

at M to datum (9.95 - 0.03)

M 90

Multiple datums

(Feature of Size w/ M ) may be used

to specify W U W U

Z X Z X

Perpendicularity

A Datum A

Two parallel planes

0.03 apart

0.03 A

Angularity 60 A Gauge

Block

60

60

60

Datum A

0.03 A B Uniform Linear Boundary About True Profile Datum B

0.03 apart

Profile Gauge must

SLOF

B A follow true profile.

of a line Profile is usually

measured with a CMM.

PROFILE

Basic dimensions (not shown) are required to

define the True Profile when datums are used. Datum A

Y Y

V

0.03 A B Uniform Surface Boundary About True Profile Datum B

Profile B A

0.03 apart Gauge must

follow true profile.

X

of a surface Basic dimensions (not shown) are required to Datum A

Profile is usually

measured with a CMM.

X

Z X Z

W U

X

define the True Profile when datums are used.

100.05 Measure X and Y location and compare to the true position.

Part (actual) position

0.03 A B C

LO

2X (Actual X - True X)2 + (Actual Y - True Y)2

B Y

This formula must be less than

True Position 20.0 True

Actual

Actual Y

True Y

the True Position tolerance

True 0.03

30.0 center

C A X Y

True X Actual X

None

Actual

100.05 Pin Position Part FUNCTIONAL Part Tolerance Zone

0.03 M A B C GAUGING of Pin Gauge Z X

True Position B

True

position

For an For an

True

position

Y

V

M (Maximum Material 25.0 Tolerance Zone External Internal

of Hole Gauge Feature Feature Actual

Condition) Hole Position

LOCATION

W U

Z X

25.0 C A Gauge Hole = Virtual Condition Gauge Pin = Virtual Condition

Gauge Gauge (Smallest Hole Size [MMC] - Position Tol.)

(Largest Pin Size [MMC] + Position Tol.)

1

0.03 A

LOF

The following is usually

Measured axis Datum axis done with a CMM:

1. Determine

Concentricity 0.03

Datum axis

2. Measure referenced

A

Datum A surface

A 3. Determine if central

Tolerance Zone axis falls in TZ Distribution/ Y

Diameter Symbol is required

Evenness of (Derived

0.03 A

A A

The following is Form Only Median

A

Datum A

usually done

with a CMM:

Z Y

V

X

Points)

Symmetry Plane

1

1. Determine

Datum plane

2. Measure both

surfaces of features

3. Determine if W U

Two parallel planes midpoints fall in TZ Z X

0.03 apart

0.03 A Datum A

Fixed + Rotated

Datum A

A

A Fixed axially

Runout

LOF

+ Rotated Can also be used

on flat surfaces

perpendicular

RUNOUT

A

to the datum axis

A

Y Y

V

0.03 A Datum A

Datum A Fixed + Rotated

A

Fixed axially

A

Total Runout

+ Rotated Can also be used W U

Z X Z X

on flat surfaces

A perpendicular

to the datum axis

A

Copyright Pareto Learning LLC - All Rights Reserved - Chart designed by Andrea Barbieri <www.andreabarbieri.net>

You might also like

- Surface Roughness by Different Processing MethodsDocument1 pageSurface Roughness by Different Processing Methodsapi-3848892100% (1)

- (BS EN ISO 17450-3) - Geometrical Product Specifications (GPS) - General Concepts. Part 3. Toleranced FeaturesDocument28 pages(BS EN ISO 17450-3) - Geometrical Product Specifications (GPS) - General Concepts. Part 3. Toleranced Featuresaditya sasmalNo ratings yet

- ASME Y14.5 Vs ISO GPS Comparison ChartDocument2 pagesASME Y14.5 Vs ISO GPS Comparison ChartMohammad Ghousuddin100% (1)

- Basic GD&T PDFDocument236 pagesBasic GD&T PDFVinothkumar MNo ratings yet

- GDTDocument38 pagesGDTAntonio CervantesNo ratings yet

- Tolerance Stack Up Analysis What Is Stack Up Analysis?Document25 pagesTolerance Stack Up Analysis What Is Stack Up Analysis?Venkadakrishnan ThiagarajanNo ratings yet

- Tolerance Stack Up Study WorksheetDocument2 pagesTolerance Stack Up Study WorksheetPeter Murray100% (1)

- Metrology and Measurement PublicDocument8 pagesMetrology and Measurement PublicKeith AdminNo ratings yet

- GDT-True PositionDocument32 pagesGDT-True PositionhamartinezNo ratings yet

- GDTP ApplicationInformationHandbookDocument10 pagesGDTP ApplicationInformationHandbookmanaswinNo ratings yet

- The New Y14.5: We've Improved The Gold StandardDocument9 pagesThe New Y14.5: We've Improved The Gold StandardVignesh PanneerselvamNo ratings yet

- True Position Use of DatumsDocument5 pagesTrue Position Use of DatumsRajesh KumarNo ratings yet

- ABC Group Checking and Gauge Standard 80-STD-D-01Document53 pagesABC Group Checking and Gauge Standard 80-STD-D-01Quy HoangNo ratings yet

- G4 - Advance GD&T and Tolerance Stack-UpDocument9 pagesG4 - Advance GD&T and Tolerance Stack-UpAnkit NaphadeNo ratings yet

- Geometric Dimensioning & Tolerancing (GD&T)Document89 pagesGeometric Dimensioning & Tolerancing (GD&T)Vijay PawarNo ratings yet

- Dimensional Engineering: Based On The ASME Y14.5M-1994 Dimensioning and Tolerancing StandardDocument96 pagesDimensional Engineering: Based On The ASME Y14.5M-1994 Dimensioning and Tolerancing StandardNarasimhamurthy AdaviNo ratings yet

- Symbols, Rules, and Guidelines Facts To Remember Facts To RememberDocument1 pageSymbols, Rules, and Guidelines Facts To Remember Facts To RememberAltaf NalbandhNo ratings yet

- GD&T SymbolsDocument6 pagesGD&T Symbolschethan048100% (1)

- Surface Roughness ParametersDocument2 pagesSurface Roughness Parametersamit02mech100% (1)

- GD&TDocument57 pagesGD&TGURAVDRNo ratings yet

- GD T ExamplesDocument10 pagesGD T ExamplesJuan Posada GNo ratings yet

- Tolerance Stack Up Analysis in Manufacturing Based Capstone ProjectsDocument10 pagesTolerance Stack Up Analysis in Manufacturing Based Capstone ProjectsAmirtharaaj VijayanNo ratings yet

- GD&T Symbols, Definitions ASME Y14Document8 pagesGD&T Symbols, Definitions ASME Y14deepak0% (1)

- Start GD&TDocument81 pagesStart GD&TVijay Pawar100% (1)

- Hexagon Pc-Dmis 07 - Editing A Measurement RoutineDocument47 pagesHexagon Pc-Dmis 07 - Editing A Measurement RoutinenalbanskiNo ratings yet

- Relationships Between Material Modifiers and FitsDocument3 pagesRelationships Between Material Modifiers and FitsDo The CuongNo ratings yet

- Catalogo Holders TungaloyDocument156 pagesCatalogo Holders Tungaloyabsalon_jarvNo ratings yet

- GD&T Glossary and Resource - GD&T Symbols and TermsDocument4 pagesGD&T Glossary and Resource - GD&T Symbols and TermsMohammed Adil100% (1)

- BA DuraMax REV 3 0 Online en PDFDocument235 pagesBA DuraMax REV 3 0 Online en PDFbeto206123100% (1)

- GD&TDocument33 pagesGD&TShasank PramodeNo ratings yet

- GDT Workbook QuestionsDocument82 pagesGDT Workbook Questionsmechlop100% (5)

- VMC & HMC PDFDocument103 pagesVMC & HMC PDFNARENDER SINGHNo ratings yet

- Accuracy of Machine ToolsDocument55 pagesAccuracy of Machine Toolsandrewscline100% (2)

- Engineering Drawings - GD&TDocument45 pagesEngineering Drawings - GD&TMichael Wood100% (1)

- Functional Gage DesignDocument32 pagesFunctional Gage DesignnaveedsidhuNo ratings yet

- Tesa Micro-Hite: The Quick and Accurate MeasurementDocument32 pagesTesa Micro-Hite: The Quick and Accurate MeasurementEnggCoordNo ratings yet

- Jigsfixtures Kuliah 1 Sesi Jun 2010Document79 pagesJigsfixtures Kuliah 1 Sesi Jun 2010JahazielNo ratings yet

- GD&TDocument5 pagesGD&Travindra_2011No ratings yet

- (A) "Basics of GD&T + Advanced GD&T" SyllabusDocument4 pages(A) "Basics of GD&T + Advanced GD&T" SyllabusSwapnil GujarathiNo ratings yet

- Geometric Dimensioning and Tolerancing: FundamentalsDocument40 pagesGeometric Dimensioning and Tolerancing: FundamentalsdramiltNo ratings yet

- Agi Zeiss Day 2016 Gdandt Presentation HandoutsDocument20 pagesAgi Zeiss Day 2016 Gdandt Presentation HandoutsJuan Posada G100% (1)

- Dimensional Quality Engineering PowerpointDocument15 pagesDimensional Quality Engineering PowerpointSalman JavedNo ratings yet

- 08m13e07 - CAM2 Laser Tracker MeasuDocument542 pages08m13e07 - CAM2 Laser Tracker MeasuifcoljachNo ratings yet

- Lecture 8 - Position TolerancingDocument26 pagesLecture 8 - Position TolerancingEdgar IvanNo ratings yet

- Rules and Concepts of GD&T PDFDocument31 pagesRules and Concepts of GD&T PDFMahender KumarNo ratings yet

- PC-DMIS HotkeysDocument8 pagesPC-DMIS HotkeysRobotNo ratings yet

- GD&T Inspection in Spatialanalyzer: Jeremy Winn Philip WilsonDocument53 pagesGD&T Inspection in Spatialanalyzer: Jeremy Winn Philip WilsonAnthuan SenoirbNo ratings yet

- GD&T Chart - 231011 - 202857Document2 pagesGD&T Chart - 231011 - 202857SanjoGsingh RajPutNo ratings yet

- GD&T Symbols and Guidelines Cheat SheetDocument1 pageGD&T Symbols and Guidelines Cheat SheetViraj ShiroleNo ratings yet

- Free GD T Wall Chart PDFDocument1 pageFree GD T Wall Chart PDFAnonymous tGFxtqNNo ratings yet

- GD&T Basics Wall ChartDocument1 pageGD&T Basics Wall ChartAmandeep SinghNo ratings yet

- GD&T Basics Wall ChartDocument1 pageGD&T Basics Wall ChartShahzad KhanNo ratings yet

- GD&T Wall Chart SrpskiDocument1 pageGD&T Wall Chart SrpskizlatkoNo ratings yet

- Series 1100 RCDocument1 pageSeries 1100 RCASYA ElectricalNo ratings yet

- Ayat RevisedDocument1 pageAyat RevisedLelisa TarekegnNo ratings yet

- Paalar Farm Plumbing Master Plan - 230502 - 141811Document1 pagePaalar Farm Plumbing Master Plan - 230502 - 141811Bharath AravamuthanNo ratings yet

- 46-2016-SUM-E-013 - OUTDOOR LIGHTING LAYOUT (As Built)Document1 page46-2016-SUM-E-013 - OUTDOOR LIGHTING LAYOUT (As Built)SivanandNo ratings yet

- Precision Machine Design Error BudgetDocument66 pagesPrecision Machine Design Error Budgetnz578427100% (1)

- Why You Should Read BooksDocument23 pagesWhy You Should Read BooksLuis Angel Martinez SotoNo ratings yet

- Press Fits PDFDocument17 pagesPress Fits PDFtooocooolNo ratings yet

- FlangingDocument12 pagesFlangingStelwin FernandezNo ratings yet

- Metal Forming Processes - Full PDFDocument91 pagesMetal Forming Processes - Full PDFAnonymous 9xvU1F100% (2)

- WuHsienChih1999 CMR PDFDocument177 pagesWuHsienChih1999 CMR PDFLuis Angel Martinez SotoNo ratings yet

- ISO 1101-2012 Tolerances of Form, Orientation, Location and Run-OutDocument110 pagesISO 1101-2012 Tolerances of Form, Orientation, Location and Run-OutLuis Angel Martinez Soto100% (3)

- SolidWorks Motion Tutorial 2011Document31 pagesSolidWorks Motion Tutorial 2011Soma Nathan0% (1)

- SolidWorks Motion AnalysisDocument37 pagesSolidWorks Motion Analysiswidi_115No ratings yet

- Press Fits PDFDocument17 pagesPress Fits PDFtooocooolNo ratings yet

- PMD Topic 2 Fundamentals of ErrorsDocument30 pagesPMD Topic 2 Fundamentals of ErrorsLuis Angel Martinez SotoNo ratings yet

- Glass Transition TemperatureDocument4 pagesGlass Transition TemperatureLuis Angel Martinez SotoNo ratings yet

- Iso GD&TDocument39 pagesIso GD&TSanjay Kumar SinghNo ratings yet

- Https - Umindanao - Mrooms.net - Pluginfile - PHP - 612121 - Mod - Resource - Content - 0 - Permutation, Combination and Probability-Exercise 03Document2 pagesHttps - Umindanao - Mrooms.net - Pluginfile - PHP - 612121 - Mod - Resource - Content - 0 - Permutation, Combination and Probability-Exercise 03Najib A. CasanNo ratings yet

- CAT Exam - Quants - (4) GeometryDocument1 pageCAT Exam - Quants - (4) GeometryMaths magnusNo ratings yet

- Math6 Q4 Mod1Document21 pagesMath6 Q4 Mod1Marieth TolentinNo ratings yet

- Modern Geom ExamDocument5 pagesModern Geom ExamJoseph AndaganNo ratings yet

- 1 Z 1 X Z 4 X y Z 1 12Document5 pages1 Z 1 X Z 4 X y Z 1 12Rohan ZendeNo ratings yet

- Std08 Maths EM 2 PDFDocument152 pagesStd08 Maths EM 2 PDFPrem Anand100% (1)

- Incidence GeometryDocument7 pagesIncidence GeometryHeartcel Babes EyasNo ratings yet

- Grade 9 Term 2 Erm Math 2022 23Document13 pagesGrade 9 Term 2 Erm Math 2022 23GuruGudiyaNo ratings yet

- Caed Question BankDocument28 pagesCaed Question BankSafeer MNo ratings yet

- Solution of Trangles Phase 2Document32 pagesSolution of Trangles Phase 2VISHESH SEHRAWATNo ratings yet

- Angles: Polygons: Edexcel GCSEDocument8 pagesAngles: Polygons: Edexcel GCSEAddy The humanNo ratings yet

- Mock Preparatory Exam 2023Document11 pagesMock Preparatory Exam 2023TondaniNo ratings yet

- Chapter 9 Trigonometric RelationsDocument20 pagesChapter 9 Trigonometric Relationskayee tangNo ratings yet

- Introduction To Draw Panels and Different Drawing Tools: University of Engineering & Technology, TaxilaDocument5 pagesIntroduction To Draw Panels and Different Drawing Tools: University of Engineering & Technology, TaxilaranaNo ratings yet

- Contest SolutionsDocument3 pagesContest SolutionsANKIT KUMARNo ratings yet

- MR 3 2011 ProblemsDocument4 pagesMR 3 2011 ProblemsgrishaNo ratings yet

- MathDocument13 pagesMathAlibasher MacalnasNo ratings yet

- RMM TRIANGLE MARATHON 1301 1400 - CompressedDocument138 pagesRMM TRIANGLE MARATHON 1301 1400 - CompressedKhokon GayenNo ratings yet

- Maths Examination Paper # 33Document3 pagesMaths Examination Paper # 33Lê Kiều TrangNo ratings yet

- Assignment 2Document3 pagesAssignment 2Aimon RaufNo ratings yet

- Day 2 - Notes - Venn Diagrams & Conditional Statements & Converses (06-07)Document9 pagesDay 2 - Notes - Venn Diagrams & Conditional Statements & Converses (06-07)Gregory SullivanNo ratings yet

- HCPDocument4 pagesHCPIshan BaruahNo ratings yet

- Lattice Planes and Miller Indices: I Materials Science Course A: Atomic Structure of MaterialsDocument4 pagesLattice Planes and Miller Indices: I Materials Science Course A: Atomic Structure of MaterialsTouseef HayatNo ratings yet

- 9.4 G GHW PDFDocument2 pages9.4 G GHW PDFnav alNo ratings yet

- Lines and Angles NotesDocument5 pagesLines and Angles NotesMidhun Bhuvanesh.B 7ANo ratings yet

- Icse MathsDocument113 pagesIcse MathsJanaki Krishnan100% (1)

- Topper 110 2 3 Maths Question Up202312041558 1701685716 1865Document8 pagesTopper 110 2 3 Maths Question Up202312041558 1701685716 1865Ruby KumariNo ratings yet

- Chapter 9 II Lines & Planes in 3D ENHANCEDocument21 pagesChapter 9 II Lines & Planes in 3D ENHANCEjuriah binti ibrahimNo ratings yet

- 13-Medians of Triangles ConstructionsDocument4 pages13-Medians of Triangles ConstructionsAymenNo ratings yet

- Crystallography Symmetry ElementsDocument11 pagesCrystallography Symmetry Elementsmarcelo VieiraNo ratings yet